new web: http://bdml.stanford.edu/pmwiki

TWiki > Rise Web>ClimbingRobot > LegDesign > StanfordTestTrack > StanfordTestTrackSummer04Tests>StanfordFootDesignTests (31 Jul 2010, DanAukes)

Rise Web>ClimbingRobot > LegDesign > StanfordTestTrack > StanfordTestTrackSummer04Tests>StanfordFootDesignTests (31 Jul 2010, DanAukes)

Stanford Foot Design Tests on Test Track

July18 Movies:

Wood surface

A number of tests were conducted on the Stanford Test Track on July 17 and 18 to evaluate foot designs and trajectories. Movie clips are attached below:The three aligned claws can be replaced by a triplet of claws to achieve intrinsecal compliance (unless compliance is not desirable for penetration). See also: SpineTriplets. -- MicheleLanzetta? - 08 Aug 2004 %ENDCOMMENT%

Felt surface

Here are some pictures and a quick movie of the new felt we have received from McMaster-Carr:Servo gain effect:

Here's a short clip and a graph demonstrating the effect of changing the input voltage to the servo amp:-- MiguelPiedrahita? - 19 Jul 2004

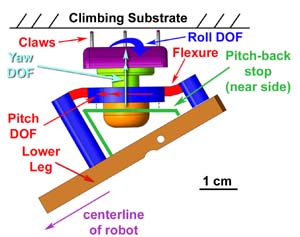

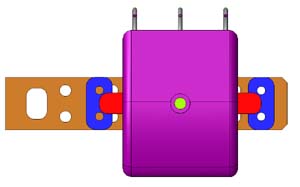

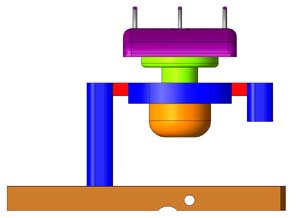

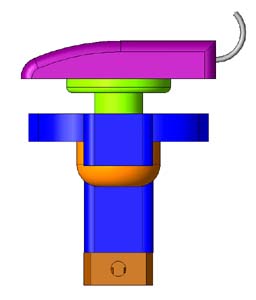

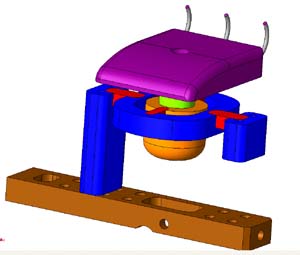

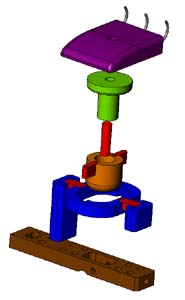

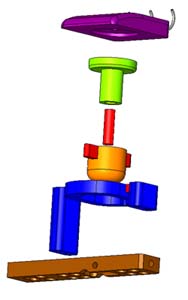

New Foot/Ankle Design July 04

Here are some video from our testing today. The leg was not acting very reliably, so we weren't able to get much testing in:

- FootTesting_July25_2004_2.mov: Gait #47

- FootTesting_July25_2004_45.mov: Gait #47 w/foot at 45deg

CMU testing results with feet

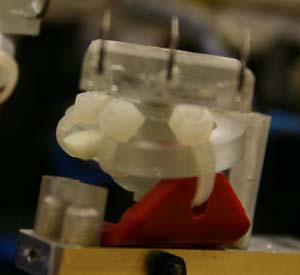

We spent several days running various robot experiments while using these feet, and met both success and failure. Here is a short description of the various failure modalities.Pitch Flexure

The pitch flexure was the primary cause of breakage, mostly because it is in tension at all times. A crack slowly forms inside the shorter post of the foot and widens until the flexure separates from the shorter post. We also noticed cracks (no breaks though) on the larger post. Superglue was mildly effective and fixing this, but only for a short amount of time. In the end, we followed Stanford's solution and used epoxy to stiffen the whole structure. In all, we broke our pitch flexures around 6-8 times.Yaw Flexure

The yaw flexure was the second item we had troubles with. While the flexure itself did not rip, like they do in the other failure modalities, it would debond from the glue which held it in place. This would occur when a foot could not detach and would end up twisting on the surface. Because there are no hard stops in the yaw flexure, the foot would twist 2 or more times fully around before the flexure debonded and and fall off, lower foot and all. The yaw flexures broke around 4 or 5 times. We used superglue to fix it after pushing the lower foot back into the socket.Roll Flexure

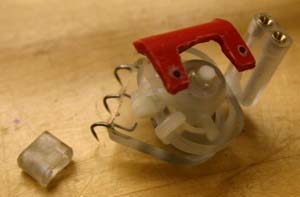

The roll flexures usually had very clean shears when they broke. These breaks did not happen until the end of testing, but we think they occurred from the pressure of pulling up on a foot that wasn't properly detached from the surface, thus pulling the flexures downward. The roll flexures only broke on 3 or 4 feet. -- ClarkHaynes? - 05 Aug 2004Stanford Testing

There are 2 ankles for testing at Stanford. Both ankle have zipties on the orbital ring to diminish pitching and roll of the foot.- Ankle #1 has pitch flexures reinforced with epoxy to diminish their effect. The foot was prepositioned to a desired pitch angle to engage claws prior to epoxy treatment.

- Ankle #2 has a aluminum bracket to stop pitching in both directions (forward and back)

Yaw flexure

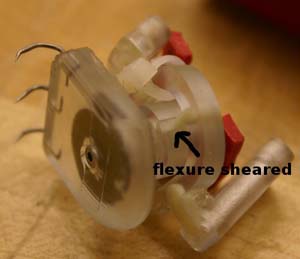

The yaw flexure failed on our ankle #1- It sheared in the middle

Pitch flexure

The pitch flexure stop failed on our ankle #1- The epoxy bond between the orbital ring and flexure broke and allowed pitching

The pitch flexure failed on our ankle #2

- It seems detachment pulling may have caused this shearing failure in the flexure

More pictures : [1] [2] [3]

Roll flexure

Cracks were noticed on the roll flexure on ankle #1, so it has been reinforced w/epoxy

On 8/12/04, the roll flexure on ankle #2 failed, so it also now has been repaired/reinforced w/epoxy

- The pulling at detachment seems to have sheared the flexure

More pictures (look closely for the cracks): [1] [2]

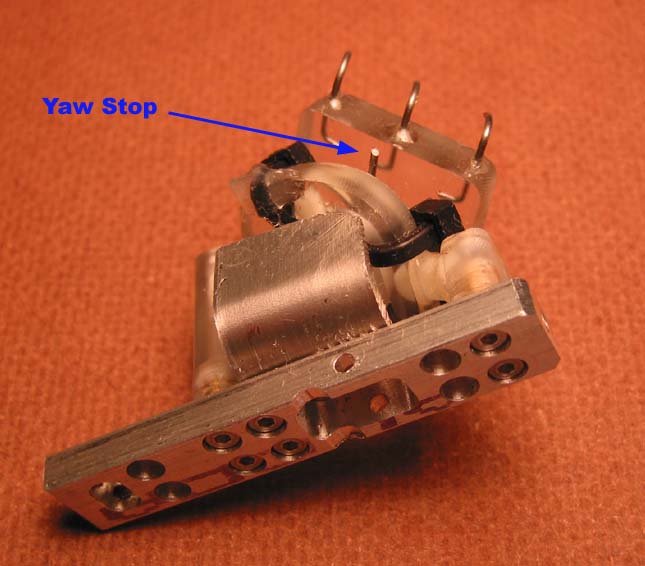

Yaw Stop

A yaw stop has been installed on one of our ankles here, to help with detachment and reduce wear due to over rotation. A small hole was drilled thru the yaw flexure mount, and a small rod of spring steel was placed into the hole and held in place by a dab of hot glue. The zipties that were previously applied to the foot to reduce pitch and roll compliance serve as limits for the stop. When these are not tight enough to hold their position as a stop, hot glue is added to hold the stops in place.

More Yaw Stop pictures Initial testing with this modification seems to show that it helps alot with disengagement. The yaw rotation was limited to appox +/- 45 deg in early tests. Movies should follow shortly, showing the difference that it can make.

Ideas, requests, problems regarding TWiki? Send feedback