new web: http://bdml.stanford.edu/pmwiki

TWiki > Rise Web>ClimbingRobot > ClimbingConcepts > SpinedSurfaces>ClawTipMeasures (01 Oct 2004, MicheleLanzetta? )

Rise Web>ClimbingRobot > ClimbingConcepts > SpinedSurfaces>ClawTipMeasures (01 Oct 2004, MicheleLanzetta? )

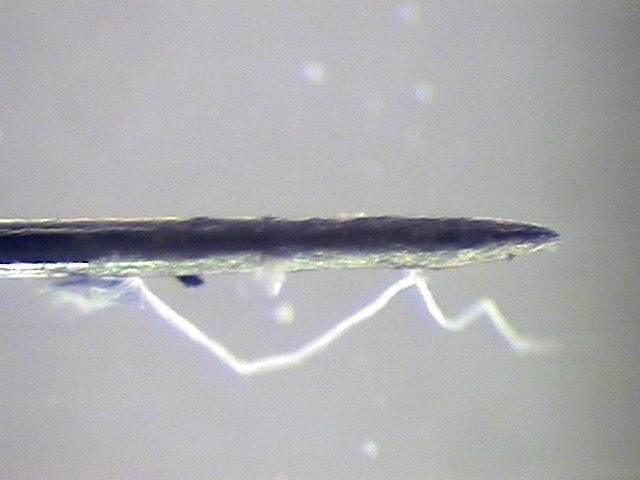

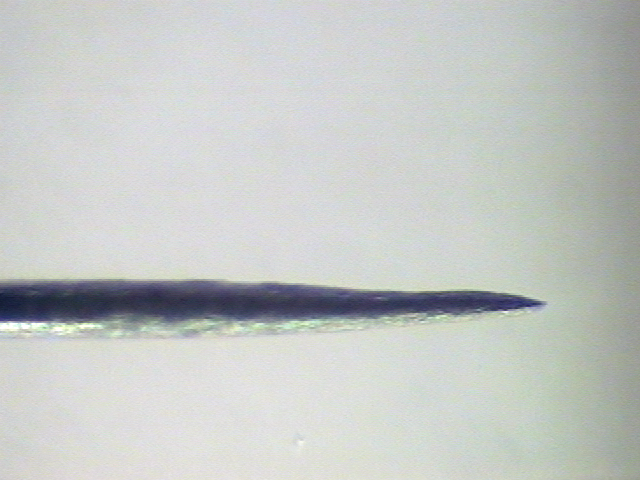

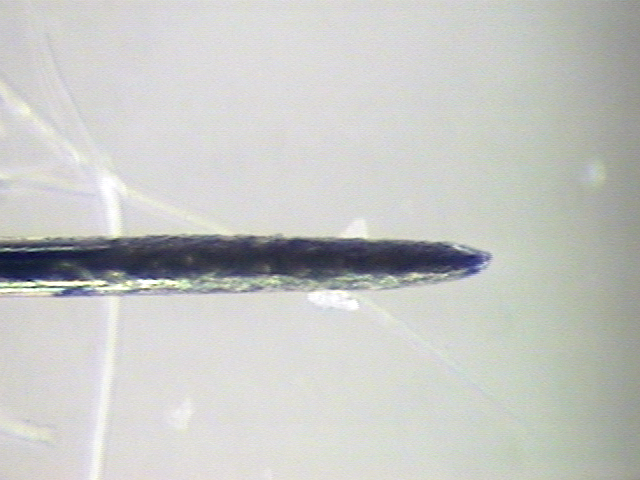

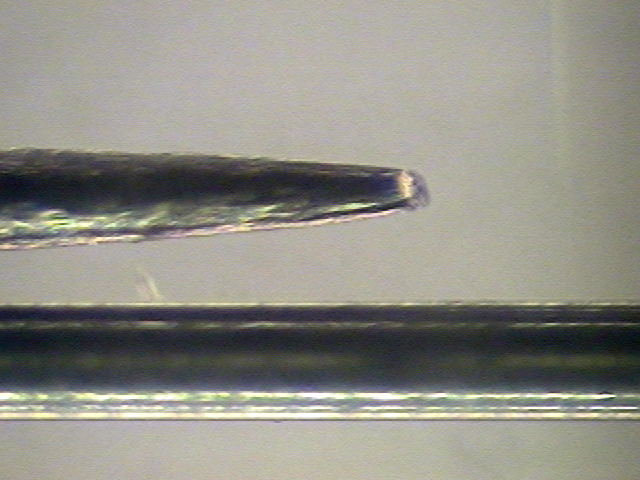

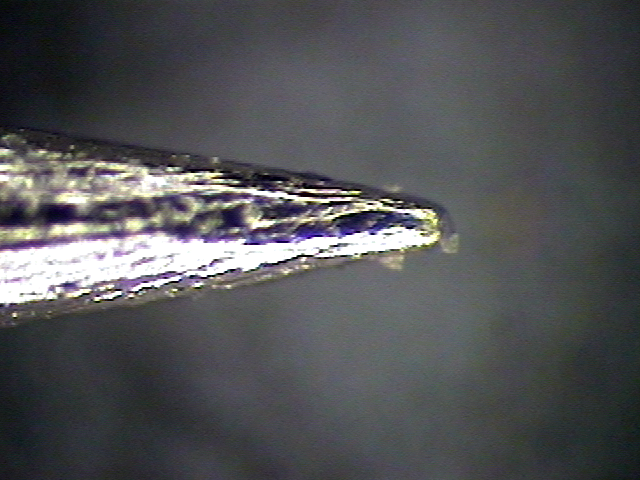

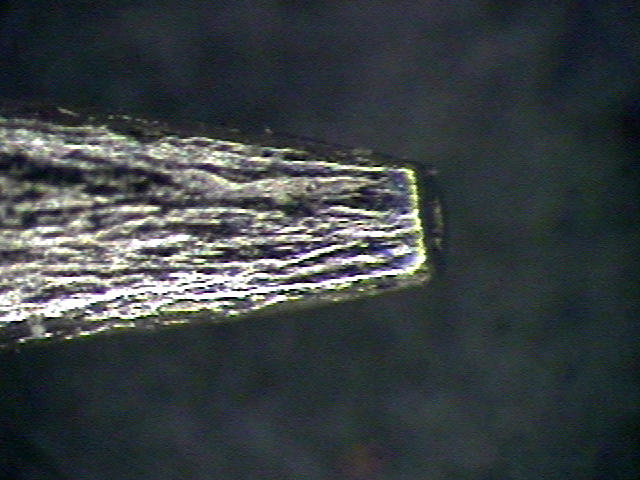

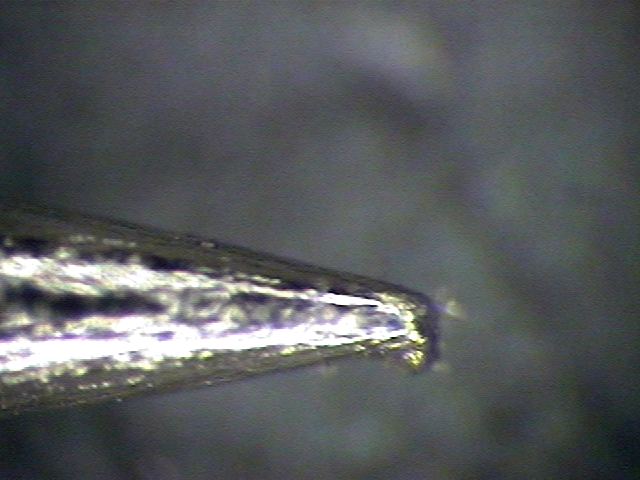

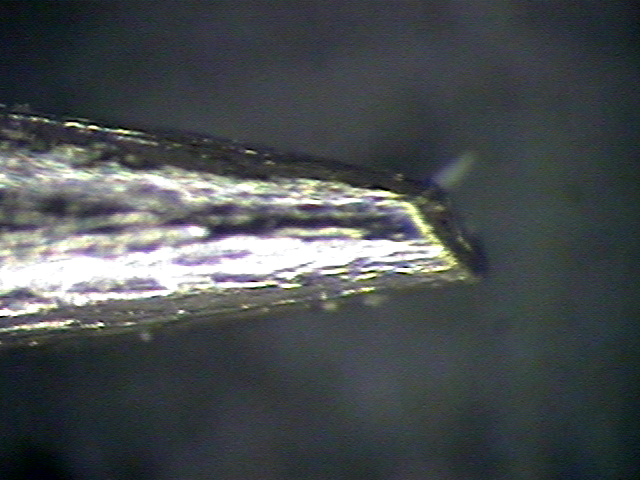

-- MicheleLanzetta? - 30 Sep 2004 - measurements and analyses of actual spine/claw tip size used in the Rise feet (NewFootDesignsJune04, FootDesign, FootAndLegTrajectoryStepTest etc.)

All images taken (51x44MB) can be found in "\\Chewie\users\lanzetta\Claw Tips"

Measurements

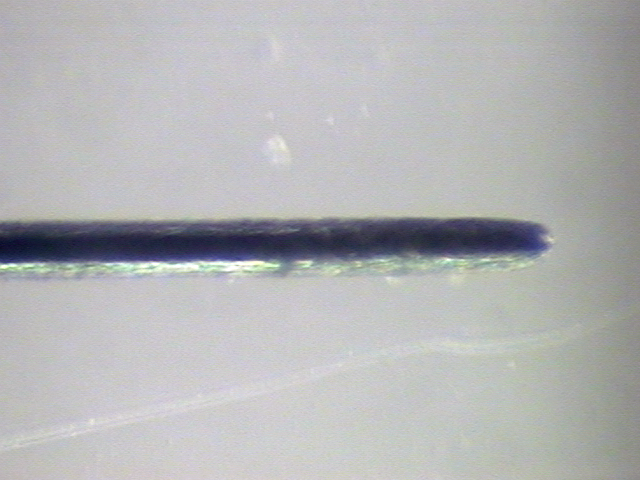

Measurements assume a calibration factor of 1.67 micron/pixel.All images taken (51x44MB) can be found in "\\Chewie\users\lanzetta\Claw Tips"

| Spine/Claw type/image filename | Diameter [micron] |

Tip diameter [micron] |

Sample images | Notes |

|---|---|---|---|---|

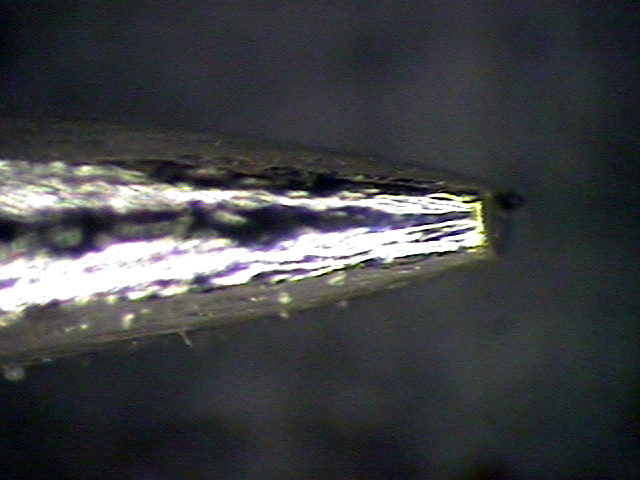

| CommercNeedleLarge.bmp | >3000 | 400 |  |

|

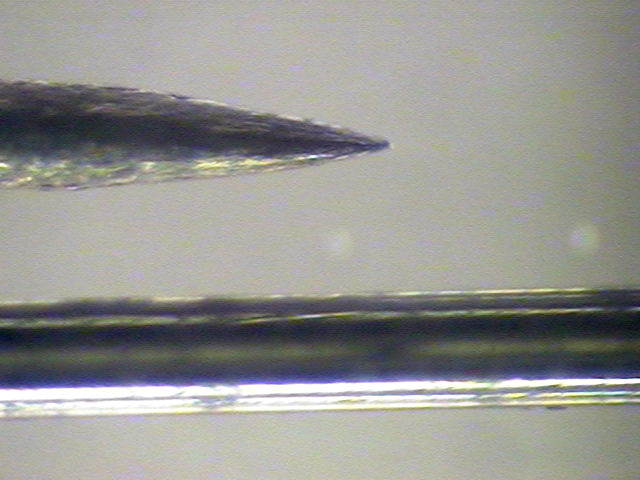

| Pin0.1_1.bmp Pin0.1_2.bmp Pin0.1_3.bmp Pin0.1_4.bmp Pin0.1_5.bmp Pin0.1_6.bmp Pin0.1_7.bmp |

100 | 25 20 30 30 25 50 20 |

|

|

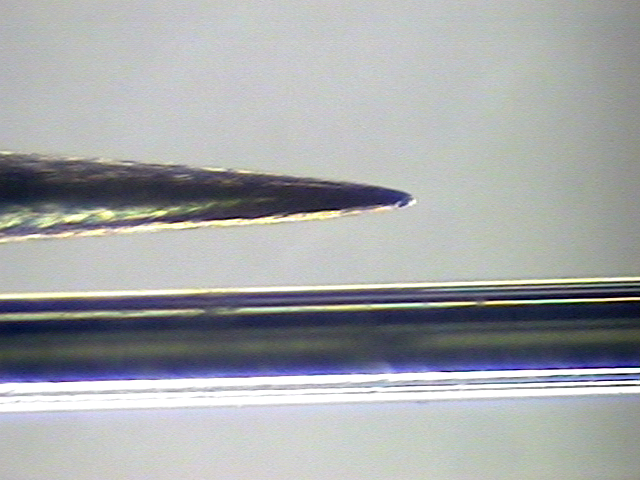

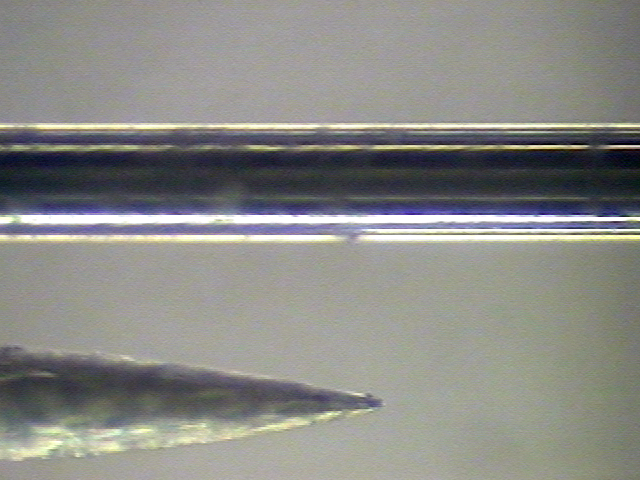

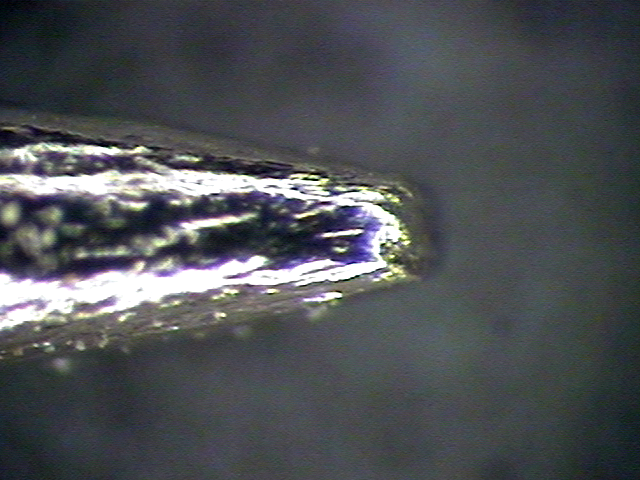

| Pin0.2_1.bmp Pin0.2_2.bmp Pin0.2_3.bmp Pin0.2_4.bmp Pin0.2_5.bmp Pin0.2_6.bmp Pin0.2_7.bmp |

200 | 20 20 50 broken 50 broken 25 15 20 |

|

|

| StdPin1.bmp StdPin2.bmp StdPin3.bmp StdPin4.bmp StdPin5.bmp StdPin6.bmp StdPin7.bmp StdPin8.bmp |

>350 | 75 200 120 70-170 120 130 160 60 |

|

|

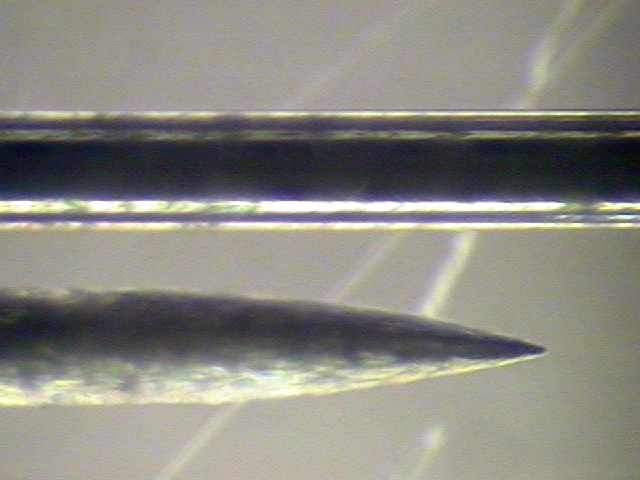

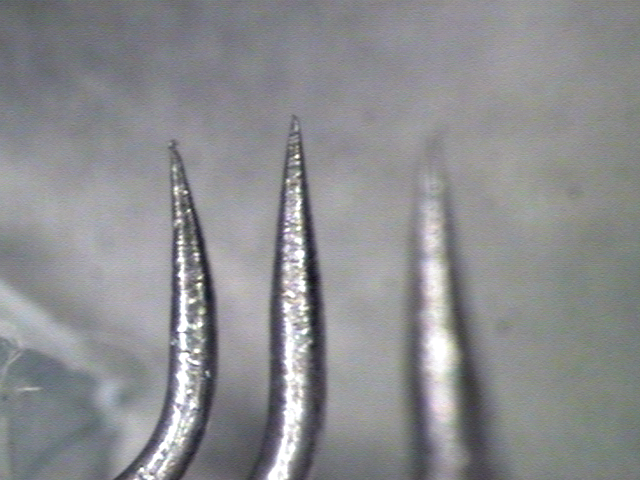

| footallthree.bmp Foot used in wall tests with carpet A clear explanation of difficult disengagement... |

200 | distorted 70 70 |

|

from left |

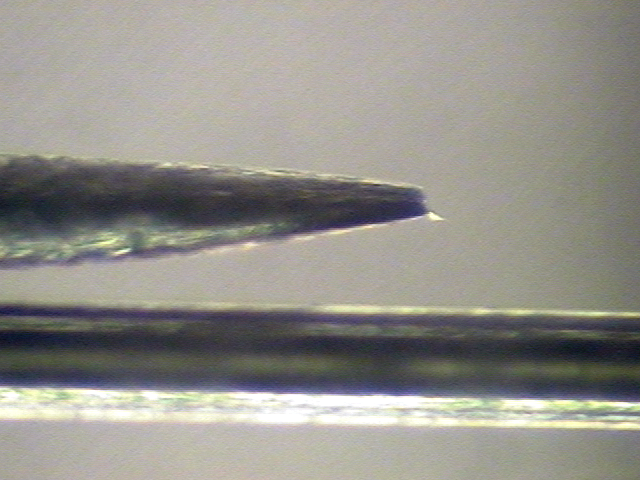

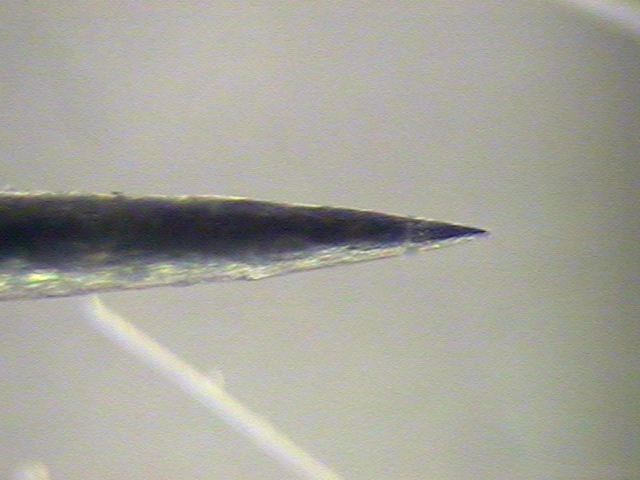

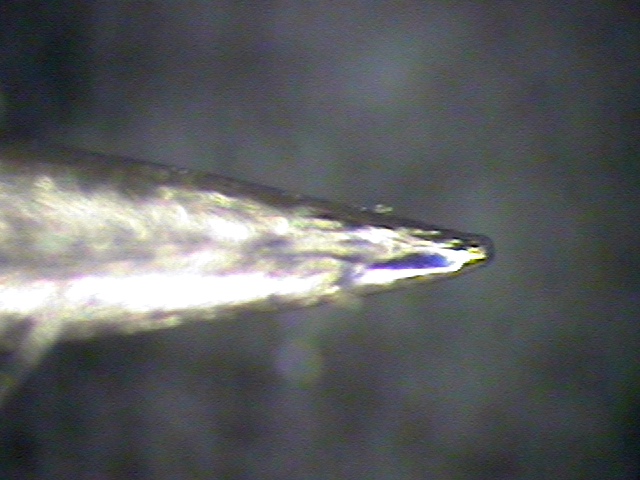

| Dana.bmp Manually sharpened by Dana |

200 | 20 |  |

|

| Surgical.bmp | 150 | 30 |  |

Conclusions

- This analysis shows that the variability among both manually made and commercial pins can be very high, so, of course, the performance of each foot should be carefully evaluated also considering the actual tip size of spines/claws used.

- Maybe obvious: smaller commercial pins not necessarily have smaller tip diameter. So commercial spine/claw material should be selected considering the actual tip size. E.g. the 100 and the 200 micron pins have the same minimum tip size.

- The lower bound for most spines/claws is found to be 20 micron (as assumed in the profilometer analysis SurfaceProfileAcquisition)

- Manual sharpening can lead to the best commercial size available (20 micron), so larger spine/claw materials can be used if required for structural reasons (less stronger spines/claws engaged)

Ideas, requests, problems regarding TWiki? Send feedback