new web: http://bdml.stanford.edu/pmwiki

TWiki > RisePrivate Web>ClimbingRobot>MicroAdhesives (15 Sep 2009, KimberlyHarrison)

RisePrivate Web>ClimbingRobot>MicroAdhesives (15 Sep 2009, KimberlyHarrison)

Meeting Notes and Goals

vandalism FutureGoals FuturePublications TestingQueue MeetingNotes StageDevelopmentGoals WetAdhesionMicrowedge Processing

FiftyProcess TwentyProcessMicro Structured Adhesives at Stanford

There are currently two fabrication methods that we are pursuing in an effort to make heirarchical and truly three dimensional anisotropic adhesive pads for StickyBot and RiSE? .Micro angled stalk designed by Sangbae

This is the first prototype that has anisotropic adhesive features. It is 380um in diameter, about 1mm long elastomer stalk. Stem comes out from surface in 70 degree angle and tip has 45 degree surfaces.

Wafer Combs

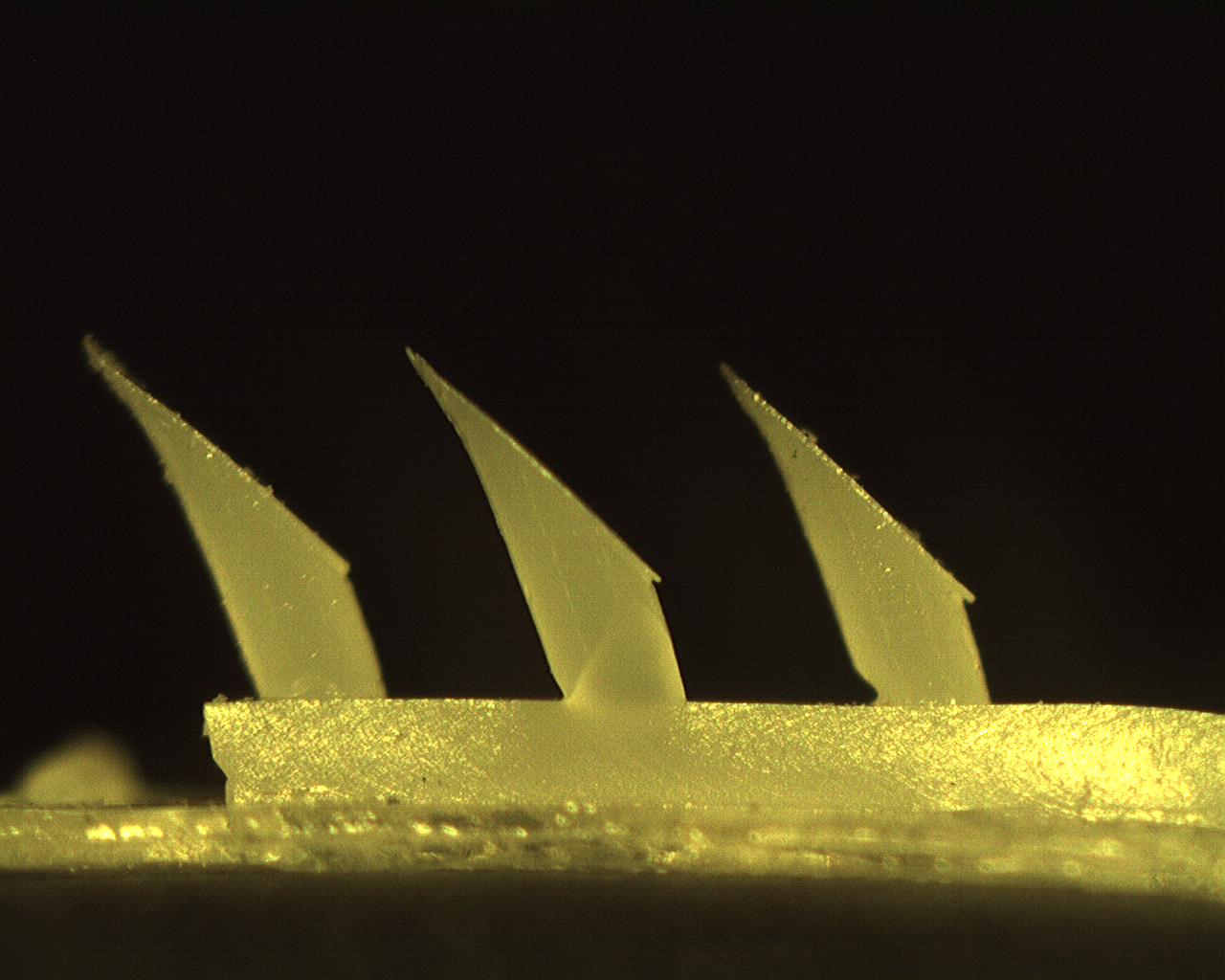

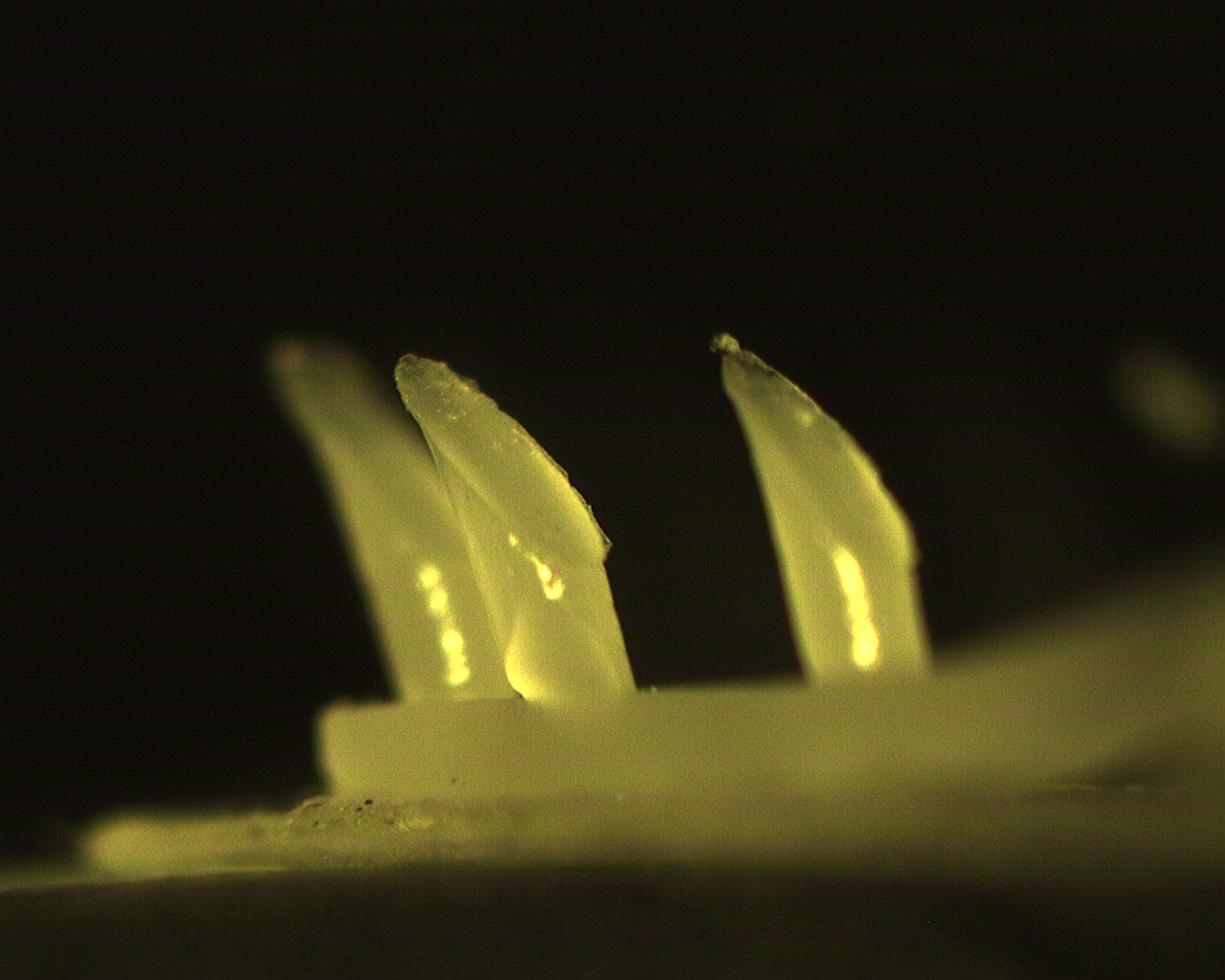

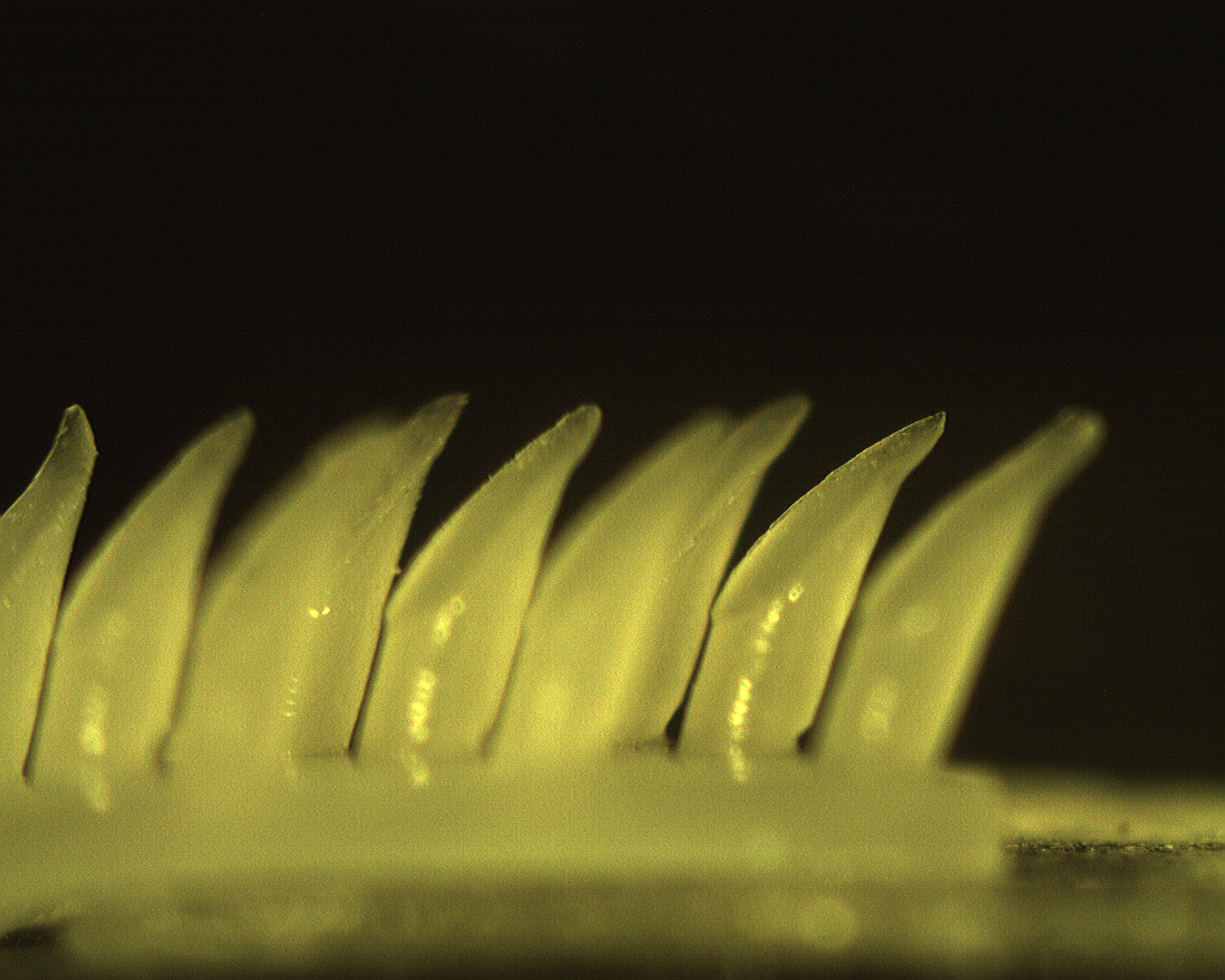

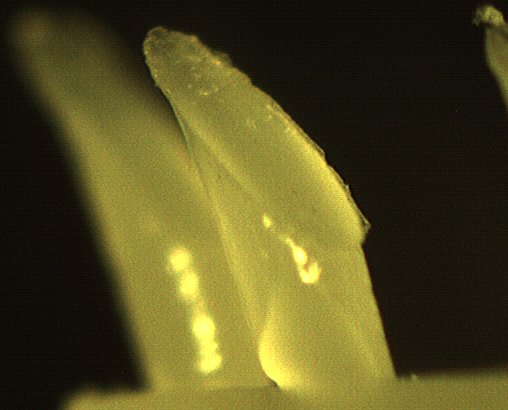

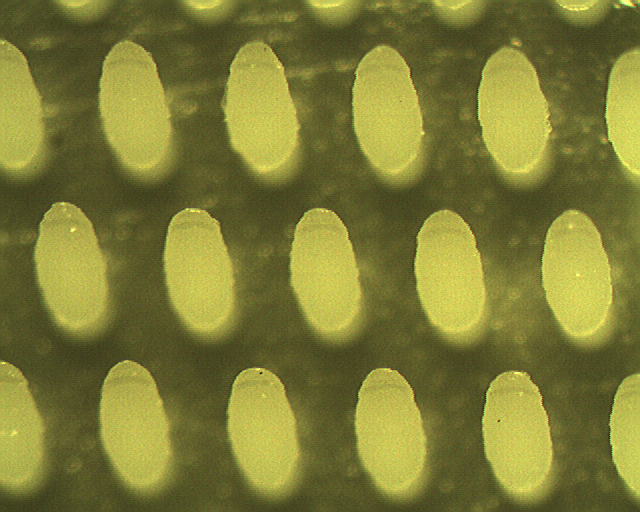

This is a method involving a deep reactive ion etch into a standard silicon wafer. Our mask contains several design variants on two stage suspensions that mimic the geckos llamelae and setae. The etched 2D shape is the cross section of the eventual adhesive pad, so after fabrication it must be molded into a soft plastic, then rotated 90 degrees and stacked in order to build up an entire pad, which can then be molded in silicone rubber. Current minimum feature size on the mask is 20 um diameter.SU-8 Procedure

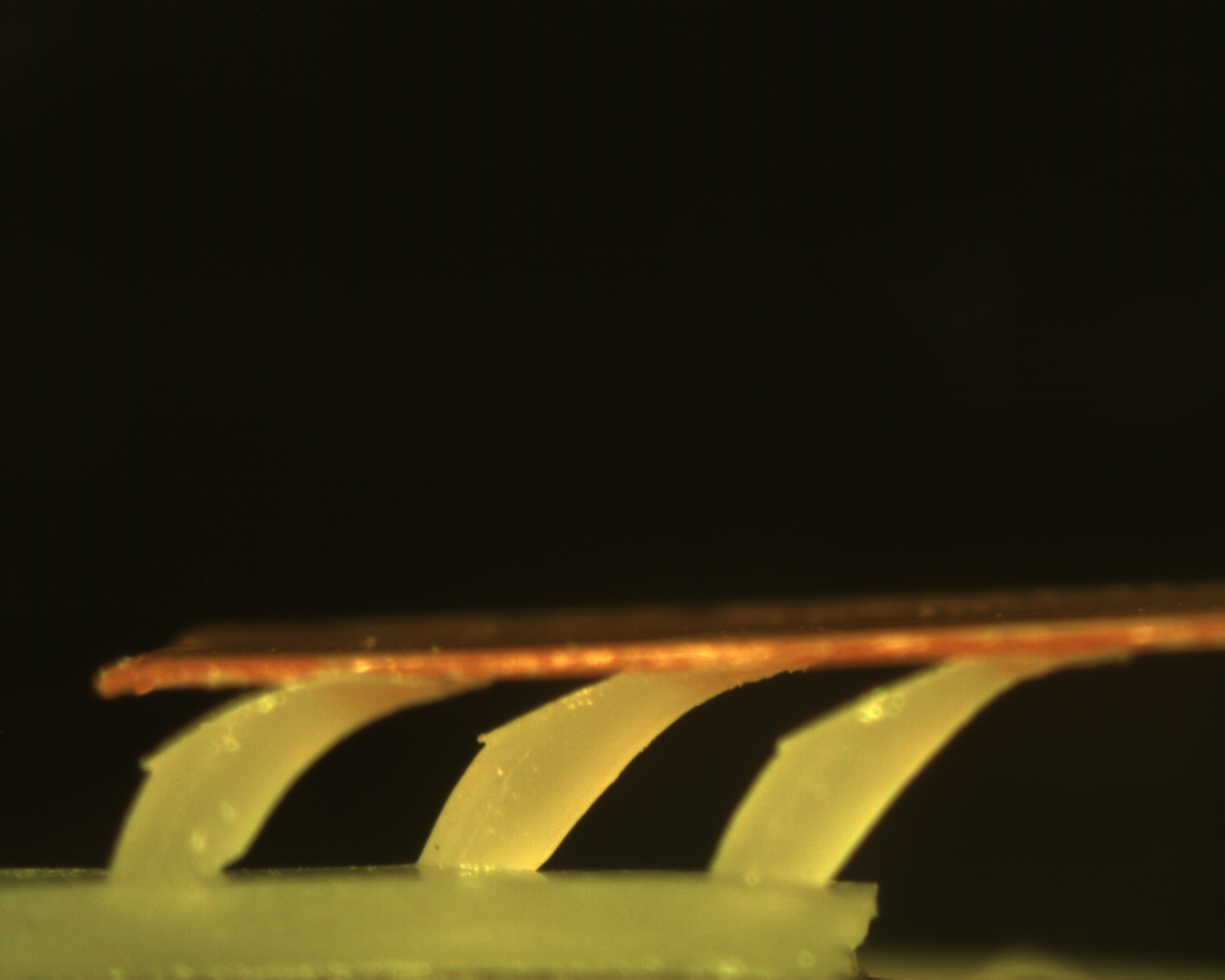

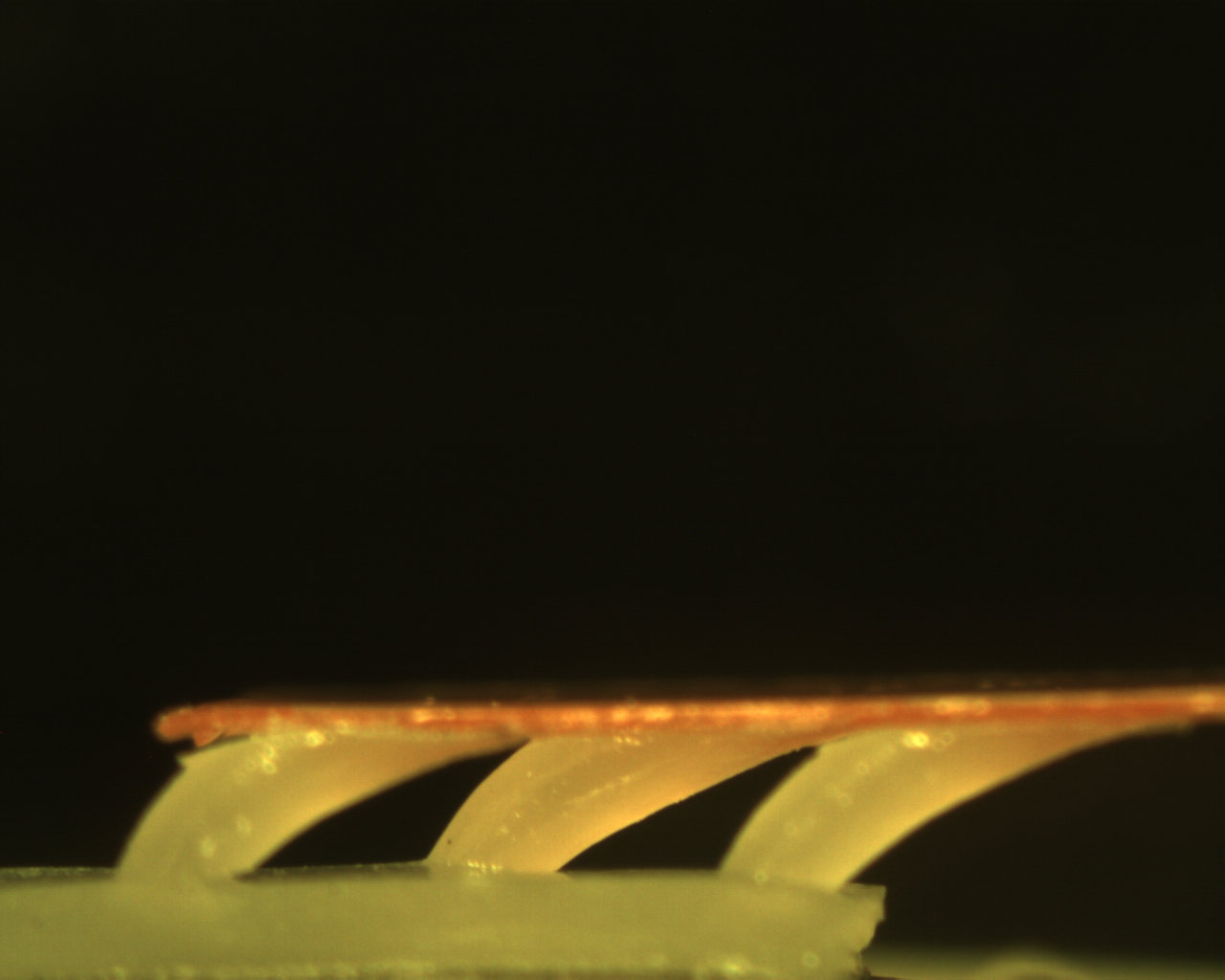

This is a method involving the negative photoresist SU-8, which we are selectively etching at an angle to yield the anisotropic tips that allow StickyBot to climb. The minimum feature size on the transparency mask is currently 20 um.- SU-8 Process Notes

- PDMS Process?

- SU-8 Wafer And Mask Holder For Tilted Exposure

- SU-8ProcessSheet.doc:

SU-8 Pictures

- Tilted Angle Test Picture, AUG2, 2006

SEM pictures of polymer stalks

Ideas, requests, problems regarding TWiki? Send feedback