|

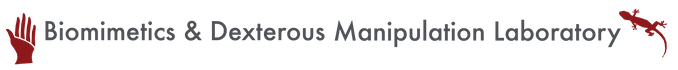

One approach used to fabricate long stroke diaphragms is to pre-stretch a fabric tube on a mandrel (A), creating a mesh that is stiff in the axial direction while permitting some radial expansion. The mesh is impregnated with Sylgard 170 RTV silicone to create a fabric that is stiff in the axial direction (B) but stretches in the radial direction (C). The final product shown in (D). |

|

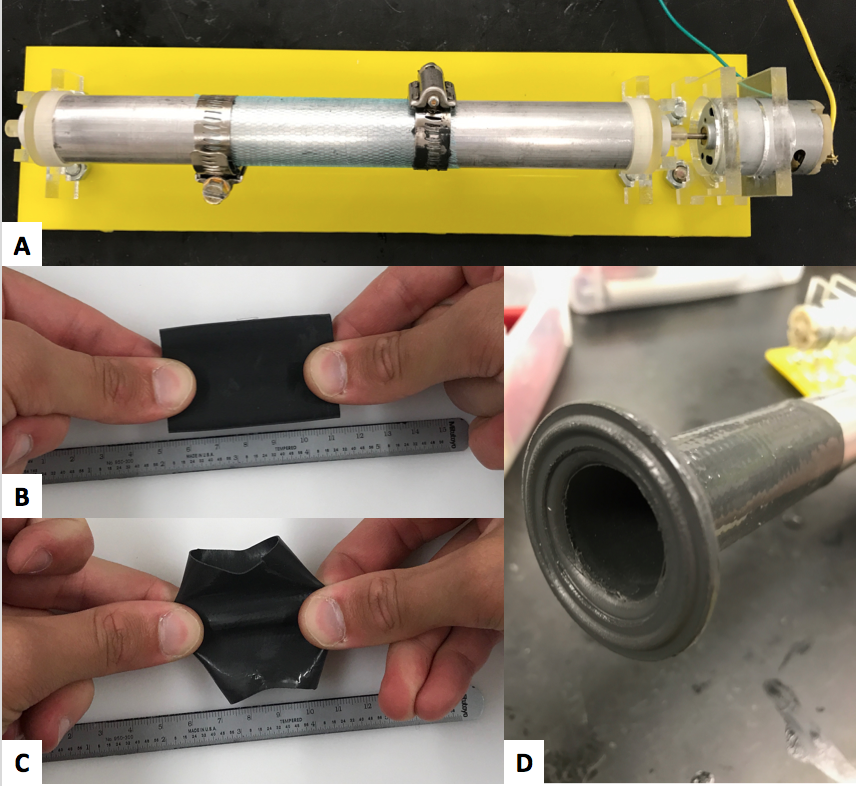

An alternative fabrication approach uses a thin ripstop nylon fabric (A) that is pre-impregnated with silicone. This fabric can be cut,coated with additional silicone (B) (Sylgard 170 RTV silicone at 600 rpm for 30 seconds) and rolled into a tubular shape (C). The final product is shown in (D). |

|

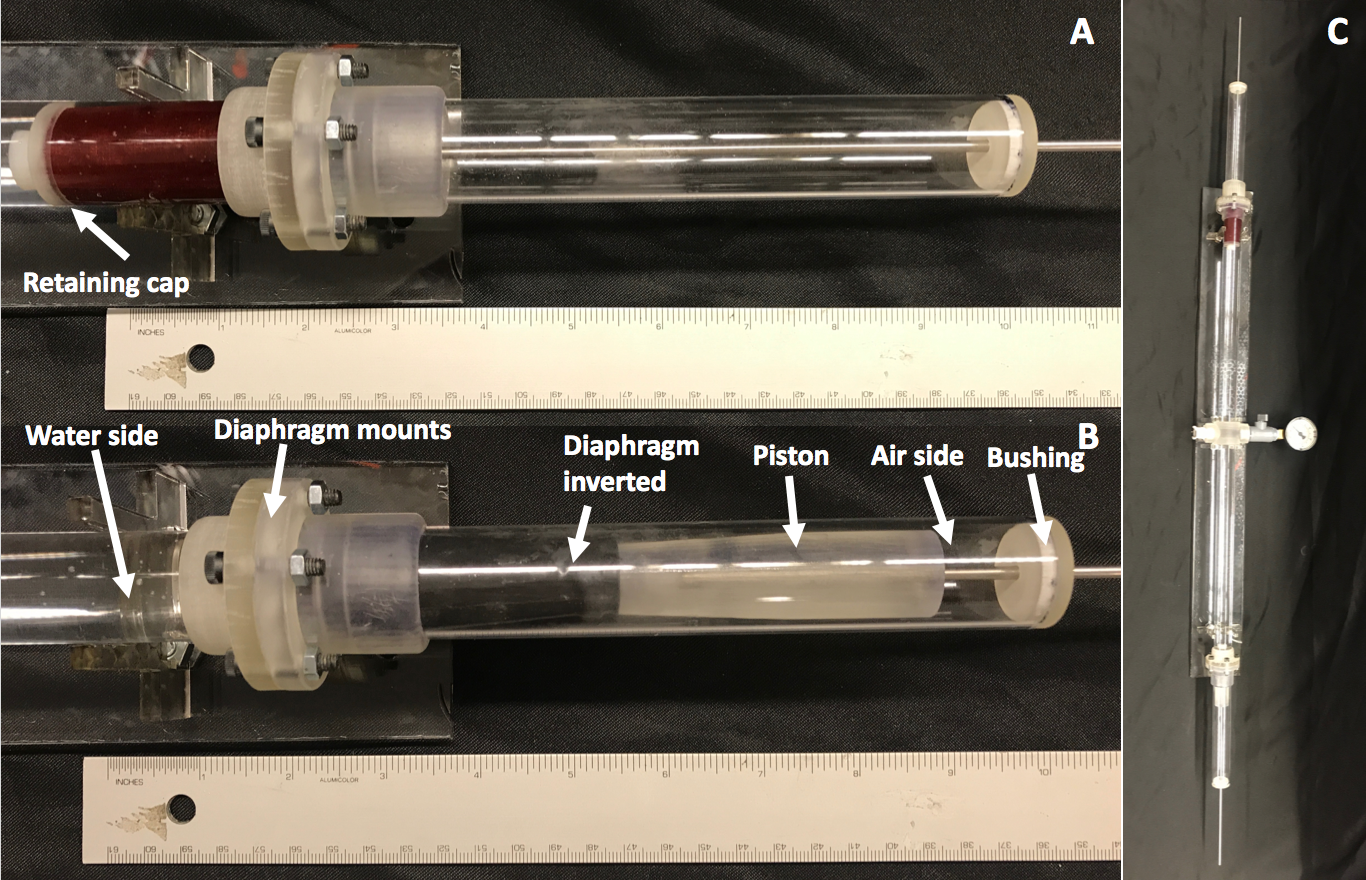

The silicone-impregnated-nylon coated rolling diaphragms have full stroke length of over 5.5 inches. If the pictured were the needle end of the system, (A) shows the diaphragm's position when the needle is fully retracted and (B) shows the position when fully inserted into a patient. The two diaphragms are connected back-to-back for testing with water in between (C) so that when one end is pushed, the other moves accordingly. Once fully inverted, the red silicone-nylon substrate is no longer visible (A,B). |