On this page... (hide)

- 1. Project Log (Weekly Update)

- 2. 07/08/13

- 2.1 06/03/13

- 2.2 05/27/13-05/31/13

- 2.3 05/20/13-05/27/13

- 2.4 05/03/13-05/10/13 - Experiment Updates

- 2.5 04/22/13-04/26/13 - Pipe Mate-Up vs. Slip Experiments

- 2.6 New hardware updates

- 2.7 03/09/13-04/11/13

- 2.8 03/08/13: Grip force sensing

- 2.9 02/25/13 - 03/04/13: Experiment setup updates

- 2.10 02/11/13 - 02/18/13: Preliminary experimental setup and AE DAQ/sensors up and running

- 2.11 09/03/12 - 09/07/12: Project kick off.

1. Project Log (Weekly Update)

This is an electronic notebook to keep track of weekly project updates for the RDS Slip Detection Project. More info on the project can be found here.

Newer entries are at the top.

1.1 08/21/13

Algorithm Performance Results: Attach:pipehandler_performance.pdf Attach:roughneck_performance.pdf

1.2 08/01/13

Recent work:

Algorithm Development.

- used Stanford Statistics Consulting to learn about other event classification methods; now have more robust method of feature & weight selection

- code rehaul for easy dataset exploration

- implementing contextual information to exclude events

- planning next round of experiments

- awaiting last set of dies to perform validation experiments

Paper Draft.

- All sections have rough draft and desired figures/tables except results & discussion sections

- No prior art found thus far regarding using acoustic emissions to identify among contact/slip events (threading, rotational slip, linear slip, impact, noise)

- Key related works include Dornfeld 1987, Mba 2006, Sikorska 2006

Preparation for Norway trip

- tickets purchased: September 1st-6th.

- Alice will fly in August 31st and land September 1st, leave September 6th

- Natalie will fly in August 26th, land August 27th, join Alice September 1st, leave September 6th

2. 07/08/13

Since Roald's visit at the end of June, we have been addressing the following items:

Slip Detection Algorithm

- Event Selection. The method we use to group events changes which variables best predict the event. For the paper (discussed below) we would like to present a method to detect and identify linear slip, rotational slip, and mate-up of pipes (threading). However, rotational slip characteristics greatly overlap linear slip and pipe mate-up, as expected. Whether rotational slip needs to be detected and identified separately is under consideration, as failures are generally associated with linear slip and successes with pipe mate-up.

- Feature Selection. We have explored several ways to identify the best AE sensor features for use in the algorithm to detect and identify slip types, including stepwise regression and using a z-test on histogram parameters. Several histograms are attached below. Next steps include refining the tests used to classify events using the histograms and exploring other methods, such as the lasso method or k-means.

- Implementation into algorithm. Our algorithm will use both a weighted sum of sensor features and a product of contextual features. Future experiments and statistical analysis will aid selection of sensor feature weights.

Future Experiments.

- vary slip speeds for different slip types (force controlled)

- vary gripping force (slip speed controlled)

- verify independence of results from dice profiles

Example Histograms.

Paper Draft

The paper will present a method to detect and identify types of slip quickly and reliably using a combination of acoustic emission sensor features and contextual information in an unusual application, automated robotic oil drilling. The harsh conditions and very high forces exclude most past approaches to robotic slip sensing.

We have completed a conceptual draft of the paper (framing of the idea, what figures ought to be included, a rough abstract and introduction, etc.) and are working to identify key papers to reference and to complete the algorithm as discussed above.

Key contact events include

- linear slip between steel pipes and the robotic gripper

- rotational slip between steel pipes and the drilling roughneck

- make-up and break-out motions of fittings on pipes

2.1 06/03/13

We experimented with 5 different types of materials and spent major efforts on finding features that are appropriate for the final slip detection algorithm. Please refer to the meetings page for more updates.

2.2 05/27/13-05/31/13

Logistic regression fit to 70% of experiment data for rotational/linear slip and pipe mateup

2.3 05/20/13-05/27/13

We've received new dies for experimental setup from McCoy Global. Unfortunately, the company had sent us the wrong # of dies and we're currently waiting on a new bottom die.

In the mean time, we have proceeded with algorithm development on the data we have previously gathered.

2.4 05/03/13-05/10/13 - Experiment Updates

21 sets of experiments were performed, altering parameters such as dB lower cutoff level, type of disturbance applied, direction of slip, etc. 3 different frequency cutoffs (35, 30, 25 dB) were tested against 7 different conditions:

- hammer on pipe (plastic)

- hammer on pipe (metal)

- pull - linear slip

- screw(CounterClockwise) - pipe threading/mate-up

- twist(Clockwise) - rotational slip

- twist(CounterClockwise) - rotational slip

- twist(CounterClockwise)/screw - combined threading/rotational slip

The results of the experiments verified our ability to detect several events:

- We can identify object impact. There is a quantifiable difference between a hammer strike and a sustained slip signal, so if the pipe bumps into something, we will not register this event as a pipe slip.

- We can obtain significant amounts of AE signals for both rotational and linear pipe on dices slip.

Currently, we are working to extract feature information regarding interface detection to enable differentiation between thread slipping, clamp slipping, and both events occurring simultaneously (indicating over-threading, poor vice grip, etc.).

Custom dies from McCoy Global are being shipped today for use in the experimental setup as well as additional regular dies to use in other scraping experiments. Replacement RIDGID upper and lower jaws (dies) are ordered as well. These will be sand-blasted and used to determine the effects of old, dulled dies.

Data Plots:

List of AE Features:

2.5 04/22/13-04/26/13 - Pipe Mate-Up vs. Slip Experiments

1. two sets of pipe mate-up experiments (we screwed on a fitting to the pipe while the pipe was held in the vice). During mate-up, the pipe holder was tightly gripping the pipe. We took data at 40dB cutoff and 35dB cutoff for hit event registration.

2. two sets of pipe-slip experiments - at both 40dB and 35dB. These slips were performed manually since we're re-setting up the power supply for the linear actuator.

3. two sets of experiments in which both slip and mate-up were happening simultaneously - at both 40dB and 35 dB

2.6 New hardware updates

force sensor mounted on top die for normal force measurements

currently installing new power source for linear actuator/witness sensor setup

2.7 03/09/13-04/11/13

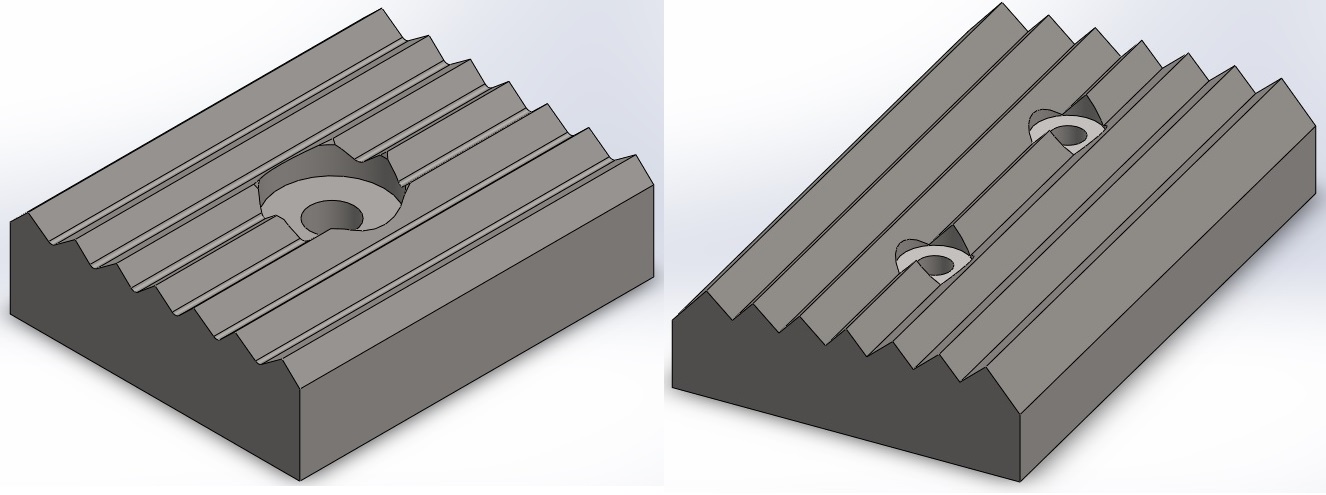

Customization of dies to accommodate the force load cells is underway. Airtronics in San Jose will alter the existing top die while McCoy Global will manufacture custom pieces to replace both the top and bottom dies.

Preliminary testing with the NI myDAQ and the AE sensor DAQ will reveal whether any relevant signal information is lost due to undersampling.

Investigation into rotational actuators has begun. Likely courses of action include purchasing a manual pipe threader or renting an electric one from Sunbelt Rentals in San Jose.

MISTRAS (makers of the AE sensor planned for use) representatives visited the BDML to discuss areas of AE sensor spplication, particularly interface slip detection.

Dedicated power supplies to run all witness sensors on our experimental setup have been purchased.

PVDF sensors from Measurement Specialties for use in another set of slip experiments have been purchased.

2.8 03/08/13: Grip force sensing

Force sensing in the pushing direction is fairly straight forward, however adding a loadcell to measure grip force is a little more complicated because there is significant tangential force during a push/slip event.

The pipe vise's moveable jaw, when opened up looks like this:

There are two halves which trap both the vise screw and the top die The die is held in place by two bumps, one on each half (you can see the hole in side of the die in the pictures.

The easiest thing to do is turn down the vise screw where it makes contact with the die so that we can attach the load cell to the die and push on it with the screw. The downside is that this will only let us make initial grip force measurements accurately; as soon as we push there will be significant force between the side of the die and the holding plates, which will support an additional load path not through the load cell.

A more precise option would be to add some sort of bearing surface at this interface so that it cannot support any normal/grip forces, leaving only the loadcell in the path.

2.9 02/25/13 - 03/04/13: Experiment setup updates

- Good news: LVDT sensors (witness sensors for incipient slip(linear)) are up and running. short video of LVDT sensor in action

- Currently, the LVDT sensors are sampled by the AE DAQ card at 100Hz or so. Alice will speak with application engineers to find way of sampling at higher data rates. AE slip events are captured along with the time driven data at specific time points.

- We have called Mistras for a high-speed parametric software add-on that will allow us to get analog data back at 2kHz.

- Quick experiments have been done to verify that the AE DAQ board can measure multiple analog input signals (+/- 10V) and is able to provide a +/- 12V voltage output for external sensors.

- Force load cell sensors have been purchased and should arrive by 03/04/13.

- Barrett and Alice have ran through the calculations associated with force scaling based on the force/sensor data from the gripper setup at RDS sent by Svein.

- We see from the data that the sensor sautrates at 26.2 kN. Assuming linear scaling, we should be able to cut the pushing force required for slip down by a factor of 5-15x.

- This is based simply on the change in length of all the dices; the RDS dies are ~35cm and ours will be 2.5-5cm.

- From their data it looks like they were saturating at 26.2kN = ~6000lbf, so we need to push with 400-1200lbf.

- Based on these specifications, we have ordered these force load cells:

- MSP6953-ND

- MSP6955-ND

- Note that the same model load cells for 1000 lbf is not in stock and have a 6 week lead time.

- Barrett and Alice have ran through the calculations associated with force scaling based on the force/sensor data from the gripper setup at RDS sent by Svein.

- Test Rig design/fabrication

- The linear push test rig is 90% designed and 80% fabricated (see images below). Outstanding items:

- pusher plate w/ load cell mount (fabricate)

- grip force load cell mount (design and fabricate)

- Linear actuator capable for 1000lbf (4.4kN)

- The linear push test rig is 90% designed and 80% fabricated (see images below). Outstanding items:

2.10 02/11/13 - 02/18/13: Preliminary experimental setup and AE DAQ/sensors up and running

- AE DAQ card manual can be found at: Attach:AE_DAQ.pdf Δ

2.11 09/03/12 - 09/07/12: Project kick off.

- Roald visits BDML to discuss project proposal for slip sensing.

- Primarily interest in detecting slip at the pipe-handler and the roughneck.

- The pipe-handler has a dedicated pipe gripper, and moves sections of pipe (maybe sets of 3 pipes already threaded together...) between the magazine and the roughneck.

- The roughneck is the more complicated section which screws new pipe into the existing stack, and RDS would like to be able to detect the slip and which section of the pipe is slipping.

- preliminary promising sensor candidates:

- acoustic emission sensor: http://www.pacndt.com/index.aspx?go=products&focus=sensors.htm

- good for steel/steel slip detection for the roughneck

- PVDF sensors: http://www.meas-spec.com/piezo-film-sensors/piezo-film-elements.aspx

- promising for plastic pipes handled by the pipe-handler

- acoustic emission sensor: http://www.pacndt.com/index.aspx?go=products&focus=sensors.htm