Christina's Haptically Updated Summer Blog 2015

On this page... (hide)

1. WEEK 9: Friday August 21, 2015

For later use: [Goal: User testing of directional feedback Goal: Start Making Powerpoint; Additional iterations can happen once powerpoint and SURI paper are finished]

The actual goal for the day was to attend the lab meeting, where all the SURIs presented their posters, which allowed us a practice run through before the poster session and we got to hear the journal proposals from some of the researchers.

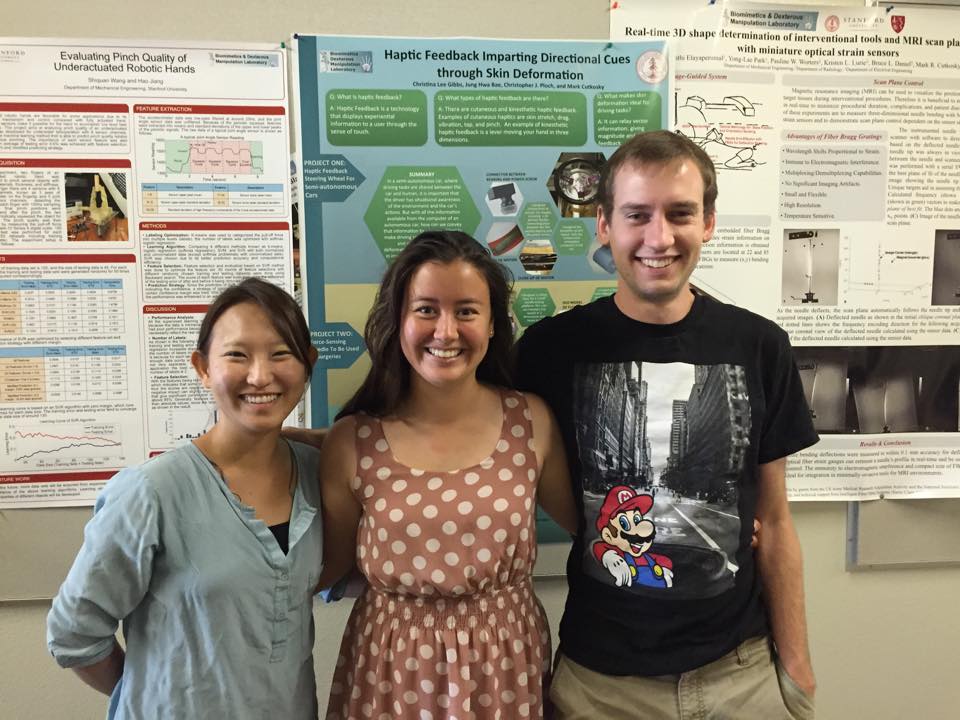

Afterwards, I spent the day at the poster session, mingling with other Haptic Feedback related researchers, oogling posters, and explaining my poster to anyone that happened to be attracted to my well-designed and colorful poster. Out of all the white/red, white/black, white/gray posters using boxes, my poster utilized hexagons and different shades of blue and green.

I finished the day writing thank you letters to my mentors in the lab. I have to say, I'm so appreciative of the opportunity to research here at Stanford. I thoroughly enjoyed this experience.

1.1 DAY 43: Thursday, August 20, 2015

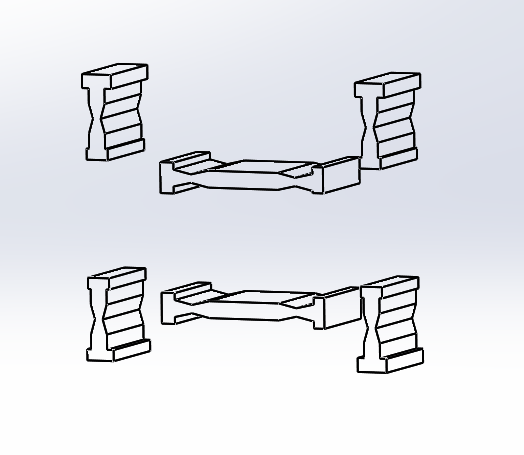

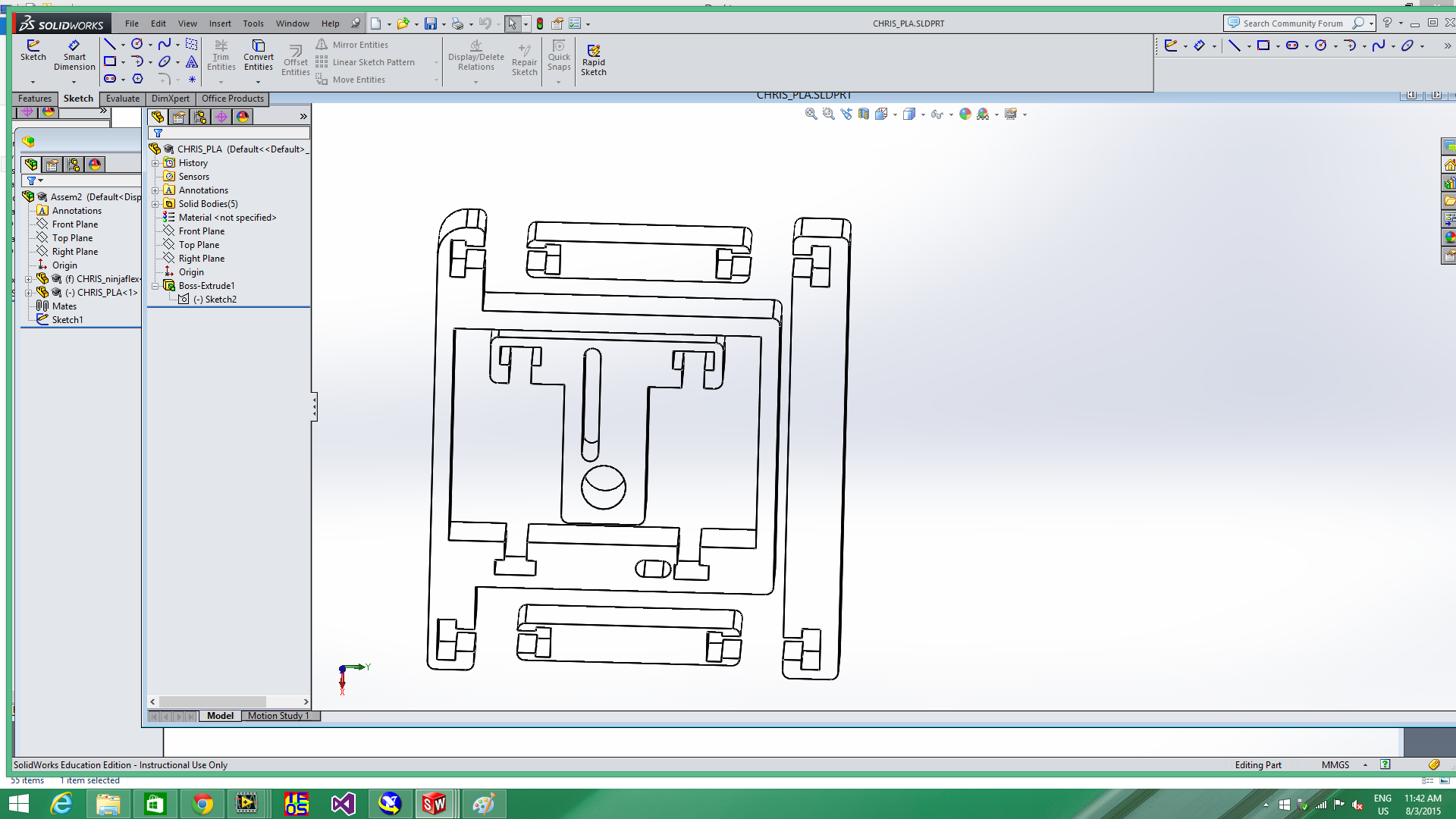

Goal: CAD two devices and print them!

What really happened was that I hadn't had time to CAD any device.

I had planned in advance to go to a tour of the Stanford Energy Facility that morning at 10 AM. I was there with Chris exploring the buildings of the energy plant. The place reminded me of the energy plant in the movie Monsters Inc. There were concrete walls, large ceilings, bright and colorful gas tubes, and people walking around in helmets. It was my first time ever visiting an energy plant.

Things I learned: the facility cost $15 billion to build, while the plant was expensive, it's been in the approval process for almost 40 years, and the building is expected to save money in the long run.

Later that day, we went back to the lab where Chris helped me edit the poster and Jung Hwa helped me edit photo clippings. After three stressful hours of typing, copy and pasting of edited versions, and labeling of the pictures, we made the deadline to print the poster at a local printing shop called Copy Factory on El Camino that was actually very affordable for one day rush printing that had a 10% discount for Stanford students. Jung Hwa drove me to the shop and helped me pay for the poster using the p-card.

Unfortunately, we missed our free lunch at the ME Lab bbq because we were too busy meeting the 2 PM poster deadline.

That night, I practiced my presentation.

1.2 DAY 42: Wednesday, August 19, 2015

Goal: Make a third iteration of the skin stretch and the brush device.

Today, I decided to forgo the production goals of the device in lieu of finishing the poster on time. I made a rough draft outline of the entire poster, and Jung Hwa and Chris helped me to generate more ideas for relevant writing content and picture content. I made a close-to-the-end rough draft of the poster.

1.3 DAY 41: Tuesday, August 18, 2015

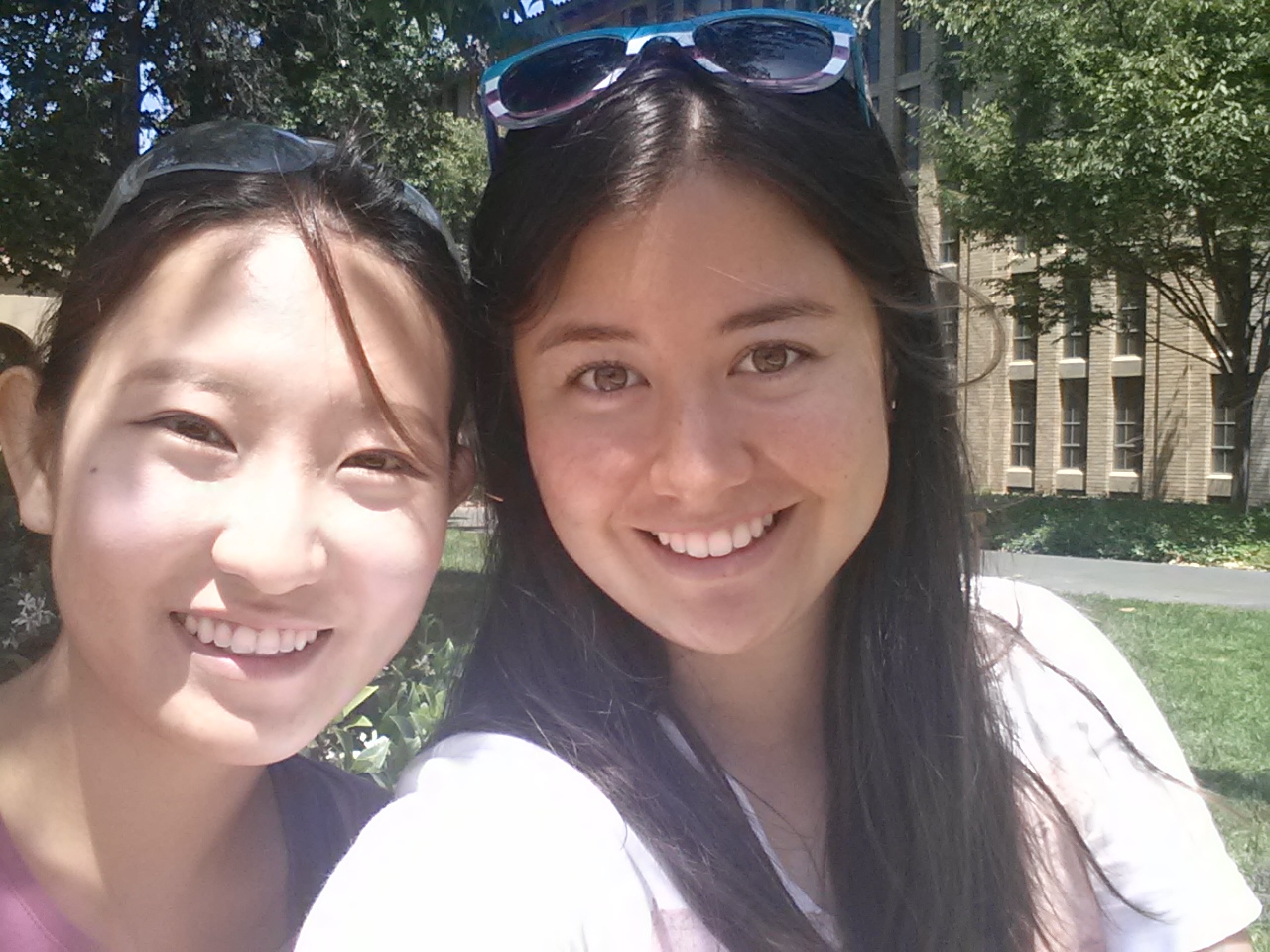

I had lunch with Jung Hwa today and we talked about my project and how I'm doing on my timeline. I decided that I should start outlining my poster and figure out the layout.

Goal: make a second iteration of the skin stretch

1.4 DAY 40: Monday, August 17, 2015

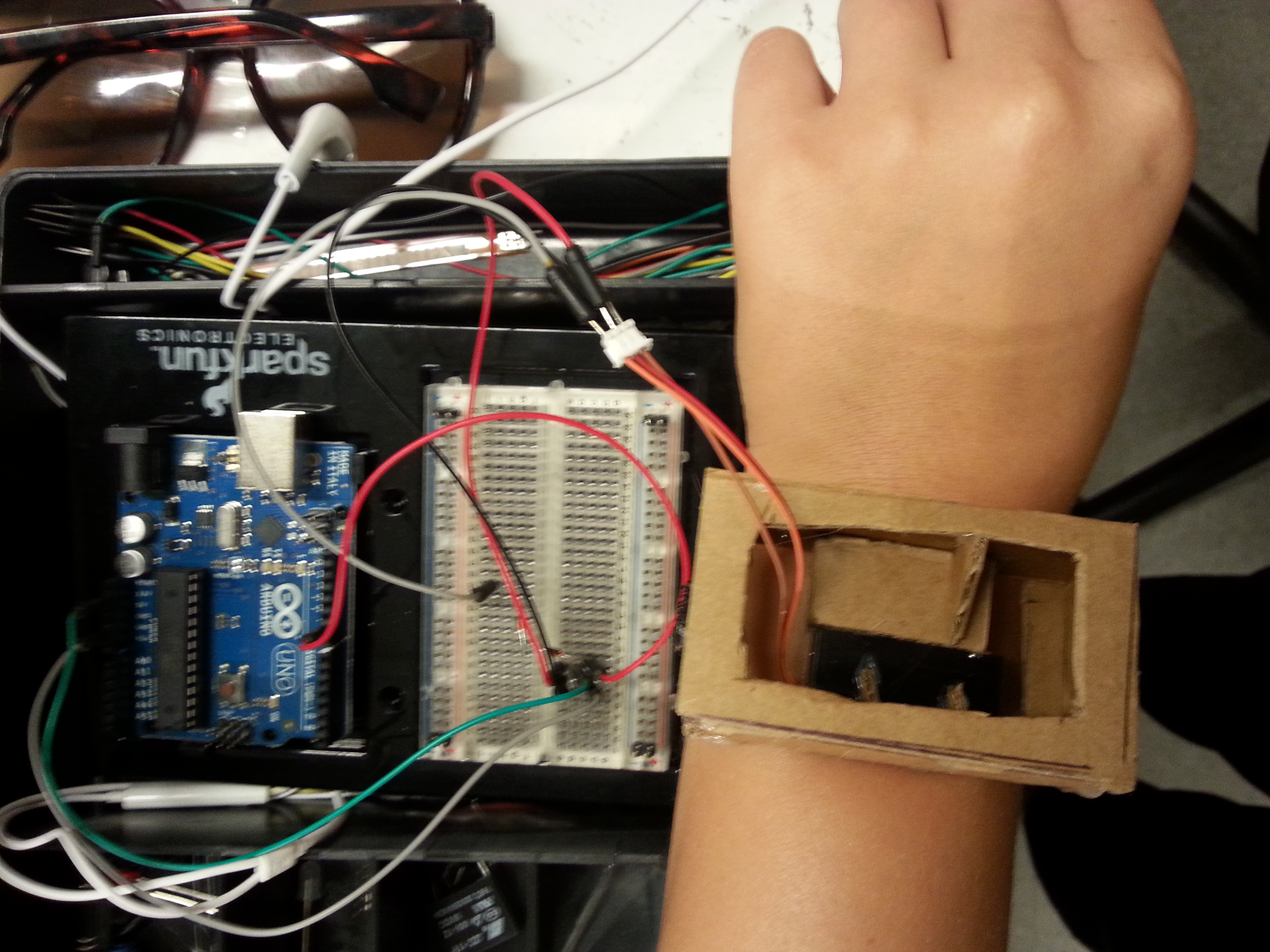

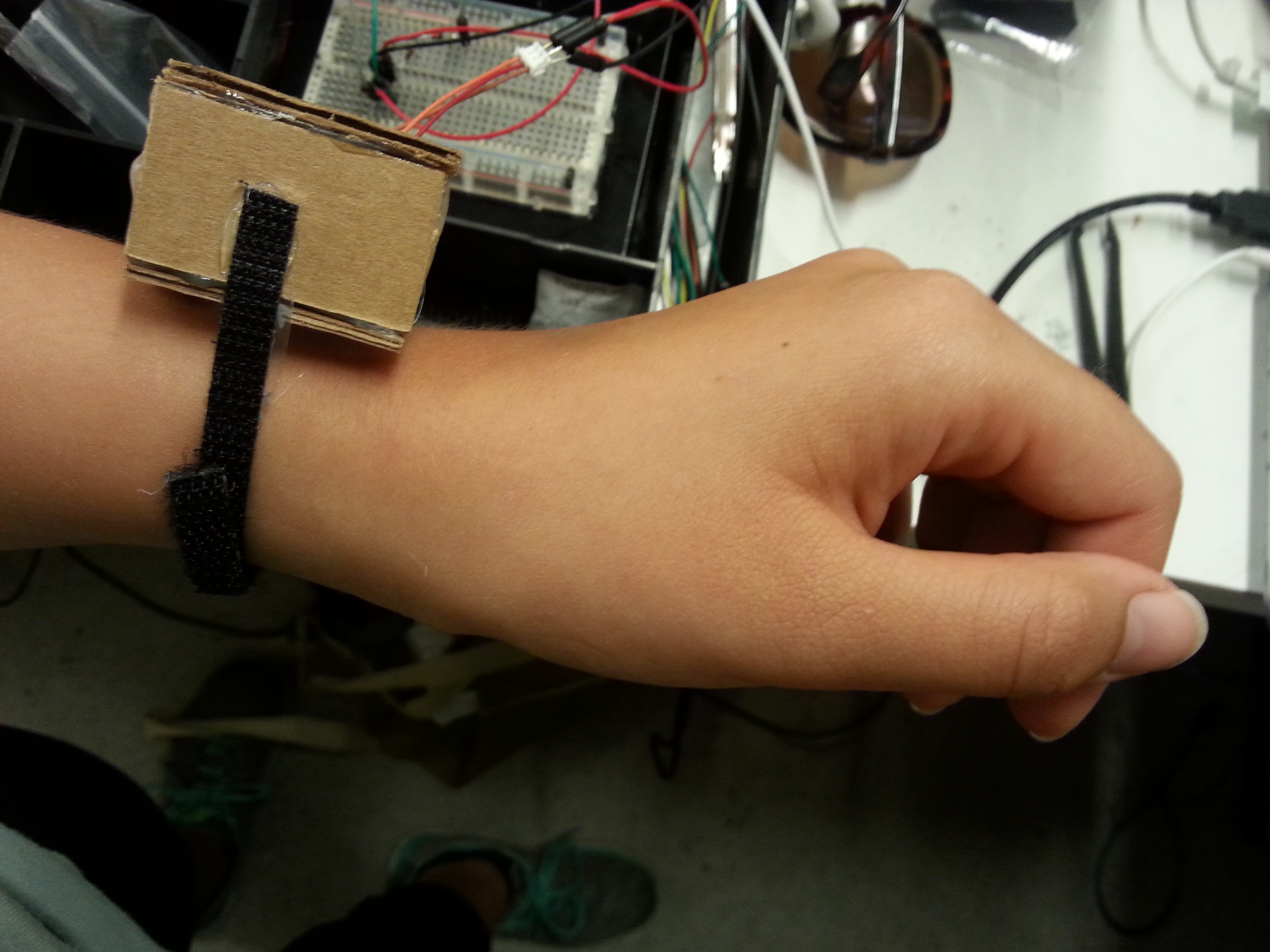

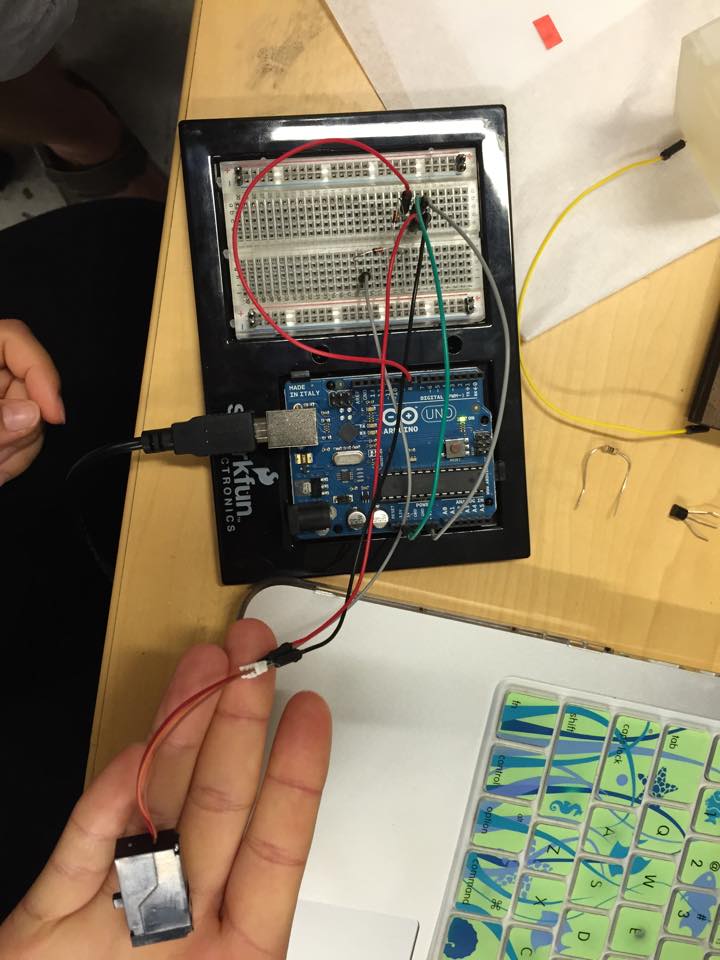

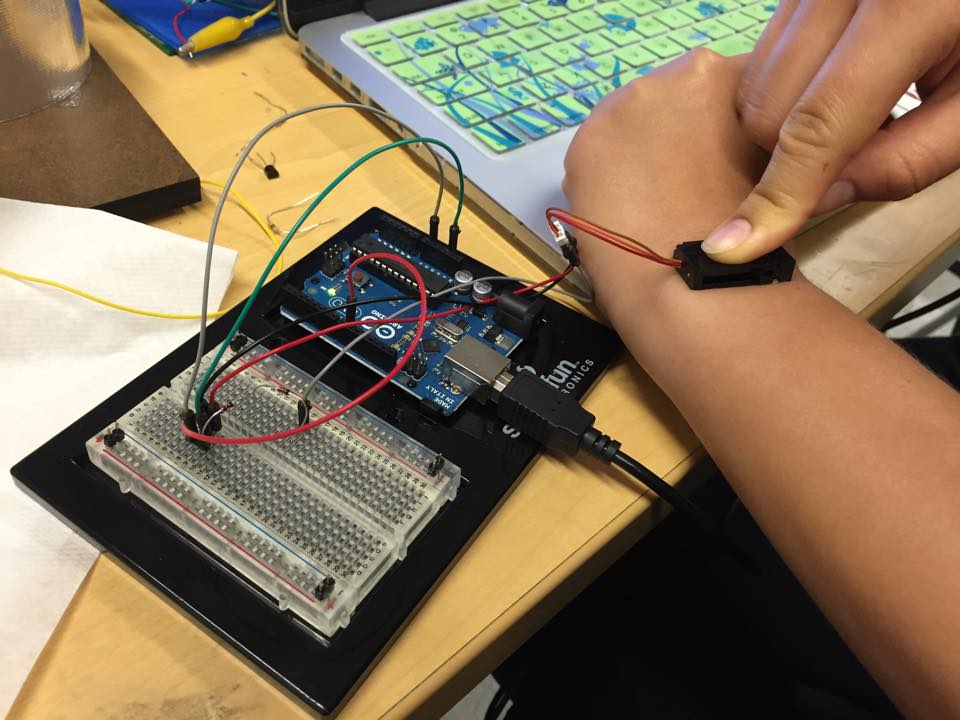

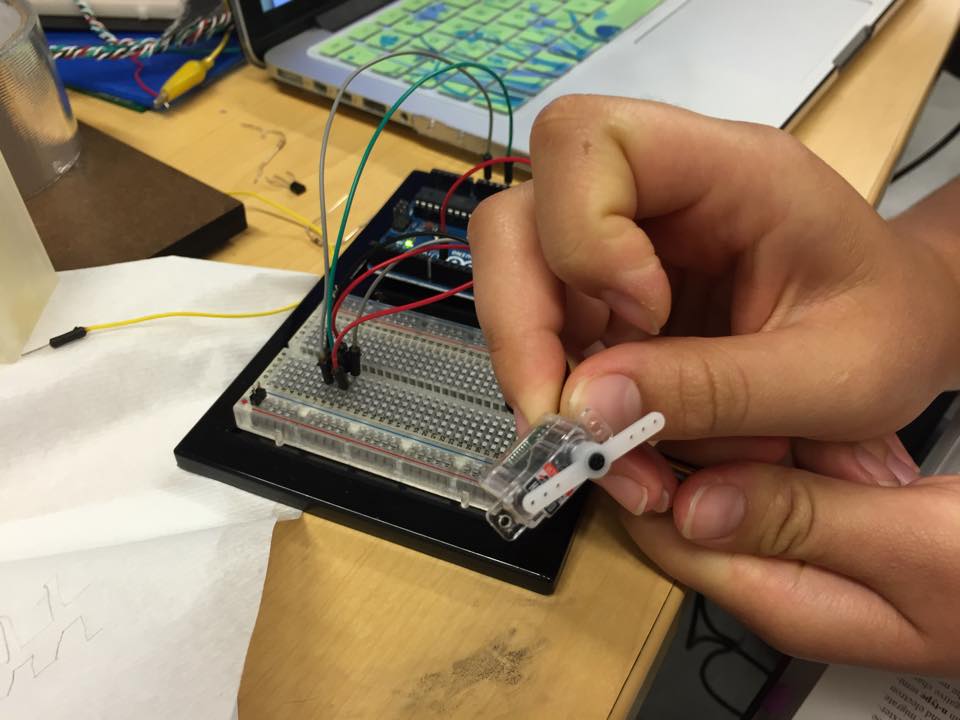

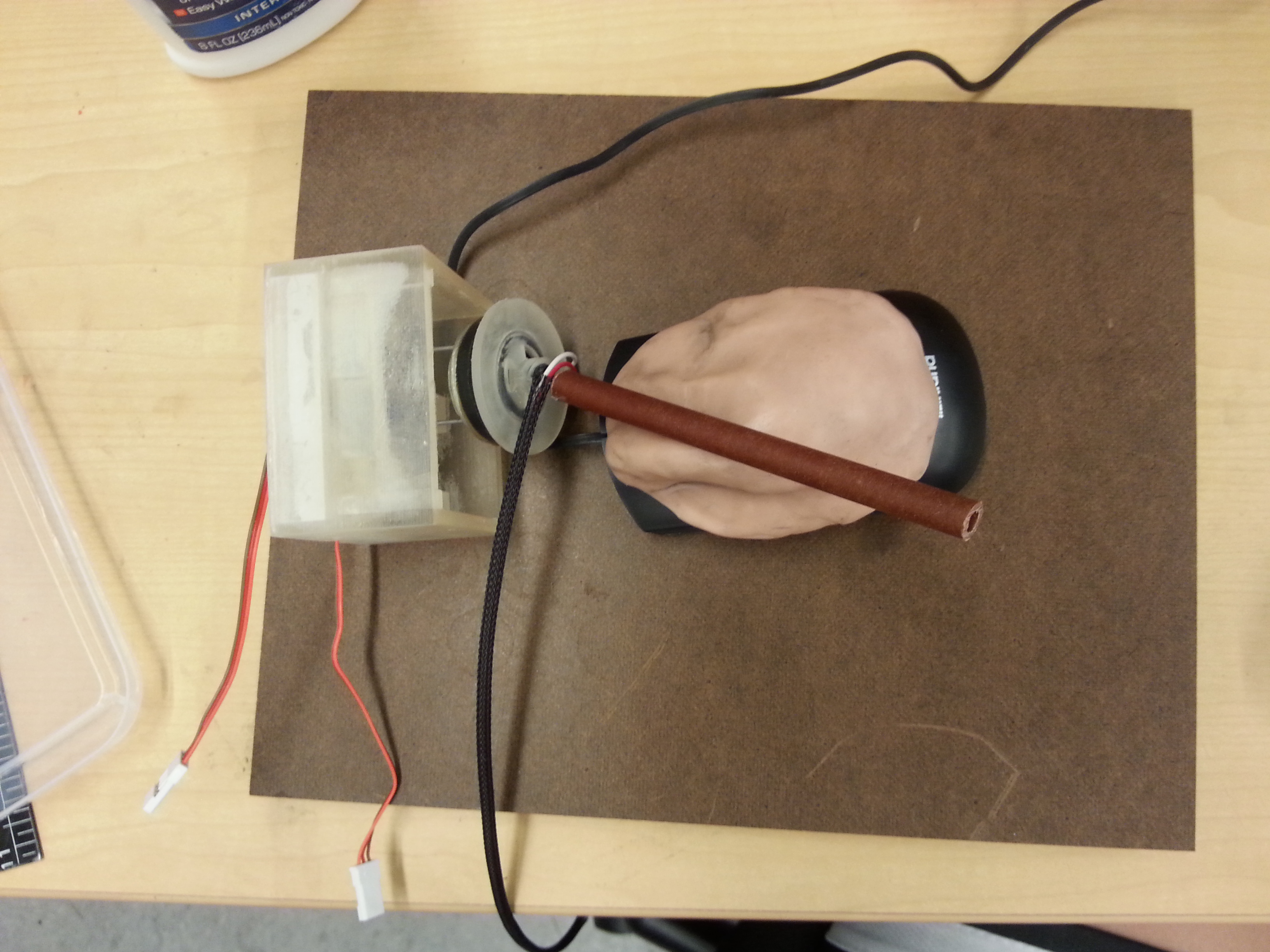

Today, I tried to make the second iteration of prototypes for skin stretch. I got one to move and make a brushing motion along the skin. Jung Hwa and Matt tried my prototype.

Tomorrow, I hope to make the second iteration for my skin stretch device.

[insert picture]

2. WEEK 8

2.1 DAY 39: Friday, August 14, 2015

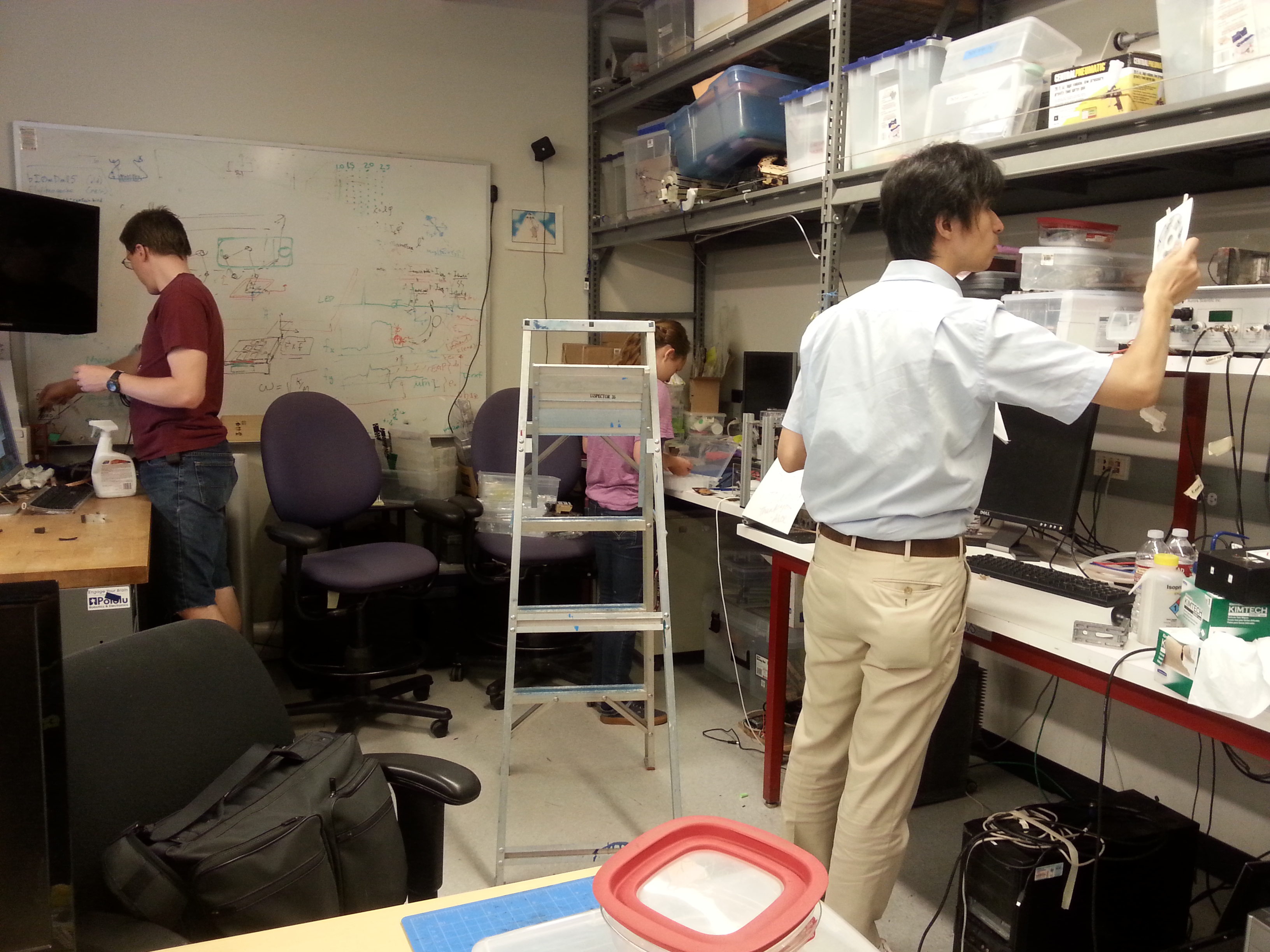

I met up with Jung Hwa and Chris in the lab in the morning, we talked about the presentation for the lab meeting. I organized a box of my protoyping materials and gave a quick run through of my ideas with Chris and asked him to bring it to the meeting. Chris and Jung Hwa stayed in the lab to get more material for their presentation on the needle.

I met Ian along the way to lab and he told me that I needed to make cut tomatoes for the lab BBQ. I went upstairs, brought a knife that I found in the red tool box, washed the knife thoroughly, and started cutting tomatoes with Katie. But then Mark asked the SURIs to go to the lab meeting, and we finished up what we could in the kitchen and sat through 30 minutes of Chris and Jung Hwa presenting on the haptic feedback needle, and I got to present my prototype ideas to the lab. The purpose of presenting to the entire lab was to solicit advice or feedback on my ideas from a larger audience than my mentors. That was good. I think I could have been more prepared and spoken louder about my ideas. Still, it was good practice. But I had to leave as soon as I finished talking. We set up tables outside, carried items from the second floor of MERL to the grills outside of Peterson, Dave helped with moving a lot of things. The SURIs arranged all the prepared food on the tables. It was almost noon, and Chris and Ian were busily trying to get the meat to cook. The pork took longer than expected to cook. One grill set all the meat on fire and the other barely held any heat at all. We had some issues to work through that day.

Problems that arose during the BBQ: we handed uncooked raw cold beef hamburgers to people, the beef hamburgers all looked charred and burned on the outside and shriveled up into tiny pieces and people wanted bigger pieces. The pork was really tasty since it was marinated, but for some people, there would be times where everyone wanted burgers and all we had were pork slabs, and other times everyone wanted the pork and not the hamburger pieces. I had to shuffle people along and call out to people in the line to see if anyone wanted what the people in front weren't interested in eating. Engineers aren't super responsive unless you call them out apparently. "Hey, you, yes you in the blue shirt, would you like a burger or are you waiting on the pork?" I was a server that day and actually met a lot of people by talking to them. I met a visiting scholar from Berlin called Sam. I also talked to people in Santiago's lab. I can't remember their names anymore right now. But they were really friendly with me. Not many people would talk to me as they waited for their meat to cook, but a few people conversed with me, so I appreciated that.

After everyone was served, we realized we had so much meat leftover! We had about four freezer bags of marinated pork leftover and some hamburgers. Ian put the rest of the hamburgers on the grill and marinated a few more pork slabs. The pork pieces were pretty huge and we still had leftovers. I can't believe we fed people for about under $2 each and still had leftovers. Mostly because people didn't really turn up to the BBQ, we hypothesize this. Another idea is that we bought meat in excess.

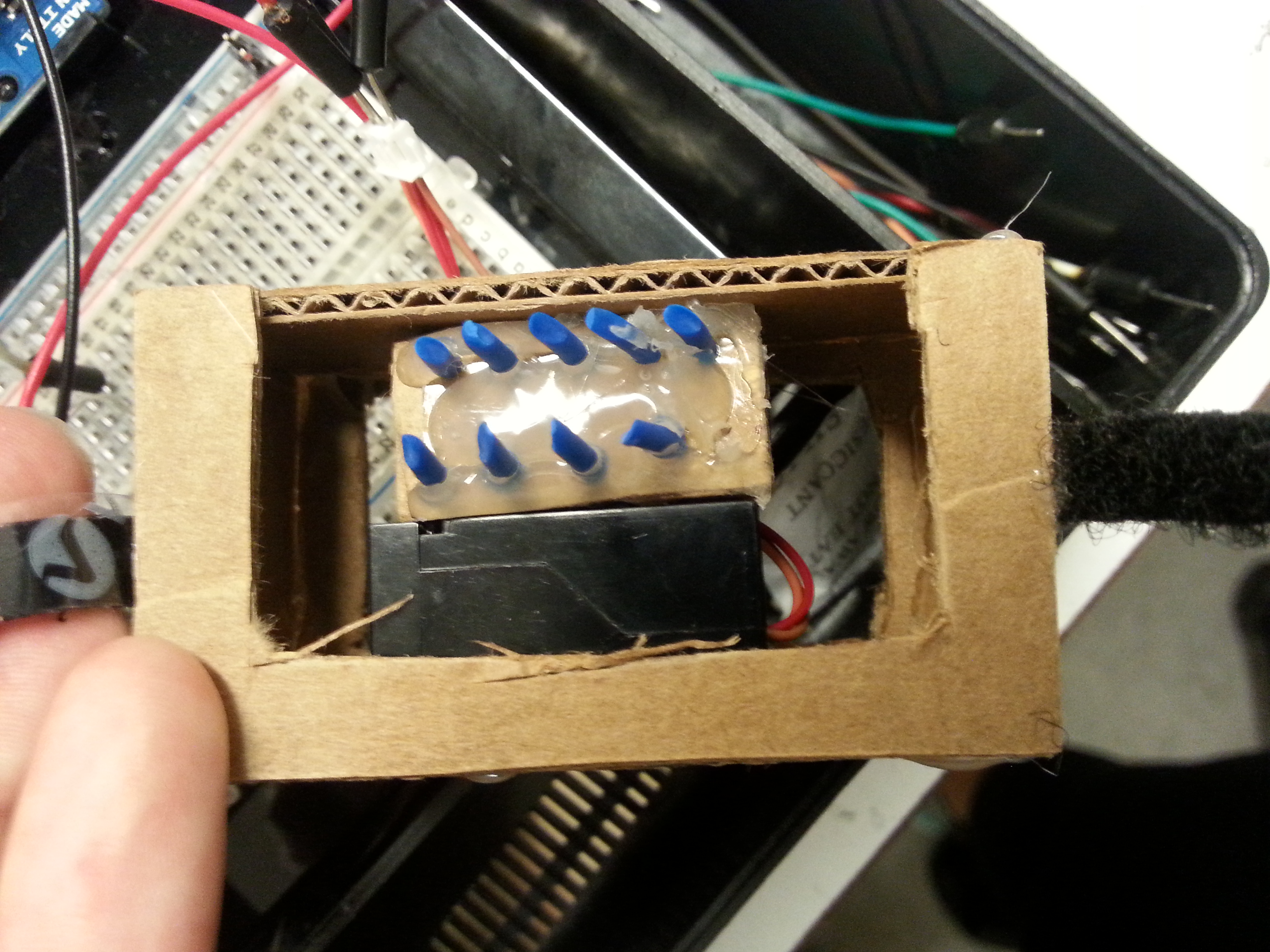

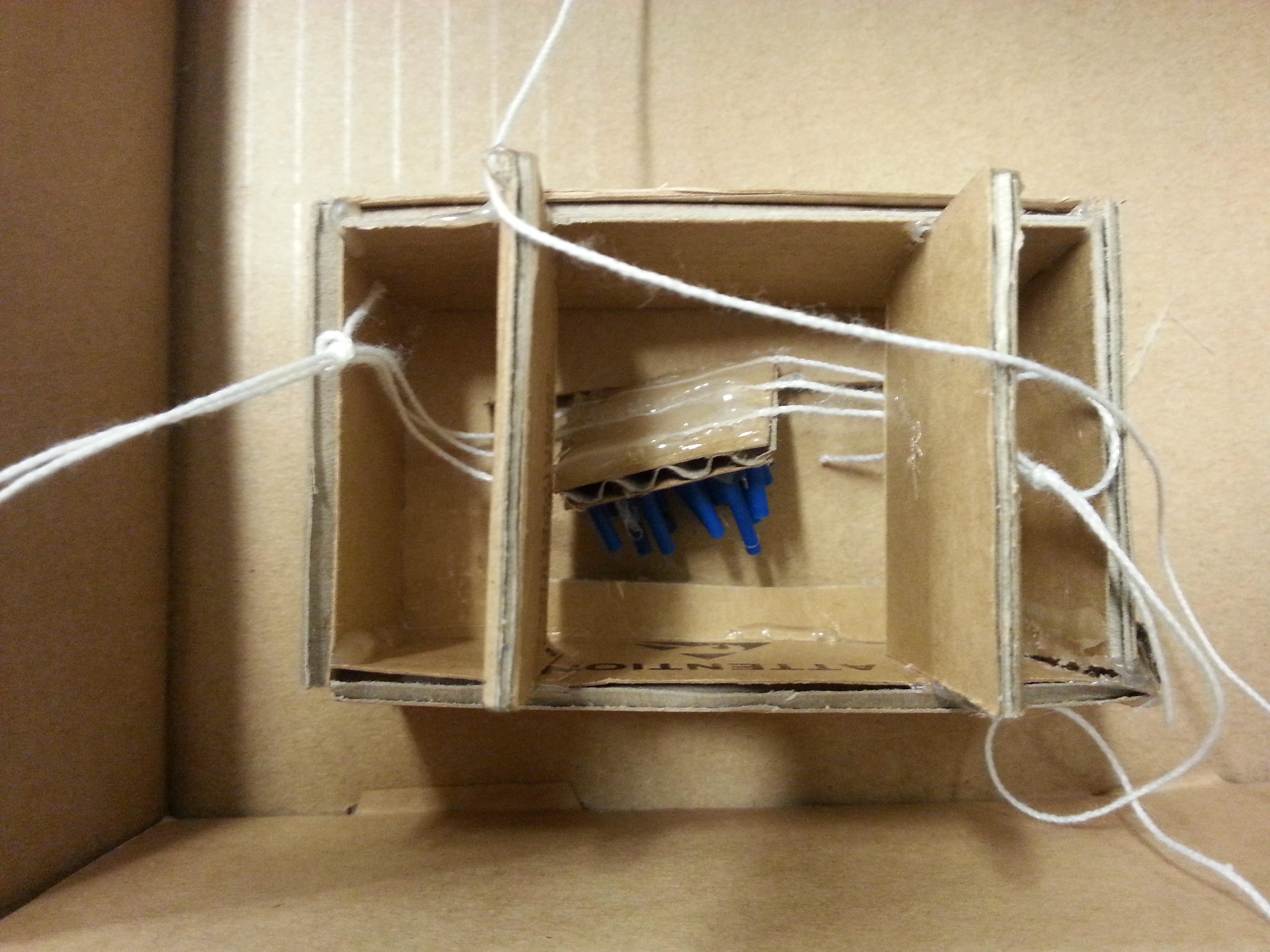

Afterwards, we had to clean up and put the tables away and the food away. Then I started prototyping the first version of my skin stretch and brushing haptic devices for the semi-autonomous car. I also got to talk to Matt and Alice about their advice on what I might want to get out of this summer experience and I clarified my goals after discussing that with them. Matt was helpful in blocking out a schedule of deadlines to make for the poster session next week.

[insert photo]

2.2 DAY 38: Thursday, August 13, 2015

- walked around the lab and picked out pieces that could be used for my prototype

- began making prototype

- talked with Crystal in the CDR about purchasing prototyping material using the p-card

- Went with Chris and Ian to buy necessary items for the BBQ at Safeway that they didn't pick up at Cash & Carry, the huge wholesale food distributor for restaurants. So we purchased cans of pineapple, cartons of soda (Ian says that Safeway is the cheapest place to buy sodas because they have contracts with the soda companies to ensure low prices),

2.3 DAY 37: Wednesday, August 12, 2015

- did a few user tests of the data

- watched a lot of transitor videos and read the BJT, felt really overwhelmed

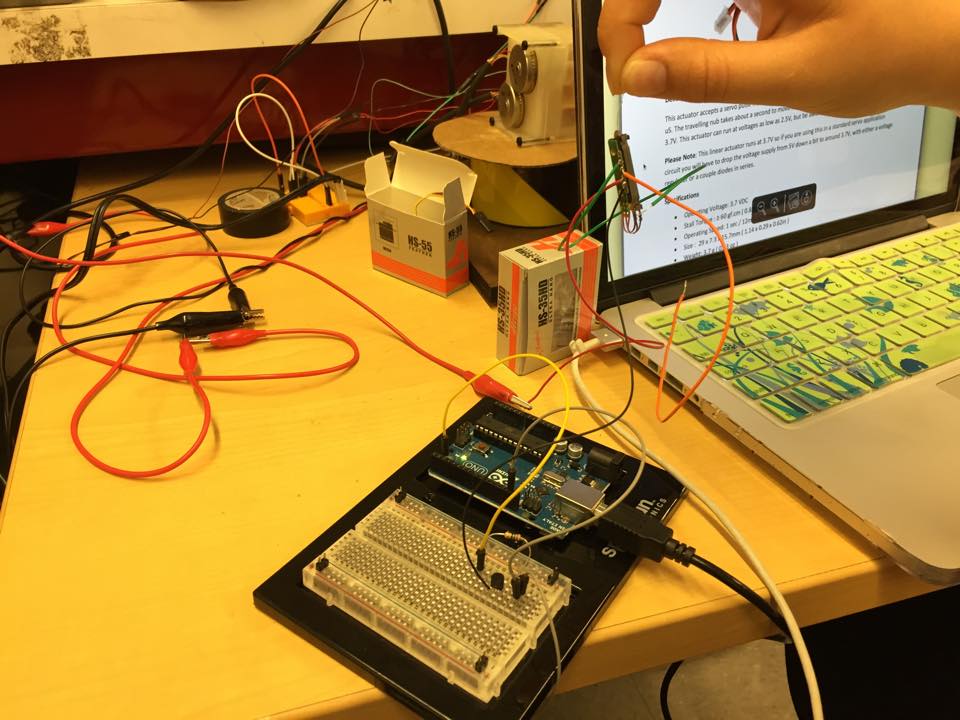

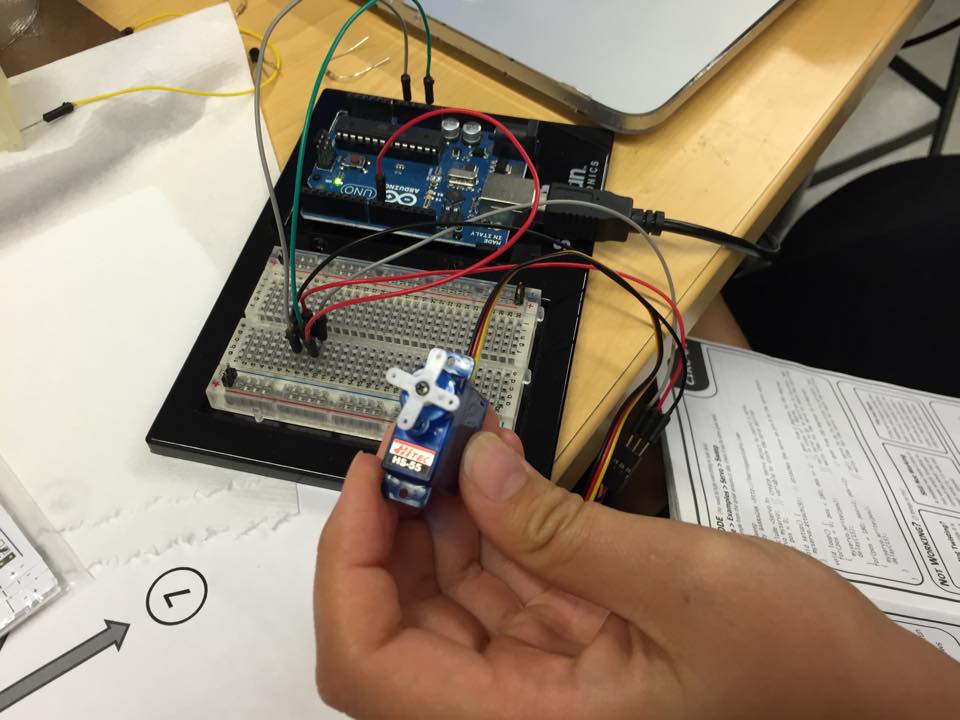

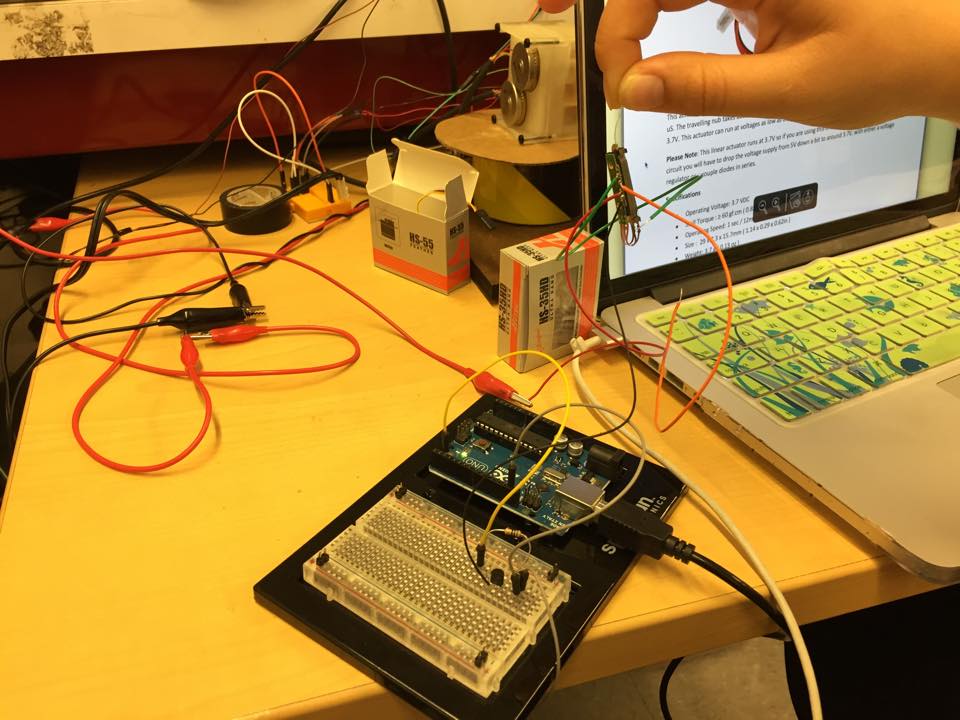

- made the servos/actuators work

- got the tables reserved for the bbq on Friday

- missed the lab get together at Dave's - oh well, indiana jones will have to wait for another time

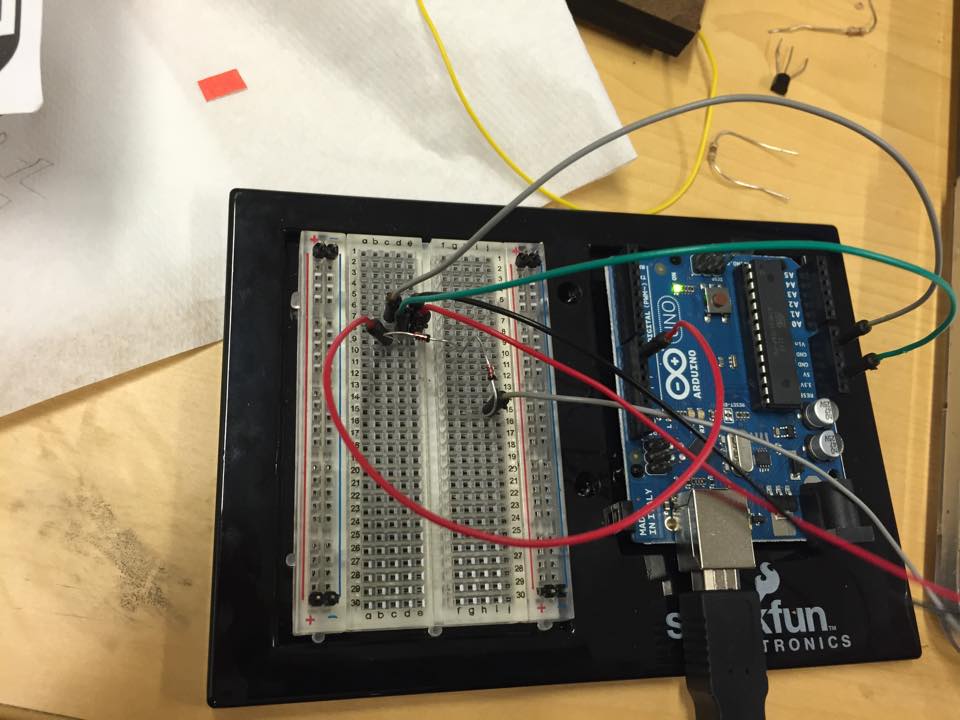

[post the pictures of them]

2.4 DAY 36: Tuesday, August 11, 2015

- soldered for the first time

- tried to make the servo work

- read up more on BJT

- went to the 2:00 PM lab swim team meeting for the first time and went over the basics of breast stroke with hannah and matt. we had a blast.

- had a nice walk with Hannah

2.5 DAY 35: Monday, August 10, 2015

- made the notes look really neat

- Anyone at Stanford, can view the google document of the notes I made for this haptic device:

- screenshot pictures of the past prototypes and added them to the notes

- the Haptics corner came over to my place for

3. WEEK 7

3.1 DAY 34: Friday, August 7, 2015

- Lab meeting

- Must make a concise list of products so far.

- continued to make the list of products out there so far

3.2 DAY 33: Thursday, August 6, 2015

I read through products, played around with the sensors. It's really easy to get distracted reading about novel products. You'll find one image that's neat, and find yourself looking at something similar but different. So I started off looking at wearables and wound up reading more about PARO, the white fluffy seal that cuddles with you, the future of robotic pets. It's interesting how Japan is gearing up for a world where the average age of its population is over 65. One article made a fascinating point that by allowing young people to leave their elderly relatives with biomechanical robotics and technology, they can make the time to be in the workforce. This technology will be useful for other first world countries as our birth rates drop as well.

Their technology is also useful for depression therapy and autistic children because the pet will respond positively to anyone that simply strokes it unlike dog therapy and doesn't have any germs or dander. This technology is also useful in allowing elderly relatives who cannot take care of a real pet to have something soft and cute and responsive around them.

I found flexible arduinos. Google images is a great way to see how people, mostly amateurs posting to open source platforms, are making products. Google scholar is great in seeing what researchers are making and how the pieces all fit together in their diagrams. I played with the memory shape alloy actuator today to see how it would fit around my hand and what I would want to do with it in a prototype. With Chris's suggestions, I looked up the data sheet of a few of the motors that he purchased. We talked about BJT, bipolar junction transistor, and figuring out how to put enough small current to get the larger current running through the actuator. I really wish that my understanding of electronics was better. I feel really slow and understanding it. Oh, there are so many acronyms to know in tech. It's a wonder we all don't sound pretentious to other people. Whenever I talk about my work, I feel like I ought to start at the beginning but that would take forever, so I just try and sum it up in the shortest way possible. I wonder what people are leaving out when they tell me about their work. I wonder what makes other people frustrated. Tomorrow I'll tinker with wiring the parts together some more.

3.3 DAY 32: Wednesday, August 5, 2015

I continued to read through articles and understand the meaning behind the pieces. I stumbled upon ME327's page taught by Allison Okamura. The class is about haptics and I read through some of the lecture slides. I thought that was very informative. I made a google document of all the websites I found. I'm glad Mark suggested I use a google doc or any thing to record my thoughts on the research papers. I still think research documents are a little overwhelming, but I definitely feel less intimidated by them. After reading through all the relevant articles I had open in my browser that day and noting the information I found relevant for my own research, my eyes glazed over and I went to Chris to flesh out the important information. Reading articles can really take the life out of you. Afterwards I just wanted to stare at the ceiling and look and the blankness of it all and let my mind wander to how I could use what I learned.

3.4 DAY 31: Tuesday, August 4, 2015

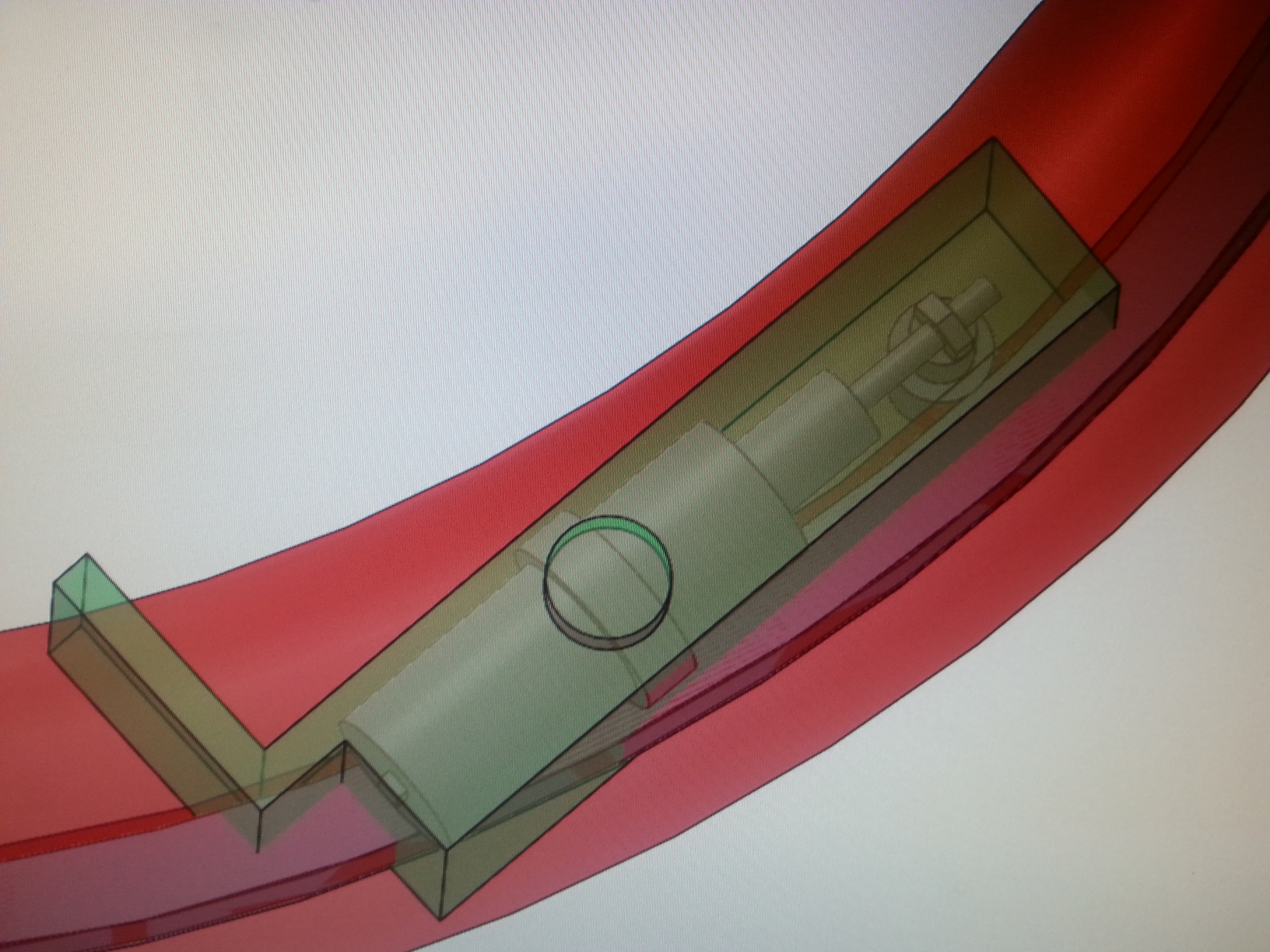

In the morning, we met with Mark in his office. We talked about our progress and where we are with helping Jung Hwa's needle force sensing prototype. There's a deadline on that, and we've all agreed to get the project to that date. We went over steps we need to take to ensure that it's working with a rough sketch of how our progress should look over the coming weeks. We also discussed what can be done for Chris's project and whether it would be wise to cut out a straight section of the steering wheel. We decided to make a lock in key piece that looks like a rabbet in order to maintain the wheel's structural integrity. I also discussed the possibility of me starting an independent project. I want to make a skin stretch wearable for use in vehicles. Mark suggested that I look up what has already been made and what designs have already been created. I agreed and started researching on google scholar.

It was rather cold and I felt under the weather around the afternoon. I got the chills and felt really unwell and went home to sleep and drink a lot of tea and warm fluids and read a few more articles.

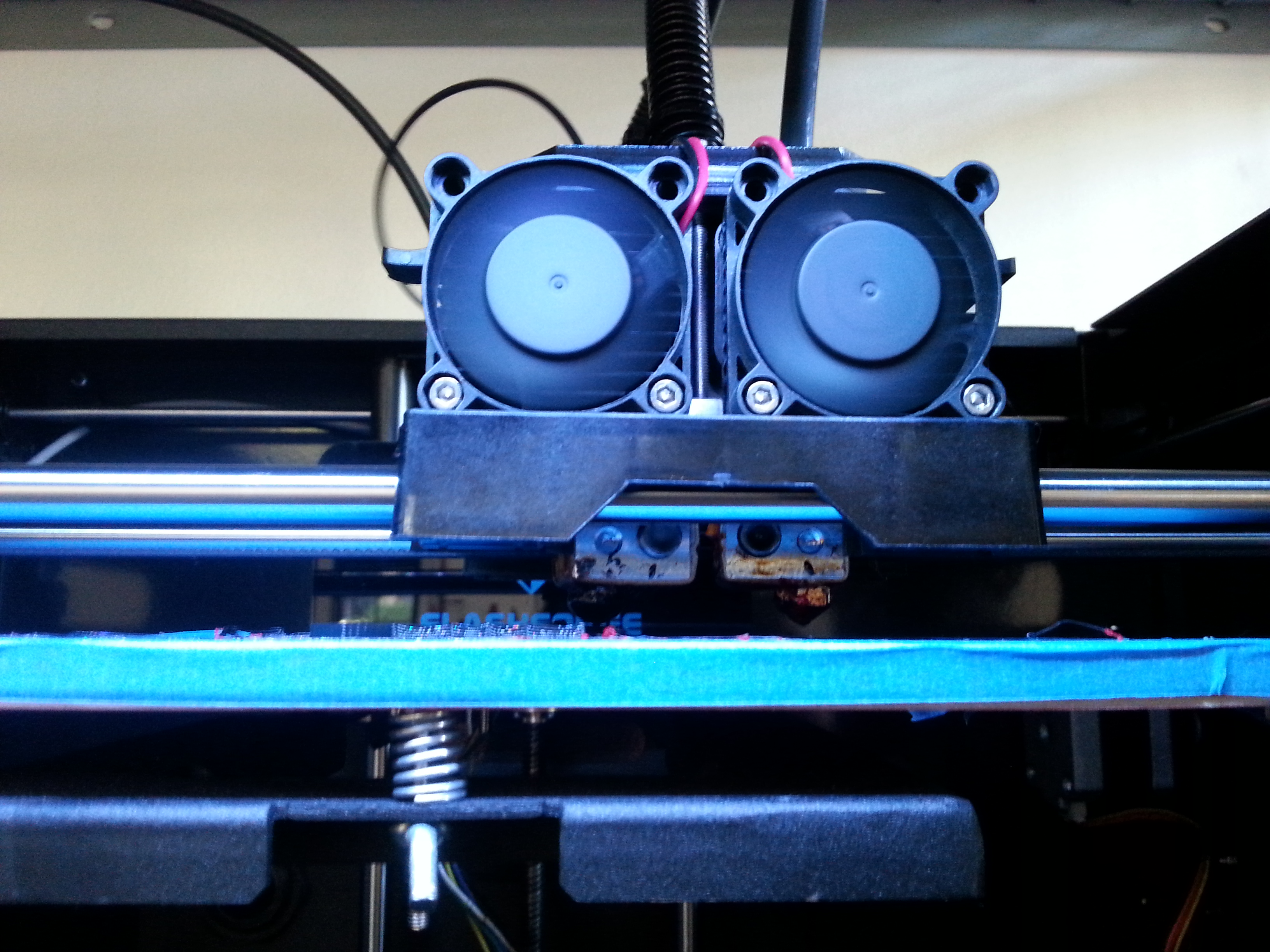

3.5 DAY 30: Monday, August 3, 2015

Today, I made a new SLDPT assembly. But the ninjaflex piece I made didn't fit into the PLA piece like I thought it would when I assembled it. So I had to address that issue and I made a new ninjaflex piece. I learned how to mate pieces when assembling them. But then, when the pieces fit together, the angles were slightly off in the divet, so I fixed the angles. Then, when I had a working CAD, I saved it to my drive and tried to place the pieces into Maker Bot to print them. Because we were using two extruders, I followed the other instruction sheet. The sheet explained that I would have to import a certain print setting to change the temperature and speed of extrusion for the left and right extruder. I didn't have this print setting, so I tried to manually put it in by hand. That didn't work out so well. And Chris complained about how the new version is weird and that he wouldn't update his. He shared a file with me that had the print settings. I used that, and exported the file for printing. But the print temperature settings weren't reaching the levels they were supposed to. We pre-heated the machine, and yet with the file in, the printer decreased the temperature. So we kept trying to upload the file with my Maker Bot, and when that didn't work, Chris tried. He had to export the print a few times before it finally had the right extrusion temperature. The Flash Forge is a very finicky machine.

When the piece printed, it was half the size of the original. It made sense to Chris since it took only 40 minutes to print. Chris may have given me a previous version to update. He went back to the lab because that's where the windows computers are, since both of us have macs. He enlarged the piece and we left the last piece in the locker printing. The print job was around 80 minutes. By then it was late, and we called it a day.

4. WEEK 6

4.1 DAY 29: Friday, July 31, 2015 (Last Day of July, then A New Month Dawns. Aka. Time passes too quickly)

We are in Old Union. There are people chattering about their debate speeches at like 5 times the normal talking speed. There are many of these people. The room smells like sweaty overeager young kids. Oh, summer camps.

- Practiced Design Thinking in the d-school with Chris

- Tried to print a STL file, but I realized I should have saved it as an SLDPT piece before converting it to STL because I didn't assemble the pieces before converting them to STL files. I realized this while in Building 520, reading the instructions for printing on the Flash Forge. Then Chris tried to fix the parts but it wound up taking too much time. So we would wait until Monday.

- Created a spreadsheet of motors to buy, bought a shape memory alloy actuator - Chris used the p-card

- Spreadsheet can be accessed by anyone at Stanford:

Lessons Learned:

- always save things to your google drive

- manage stress

- save your files in an easy to access way

4.2 DAY 28: Thursday, July 30, 2015

- Chris said that I should start designing the dream prototype

- so I started drawing images of what I think this wearable should look like and behave like before I start making it

- drawing is fun

4.3 DAY 27: Wednesday, July 29, 2015

- looked at wearable article

- youtubed wearables to see what parts people are using

- tutorials on youtube

- I have a deadline to buy parts before the end of August.

- Spent most of the day creating a new flexure that has a more flexible ninja part

- Highlight of the day: Chris has to login to find the original document of the flexure about six times. That was so funny.

- The printer had gone missing, so we couldn't print the flexure; A mystery that we will unravel for another day

- Old Union has a crazy number of debate kids; it was almost laughable; in fact it really was a little amusing

- Chris butt called his grandma and then had to take the call

- Old Union smells like sweaty kids and if you close your eyes all you hear are the voices of kids rehearsing their speeches about government issues at around five times the normal speed of conversational talking. "My proponent may think this...." "But it would cost the government xxx"

"My idea is viable because ___"

I felt like I was in high school all over again.

4.4 DAY 26: Tuesday, July 28, 2015

- looked for Jung Hwa's papers, slightly

- made new CAD models of a less stiff flexure

- I learned about lithography, and other printing types

- sat in the D-school and met a visiting scholar from Italy who works in Larry Liefer's lab. She was very excited to have a conversation about the success of her project with someone on her phone. She seems interesting. She had a small conversation with me, asking me to watch her bag while she went to the restroom. Then I met her again outside of the CDR.

- had lunch with the SURIs :)

- ruined Chris's perception of the worker's constructing the new administration building outside of MERL. Youtube strikes again!

- Highlight of the day: I got a really nice email from Atsuo. That was very touching.

4.5 DAY 25: Monday, July 27, 2015

- read some wearable research papers sent by Chris for inspiration on the design

5. WEEK 5

5.1 DAY 24: Friday, July 24, 2015

- lab meeting.

- Chris went to a GM event and gave a presentation, he didn't get back to lab until 5.

- lab bbq

- talked to people who have cadavers in their fridges

- made lists of project ideas

5.2 DAY 23: Thursday, July 23, 2015

I scoured the internet today looking for wearable, arduino, 3D printing, laser cutting projects and ideas. I need to familiarize myself with the arduino world.

I had a tour of the Larry Leifer's Design X Lab. I saw presentations on autonomous ottomans, autonomous things. They talked about wizard of oz prototyping with improvisation.

5.3 DAY 22: Wednesday, July 22, 2015

We celebrated in a Korean way outside and talked. Jung Hwa is leaving us on Thursday for her two week summer vacation plans. We talked about what still needs to be implemented in her project and she sent me two google documents on her plans for user testing of the haptic feedback device on her needle platform. The pen will move in 8 directions and the user will need to identify what direction. We discussed the idea in more depth and the purpose and functionality of the design. We decided that the pen should sit perpendicular to the platform rather than lie linearly to the platform. I can make a new platform to incorporate this idea. So I will be making a piece of the next iteration. We also talked about how I feel like I would like to do an independent project along side Chris's and Jung Hwa's research. I started searching for ideas.

5.4 DAY 21: Tuesday, July 21, 2015

I browsed more arduino sites. I scanned the sites to gather a sense for what were hot topics in the arduino world. I also checked out several tutorial sites. I like adafruit the most though. I found a great comic. And I found myself looking in to a research project called the Corona research project that would allow a person to walk around a room in this church and hear the noises echoing as though a feast is happening. Jesters would be talking in one corner. Minstrels in another area of the room. Courtiers in another area, and so on. And based off of the sensors on your phone that would detect your location, the sound and noises would change in real time. I thought that was a really neat idea. The researchers joked that I should go around our lab and record people talking and explaining their projects and anyone that walks around the lab would hear the researcher's explanation of their projects.

What I learned today/my notes:

Digital information is binary. Analog can hold a range of information. Digital information is either 1 or 0, on or off. Analog information is characterized by its continuous nature. It can have infinite number of possible values.

Voltage is a measure of electrical potential. The speed of flow is determined by voltage Current is the amount of flow through conductive material. Amps The ďcurrentĒ amount of flow moving through the pipes is current and can change with V and R Restistance is a materialís oppositition to flow of electric current. Ohms Resistance increases or decreases flow. Load (light bulb). Every closed circuit has an energy source and a load. The load converts the electrical energy of the battery. The schematic is a drawing representation of the circuit using electrical symbols for the components. A battery is a DC power source. Direct Current. Donít really understand AC, alternating currents.

In DC circuits, the current always flows in one direction. In AC, the curent flows in opposite directions in regular cycles. that is so bizarre.

Arduinos are supplied with 5 V of power from the usb connected to your computer.

Integrated Development Environment is an IDE and it combines a text editor with a compiler and other features. The IDE allows you to write SKETCHES or programs that you can upload to the arduino board.

Setup happens once as the program begins running. Loop repeats again and again These are both functions. An LED (light emitting diode) has an anode that connects to the power and a cathode that connects to the ground.LEDs can only trasmit current through one direction.

I wonder why the verify button was necessary. I guess its a debugging tool.

I learned how to use the debug window to see what numbers the arduino is processing. The larger the the resistance, the dimmer the light. MiliCandella measures the brightness. The higher the candella, the higher the brightness. LEDs have a limit to how much voltage and resistance it can take, if you donít limit it, youíll kill your LED.

Idea: timed LED arduino light show.

There are 3mm, 5mm, and 10mm. Most of my LEDs are 5mm (measured diameter of the LED). 10mm LEDs are just like 5mm LEDs but with bigger heads. 3mm LEDs are good for indication. 5mm LEDs are good for illumination. 5mm LEDs can have clear or diffusing heads.

Diodes are called diodes because they only work in one direction.

You must always use a resistor. If the current increases, the LED is brighter. If the current decreases, the LED is dimmer. For 99% of LEDs, youíll want to use 20 milliAmps (.02 A) and sometimes for more brightness, youíll want .03 A

V = IR Georg Ohm (George without the e) a german physicist discovered this relationship

Learn about binary.

http://playground.arduino.cc/uploads/Main/arduino_comic_v0004.pdf

This is a great comic!

Potentiometers are also called pot.

5.5 DAY 20: Monday, July 20, 2015

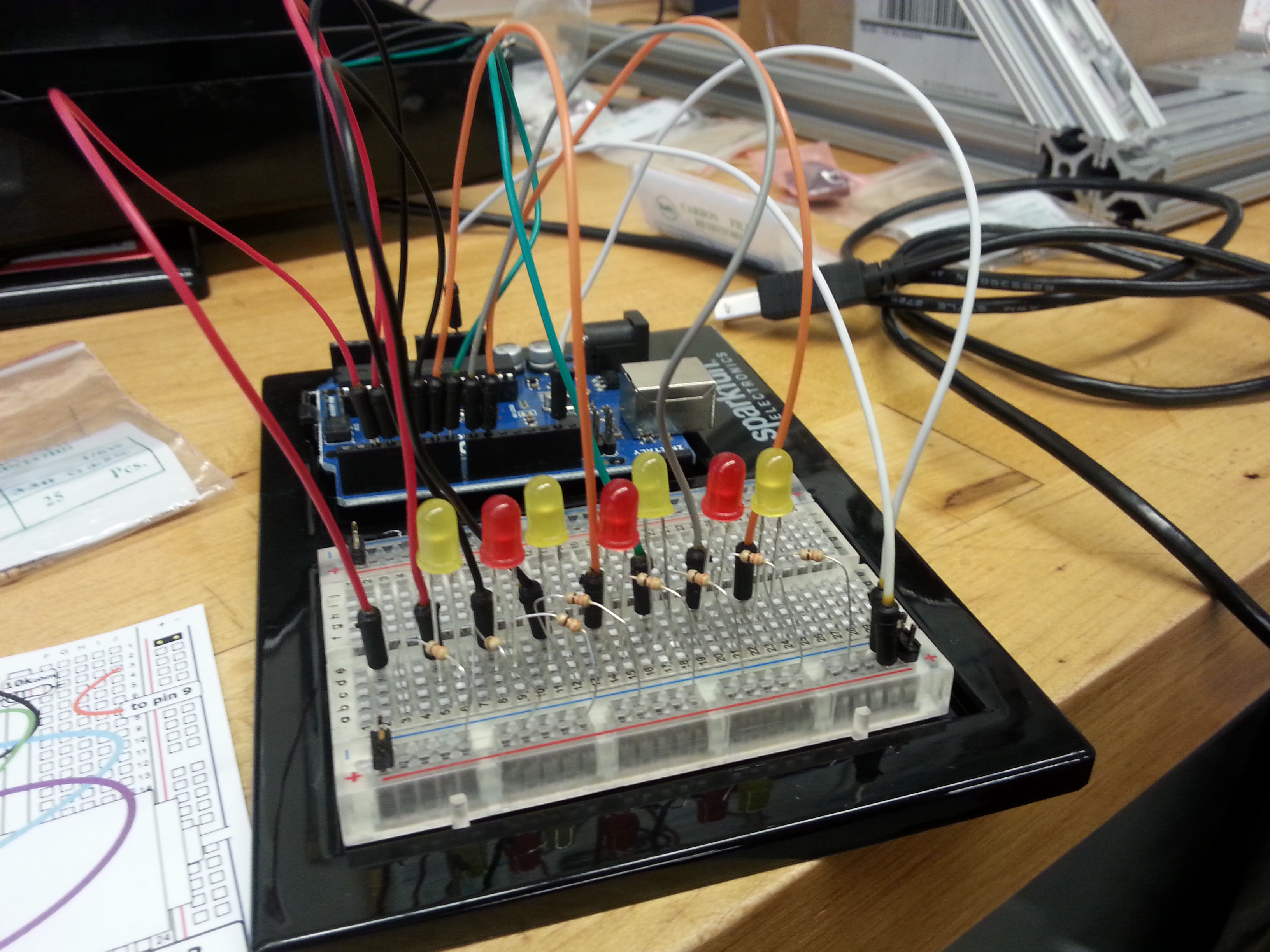

I continued to finish the SparkFun's tutorials: I looked at using potentiometers, a photosensor, and a using 8 blinking lights with a shift register. The shift register was slightly confusing for a tutorial because it required so many wires. I plugged in several in the wrong spots, so Chris helped me look through which wire connected to which wire until it was fixed. The lights were quite pretty.

6. WEEK 4

6.1 DAY 19: Friday, July 17, 2015

I went to the lab meeting. I heard a presentation by Atsuo and Amy on their circular lenses that use electroactive polymers. They've been doing testing on that. They can make the lenses expand and they also want to make them bounce.

Then we had the lab's first SURI bbq of the quarter between the D-school and the CDR. The lines are long and it takes time to cook enough food for everyone. This is something we should maybe consider for our BBQ: logistics. I wonder how long it took for their lab to prepare everything.

I worked on putting together a few more arduino tutorials.

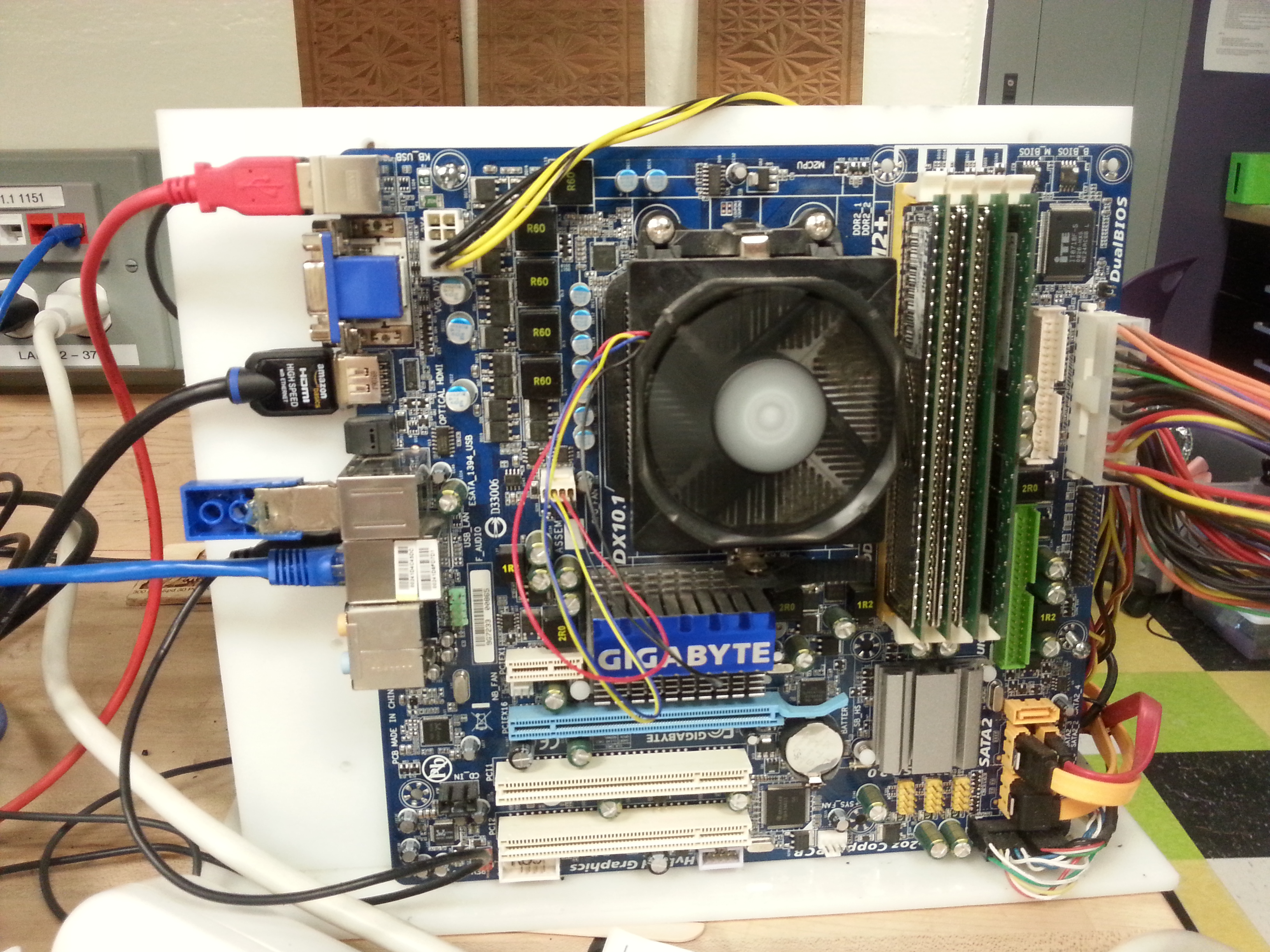

I also learned how to install a solid state drive today.

6.2 DAY 18: Thursday, July 16, 2015

Chris came back today! With a shaven face, a new t-shirt, new shoes, and a haircut! It's like he's a new person! The haptics corner celebrated by going to Thai Cafe for lunch to catch Chris up. Chris has been informed of most relevant events in our lives since he's left. He's become an honorary girl for the day, too. Jung Hwa, Nina, and Chris-tina. Of course, we painted our nails and talked about boys, and we all feel better about it now. Okay, so we didn't actually paint our nails and talk about boys. But we did catch him up on our lives. Like all the presentations and how we've been catching up.

At 2 PM, I went to swim club for the first time and no one was there. Still, I got to practice and exercise.

I read through an Google's published rules for Material Design. It was interesting how they're trying to achieve uniformity across platforms and programs. That took awhile to digest.

Afterwards, I wrote code for a few more example arduinos projects. I'm still figuring out C.

Also, I still can't figure out why my portrait images are converted to landscape on my blog. Their attachments alone are in the portrait position, so I guess we can all just turn our heads at the necessary times when reading through my blog. From now on, to make things easier, I'll just take everything that I want to post to the blog in a landscape position.

6.3 DAY 17: Wednesday, July, 15, 2015

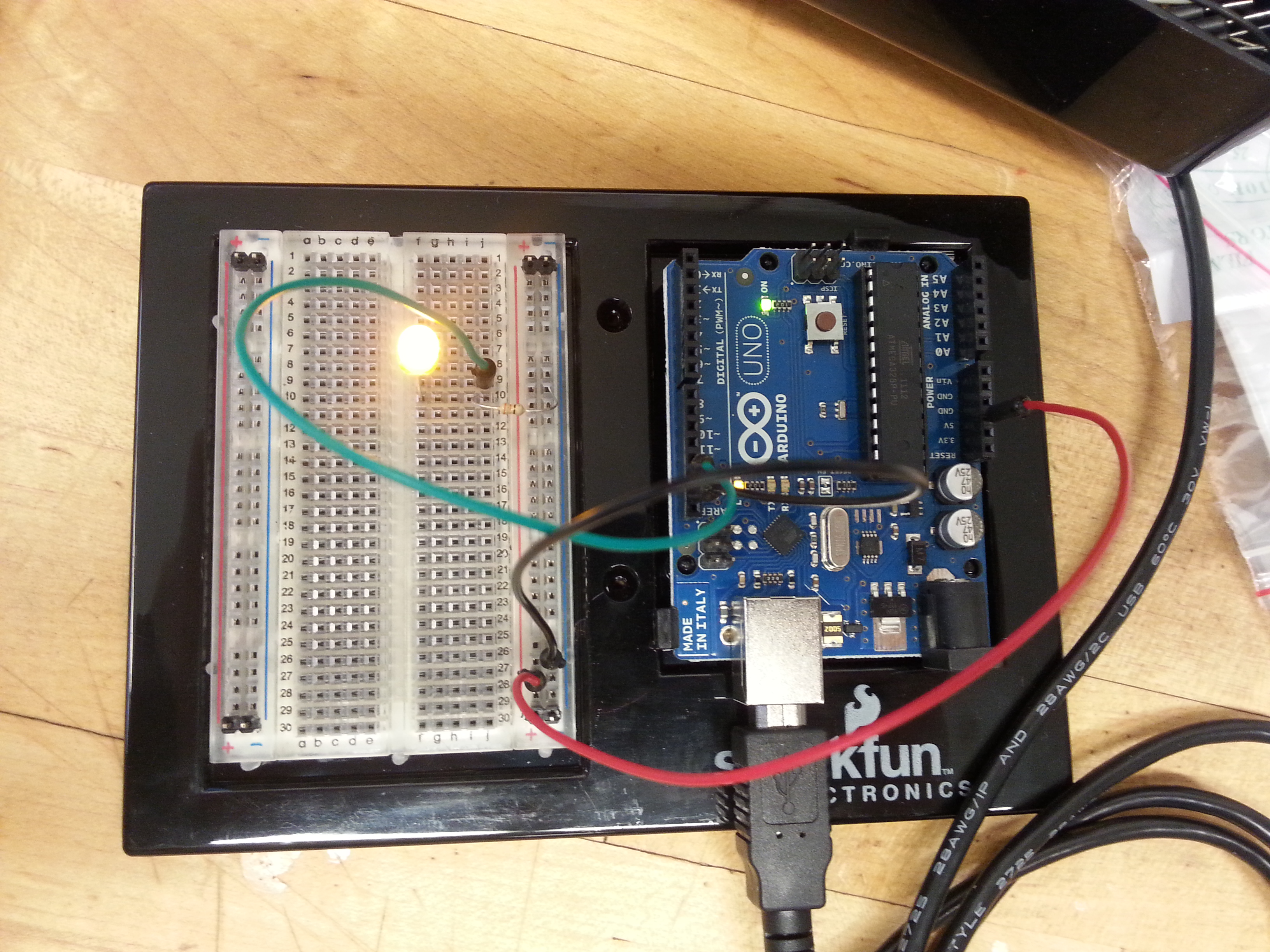

Today, I coded up the example arduino code and connected the necessary pieces for the project.

I made a blinking LED, a series of blinking LEDs, and had a motor run.

6.4 DAY 16: Tuesday, July 14, 2015

I have been up since 2 AM because I decided to fall asleep after getting back from the lab around 7:30 PM. Was this a great decision? Probably not. But I got a lot of cleaning and laundry and reading done. I mean, what else do you do in the quiet of the night when everyone else is sleeping?

Today's Goals: -Learn how to code in C on arduino applications.

Goal accomplished: I read through the entire Sparkfun Manual.

The Sparkfun manual covered relevant coding language, pieces involved in the arduino

6.5 DAY 15: Monday, July 13, 2015

Hello World!

It's a Monday! And what a great Monday, too. Because I have the BEST job in the world this summer (cue I'm A Believer by Smash Mouth).

Let me list the ways I love thee, oh, research:

- My labmates are the nicest, friendliest people in the world!

- I get to stick with Jung Hwa, like all day. Um, that's fabulous.

- I am given the opportunity to stretch the limit of my understanding of SolidWorks, watch how CNCs work, play with servos, and talk with everyone about their projects.

- I have free reign of a playground of circuits, bolts, tools, and you-name-it-we've-got-it-things. So much cooler than legos!

- I have a parrot drone to play around with.

- I get to think about and solve mechanical problems.

- I get to be involved in the prototyping process.

- I get to read articles and take the space to understand how batteries and how touch screen phones work.

- I get to present and communicate with Stanford's Industry Affiliates.

- I'm going to be involved in user testing- Whoo! Which really means I'll be seeing the whole gauntlet of the design process.

Whoever said research was boring was very wrong. Research is fascinating and I love how useful and promising all the projects in this lab are. It's amazing to be a maker. Okay--boring is relative. I think plain biology research is boring, but with mechanical engineering research, I feel a real spark. I think it could be love.

Okay, so what have I actually done today: Jung Hwa and I visited the Transformative Learning Technologies Lab. When we walked in, I knew that I loved whoever designed the room. The walls were painted in bright green and purple colors. When you first walk in, your eyes are drawn to the laser cut DURON tempered hardboard and plywood creations. I saw a tree, a t-rex, a spine vertebrae that moved in a wave. One counter was lined with 3D printers, some with two extruders of PLA and others with just one extruder. I thought it was fascinating that there were different designs to making 3D printers. I wonder why some had closed platforms and others had open platforms. I found a 3D doodle pen laying about. I've seen them in pictures but it was so cool to see the products of the doodle pen in person.

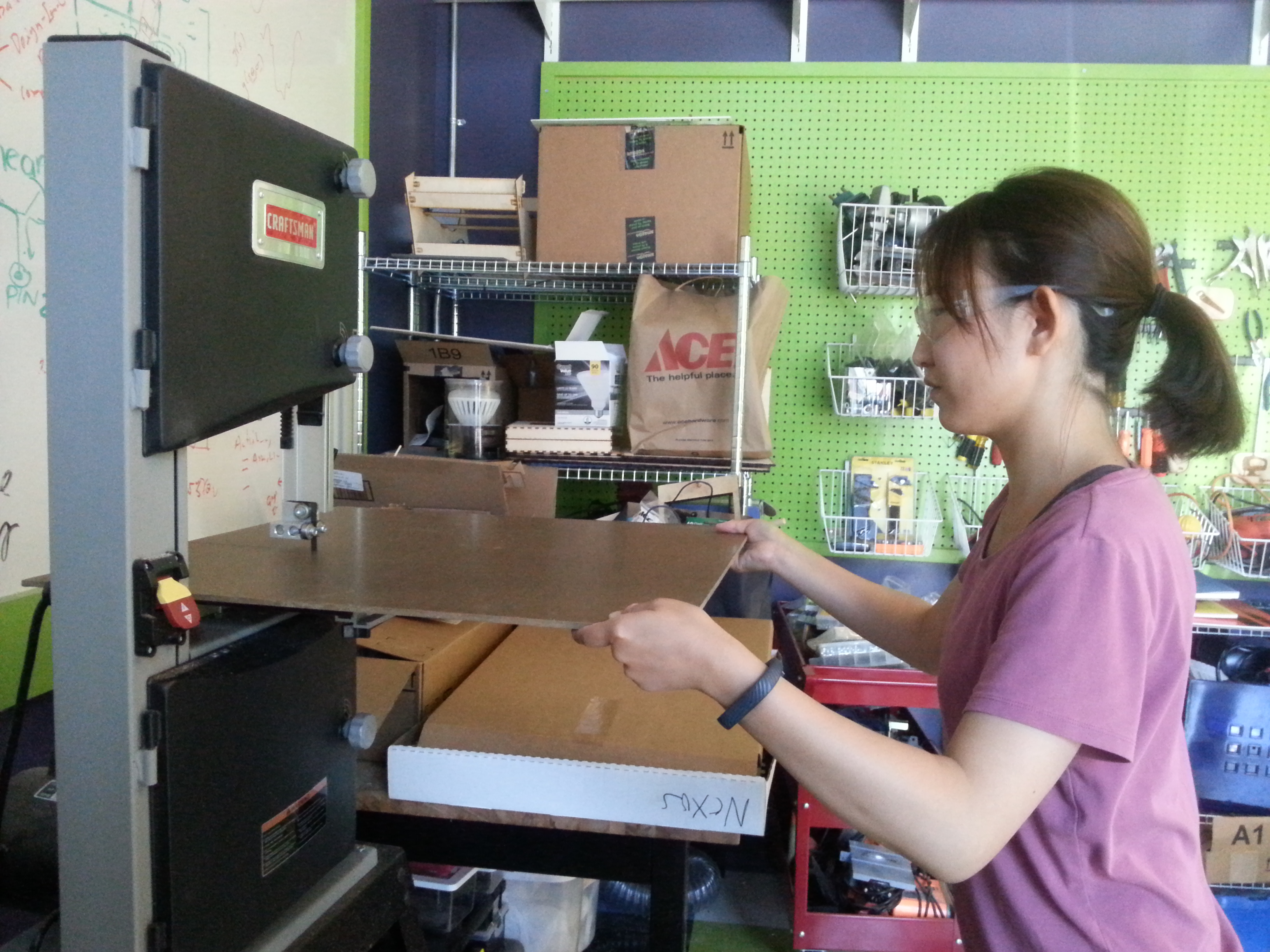

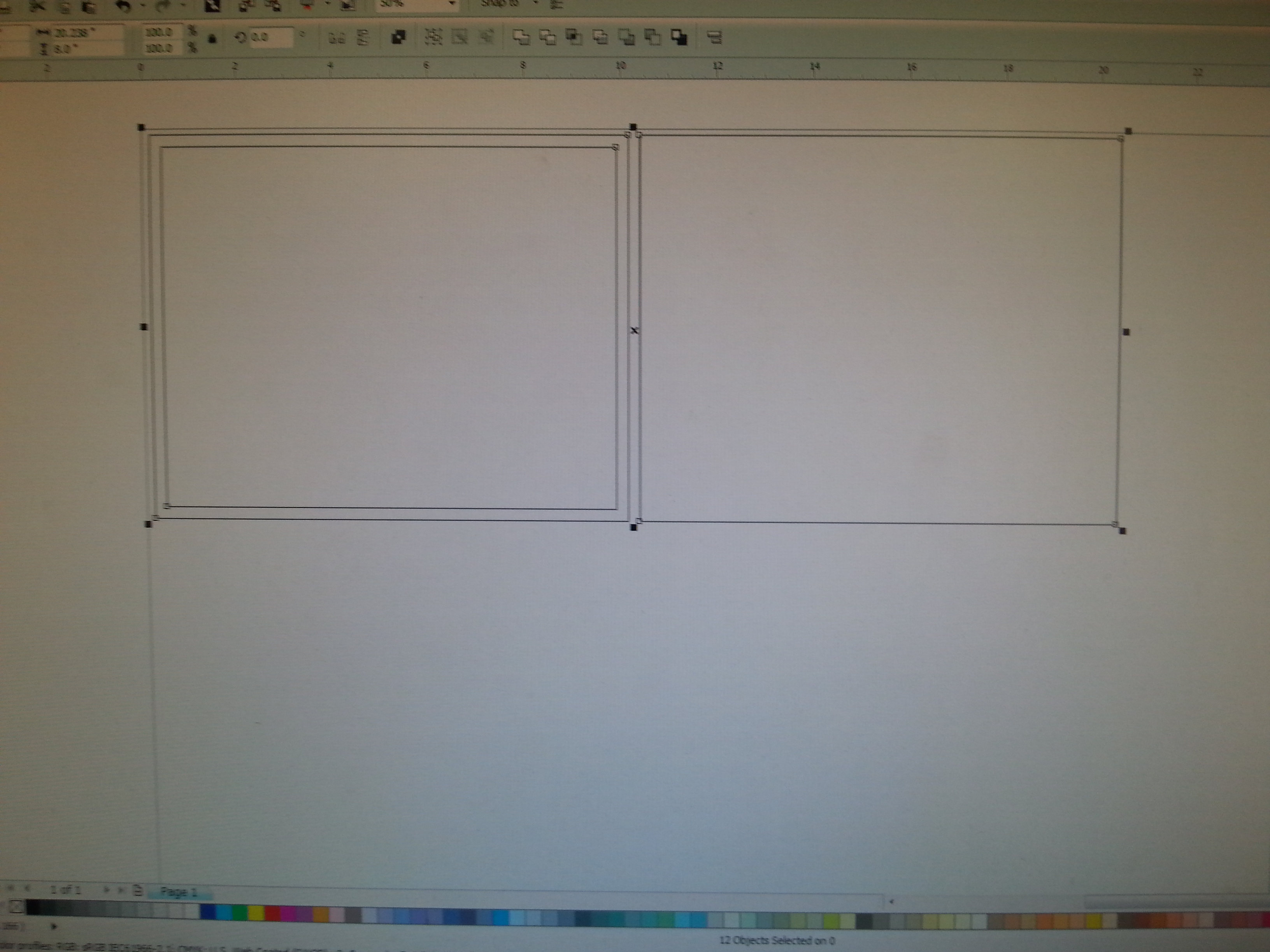

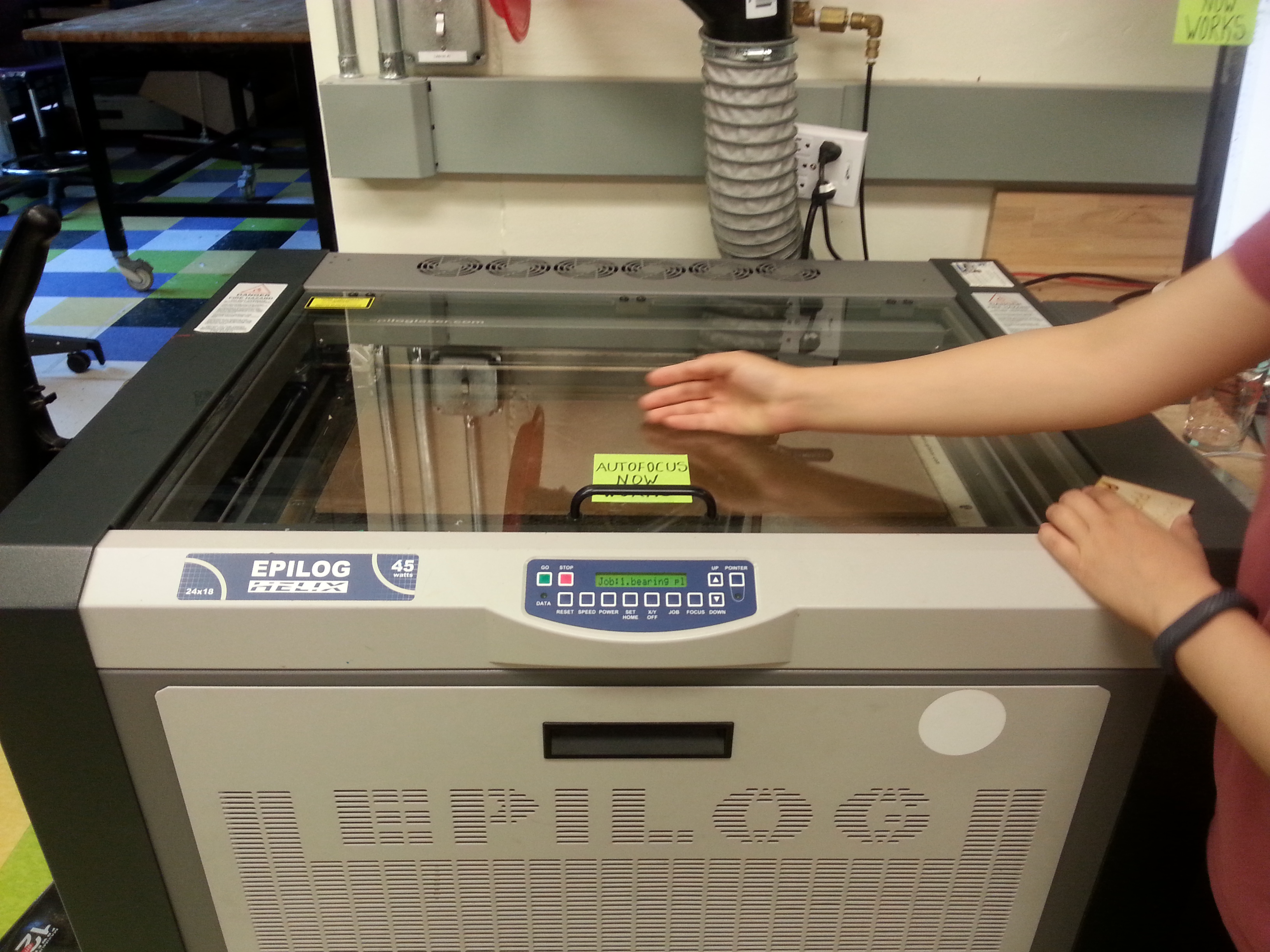

We then cut a piece of DURON on a band saw and placed the duran in the laser cutter. We uploaded the SolidWorks design to CorelDraw4, and then uploaded the CorelDraw4 to the Epilog Laser Cutter and cut the pieces.

Then on our way back, we splashed through the fountain outside Green Library as a minor break before heading back to lab.

Once back at lab, I glued the laser cut box with Elmer Multi-Purpose Glue. The box is really a platform for the plates. We decided to use a mouse to maneuver the mouse and placed a sculpey. I heated the sculpey, already melded by my hand in the toaster and had the material harden. The idea is that the prototype can be made specially for anyone with a ceramic like material that can be placed on the mouse. The other idea is that we can use a soft material like silicone or rubber and have that stick around the mouse in a large layer, to ensure the comfort of the user rather than having to use a molded hard ceramic piece as a maneuvering tool.

Goals for tomorrow:

- Actually, join the swim team at 2 PM, and try NOT to get tan. I've reached maximum capacity for sun damage this summer. So I plan on applying copious amounts of sunscreen. I also plan on getting ridiculously fit. In my world, ridiculously fit means being able to flex my abs and my biceps. I can totally do this.

- Dissect and build code for the MRI force sensing needle.

- Figure out C on arduino.

7. WEEK 3

7.1 DAY 14: Friday, July, 10, 2015

I attended the lab meeting. Today was our first lab meeting of the summer. The first two Fridays of the program were taken up with the lab retreat and Fourth of July holiday. All the SURIs presented their progress for the summer. A few of the PhD candidates presented their work and then passed around their models. It was a nice combination to hear them explain their work through the powerpoint slides and another thing to connect the conception and process to the physical product.

I gave a last minute presentation of my work so far. I think all the SURIs can agree that having to present from their work from their blogs have made us realize the importance of updating our blogs. It was a challenge to synthesize three weeks into a short understandable explanation. There are a lot of details that I think are normal, but in an effort to not sound pretentious I realized I didn't know where to strike the balance between explaining details as though no one knew what I was doing and explaining the week the way I would to myself. I also realized that people besides Mark will indeed be reading these blogs, like everyone else in the lab during the meeting. Right now, I have bullet points and parenthesis notes detailing how I should insert images stored on my google drive. I hope that by next Friday my blog's format has paragraphs and images.

Afterwards, I talked with Jung Hwa about her project. We decided to build a box platform to contain the well-lubricated ball plates. Jung Hwa drew a sketch (pictured below) of a CAD model that I could create. I drew the initial lines with smart dimension. Then I measured the plates and figured out what dimensions the sides of my boxes should have. Jung Hwa also said I could help her make a comfortable hand tool to let the user rest their hand on while using the needle. I said we could use sculpey as an initial prototyping model. We both agreed that would be a good choice for now.

By then it was lunch time, so I asked Katie if she wanted to get lunch together. She agreed and we biked to Lagunita Dining. New area of self-awareness: I will bike as close as possible to all places that I go to. Walking is absurd. Katie was much more relaxed and didn't mind walking a bit from her bike parking. Some days are just walk as little as possible days. That was Friday. We lunched and chatted. I felt like being spontaneous and doing something physical, so I suggested we could take a walk around Lake Lag before heading back to the lab. We walked around the cavernous dusty weed-filled earth called Lake Lag. I feel like we should really rename the lake. I know it was once a lake but it feels like such a misnomer now. The lake feels like the same terrain around the dish. I have a few suggestions: Lagunita Earth, Dry Lagunita, Lagunita's Backyard, Bone Dry Lagunita, Lagunita Basin, Lagunita Park, Lagunita Preserve. Something that just excludes the image of water because there is none there. Last Friday, everyone in the Stanford network got a text alerting us that there was a fire at Lake Lagunita that was caused by a fallen UAV(Unmanned aerial vehicle), in this case a model airplane, that ignited a fire in the dry brush in that area.

Apparently, Li-Po batteries used in drones are extremely delicate and given a harsh impact with the ground, especially if it's dry, can ignite a fire. The construction of Li-Po batteries cause them to have a tendency to build up internal gasses while charging. Like, if there's any kind of battery warning you should definitely pay attention to, it's a Li-Po battery. When the gasses reach a certain point, the battery expands and then explodes in a fire. In this case, the Li-Po battery with its sensitive chemistry if punctured or given a significant impact, like hitting the ground, can vent their gases into the air or surrounding environment, causing a fire.

Why Lithium Polymer batteries are cool: In comparison to Nickel-Metal Hydride battery (usually reusable batteries with 2-3 times the capacity as Nickel Cadmium batteries), LiPo batteries are lighter, have a variety of shapes and sizes, have higher capacities (so they can hold more power), higher discharge rates. Why Lithium batteries aren't ideal in comparison to NiCd and NiMH batteries: LiPo batteries have shorter life spans, are volatile if punctured from a significant impact, and require special care in their charging, discharging, and storage.

So we saw the burned area of Basin Lagunita, and I took a selfie with the fire. I felt like I was part of the news story that I read by actually seeing the charcoal burnt black earth. Yum, rich in carbon. I wonder how long it will take for plants to regrow in that area. I guess I'd need to know what the soil chemistry of that particular area is like to know whether having ashes actually helps in pH levels or something.

We biked back to the lab. I talked with Jung Hwa with my design process. I wanted to verify that I was making the pieces in the right dimensions. I asked her whether we should make the pieces really tight. I asked whether the laser cutter would cut the acrylic pieces slightly smaller than our specific cuts. I wonder if the laser cutter realizes the laser has a .004 inch error margin and compensates by increasing everything by .004 or if people just make their pieces realizing that margin of error and compensate by adding .004 in the necessary areas of their products. So we did the latter and added .004 in the necessary areas. I also left a margin of space for the plate to move in the platform. Because it would be bad design to make the plates fit in perfectly and tightly in the platform.

Mark then visited us and we showed him our design. He said that we need the plates to have a lot of room to move. So we decided to only use two out of the three plates. And we decided to redesign the box to only have two pieces and have more space to move. The previous design had five pieces. I made the CAD designs, and showed them to Jung. She helped me assemble the pieces on one 18" x 24" piece on SolidWorks. Because of complications, we decided to laser cut everything on Monday morning.

Realization: I've been telling people I work at the BiomimetRICS & Dexterous Manipulation Laboratory. It's a mouthful, but I meant to say I'm in the Biomimetic & Dexterous Manipulation Lab.

7.2 DAY 13: Thursday, July 9, 2015

I finished wrapping up the new presentation for Aisin AW: I added a few new slides (images below) on the pieces we made with print screens of the SolidWorks designs, and practiced the presentation. Jung Hwa fixed the code last night and continued to adjust the code today. She tried to call Sung Jun but he went to Korea last night. Basically everyone who knows anything about piece of the project that we don't know about have gone: Chris and Sung Jun. But we made do!

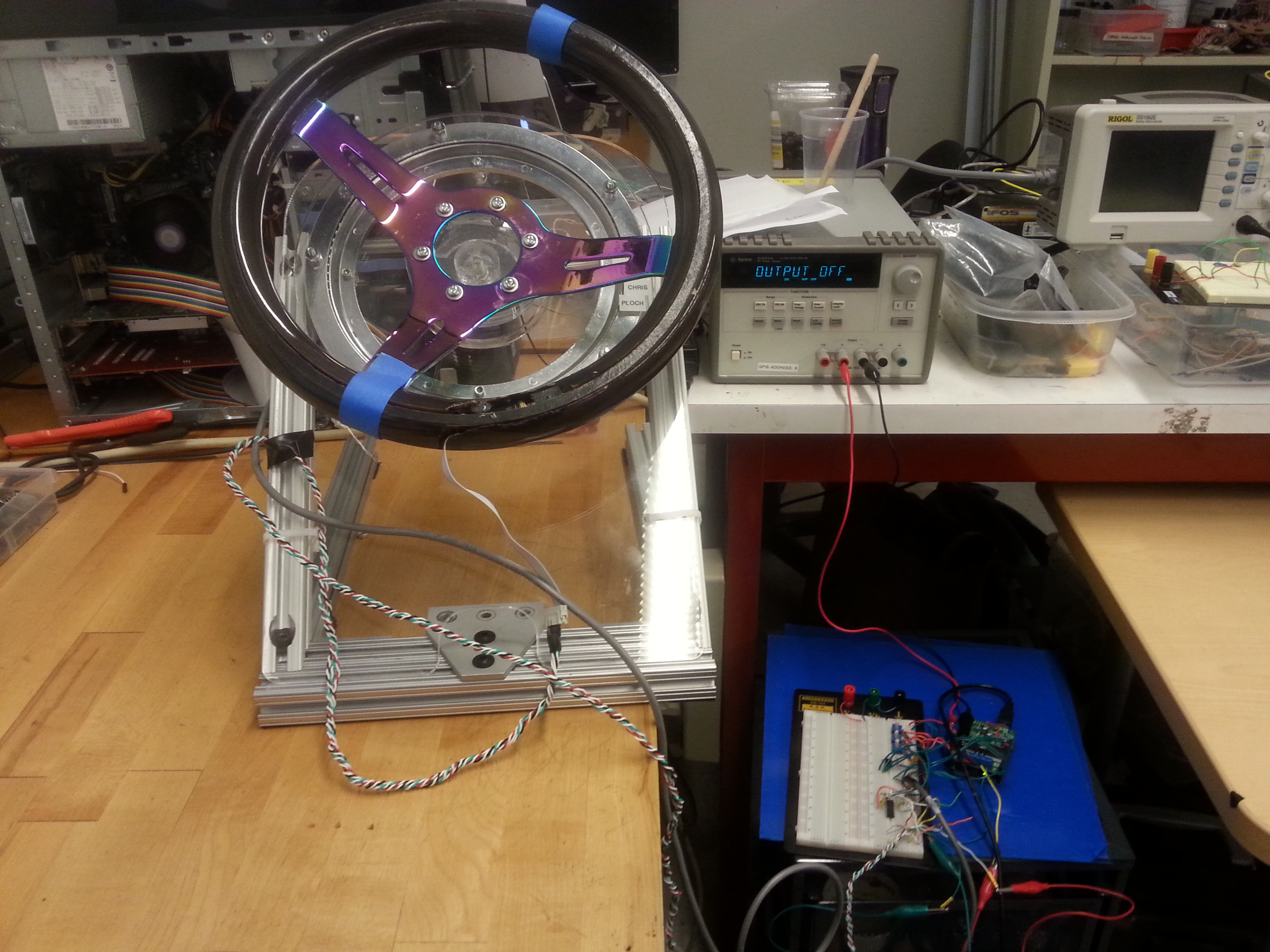

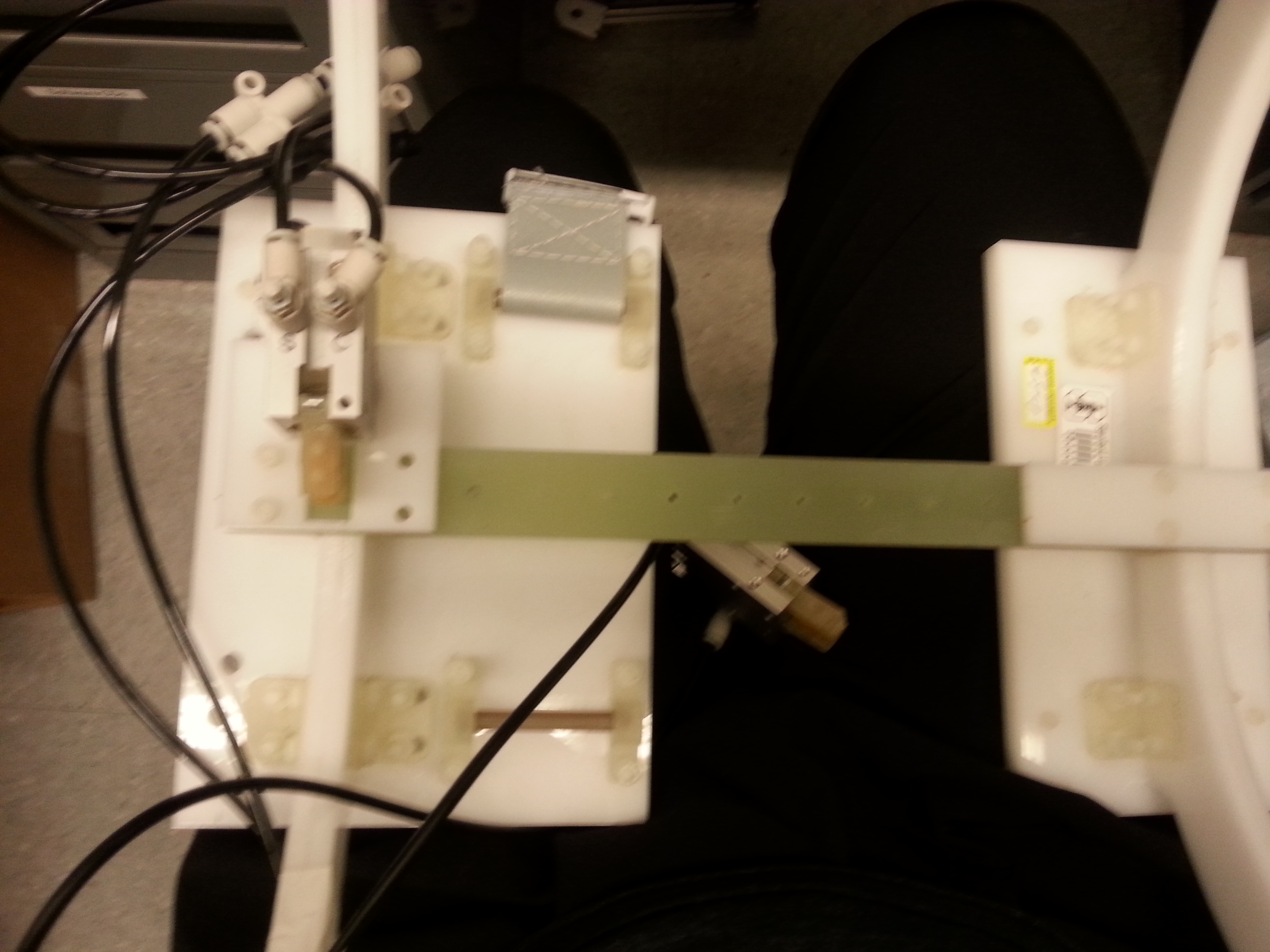

I helped Jung hwa finish putting the steering wheel onto the platform Inrak and Chris made. I called Chris to make sure he was ready to Skype at 3:00 PM our time from a Michigan McDonalds. I assume he's having fun camping. Obviously, the platform and steering wheel weren't made for assembly and we struggled with putting all the parts together. By then it was 2:40 PM and we were running late on getting to VAIL to meet the Japanese Business men from Aisin AW. I carried over the power box on my laptop and the arudino and wire parts without tipping over-- a victory!

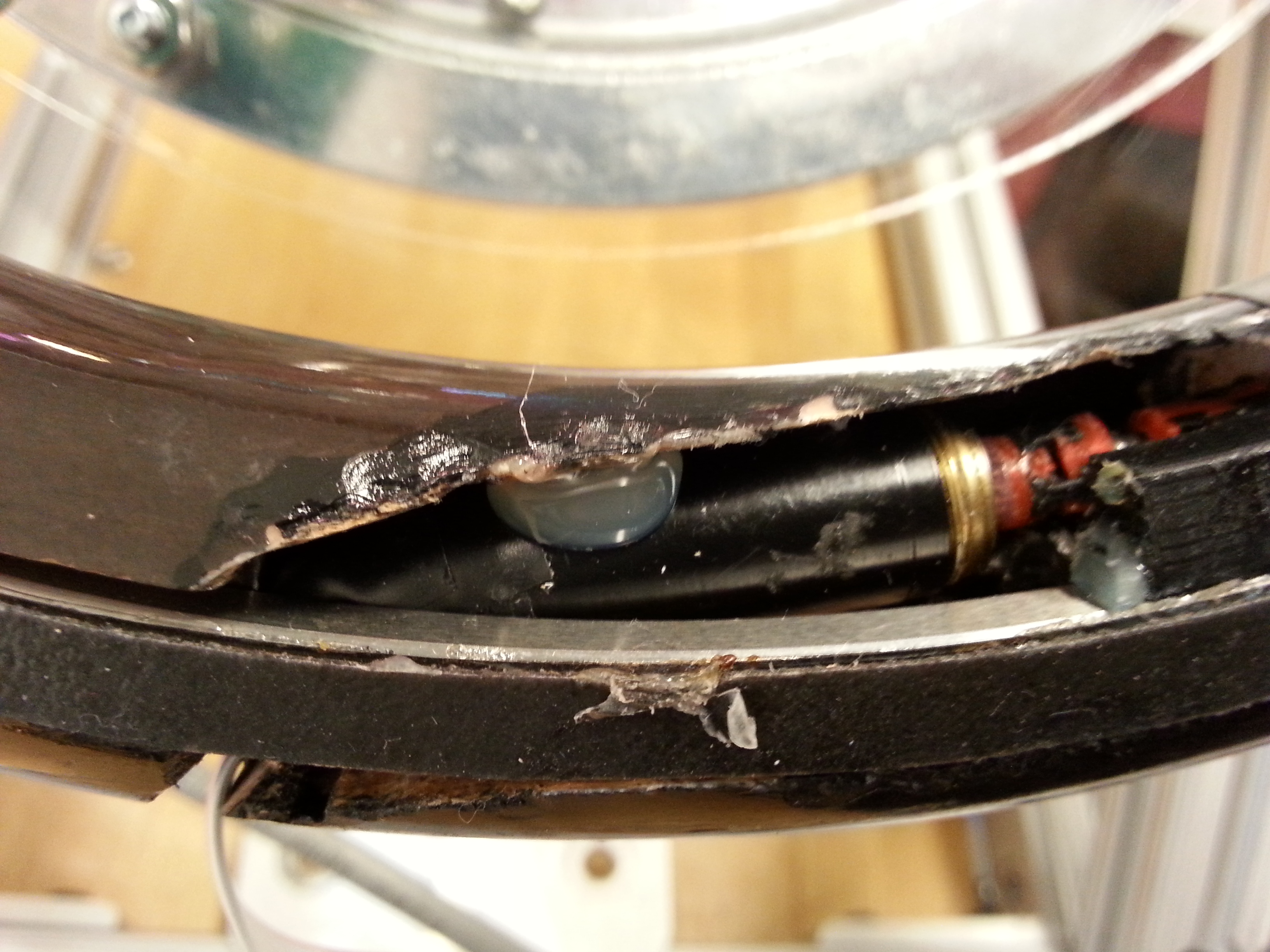

Jung hwa carried the platform and the steering wheel. I couldn't find mark in the CDR, the lab, or his office, so we left anyways. I got there by 2:59 PM, found out from Larry that we didn't book the room with Adele, we started setting up anyways. I saw the businessmen coming over and asked them if they were from Aisin. I greeted them and shook their hands and luckily Mark was also walking through the door. Mark showed them around while Jung hwa and I set up the demo and the presentation. I got Chris up on Skype and we waited about 15 minutes until the Businessmen finished the driving simulation. That's always a crowd pleaser. Then they arrived, and I introduced myself and was really nervous. Luckily, Mark did most of the talking and I explained a few slides. Jung Hwa did a great job setting up the demo but unfortunately a connecting piece made out of Ninja Flex absorbed too much of the force applied from the servo that we didn't get the result we wanted. After two out of the three businessmen used it, the delicate demo broke. Jung Hwa tried to fix it and then showed the last businessman. At the end, they left and gave me their business cards. What I will do with them, I don't know.

Jung Hwa and I went back to the lab and cleaned up our station before taking the rest of the day off, which by then was 5 PM, so that was the time we would leave anyways. We finished the long stressful period of meeting the deadlines! Whoo!

7.3 DAY 12: Wednesday, July, 8, 2015

I tried using Bondo, plastic wood to fill in the cracks in the wood. I didn't work how we thought it would. scrapped that idea. Inrak came over and prepped me and helped me glue the servo and the plastic pieces and the ball bearing together. Mark suggested using a clay like material that we would bake. We got this material from the ME 310 lab in the D-school.

I fitted it into the steering wheel, which was covered in saran wrap to protect it. Then I took the material out and baked it in the small toaster oven near the soldering station. We fit it in, and because I couldn't figure out what else to do. The code didn't work, and Jung Hwa was working on it. That day Jung Hwa had a friend that fell down the stairs so I worked on my own and just tried to figure out how to make the steering wheel look alright.

7.4 DAY 11: Tuesday, July, 7, 2015

I made the second iteration of the piece the connects the fine pitch screw and the thin section bearing. This time we would use NinjaFlex and PLA. Jung Hwa would come in around 3 PM that day. I was really frustrated with Solidworks and decided to start anew with the SolidWorks model because I couldn't adjust the dimensions. Mark said I should make the top piece longer so that there would be more surface area with the thin section bearing so that the glue would have a better chance of sticking. I doubled the width in the second model. Totally scrapped the last file. I also learned how to use an assembly of two pieces in SolidWorks.

Arul again was a life saver and helped me make the second piece. I learned a lot about how I was inefficient and used SolidWorks the wrong way when he showed me. Like instead of making an oval and then trimming it to get the right angle, Arul just used an arc and we also smart dimensioned everything!

I find planes, merging, and working with curved surfaces to be a tad confusing. Maker bot did not like the assembled SolidWorks files. It just wouldn't show up. We had to use a different kind of file, we just unchecked a box that said the pieces would be assembled in the SolidWorks file and everything went smoothly until it didn't.

Things that went wrong: the PLA extruder did not extrude in about two of the prints, the temperature settings weren't being saved, and the red and black pieces were sticking to each other.

7.5 DAY 10: Monday, July 6, 2015

I brought bread to the lab. People enjoyed it.

I spent the day creating on SolidWorks a piece that would fit in between the fine pitch screw and the thin section bearing. This was the first iteration of this piece. I was confused with merging, so I asked Arul and he assisted me. I learned that I should use centerlines and smart dimensions more. I made my second SolidWorks piece ever! I printed it in Building 520, a building used for Mechanical Engineering, Thermosciences. There's a nice studio room with long windows, high tables and colorful stools.

Against the wall held in a caged shelf exists a magic 3D printer. It's called a Flash Forge 3D Printer. It's neat in that it has dual extrusion. You can print with two different kinds of plastics, NinajaFlex filament and PLA filament.

We had a really hard time figuring out the password for the lock but after a few walks to get the right answer we opened the cage! We used a program called MakerBot. We formatted the print materials that we uploaded using the SolidWorks files. Then we formatted the temperature of the extruders and the platform. We also formatted the speed of the extrusion. Somehow these formats wouldn't be saved like we thought it would and we repeated these processes a few times before giving up and just manually formatting it on the 3D printer and not makerbot. It was a little confusing because the quick start guide somehow did not quickly start us.

We finally printed the piece and went back to see how it fit with the thin section bearing. It fit okay but we didn't like how it was all made of PLA. It didn't flex like we thought it would and we were slightly concerned. I tried to file down the curved section of the piece to make it bend more. That didn't work. Then I found Sung Jun outside and we asked him about the code. He came in and helped us fix it.

8. WEEK 2

8.1 DAY 9: Thursday, July 2, 2015

I was still figuring out how to understand C language on arduino. I messaged Chris about the code, trying to see if he understood why the code wouldnít work. Jung Hwa and I spent the day figuring out how to make a better design for the connecting piece between the screw and the thin section bearing. Mark gave us some advice on how to make it.

8.2 DAY 8: Wednesday, July 1, 2015 (A Proud And Nervous Day for Nina)

I spent the morning prepping myself for the presentation. Chris copied me on the emails to Larry, and I told Larry when I would be there. I wasnít sure exactly how all of this would work out, logistically, with the businessmen and what the tone of the meeting would be like. I assumed there would be a lot of people there presenting their prototypes. I went over the slides about three times until it felt natural. Then I headed to lab to see what work Inrak, Sung jun, and Chris did. The last uncertainty was whether the code would be ready by tomorrow. I messaged Chris and he was unaware of whether the code was functional but apparently Inrak and Sung Jun had stayed until 6 AM that morning to finish the prototype.

When I got into the lab, I had twenty minutes to decide whether to take the prototype with me. I didnít know how to bring the protoboard, the arduino, the code, the power source, and the platform holding the steering wheel. I didnít know how they all worked together at all or at what Volt the arduino operated at. I asked Arul and Chris (the SURI Chris) what to do. They told me I should just take a picture of it and include the picture as my final slide.

So I decided not to bring a non functional steering wheel, and my excuse was that I couldnít bring the power source with us.

The amount of people involved in the meeting were less than expected. I thought that there would be more PhDs presenting, but I was the only one presenting a prototype. I hoped that they wouldnít ask me many questions because I couldnít really explain anything further about the motivation or the previous prototypes that I only roughly understood based off of the slides. I understood the current prototype because I had been there for every stage of it being built. So I could expand a lot on just that one picture. I was also glad that Adele wanted me to go first that way I wouldnít have to wait in nervous anticipation. Generally, in presentations, Iíd rather go first rather than be compared to the person who came before me. Unless I need to buy myself some time, going over the order of things to talk about in my head.

I thought it went decently. The conference room was just spacious enough to give everyone about two chairs in between the next person. Everyone had a water at their desk. The laptop connected well enough to the TV screen at the front of the room. The Japanese businessmen sat on one side of the room, and Adele and I sat on the other side.

At the end of the meeting, I got a Komatsu yellow bulldozer key chain. Iím not sure when Iíll use it, but itís a neat little souvenir from my first presentation to people in industry.

Since I was at VAIL, I decided to talk to the engineers there about the X1 simulatoróthe car I would eventually be putting the wheel on for user testing. I had only heard about it in the presentation, but there it was right outside the conference room. I learned about where they put all the batteries, the engine, the controls, and some sensors.

I also saw one of my friends who works on the Solar Car Project, so I decided to talk to her about the car. She got a research grant just to continue working on the car for the summer with a few other members of the team. I think thatís really cool. They also have a CNC machine. Something I didnít realize: the space for one person is really tiny in that car.

I headed back and tried to figure out with Jung what was done to the steering wheel. We tried to take apart the steering wheel platform, and realized the difficulty of disassembling it. The steering wheel platform was not made for assembly.

Once we got it apart, we tried to look over the code and then ask Sung Jun exactly what he coded.

Jung Hwa helped me download the arduino software and showed me how to look over the example code. I looked at that for the rest of the day.

8.3 DAY 7: Tuesday, June 30, 2015 (The Infinitely Long Day)

I stuck with Chris in the HTDL making the design for the cut out on the steering wheel. We have to really make sure that we're cutting out the right portion so he used a diagram on SolidWorks to figure out the right dimensions. Then he made a design on SolidWorks, and we asked Lakhbir if the design were possible. Lakhbir gave us some feedback and then we CNC-ed a piece of the motor on the by around 4 PM that day. We put in the servo and the other pieces that we had in hopes that it would all work together within the steering wheel.

I did a lot of watching today in the HTDL, not much for me to do, but I did ask a lot of questions.

Inrak put together the platform for the steering wheel to be placed on.

Chris worked on the Grizzly that night trying to make all the parts fit together well.

I looked over the powerpoint, and then Chris explained the powerpoint to me. I stayed until 11 PM and then finally left. Chris went home around the same time as me so that he could finish his packing for his 6 AM flight to Michigan.

Iím a little bit nervous because tomorrow Iím presenting to a group of Japanese Businessmen at VAIL.

8.4 DAY 6: Monday, June 29, 2015

Fun thought of the week: maybe I will bring my bread experimentations to lab.

I came to lab, Chris showed me what he worked over on the weekend. He used lego parts to create a lever arm rotator with his linear actuator. We went immediately to HTDL (High Temperature Dynamics Lab) to use the CNC (Computerized Numeric Control) with Lakhbir, the lab mechanic. He gave us some advice on how to use the CNC. Chris learned how to use MasterCam, which is like SolidWorks but slightly different and works with the CNC in the lab, unlike Solidworks. He made the design. Then I watched Lakhbir exude some of the parts on the program and then save it to be put on the machine. We then spent the rest of the morning watching the CNC machine use the drills. There was a copper piece being cut out using a drill for an Earth Science Research project. The machine spits this liquid which is 97% water and 3% cutting oil, from two nozzles and looks a lot like milk. Chris thinks that the liquid is used on some pieces and not on others is for two reasons: 1) the liquid smooths out the cuts, and 2) the liquid cools down the metals.

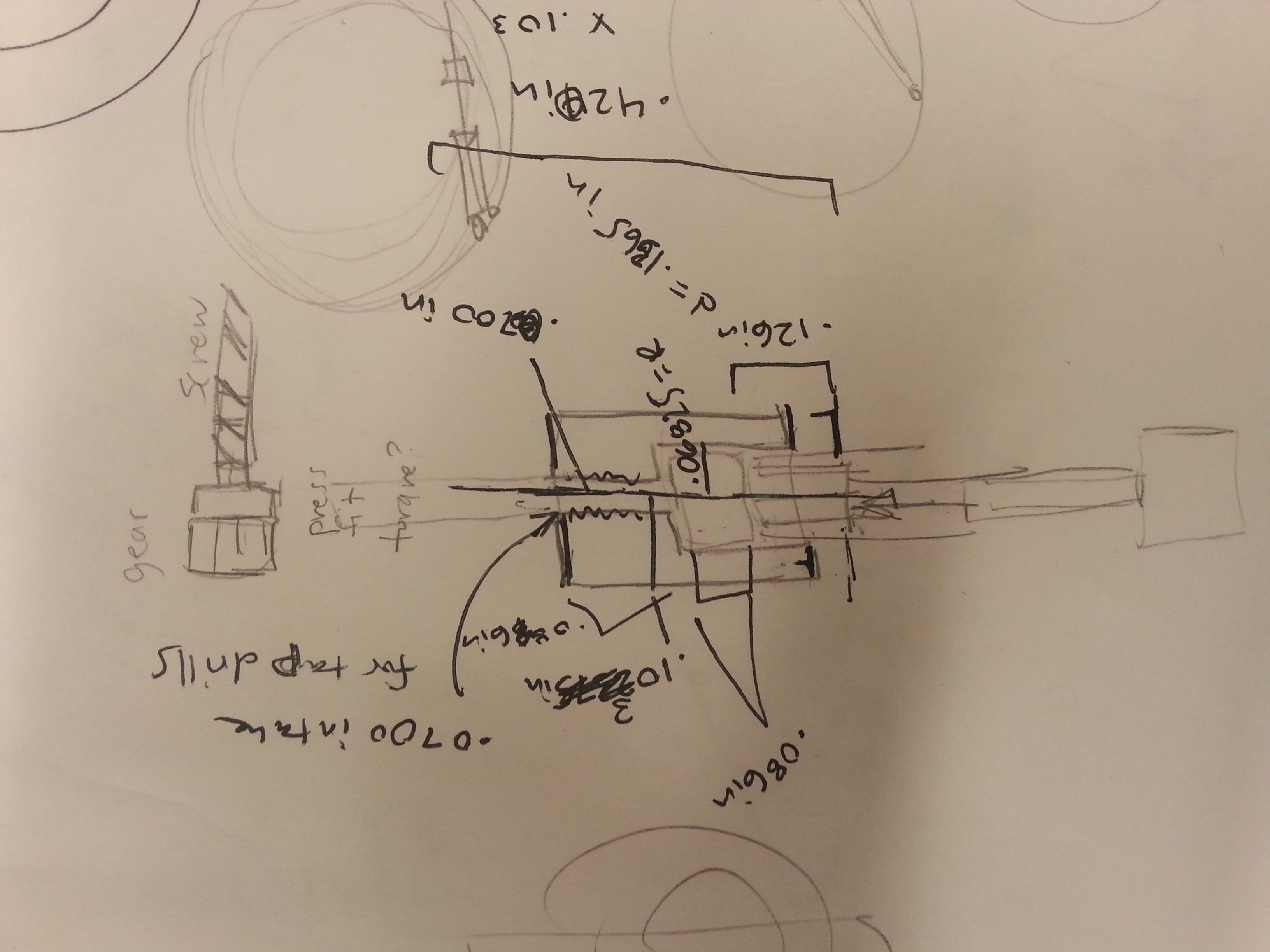

Chris put together some circles on the program using measurements from the caliper that we have.

I watched someone make a piston part for the Automative Lab using a lathe. They used oil to smooth out the cuts. For some reason, it made a lot of smoke when they did that. Perhaps using the lathe on aluminum creates a lot of heat and the oil is then evaporated in smoke. I thought that was really interesting to watch. Aluminum is an easier and more malleable metal to cut with. Copper is pretty malleable, too, but it's also really strong and not corrosive and doesn't rust. Steel is really hard to cut.

Back to Chris, we set up the machining and we watched the wood being cut. I asked Lakhbir about the CNC, and he said that all the drills were made of carbide. Some of the drills in the lab use high speed steel.

Katie Hahm showed me what code she was working on, and the different programs, Blender, Slider, etc.

Chris was sewing up his quad copter, trying to work within the framework that he had for his prototype. It's hard to make all the parts fit in really tightly.

Isabel was working on soldering cool things. Maybe sheíll teach me how to solder sometime. Although, soldering sounds rather dangerous because the fumes are toxic and the process involves lead. But the burning metal and microscopes look really cool. Iím sure itís a useful skill to learn.

Bad news: we got shreds of wood in the really expensive thin section bearing. We need to either use paint thinner to dissolve the wood or blow out the wood with high pressure air.

Inrak stayed late with Chris to design a platform for the steering wheel and then laser cut it.

9. WEEK 1

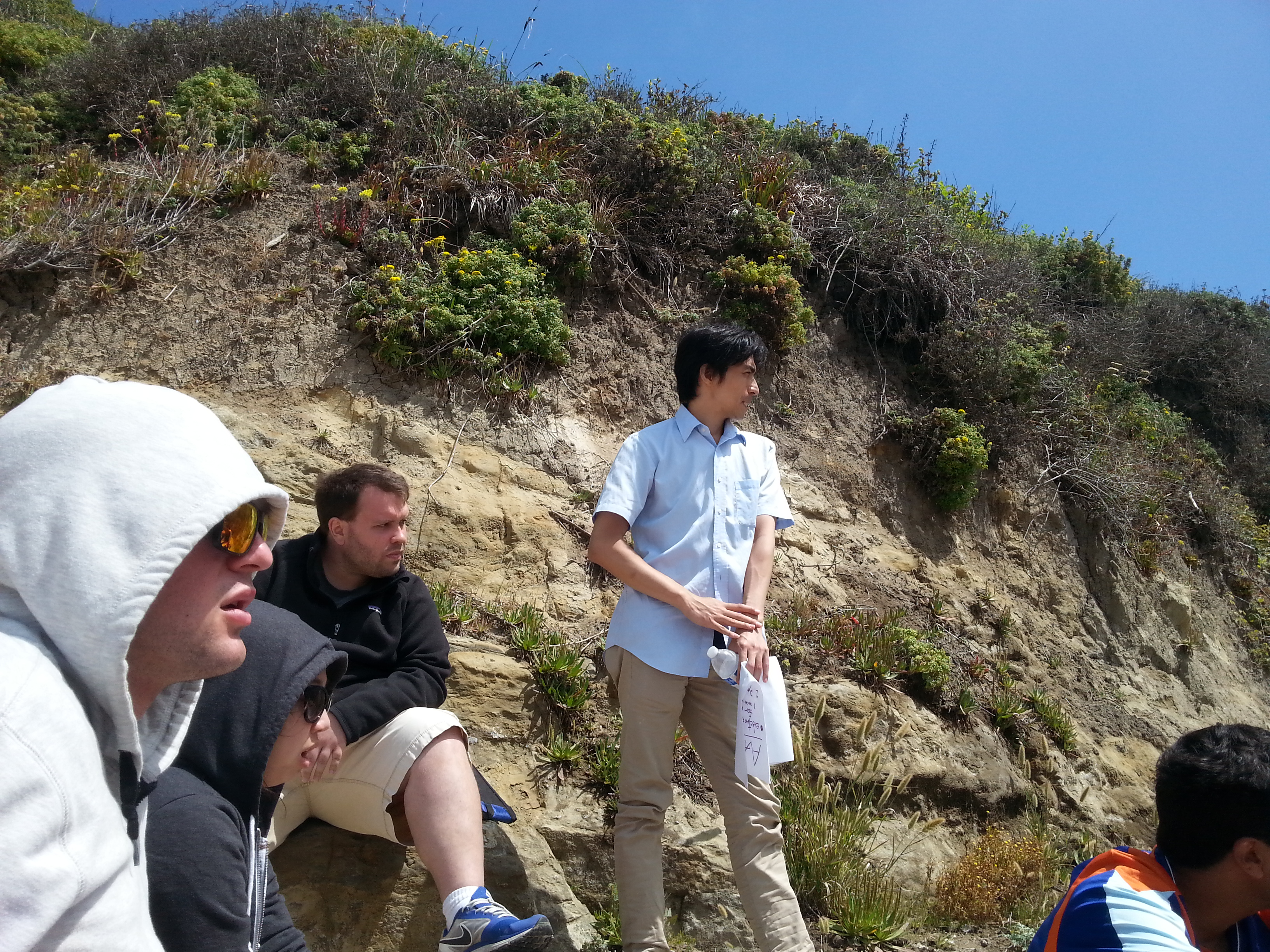

9.1 DAY 5: Friday, June 26, 2015

I went on the picnic retreat. Everyone left at 9 AM to Pescadero Beach, but then we decided to drive North to another beach with picnic tables and grills. We played football and snacked on hummus and veggies and chips and salsa. We ate a lot of the snacks so by the time the burgers were made, I was already full. The black bean burgers were actually really good. I spread guacamole on the burger, squeezed between a brioche bun. Ultimately, it was a good burger. I was satisfied.

I didnít wear any sunscreen that day. Somehow I forgot how sunburned I could get because I hadnít really been out of doors for an extended period of time for awhile. I would have put on sunscreen that day, but we got up so early, and I didnít want to be all oily and the beach was so windy that I didnít want to have sandy oily skin. Thatís very unattractive.

But I learned my lesson. Iíd rather suffer through oily sandy skin than be sunburned to a crisp. I didnít realize how burned I was until I got back to the lab and visited the restroom. The back of my legs, my forehead, my nose, and my shoulders were all bright red.

->

->

9.2 DAY 4: Thursday, June 25, 2015

Today we cleaned up the lab. I took apart Jung's needle haptic feedback machine for doctors. I only kept the metal bearing sliders in tact. I took out resistors and capacitors from proto boards. I zip tied cables.

I learned where the bolts and nuts and screws go, learned where the protoboards go, and the difference between carbon fiber pieces and fiber glass sheets and acrylic sheets which are under the table. I wiped down monitors and tables. Yay for dust free monitors and computers!

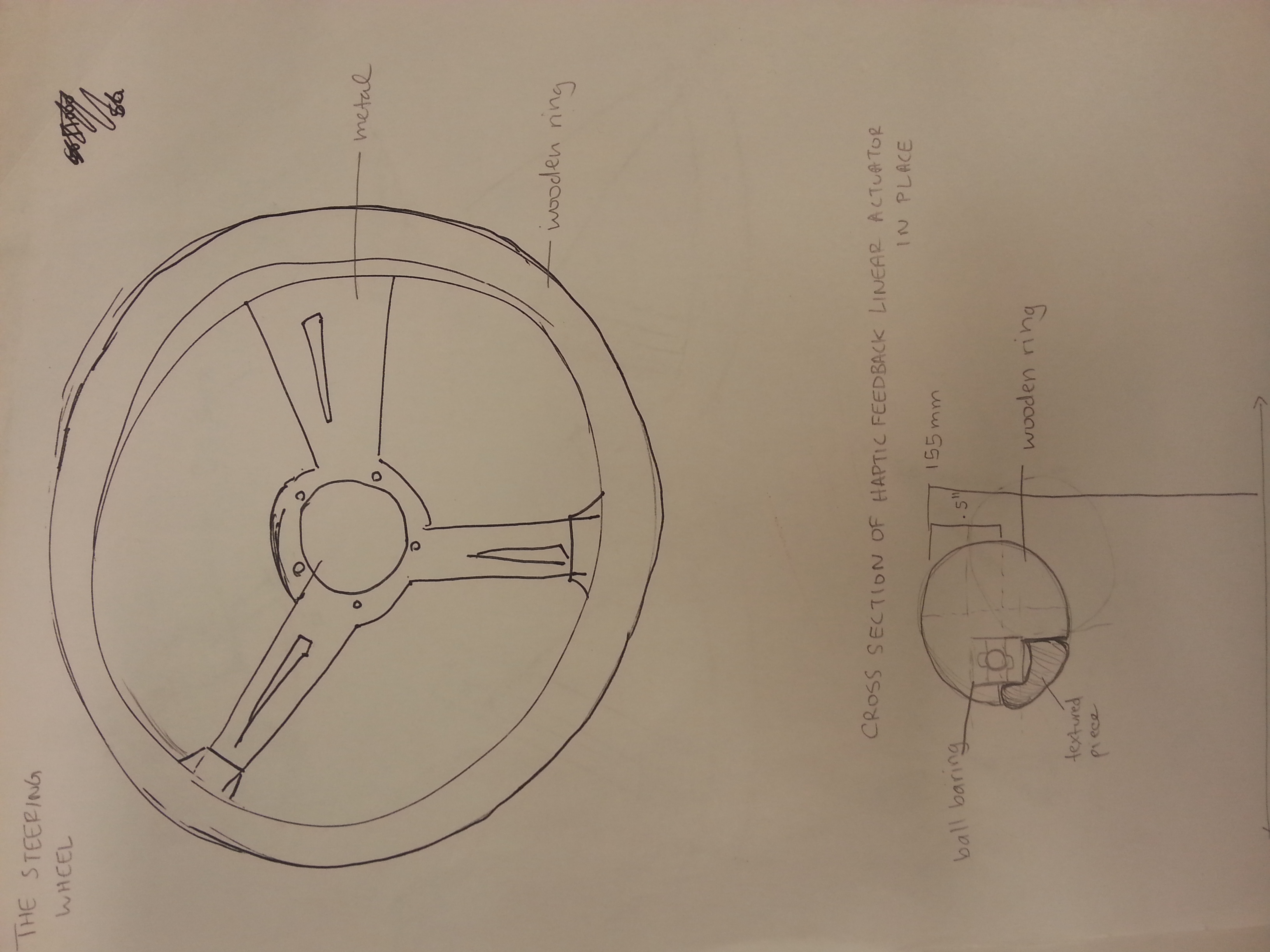

I had lunch with Jung and Chris at the Thai Cafe. Then we went back and I read through some articles (insert articles and by whom). I discussed a design for putting in the actuator within the steering wheel, we decided that the most unobtrusive design would be in the back of the steering wheel, we would need to cut a quarter cross section of the wheel out.

I drilled through the old prototype steering wheel to see how far the metal ring inside the wooden steering wheel went. We think we can make an adequate cut through the steering wheel to place a behind the scene linear actuator. We will await advice and feedback from Cutkosky tomorrow.

Chris showed me how to use the Grizzly milling machine and we used a 30 screw.

Before we left, we sent in the Solidworks plastic connector piece to Hannah to print tomorrow at the Education School's 3D printing machine around 1 PM. We're hoping it worked out.

Cool news of the day: Morgan gave me his Parrot Drone. Yay I get to figure out how to use it!

9.3 DAY 3: Wednesday, June 24, 2015

Today, I met Cutkosky for the first time this week!

In other news, Chris feels like a TA except I'm with him 8 hours a day and can ask as many questions as I want. Itís really great! Itís like there are office hours all day. Plus, there are like 5 other ďTA"-like people in the lab almost always, too, and they're all really nice and friendly and want you to succeed. :)

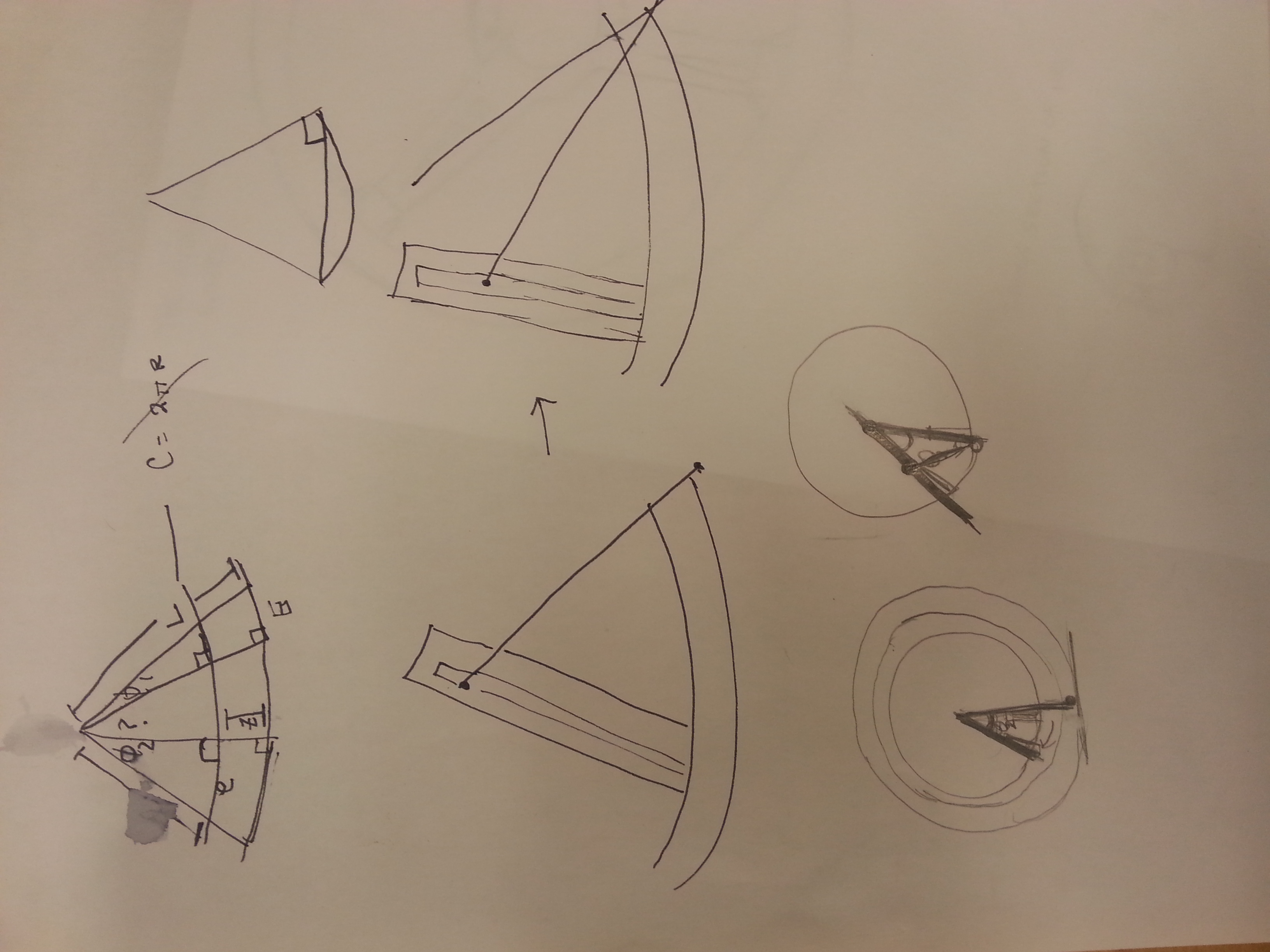

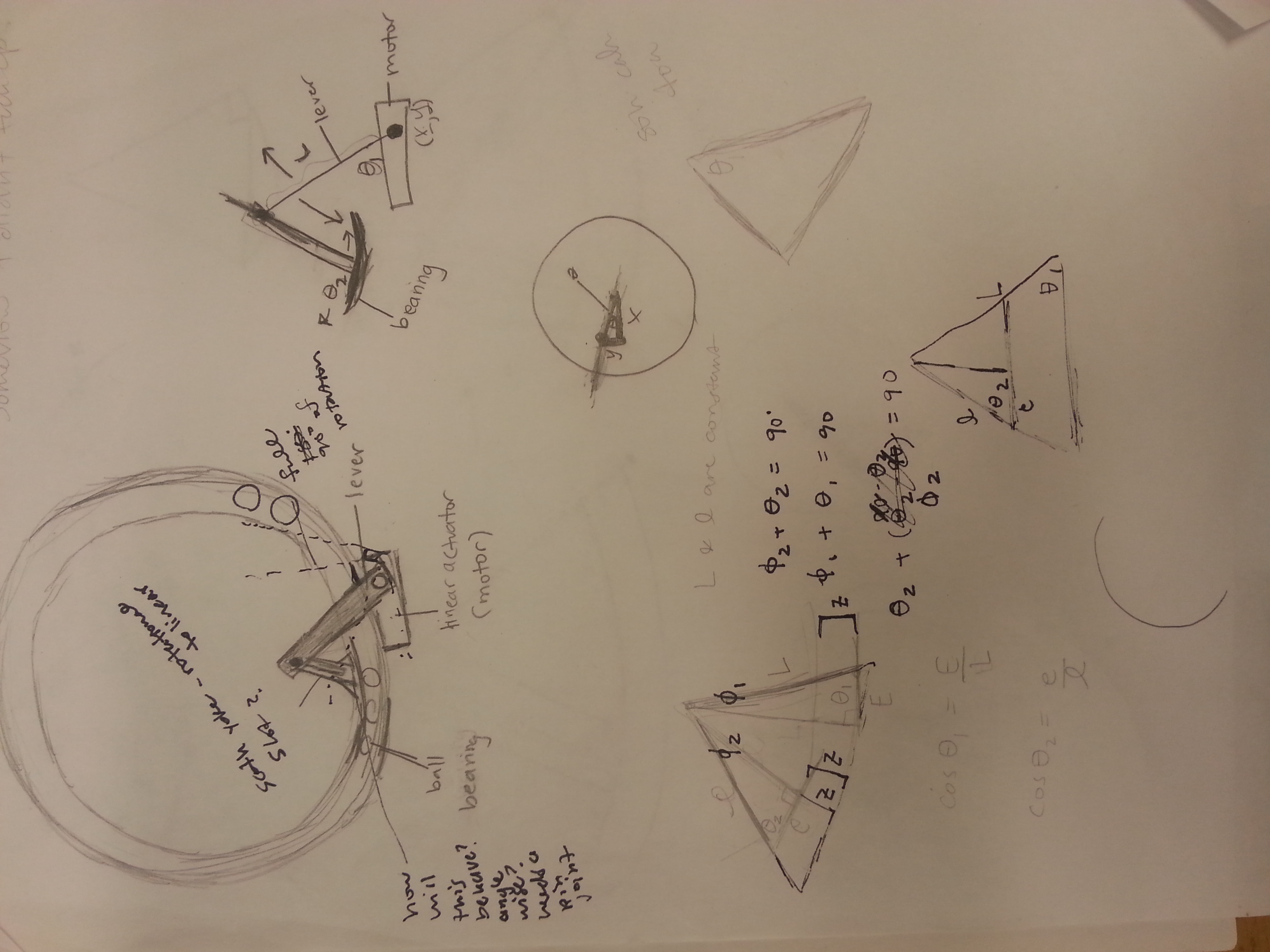

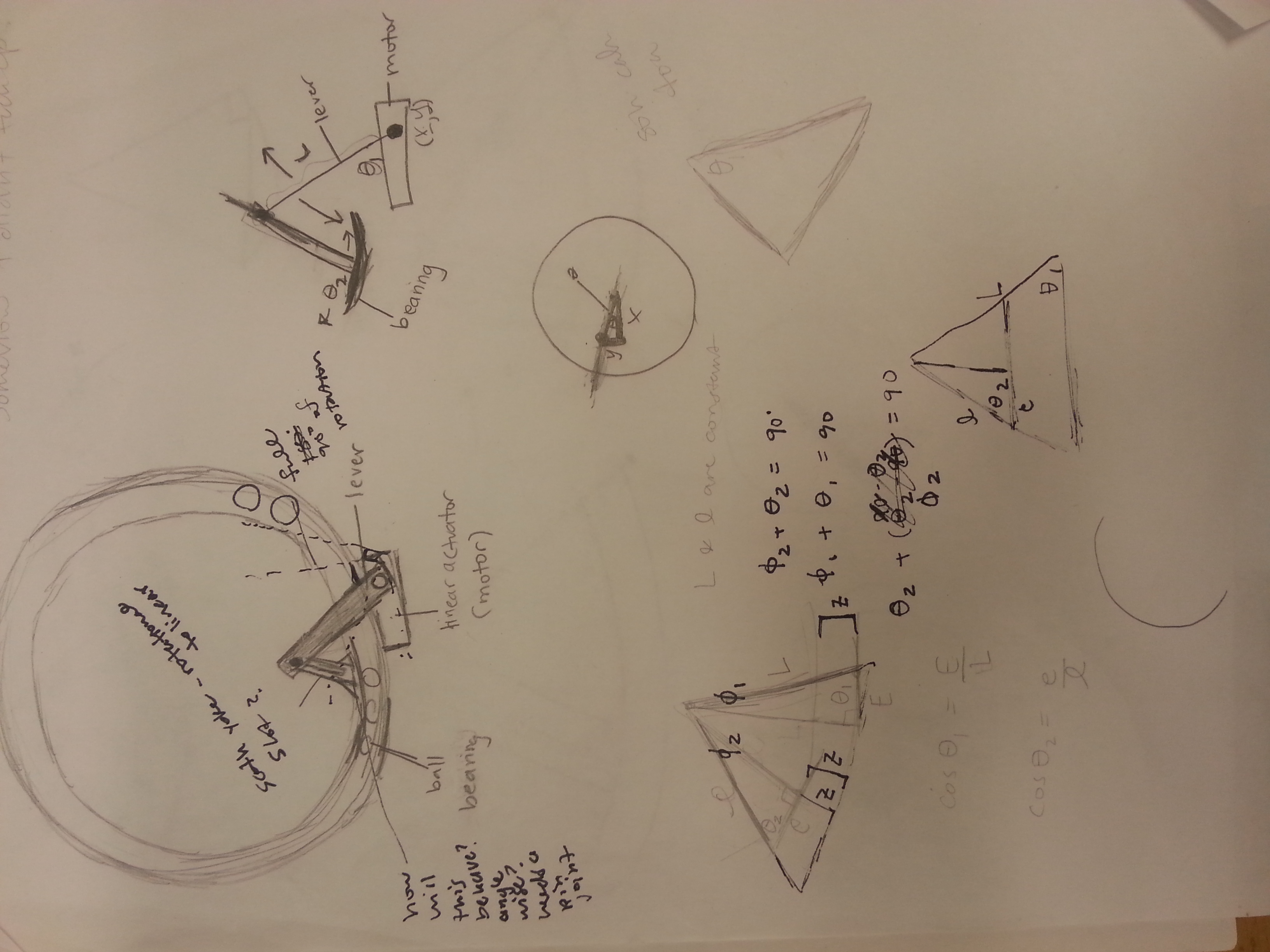

I worked on the math of figuring out the angles using variables and vectors. I also talked with Cutkosky about the idea, he suggested that we go with another design for the linear actuator, so it was back to the drawing board.

I read over a few more articles, and I should probably skim them more. On my to do list: I need to look over the haptic database full of important research papers to skim. We tried to clean up the desk for 20 minutes and gave up shamefully and just called it a day and said we would clean up the next day. There are so many wires and motors and small pieces lying about.

9.4 DAY 2: Tuesday, June 23, 2015

I spent all day figuring out where to buy a 13" steering wheel. I messaged people from craigslist in the SF bay area, eBay (where I showed Chris how to send a personal email to a seller), tried to scour the internet for warehouses and dealerships and auto-part companies.

Eventually, we called the manufacturers of 13" steering wheels to confirm because the last one Chris bought was a dud and misrepresented because the outer ring measured about 14" rather than 13" which was the listed dimensions.

Then, we sketched some designs to place the actuator and I discovered that an actuator is just a fancy name for a motor. I also then learned what servos were. Lots of new cool mechanical part names exist. Chris assigned me with math to figure out what angles the mechanical lever will operate in. I also was tasked with figuring out the relation between the changing angles in the model.

9.5 DAY 1: Monday, June 22, 2015

I attended the ME Summer Undergraduate Research Institute (SURI) kick-off event in the morning. Students met outside of the Engineering Building, 540, and munched on bagels and fruit and socialized with other summer undergraduate researchers. It was a good way to get to know the crowd of fellow students also beginning mostly for the first time in research. We were briefed on deliverables for the summer in a powerpoint presentation by Perry Thoorsell in under twenty minutes, and then we found our way to our respective labs.

We spent the next half of the day setting up blogs, logging into computers and making profiles for ourselves, and familiarizing ourselves with the research coming out of the lab.

At MERL(Mechanical Engineering Research Laboratory), we found Hannah, a PhD student in the lab, who briefed us on the BDML's specific deliverables, the blog. She helped set up our user logins.

Then, Amy, a post-doctorate, introduced herself and gave us a tour of the wind tunnels. We saw both open and closed wind tunnels. I was impressed by the machines because I have never been in a real wind tunnel room before. She turned one of the open wind tunnels on to demonstrate how it worked, and I was surprised at how it really filled the room with air. The air was passed through in sub-sonic speeds. She explained how her research relied on making wings that used adhesives that moved according to sheer forces because of the microscopic triangles that slid against each other when force was delivered. It was gratifying to see the microscopic materials in a video perform that action.

Afterwards, we got a sneak peek in the Lentik lab and their new closed wind tunnel that is being built. We got to see the diagram and how the tunnel is being built. She explained that air is controlled by being passed through honeycomb slots in sections of the tunnel to direct the flow of air. Some students she said start with one project and change by halfway through the research project. Some do several projects. Research with SURI appears to be whatever you want to make it. You put what you get into it. The resources are all here, you just need to ask, think, and act. I'm excited for what developments may occur this summer.

Then, Morgan explained all the posters of research on the wall, and who was working on those. We saw tiny drones. We saw the biopsy needle prototype that senses and gives haptic feedback on when the needle penetrates skin. We were told what materials were up for grabs and which ones belonged to people in the lab. Morgan says he may need help on his project, and other SURI students seem to be interested in helping as a side project along with their own main research projects.

Later that day, I talked with Chris Ploch about his ideas for his research project and how I can be involved. Apparently, I will also be in charge of meeting a business and convincing them to fund the project in two weeks. I hope I can catch up on all the material that I need to understand and that we get a good prototype working by then. Chris says he'll be gone for two weeks, so I suppose I will be working by myself and skyping with him occasionally.

Everyone in the lab seems very impressive. I'm amazed by the amount of things lying on all the tables, the amount of electronics, the amount of people in the lab, the buzzing on the machines. I feel hopeful and excited to be apart of what's going on in the lab. It's a new environment and there's a lot to learn!

I slightly feel like I'm making a blog in an environment similar to the Avatar, which was a totally cool movie.