Categories:AdhesiveManufacturing, Manufacturing

This page describes the process of casting adhesive features on flexible Kapton backings. Molds can be manufactured via micromachining, or may be a daughter mold, but must have geometry defining the reference flat with wax, and not tape pillars. This process uses a porous ceramic plate for fixturing the film; if a flat one is not available, or is scratched, see how to prepare a new one.

You will need:

- Adhesive mold.

- Polymer.

- Primer.

- Kapton film, 0.001"

- Porous ceramic tile, lapped.

- Methyl cellulose gel.

- Spatula

- Steel rolling pin.

- 7x7 glass sheet.

- 6x6 silicone spacer sheet.

- 6x6 steel weight plates.

- Acetone in squeeze bottle.

- Kimwipes.

- Nitrile gloves.

1. Fixture the Kapton Film

|

Time Estimate:

| 30 min.

|

|

| Overnight to dry bond.

|

- Locate one of the porous ceramic tiles, and place it on a paper towel, lapped side up. Wipe with a dry Kimwipe to ensure the surface is dust-free.

- Cut a square of Kapton film approximately 6.5" square. Clean one surface of dust with a Kimwipe wetted with acetone.

- Locate the container of methyl cellulose; this is a 1:30 by mass solution of pure methyl cellulose in water. The resulting gel-like glue is completely non-toxic, and readily dissolves in water after being dried.

- Use a spatula to spread a reasonable amount of methyl cellulose gel across the middle of the ceramic tile.

- Carefully lay the Kapton sheet over the tile, ensuring it overlaps all four edges, and that the clean side is down.

- Wipe the top surface of the Kapton lightly with a Kimwipe to remove dust. Also wipe the steel dowel pin to clean it.

- Place the steel dowel pin on the Kapton, in the middle of the glue. It should be in position to squeeze half the glue in each direction.

- Applying firm downward pressure, roll out the Kapton film until flat. Some glue should squeeze out all four edges. Take care to keep glue from squeezing onto the roller or top surface of the Kapton.

- Slide the tile on the paper towel to the edge of the table, place a cleaned 7x7x0.375" glass plate on top.

- Flip the assembly, then carefully remove the paper towel.

- Place a 6x6" silicone rubber sheet on top of the ceramic tile.

- Make as many of these glass-Kapton-ceramic-silicone stacks as necessary, then stack them all up.

- Set the 6x6x0.5" steel weights on the back, and let the glue dry for about 24 hours.

|

|

2. Cast the Adhesive

|

Time Estimate:

| 30 min.

|

|

| Overnight cure at room temperature. Possible to heat-cure depending on mold material.

|

- Lightly sand the Kapton face of the bonded tile-Kapton stack with approx. 600 grit sandpaper. Sand in both perpendicular directions and both diagonals.

- Wipe off the Kapton to remove sanding dust using a Kimwipe wetted with acetone.

- Apply primer to the Kapton. Lay one Kimwipe next to the tile, and fold another into a square. Wet the square with the PR-1200 primer, and then quickly wipe over the entire Kapton surface. Immediately lightly wipe the Kapton with the second Kimwipe you laid out earlier. There should be a little pink on this second Kimwipe if you added enough primer.

- Allow the primer to dry for 2 hours.

- Take the Kapton and the mold to the TLTL, and mix approximately 20g (10g A + 10g B) of Sylgard 170 silicone.

- Thoroughly degas the silicone in the vacuum chamber.

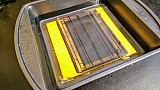

- Place the mold on an acrylic sheet, and pour the silicone onto the mold along the center. Avoid entraining bubbles.

- From one edge, set the Kapton on the mold, and gently set it down fully, again avoiding entraining bubbles.

- Apply firm pressure around the edges of the mold until the Kapton seats on the mold. It will stop sliding around when the thin film between the Kapton and the reference surface has been squeezed out.

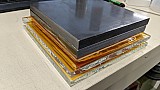

- Place both rectangular weights on the back of the mold, and allow to cure overnight

|

|

3. Demold the Adhesive

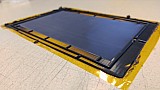

- Remove the mold and adhesive from the acrylic plate.

- Place the mold and adhesive in a water bath for about an hour; at this point, it should become relatively easy to shear the ceramic tile off of the adhesive.

- Thoroughly wash the ceramic tile in cold water to remove all remaining methyl cellulose.

- Rinse the back of the adhesive in cold water to remove all residual methyl cellulose.

- Release all silicone stuck to the sides of the mold to avoid delamination when peeling the adhesive out of the mold.

- Beginning at one corner, gently peel the adhesive out of the mold.

- Trim excess Kapton.

|

|

4. Materials and Vendors