new web: http://bdml.stanford.edu/pmwiki

TWiki > Rise Web>TWikiUsers > DanaUng>EmbeddedAdhesive (12 Dec 2004, DanaUng? )

Rise Web>TWikiUsers > DanaUng>EmbeddedAdhesive (12 Dec 2004, DanaUng? )

Documentation/ Experimental Procedure:

Conversions for dissolving KOH or NaOH

1 molar solution of KOH = 56.1002g KOH/ 1 Liter H20 = 56.1002g KOH/ 1000g H2O? 1 molar solution of NaOH = 39.994g NaOH/ 1 Liter H20 = 39.994g NaOH/ 1000g H2O?

Process for embedding filter in a urethane substrate:

- Place double-sided sticky tape (thin scotch tape) on a plastic film

- Firmly press the filter onto the sticky tape

- Properly mix the desired urethane hardener and resin in a beaker

- Degas the mixture

- Pour the urethane on the plastic film on the filter

- Degas the poured urethane

- Let the urethane cure

- After the urethane is cured, peel the urethane off the plastic and peel the tape off the urethane

Process for dissolving a filter embedded in a urethane substrate:

- Mix 5g KOH with 90g H2O? to form a 1 molar solution of KOH in a glass beaker

- Wear gloves

- Measure the appropriate amount of KOH

- Pour hot water in the beaker

- Pour the KOH in the hot water

- Mix the solution with a stirring rod

- Note: KOH absorbs moisture quickly so be sure to quickly reseal the stock KOH. Wear gloves - KOH is caustic and will burn the skin and eye.

- Placed urethane substrate in solution.

- Waited 12 hrs.

- Removed substrate from solution, and rinsed with water

- The KOH solution does not need special disposal because of its low concentration. Pour it in the sink.

Pictures:

- Before KOH:

- Before KOH:

- After KOH:

- After KOH:

- After KOH:

- After KOH:

Pictures under the microscope:

Sample 1: Hairs casted in 90A

- 50x

- 100x

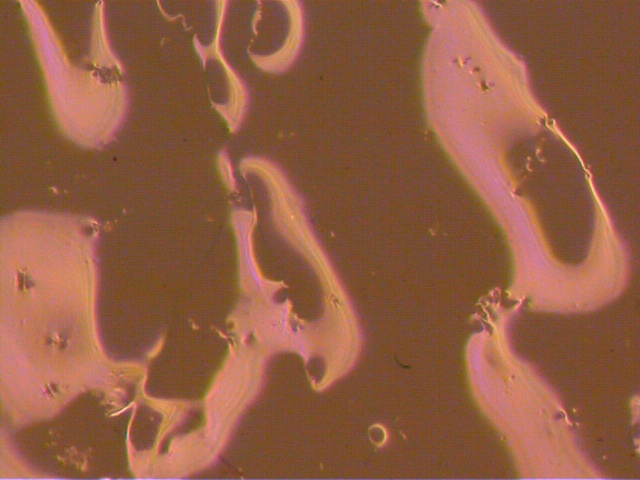

Sample 2: Hairs casted in 20A.

These pictures may be bad pictures and may be of the residue left by the double-sided tape.

- 8x

- 50x

- 100x

Sample 3: Uncasted hairs in the filter

- 8x

- 50x

- 100x

Results from first cofabrication (11/26):

- This first cofabrication was of sample 1, with hairs casted in 90A. I am not sure how successful the etching was. Just by touching, the surface where the hairs are supposed to be has a different texture than the surrounding urethane. This leads me to believe the etch was successful, but the different texture could just be roughness of the urethane after the filter was etched away. To be sure, I need to look at the filter under an electron microscope or just test the foot to see how much friction it has.

Results from second cofabrication (12/10)

- This second cofabrication was of sample 2, with hairs casted in 20A. The hairs did not seem to stick to the 20A as well as the 90A. The 20A was weak and was easily damaged when I tried removing the double-sided tape. However, I am still not sure if the hairs are there, even after looking through the optical microscope. I could not see clumps of hairs.

Ideas, requests, problems regarding TWiki? Send feedback