Categories:AdhesiveManufacturing, Manufacturing

Lapping a New Plate

- Take a ballpoint pen and lightly mark over one face of the plate.

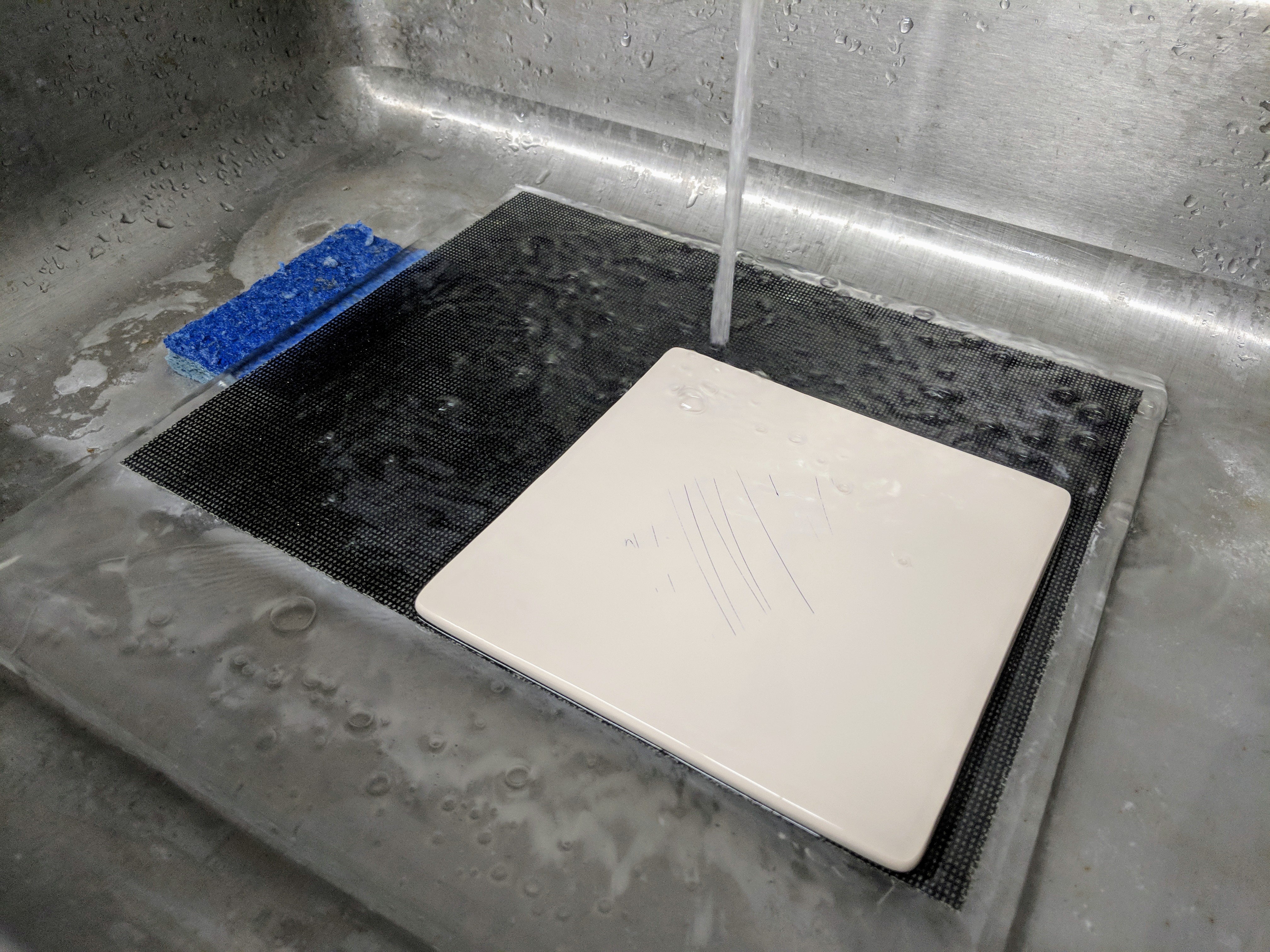

- Place a 12x12" glass plate in the sink, and the 80 grit sanding sheet on top. Turn on the water to a moderate flow, and adjust the temperature to be comfortable.

- Using back-and-forth motions, sand the marked face of the tile until all ballpoint marks are gone. Turn the tile periodically to avoid asymmetric sanding.

- Using very light pressure and a figure-eight lapping pattern, continue until large scratches are removed, and the entire surface is defined by the sanding.

- For the 220, 400, and 1000 grits, repeat this light-pressure, figure-eight lapping process, staying at each grit long enough that scratches from the previous grit have been removed.

- Rinse thoroughly and inspect. The lapped face should have a satin finish and appear completely flat.

- Dry the tile, either at room temperature overnight, or in the oven for about an hour at 65°C.

|

|

Refinishing a Used Tile

Perform steps 4-7 above, starting at the grit suitable for removing the defects. For refinishing small residues or discoloration, performing the final polish at 1000 grit is often sufficient.

Materials and Vendors

| PN | Vendor | Item |

|---|

| 60507 | CoorsTek | Porous ceramic plate |

| 8476K23 | McMaster | Glass plate for lapping, 12x12" |

| 4677A69 | McMaster | Sanding mesh, 80 grit |

| 4677A64 | McMaster | Sanding mesh, 220 grit |

| 4677A61 | McMaster | Sanding mesh, 400 grit |

| 6835A75 | McMaster | Sandpaper, 1000 grit |