new web: http://bdml.stanford.edu/pmwiki

TWiki > Seabed Web>SeabedMain>MeetingNotes20090722 (22 Jul 2009, BarrettHeyneman)

Seabed Web>SeabedMain>MeetingNotes20090722 (22 Jul 2009, BarrettHeyneman)

Pre-Meeting posts:

| SMC | Rotary Actuator | 3 | Main Actuator for Finger |

| SMC | Rotary Actuator | 1 | Input to main finger actuators |

| SMC | Tube Fitting | 6 | Hydraulic accessories |

| SMC | Tube Fitting | 2 | Hydraulic accessories |

| SMC | Pneumatic hose | ~20ft | |

| SDP-SI | 20mm Gear | 6 | connects rotary actuator to finger link 4 |

| SDP-SI | 30mm Gear | 2 | guides rotation of 2 fingers on base |

| SDP-SI | 40mm Gear | 2 | guides rotation of 2 fingers on base |

| SDP-SI | Bearing, 4mm bore | 12 | finger housing |

| SDP-SI | 4mm Thrust Bearing | 3 | supports loads for three fingers attached to base |

| Motor | 1 | Orients 2 fingers | |

| Actuated Valve | 1 | for zeroing of rotary actuators | |

| Check Valve | 1 | for zeroing of rotary actuators | |

| SMC? | Short Cylinder | 3 | Adjusting internal forces on second phalanx |

| SMC? | Long Cylinder | 3 | Adjusting internal forces on second phalanx |

| SMC? | Hydraulic actuator | 1 | Input actuator for internal force adjustment |

Meeting Notes

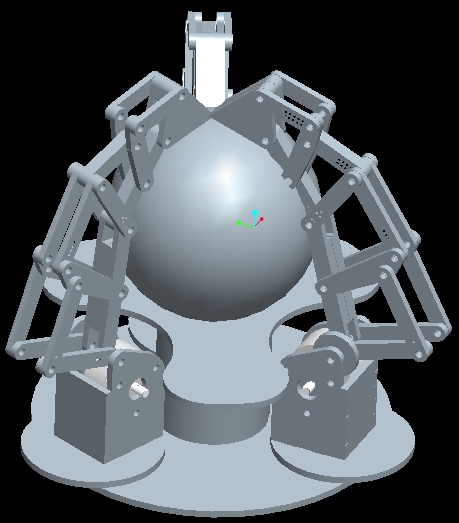

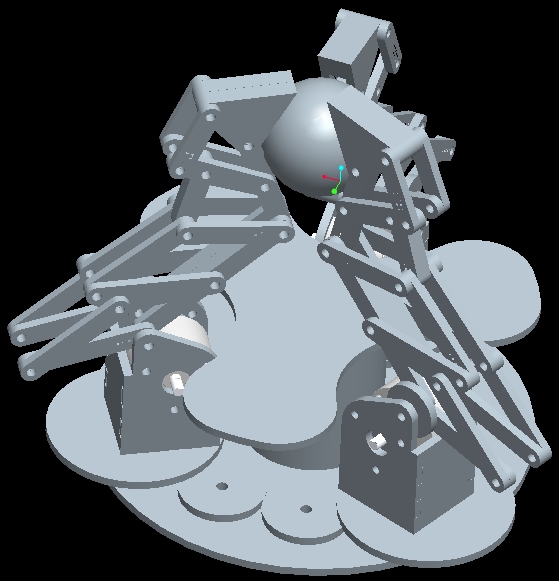

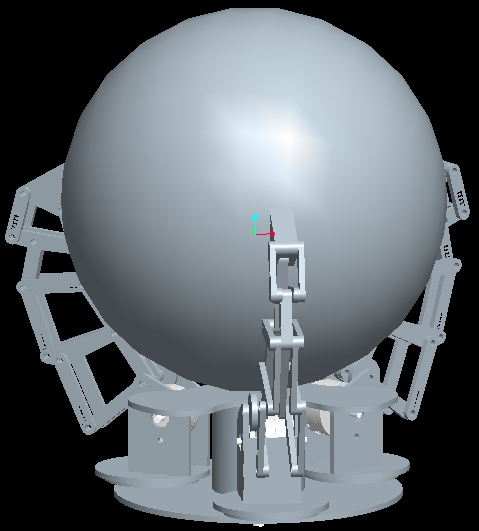

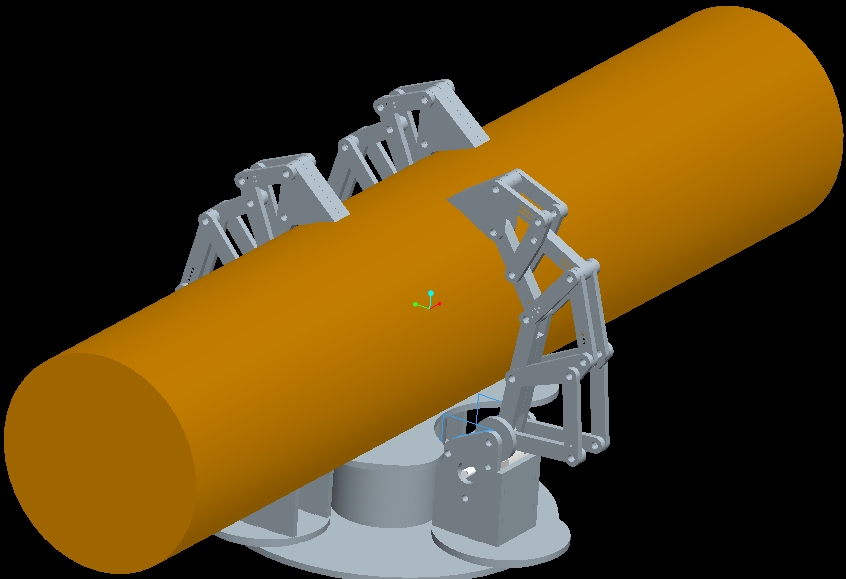

- Dan briefed everyone on current design status

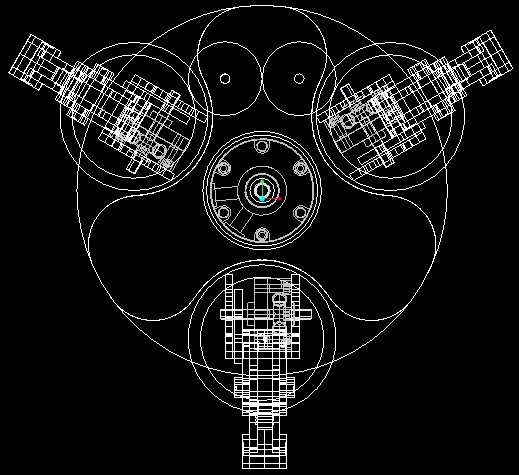

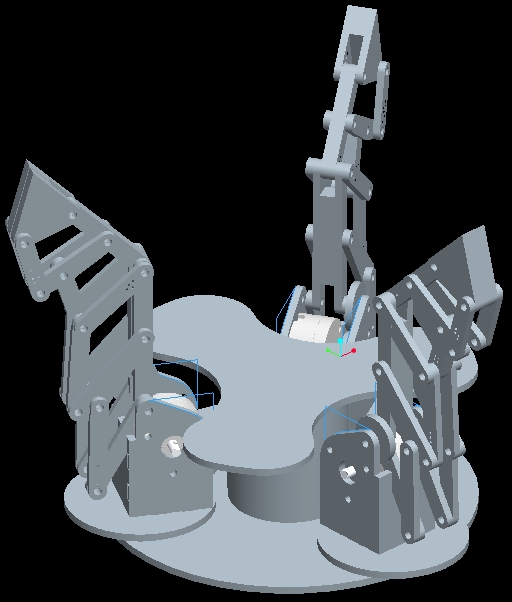

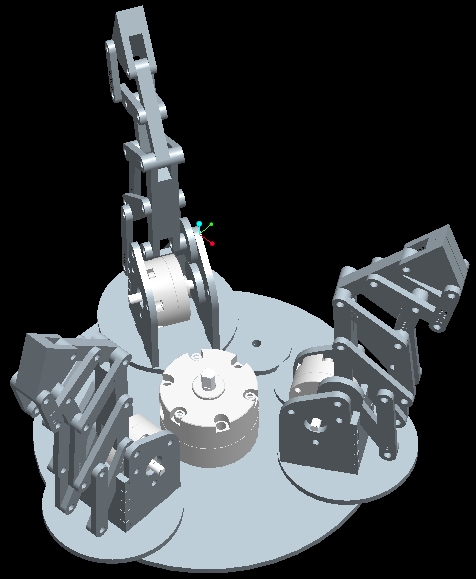

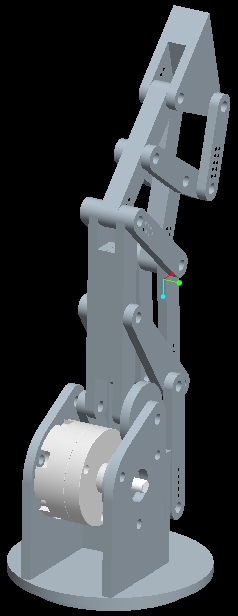

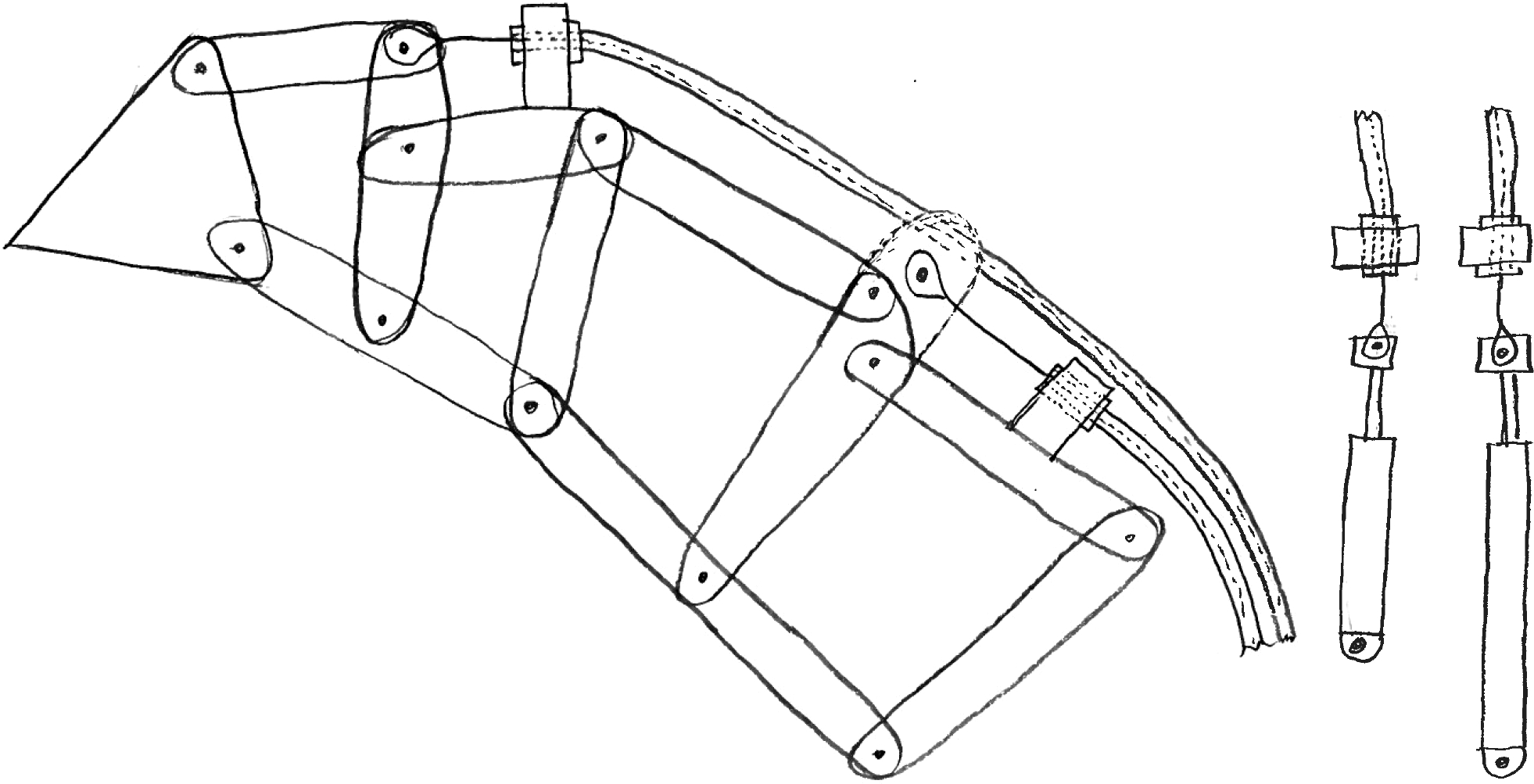

- Palm and finger housing

- Rotary input motor

- Attachment between input shaft and rotary hydraulic master

- Cable routing on back of finger to apply internal forces instead of inside finger structure

- Cables tie back to hydraulic slave cylinders in the base, so no hydraulic routing through finger.

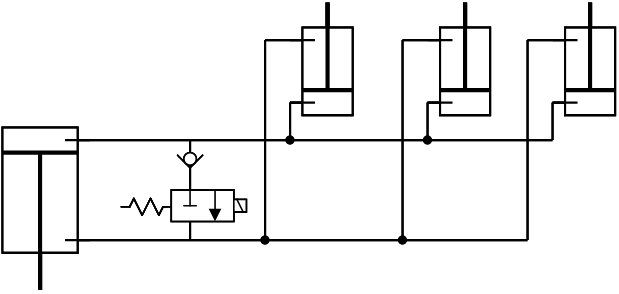

- Drawback of vane-type rotary actuators is leakage between two sides of hydraulic system

- Add a valve/check valve for zeroing the position of the fingers and equalizing the hydraulics.

- Should look at exactly what we want to do for the demo

- Determine what the capabilities of the demo hand

- Probably similar to the grasp renderings above

- Sensors in the finger

- One encoder on the gear orienting the fingers

- Need at least 3 position sensors per finger

- placement is flexible

- likely use 4+ per finger for redundancy and perhaps optimizing linearity

- Converting models

- Get a version of the hand/fingers up on basecamp so that energid can look at converting these linkages (might need to do some custom work)

- Notify Jim Bacon - does the work on the Solidworks converter

- Next meeting in 2 weeks, without Roald

Ideas, requests, problems regarding TWiki? Send feedback