new web: http://bdml.stanford.edu/pmwiki

TWiki > Rise Web>TWikiUsers > SimonScheffel>FirstPrototype (29 Aug 2005, YongLaePark)

Rise Web>TWikiUsers > SimonScheffel>FirstPrototype (29 Aug 2005, YongLaePark)

FSA Prototype 1 Fabrication and Test

People

SimonScheffel, YongLaePark with the help of: WillP and MiguelPiedrahitaConcept

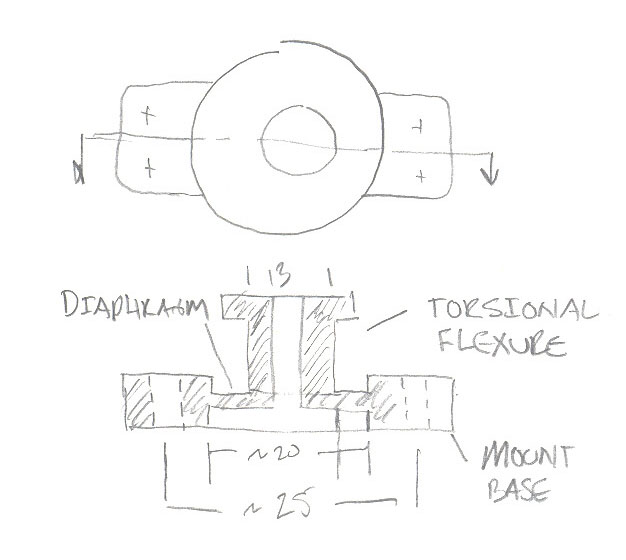

Keeping the current ankle design in mind, integrate functionality which allows for measurment of normal and tangential forces which occur at the gecko's foot. The idea is to take incorporte a diapragm-flexure into the ankle shown below, to enable:- Normal Force measurement by monitoring compressive strain

- Shear Force measurement by monitoring differential bending

- Layouts featuring diapragm a)"in" the flange, b)"above" the flange:

First Prototype

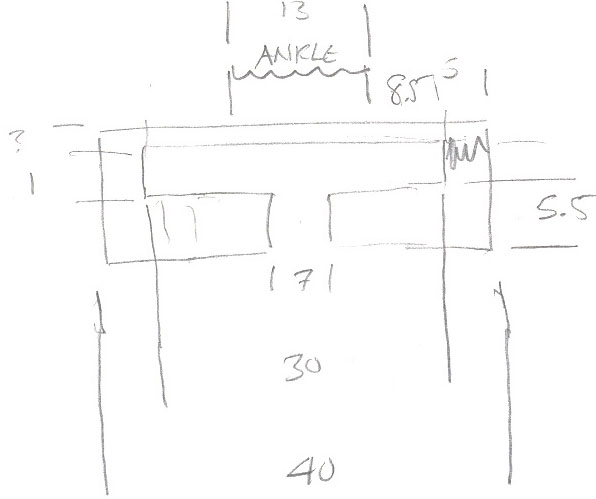

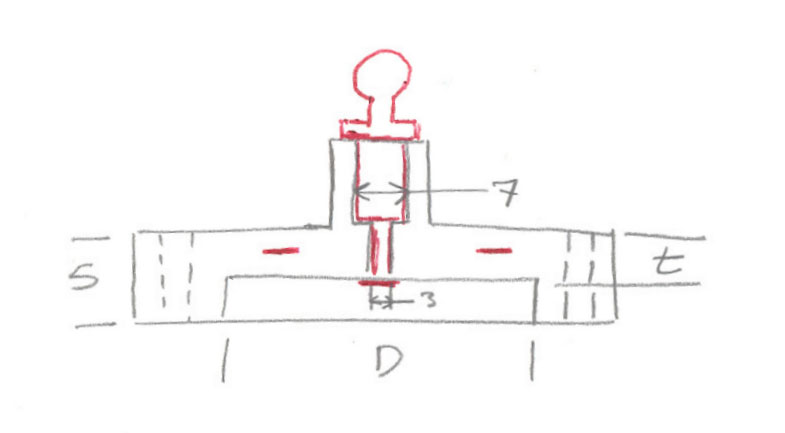

At this point, we have decided to produce a simple prototype in order to charachterize how a PU diaphragm may function as an insturmental component. The sectional image below shows a simple plate, with diaphragm thickness, t and diameter, D. We will produce various "load cells", with three diaphragm thicknesses (1, 1.5, and 2mm) and two diaphragm diameters (~20mm and 30mm). We plan to embed pairs strain gages in a few of these load cells (maybe more if assembly is fast enough), at opposing sides of the diaphragm, so differential measurements may be used in observing bending forces due to applied moment about one axis. Also, Tensile and compressive forces may be observed. Below, the image shows two horizontal red lines, this shows approximate placement of the gages, which will be a little off of the diaphragm's neutral axis (centerline). Also, notice the ball-joint (shown in red). A ball-joint test fixture will be developed, which allows for transmission of tangential forces to the ankle joint, so bending in the diaphragm may be accurately charachterized by via loading experiments and calibration.

Prototype 1 Fabrictaion

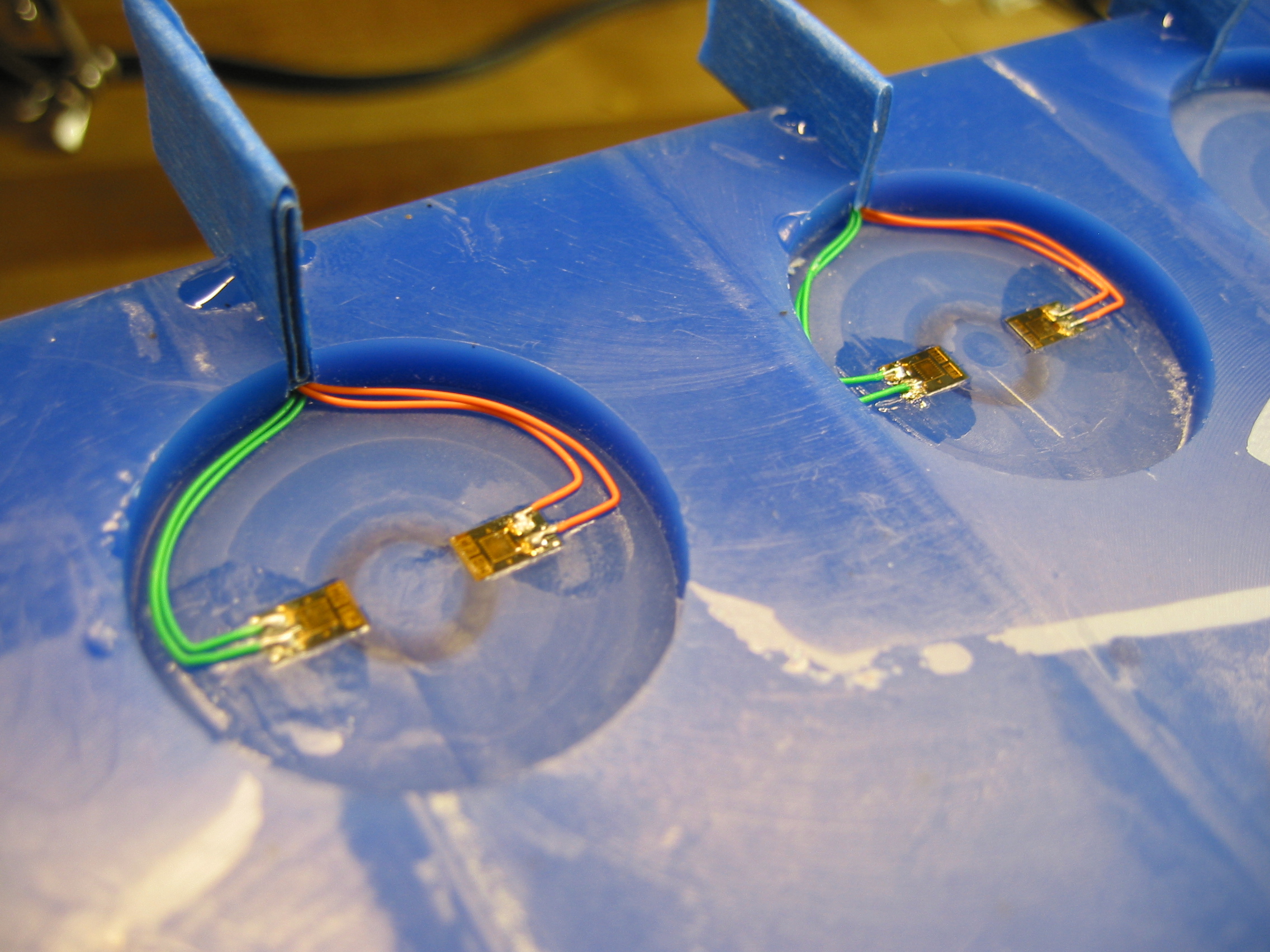

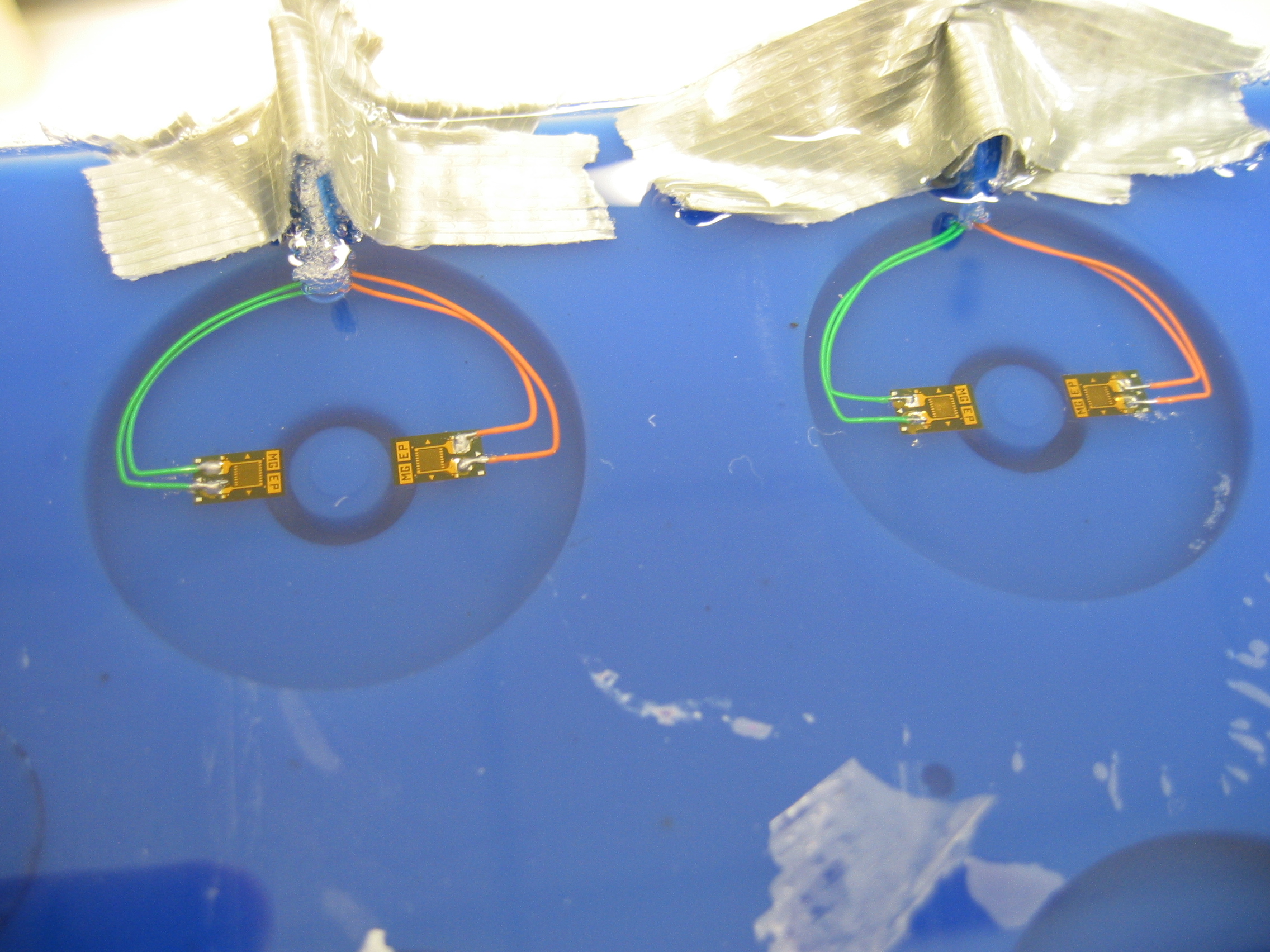

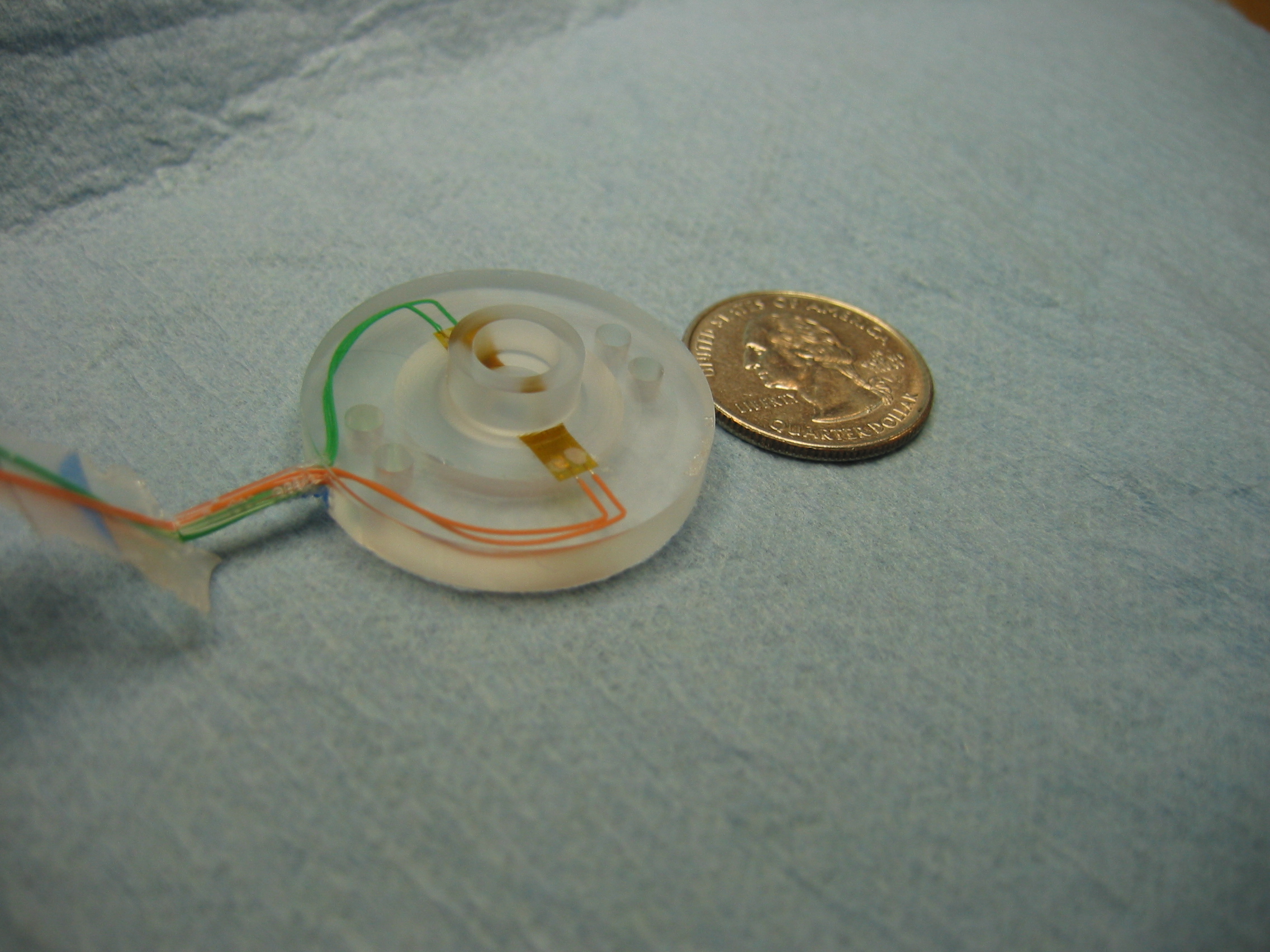

The two pictures below show the first couple of steps in this fabrication process. Pic 1 shows the strain gages mounted on the 1st quartile thickness of what will be the sensor's diaphragm, and Pic 2 shows the sensors after the final PU pour. Following this step, pockets will be machined, to create the diaphragm's thickness, and 4-hole patterns will be machined for mounting points.

-- SimonScheffel? - 11 Apr 2005

-- SimonScheffel? - 11 Apr 2005

Force Calibration of Prototype 1

Force Calibration of Prototype 1 was conducted using a scale and a height gauge.- Prototype 1:

- Test Circuit:

- Test Setup:

- Close Look of Test Setup:

- Test Result:

Force Calibration of Prototype 1a

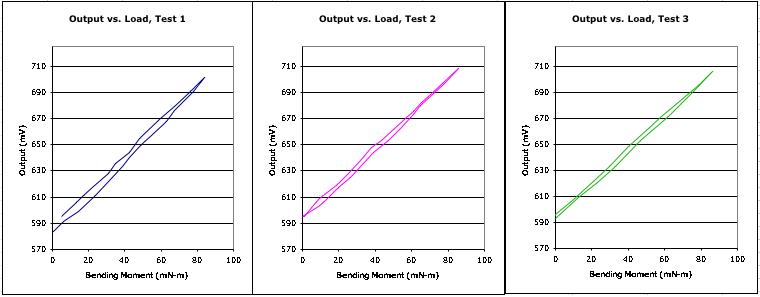

This calibration is similar to the one done on Prototype 1. The same tests were run on another transducer, which has a larger diaphragm (and theoretically more sensitivity due to decreased stifness). Experiment Meta Data:- "Large" Diaphragm

- -Diameter = 25mm

- -Thickness = 1mm

- 2-gage bending setup (same as test on prototype 1)

- -120-ohm metal foil strain gage, GF 2.065 (vishay EA-06-060LZ-120)

- -Gages bonded to diaphragm surface, not embedded in the "1st quartile"

- Static loading (~.5N incriments about every 30 seconds)

- 3 Hysterisis Plots:

Ideas, requests, problems regarding TWiki? Send feedback