Categories: Adhesion, Manufacturing

On this page... (hide)

- 1. Microwedges

- 2. Fabrication

- 3. Performance

1. Microwedges

In an effort to create a highly directional/controllable adhesive for climbing while taking into consideration manufacturability, we began making tapered structures. The tapered structures in profile have a cross-section that is wedge-shaped with various base diameters of 20-40 um and heights of 70-120 um and are referred to as "microwedges".

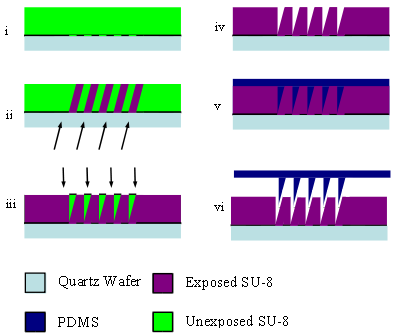

2. Fabrication

Microwedges are made in large arrays by casting PDMS into a mold created via a photo-lithographic procedure. The mold in this case requires a dual-exposure lithographic process using SU-8 as a negative photoresist. This work is done at the Stanford Nanofabrication Facility. The first, angled, exposure is done from below, using an aluminum mask directly deposited on a UV transparent quartz wafer. The second explosure is from above, through a contact mask.

Photolithography process diagram

3. Performance

D. Soto, G Hill, A Parness, N Esparza, M Cutkosky, and T Kenny, "Effect of fibril shape on adhesive properties," Appl. Phys. Lett. 97, 053701 (2010), DOI:10.1063/1.3464553.