On this page... (hide)

Running set of notes from various meetings and telecons (new entries at the top please)

1. 06/10/13 Telecon Agenda

- SDK update.

- New Experimental Results update

- Preliminary algorithm walk through

Attach:RDS_Preliminary_Algorithm_Walkthrough.doc

- Next steps:

- test with different velocities

- different dices

- different sensor placement locations

2. 05/27/13 Telecon

Preliminary RDS June Meeting Agenda

- Walkthrough of hardware setup

- Walkthrough of data collection system + sensing pipeline

- Demonstration of experimental setup/data collection with various pipes/dies

- Demonstration of slip detection algorithm

New BOM with alternate vendors for AE sensors/data acquisition systems: Attach:BOM_Alternate.xls

Updated requirements document: Attach:RDS_RequirementsUpdate_052713.doc

3. 05/15/13 Telecon

- Image from Roald to discuss for today's meeting:

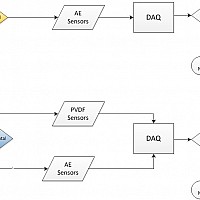

The bom has been updated to reflect a system schematic of where components are to be placed. As per our discussion last meeting, the pipe handler is no longer required to sense plastic pipes but only metal pipe slips, therefore the PVDF components have been taken out of the BOM. Please save the BOMs as an .xlsx extension

A few note regarding the BOM:

- For the AE sensors, cable connection to the DAQ board is available at various lengths.

- Power supply for DAQ/sensors requires 28V - specification document only mentions 24V available.

Meeting Agenda:

- new data updates

- pinpoint sensor placement location in pipe handler

- go over specifications/requirements at this point

- go over final deliverable system features - available now:

- real-time data viewing to observe different types of slip

- front end alarm system that trips when certain slip conditions are met

Upcoming Experiments:

- coincidence sensing with different sensor locations (for roughneck! + pipe handler?)

- new dice scheduled to be delivered tomorrow

- repeat experiments with grinded teeth on dice

- experiment with external vibration sources

4. 04/16/13 Telecon

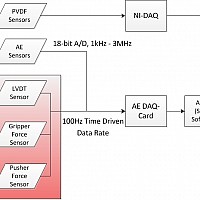

4.1 System Schematic:

4.2 Bill of Materials:

4.3 Updated Timeline:

Attach:ProjectTimeline_041613.doc

5. 03/19/13 Telecon

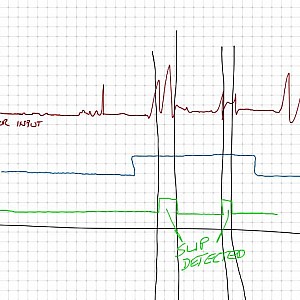

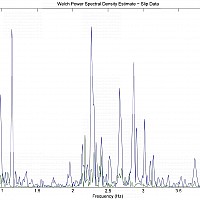

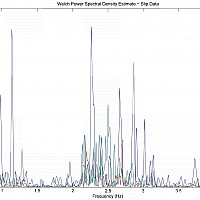

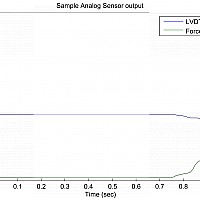

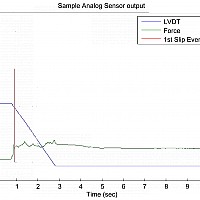

5.1 Initial data plots from slip events with force/position sensing:

5.2 Issues discovered as we've started using the system and gathering data:

- AE board power doesn't seem to be adequate; either it doesn't meet its specs or the LVDT/Force sensor conditioning boards are drawing more than they say.

- System stiffness is poor due to the vise itself and its attachment to the frame

- The vise hinges open, and this hinge point is a source of flexibility

- The vise base is attached to 80/20 with a few bolts clamping it vertically, but this doesn't constrain it well enough in rotation (due to the moment applied by the pipe.

- Possible solution is to machine some vertical flats and mounting holes on the vice base itself to properly mount to 80/20 frame.

- Clamping force sensor needs to be integrated. Since we don't have real dices yet we don't want to modify the clamping screw which means we need to modify the hardened upper dice we currently have. Need to get some new endmills which can handle the material.

5.3 For next time:

- Streamline data collection/processing

- Test witness sensors at higher frequency

- Finalize setup (addressing issues we've found)

- Give Roald an updated timeline

6. 03/04/13 Telecon

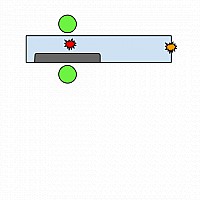

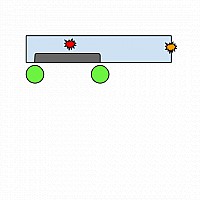

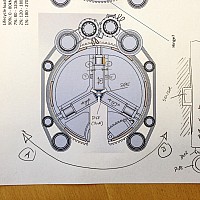

- Image from Roald to discuss sensor locations in the roughneck:

- The dises are on blocks which are pushed with hydraulics

- In the final solution it's desirable to not have the sensor move with the blocks

- Can it slide on the block?

- Can we keep the block's channel solid, and couple to the "back" side of the channel

- Emissions would have to couple dise->block->channel wall->sensor

- channel should be lubricated, so that may be an adequate couplant