new web: http://bdml.stanford.edu/pmwiki

TWiki > Rise Web>ClimbingRobot > ClimbingConcepts > SpinedSurfaces > SpinyBot>SpinyBotIIToeComplianceFEA (18 Mar 2005, SalomonTrujillo)

Rise Web>ClimbingRobot > ClimbingConcepts > SpinedSurfaces > SpinyBot>SpinyBotIIToeComplianceFEA (18 Mar 2005, SalomonTrujillo)

Finite Element Model of SpinyBot II toe compliance

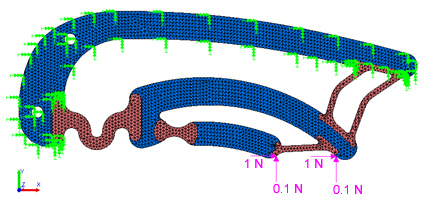

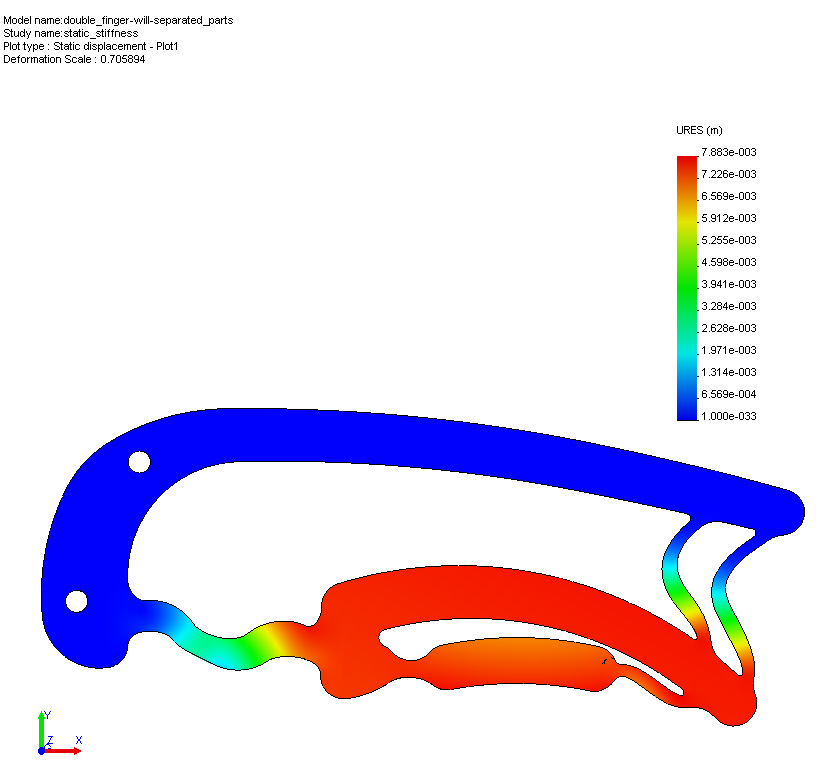

Using Cosmos Works (Solid Works) FEA, the solid model of an individual toe was parsed and automeshed. A preliminary model with applied forces at the locations of the two toe spines are shown (forces shown in Newtons). The green arrows on the outer frame indicated a fixed boundary condition. Show below is a contour plot of the displacements resulting from the above load conditions (displacements in meters). The preliminary model uses material properties of Nylon6-6 for the "hard" material and rubber for the "soft" flexure material.

Show below is a contour plot of the displacements resulting from the above load conditions (displacements in meters). The preliminary model uses material properties of Nylon6-6 for the "hard" material and rubber for the "soft" flexure material.

An animated plot of displacement can be seen here.

-- WillP? - 05 Jan 2005

An animated plot of displacement can be seen here.

-- WillP? - 05 Jan 2005

Stiffness Matrix Extrapolation

I have attempted to produce stiffness matricies from the FEA model of the toe. I added spines to each of the flextures such that the model can apply loads and measure displacement (especially rotation displacement.) Unfortunately, the results were not conclusive. I attempted to apply very small loads to yield a linear result. I applied a force of 1e-4 N in X and Y directions and a torque of 1e-4 N cm in the Z direction. These forces/torques are of the small order of magnitutide of those that I applied to the Working Model toe to yield a linear result. This is the resulting matrix for the inner spine (In the Solid Words frame):| 177.8232 | 70.2786 | -147.4570 |

| 2.1696 | -0.0424 | -0.1698 |

| -517.3332 | -202.3524 | 428.6857 |

Dimensions: X, Y, Theta The order of magnitude of the matrix is different due to the difference of materials chosen for the model (nylon & rubber). However, the negative Kyy component is very odd. After computing the eigenvalues of this matrix, I noticed the matrix is not positive definite, which means it cannot be a stiffness matrix (otherwise the toe could produce energy rather than store it). Enforcing symmetry on the matrix does not solve the problem. This seems to be due partially to the limitation of using a FEA model, and partially to the method of extracting rotational displacement data from the model. -- SalomonTrujillo - 18 Mar 2005

Ideas, requests, problems regarding TWiki? Send feedback