May 2013

May 2: Videos of quadrotor perching on ceilings and other surfaces picked up by Popular Science for a short article.

May 12: Static and Dynamic modeling and analysis for the latest mechanism.

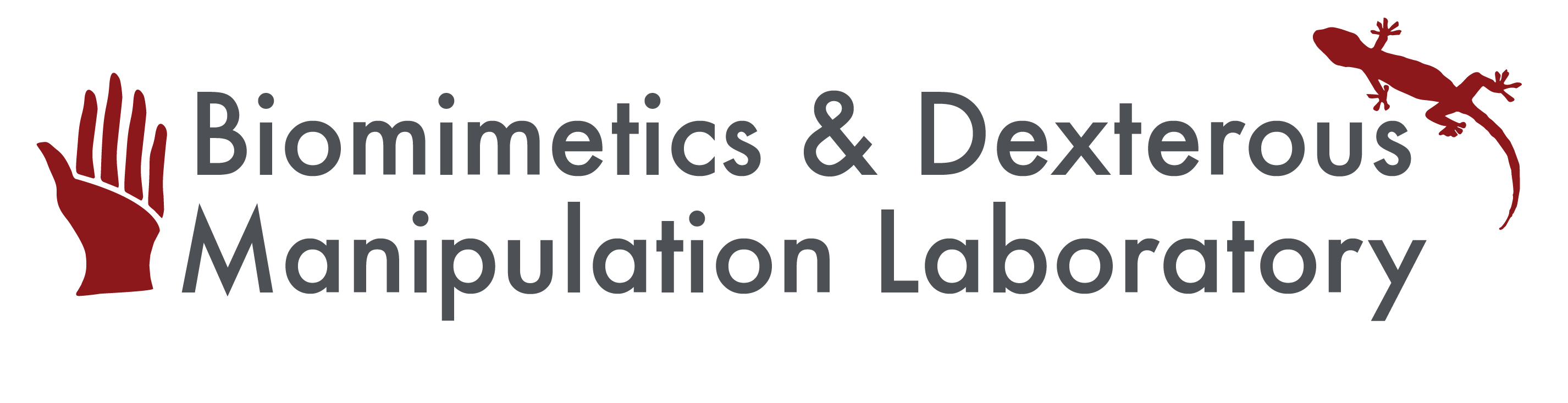

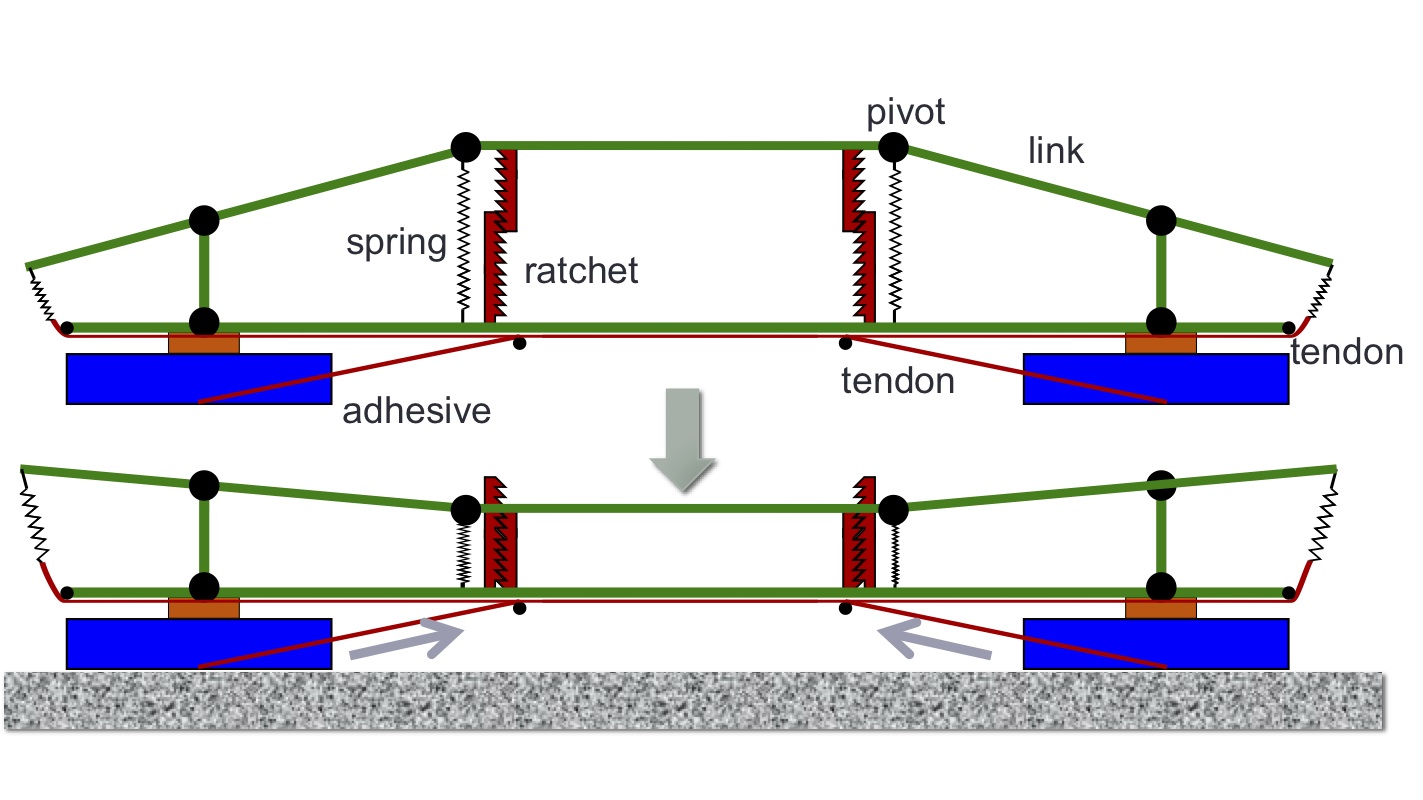

The latest mechanism design is a reduced version of the previous one with the upper board reduced to a point. In this way this point is a universal joint that can facilitate passive self-alignment. Comparing to dry adhesives, spine mechanisms should be able to travel more to get attached and engaged to the asperities of the landing surface, but the basic configuration shown in the picture is similar.

During the whole landing process, there are mainly 3 phases. First the foam is compressed and the triangle collapse to make the pads/spines ready for attachment. Second the tendon strings are tightened and mechanism is locked by latch or ratchet. Some collision also occur in this phase. Finally the mechanism becomes one rigid body and the airplane starts to consume energy and pull the mechanism.

Triangle mechanism prototype

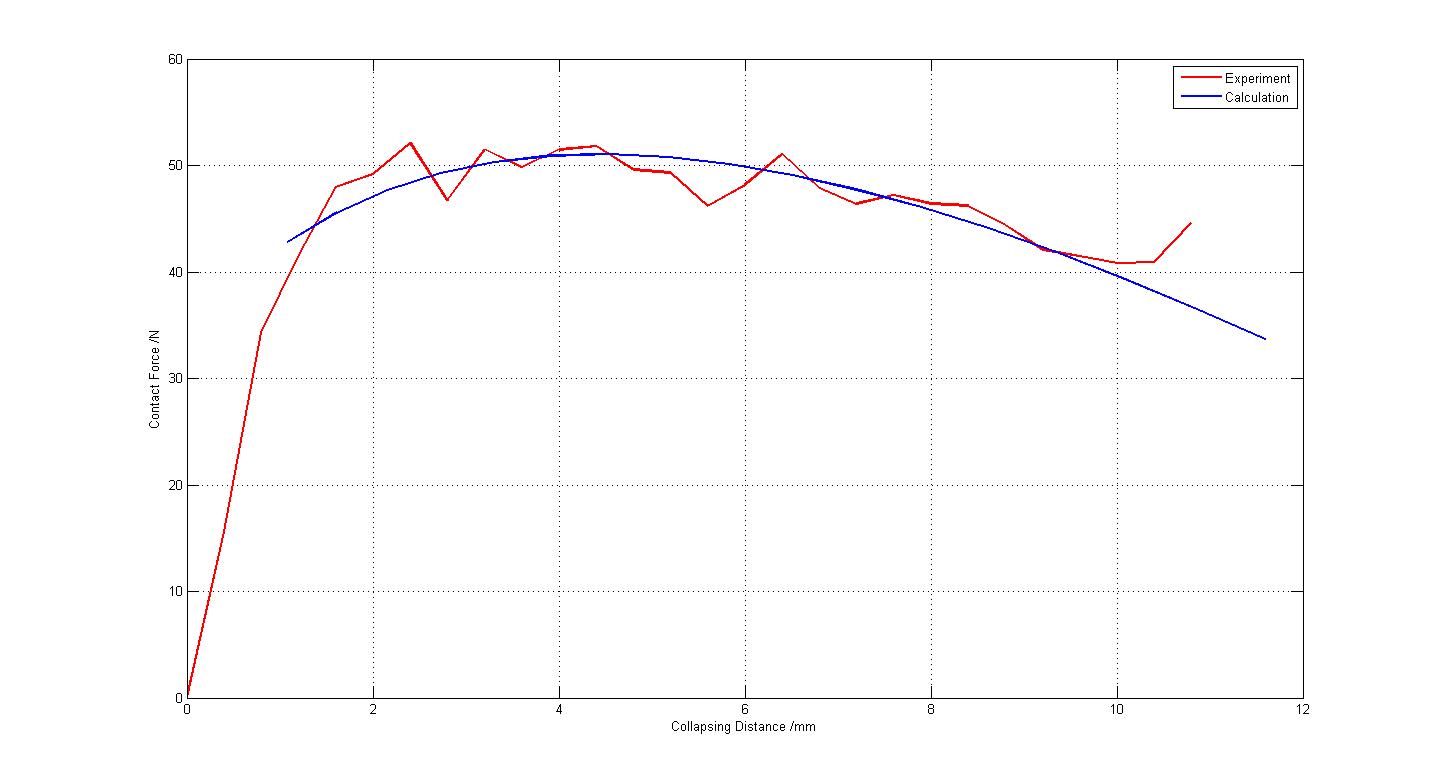

For the first phase, because the quadrotor is much heavier than the mechanism and the rubber band in the mechanism is very weak, there is little energy absorbed. So it is almost constant speed for triangle collapsing. Under this assumption the input/output force relationship is analyzed as a function of the collapsing displacement. It's verified with experiment for very-low-speed/static case. For the second phase, collision is simplified with a single coefficient to calculate how much energy is lost. For the third phase, the whole mechanism is locked to become a rigid body, and all the force applied by the airplane is directly transmitted to the pads/spines. Modeling of the sheer and normal forces are compared with the safe region data/functions to determine whether it is a landing success or a landing failure.

Low Speed Contact Force Verification

March 2013

The current designs involve a combination of light struts, springs, tendons and brakes or ratchets to:

- align the incoming quadrotor to the surface

- absorb and "harvest" the kinetic energy of the quadrotor

- apply shear forces to load the adhesives or microspines

- maintain the internal forces for release on demand

The design implications of these requirements are discussed briefly below:

prototype mechanism for rotorcraft perching

Alignment: -- This requirement leads to a mechanism for which moment of inertia is low in comparison to the torques imparted when the "feet" first make contact with the surface and for which the initial friction is not high

Kinetic energy recovery: -- This requirement leads to the use of approximately constant force springs so that the main interaction force perpendicular to the surface quickly ramps up to a desired threshold, decelerating the quadrotor rapidly without excessive force.

Applying internal shear forces: -- This requirement leads to the use of a mechanism involving tendons and struts to load the attachment pads in oppositioin so that they can provide adhesion and sustain tensile forces perpendicular to the surface.

Storing internal energy for later release - This requirement leads to the use of ratchets that maintain the internal forces until release is desired (e.g. using a small shape memory alloy actuator)

Videos

- Quadrotor perching on smooth acrylic panels at U. MD in Sean Humbert's lab using Stanford perching mechanisms

- Tests of a microspine perching mechanism on rough concrete

- High speed video of tests using a launcher to throw quadrotor at inclined surface

- New Spine Mechanism with TriangleConfiguration on YouTube