On this page... (hide)

1. Private Seabed Rig electronic pages

New lab notebook for project updates: RDS_2012_ProjectLog

Telecon notes/minutes: Meetings

1.1 Background

Discussions with Robotic Drilling Systems (RDS), AS (formerly Seabed Rig) indicate a need for:

- sensing of gripper/tool for contacts, slippage, etc -- RDS want to know when an expected grip has been made, when something is held securely and when something starts to slip. Object/world slippage might be normal and expected; object/hand slippage might be undesirable and an example of the kind of thing the Divergence Alert System (see below) should attend to. The physical scale is quite large (e.g. for the "roughneck").

- a "Divergence Alert System" -- This is a sensor fusion problem in which various sensors (contact, cameras, laser range finding, acoustic, etc.) are used to provide a sense at each instant of whether the system is functioning as expected and, if not, to alert human operators or supervisors about the nature of the "divergence."

- human interface -- the problem here is to address how exactly will the divergence alert system and other elements display information through a combination of text, augmented reality graphics, haptics, etc.

The first item is relatively focused and is a direct extension of work Barrett and Alice are starting in August 2012. The second two will probably involve CDR in more of a consulting or advising role. They involve a big system for which we certainly will have useful advice, but are at a scale and complexity were we cannot build much, except for "proof of concept" demonstrations for particular ideas or targeted examples.

For some sensing background see the 13Aug2012 sensing slides from the Red Sea Robotics project.

from Roald Valen's email in the spring:

Suggested projects to start on Slip detection. This is what we have discussed a couple of times at a good project. Lets have a refresh talk on this one.

DAS sensor kit. The DAS (Divergence Alert System) shall detect divergences between the calculated world and the actual world. To get the correct ´view´of the actual world, we are dependent of having a technology to see the world independent of the environmental condition e.g raining, snow, sun etc. I will make a more detailed explanation during the meeting

1.2 Proposed Timeline, Tasks, Deliverables

Assume a start date in October or November of 2012

Q1

Slip Sensing

- Initial prototyping and testing of slip sensing approaches. PVDF is one leading candidate, but it is also worth looking at sensors based on physical displacement (see Ulmen & Cutkosky chapter on Dynamic Tactile Sensing for "Motion Detection" examples).

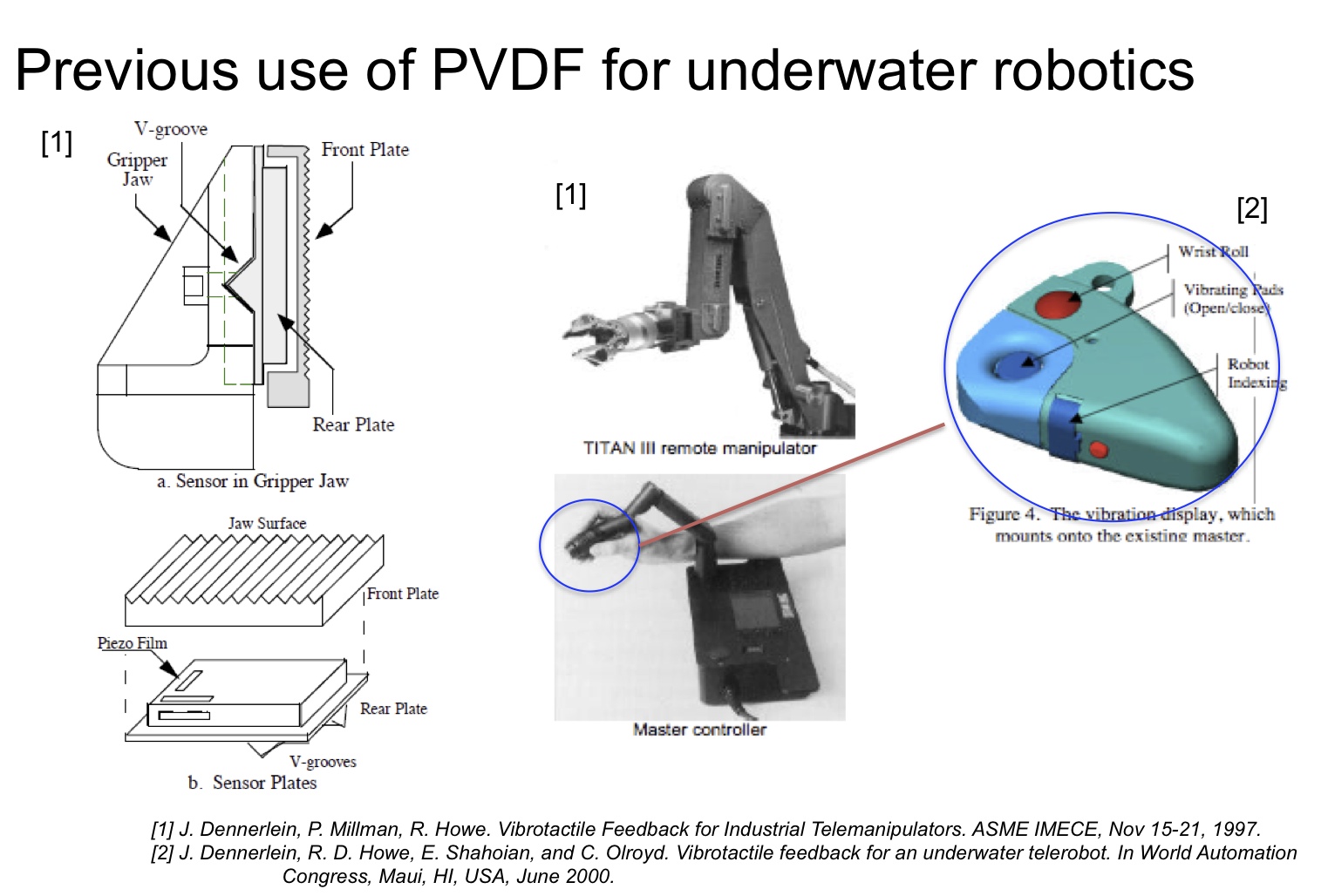

- Initial PVDF sensor design for a fractional scale metal gripper that can grip pipes and similar objects. This sensor will be adapted from previous work (e.g. Dennerlein et al. and the Red Sea Robotics projects). See Figure at right for summary of the Dennerlein et al. approach.

- Initial tests of PVDF and/or competing approaches. We wish to obtain better ability to discriminate between hand/object and object/world slippage than in the case of Dennerlein et al. At the same time, we need greater physical robustness and tolerance of high grasping forces than is required for the Red Sea Robotics hand and most other robotic slip detection schemes.

Divergence Alert and Interface

- Initial research to determine precedents for "divergence" detection and display in robotic systems

Deliverables: Q1 report with designs, literature review and preliminary test results

Q2

Slip Sensing

- Initial tests of encapsulated PVDF (and/or competing approaches if Q1 results are favorable) and gripping surfaces on a fractional scale gripper in salt water gripping pipes and similar objects.

- Metrics:

- maximum and minimum forces (minimum detectable force, maximum force before saturation)

- characterization of sensor linearity, signal/noise ratio

Divergence Alert and Interface

- Draft initial recommendations for sensor suite for "divergence alert" for a specific task or set of tasks to be determined through discussion with RDS.

Deliverables: Q2 report with designs, literature review and test results

Q3

Slip Sensing

- Converge on preferred slip sensing design. Develop electronics and gripper surfaces design

- Initial communications protocol

- Tests of gripping, pulling and performing basic manipulations on pipes and simlar objects Metrics include ability to detect:

- gripper object making and breaking contact

- object hand slippage versus object/world slippage

Divergence Alert and Interface

- Continued evaluation of sensor suites for divergence alert

- investigation of appropriate machine learning algorithms divergence alert and development of design guidelines for divergence alert learning systems

- develop proof of concept experiments for divergence alert, utilizing the slip sensing and other sensors (e.g. force torque, vision)

Deliverables: Q3 report with designs, literature review and test results of slip sensing and of initial proof of concept tests for sensor fusion and divergence alert

Q4

Slip Sensing

- Demonstrations of integrated (fractional scale) solution for detection of important events including slippage, contact, scraping.

- Tests using fractional scale gripper on Adept robot with gripper in salt water

- Design guidelines and documentation for RDS for scaling to the full-size version

Divergence Alert and Interface

- investigation of haptic feedback (direct telemanipulation and supervisory, for divergence alert) for slip sensing as a component of divergence alert

- tests of learning that includes slip and other selected sensors (to be determined through discussions with RDS) for divergence alert proof of concept prototype

Deliverables: Q4 report with designs, literature review and preliminary test results

1.3 References

J.T. Dennerlein, P. Millman, and R.D. Howe, Vibrotactile Feedback for Industrial Telemanipulators, Sixth Annual Symposium on Haptic Interfaces for Virtual Environment and Teleoperator Systems, ASME International Mechanical Engineering Congress and Exposition (ASME IMECE), Dallas, Nov. 15-21, 1997, DSC-Vol. 61, pp. 189-195.

Useful older paper describing placement of sensors, signal conditioning and results obtained with PVDF strips sandwiched between a hard substrate and an outer cap for the finger(s) of an underwater Schilling gripper. Strips on the side respond to shear loading. Discussion of impedance, frequency response etc. Users wanted to boost the low frequency content.

J. Dennerlein, R. D. Howe, E. Shahoian, and C. Olroyd. Vibrotactile feedback for an underwater telerobot. In World Automation Congress, Maui, HI, USA, June 2000.

Short paper that shows the gripper and master/slave system for using PVDF with a Schilling underwater robot arm. Nice image of the voice coil vibration display in the master

P. Kampmann and F. Kirchner, A tactile sensing system for underwater manipulation, HRI Workshop on Advances in tactile sensing and touch based human-robot interaction," 7th ACM/IEEE Intl. Conf. on Human-Robot Interaction, 5 March 2012, Boston.

Short paper on a sophisticated multi-sensor solution for an underwater hand. The system includes piezoelectric PVDF sensors for transient signals, optical fibers for steady pressure sensing and force/torque sensors in each finger

Lemburg, J., Kampmann, P., Kirchner, F., "A small-scale actuator with passive-compliance for a fine-manipulation deep-sea manipulator," OCEANS 2011 , vol., no., pp.1-4, 19-22 Sept. 2011

Short paper with more details on the design of the hand used with sensors above. Three fingers, under-actuated, hydraulic, with rotatable finger bases for wrap versus opposed grip

L. Seminara, L. Pinna, M. Valle, L. Basiricò, A. Loi, P. Cosseddu, A. Bonfiglio, A. Ascia, M. Biso, A. Ansaldo, D. Ricci and G. Metta, Design and Fabrication and test of arrays of piezoelectric transducers for robotic tactile sensors, 7th ACM/IEEE Intl. Conf. on Human-Robot Interaction, 5 March 2012, Boston.

Using inkjet printed conductive ink to make electrode array patterns on PVDF for sensor arrays

Cutkosky, M. and Ulmen, J., Dynamic Tactile Sensing in The Human Hand: A source of inspiration for robotic hands, V. Santos and R. Balasubramanian, eds., Springer Berlin Heidelberg, 2012

Inductive slip detection: http://ieeexplore.ieee.org/stamp/stamp.jsp?tp=&arnumber=5637534

given the large clamping forces something that works on relative motion or detection of gouging of the steel associated with slippage would be desirable.

acoustic emission slip detection: http://ieeexplore.ieee.org/xpls/abs_all.jsp?arnumber=1087812 (Dornfeld).

1.4 Notes

from notes by Alice and others: project goals: grip vs. slippage - machine learning algorithms for slip detection - answer questions on contact location and size of impulse designing a sensing system that is light weight, versatile, and low-cost potential collaboration with Mark Levoy from the Computer Graphics Lab

Slip detection/discrimination and related sensing is needed at a few stages in the process for both gripping and connecting pipes. In addition to slip we'll probably want to detect contacts between the various grippers and pipes, as well as between held pipe and the roughneck, etc, when starting to thread them together.

possibly microscope image of threads being investigated.

temperatures on the order of -10 to +40 deg C.

possibly use acoustic emissions sensor? http://www.pacndt.com/index.aspx?go=products&focus=sensors.htm

old but useful CMU survey of many sensor types for robotics: http://ieeexplore.ieee.org/xpls/abs_all.jsp?arnumber=1087812

Particle filter based noise removal method for acoustic emission signals Changjiang Zhou , Yunfeng Zhang,

Sept 4 Kickoff w/ Roald (Barrett's notes)

- Milestones:

- 2012 Nov changed to having leading candidates for technology rather than the technology.

- "To be used to start implementing..."; the engineers at RDS would like info ASAP on the sensors chosen so that they can take them into account when (re)designing the roughneck, pipehandler, etc.

- RDS is building a gripper testing rig so they can apply loads to held pipe and determine the limits of their gripper design. It would make sense for us to travel (October?) to see some of that testing and take any relevant measurements of forces etc on the gripping surfaces.

- General

- Wide range of pipe diameters (~3" - ~2', exact specs TBD)

- Vibration sensors (accelerometers?) will be installed on most of the machinery. May be useful to incorporate.

- Should have grip force, pipe diameter, spin speed/torque measurements from the various machines to use as input to detection algorithms.

- Pipe surface will be rough, possibly marred from previous use, covered in MUD/oil/water/etc.

- "Hazard area" will be available for any electronics which don't need to be EX rated. Doesn't include transducers and any local signal processing required.

- Roughneck

- Moving collet/chuck will be free spinning, no wired connection to sensors.

- Inductive (or other) coupling not a primary concern. RDS may need to solve that problem themselves for other reasons.

- Concentrate on compact, low-power electronics that can be EX rated

- Fast "spin-in" motion for ~7 turns to thread the pipes together, followed by high torque "make-up" ~1/4 turn.

- High grip force and applied torque, on the order of 10,000 N (unclear on exact torque, spec TBD)

- Dirty environment may include MUD/oil/water seeping out of pipe interface during threading

- More of a slip discrimination problem than pipehandler/robot, since there will be steel-steel slip at the pipe threads

- Moving collet/chuck will be free spinning, no wired connection to sensors.

- Pipehandler/Robot gripper

- Pipehandler has two grippers separated by some distance, robot will only have one.

- Interested in linear slip along pipe axis and away from "palm" of gripper, as well as rotation parallel to palm, perpendicular to pipe axis.

- Don't care much about rotation about pipe axis.

- May need to distinguish between these different motions.

- Contact detection may be quite useful here (maybe not as much on roughneck)

- Requirements/Specs

- Power supply is limited by connection to "Hazard Area" box; may be further limited by non-contact (inductive) coupling in the roughneck.

- "Response time" is only at the low level of identifying a slip event.

- Slip distance of 2mm is only approximate. Key point is they are OK with identifying gross slip as opposed to incipient slip.

- Continuous "slip occurring" signal vs. discrete "slip onset" signal TBD. RDS seems ok with either, will likely depend on sensor capability.

- Interfacing with Siemens components not really a priority; as long as the signal output from the transducer and any first stage(s) of processing is a standard format RDS engineers can work out the interface.

- "Maintenance Free" requirement may be negotiable; the gripping surfaces are often replaced, so if the sensor is easily accessible (and automatically calibrated) it may be reasonable to have it replaced on a similar schedule.