new web: http://bdml.stanford.edu/pmwiki

TWiki > Rise Web>FootDesign > RiSESpinyFeetJuly05>SpinyStickyFoot (21 Aug 2006, DerrickJue? )

Rise Web>FootDesign > RiSESpinyFeetJuly05>SpinyStickyFoot (21 Aug 2006, DerrickJue? )

-- DerrickJue? - 21 Aug 2006 - Update of prototypes towards developing a SpinyStickyFoot.

Toenail Designs

Design 1:

As a primliminary test, spines were attached directly to the current Stickybot feet. When tested manually on the walls outside of MERL, these modified feet seemed to gain good holds on the wall with ease and supported approximately 300g mass. However, only a maximum of two spines could engage on the wall on any given time and sometimes only with pitching of the foot.

Design 2:

As a primliminary test, spines were attached directly to the current Stickybot feet. When tested manually on the walls outside of MERL, these modified feet seemed to gain good holds on the wall with ease and supported approximately 300g mass. However, only a maximum of two spines could engage on the wall on any given time and sometimes only with pitching of the foot.

Design 2:

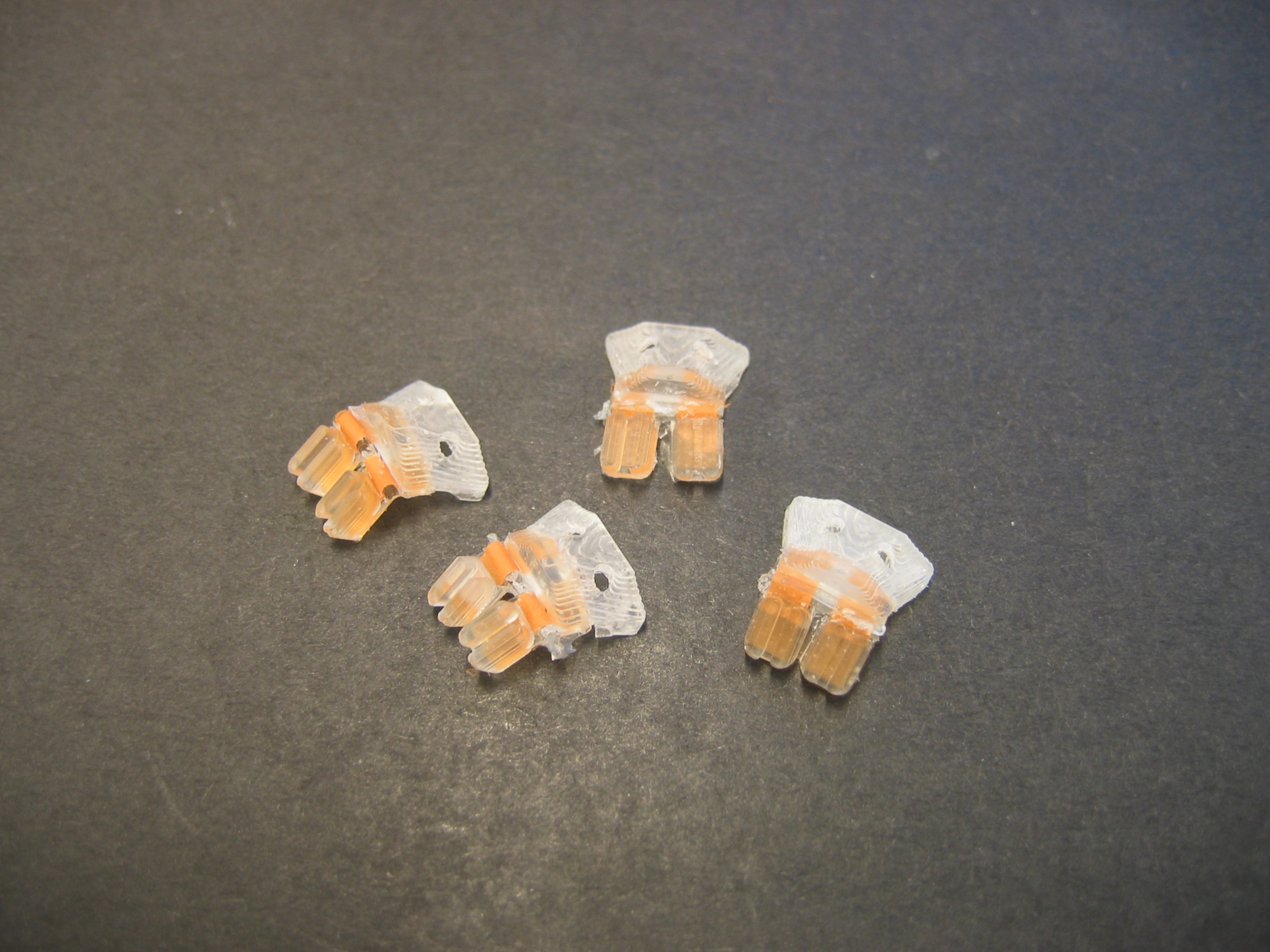

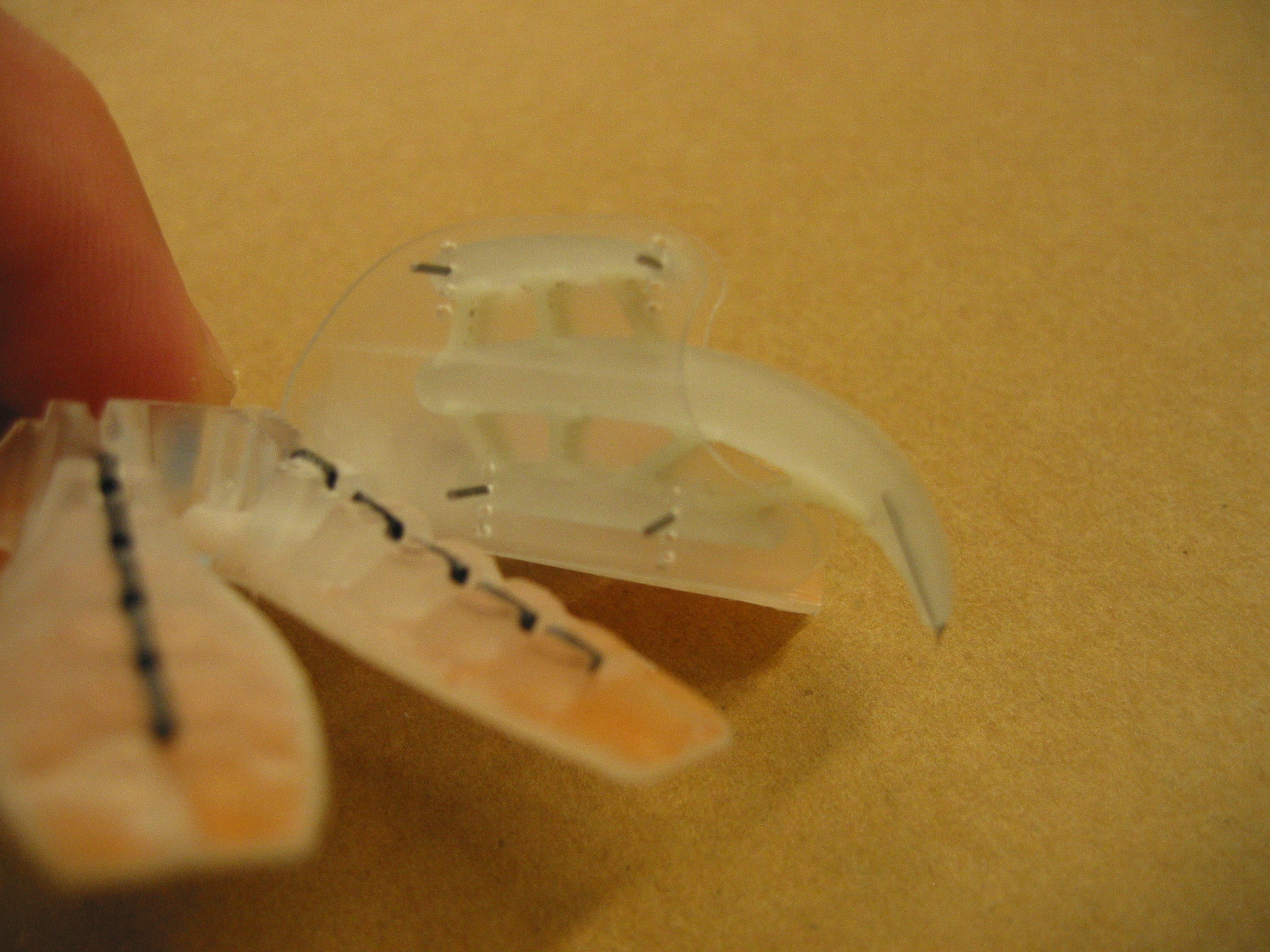

This second generation toenail prototype addresses issues of durability, and functionality faced by Design 1. Design 2 can be screwed to (and removed from) the last segment of any of the current Stickybot toes; modularity allows for performance with or without spines without reconstruction of Stickybot's leg components to accomodate an entirely new foot. Several varations using the same screw setup are also made possible without haivng to alter the foot itself. While Design 1's rigid spines could reasonably allow for only one or two engagements, Design 2 (cast from hard 72DC and softer 50A polyurethane) increases the probability of multiple engagments by employing a fabric manufacturing technique similar to the one used in creating Stickybot feet - it differs in that it allows for some stretching of its segments parallel to the wall (giving functaionality similar to RISE feet) while providing a hardstop to prevent overextension. Shown here without spines attached, Design 2 has a spine embedded in each of its two flextures.

This second generation toenail prototype addresses issues of durability, and functionality faced by Design 1. Design 2 can be screwed to (and removed from) the last segment of any of the current Stickybot toes; modularity allows for performance with or without spines without reconstruction of Stickybot's leg components to accomodate an entirely new foot. Several varations using the same screw setup are also made possible without haivng to alter the foot itself. While Design 1's rigid spines could reasonably allow for only one or two engagements, Design 2 (cast from hard 72DC and softer 50A polyurethane) increases the probability of multiple engagments by employing a fabric manufacturing technique similar to the one used in creating Stickybot feet - it differs in that it allows for some stretching of its segments parallel to the wall (giving functaionality similar to RISE feet) while providing a hardstop to prevent overextension. Shown here without spines attached, Design 2 has a spine embedded in each of its two flextures.

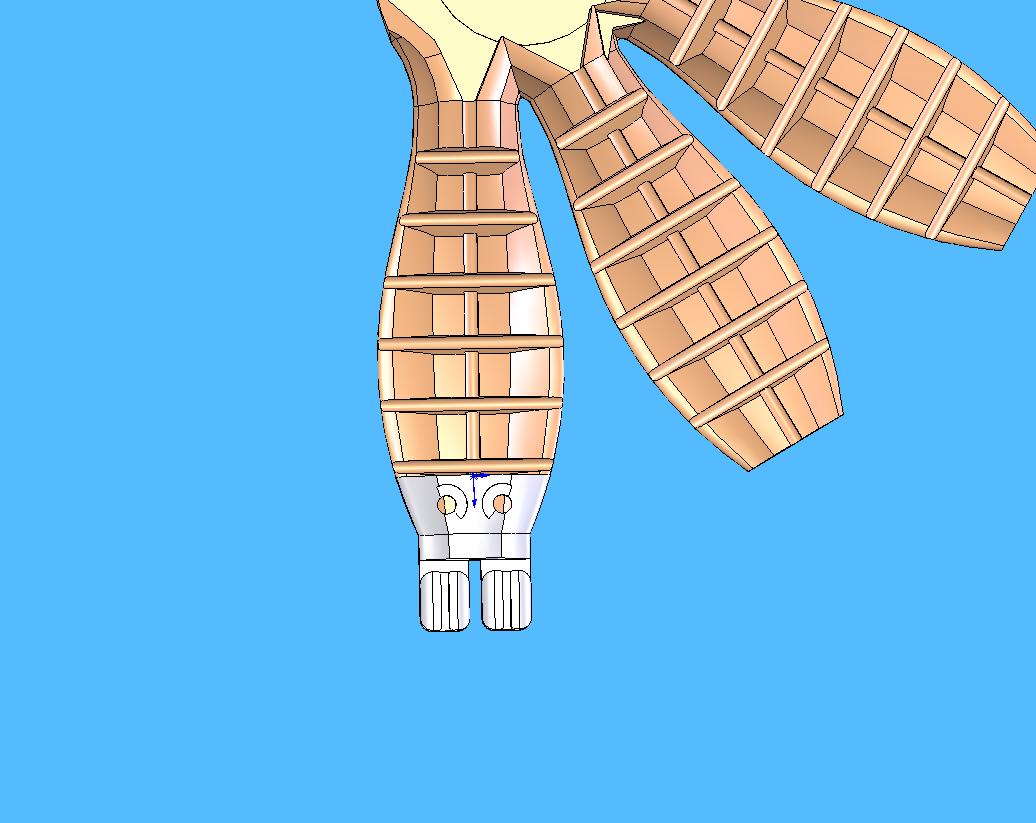

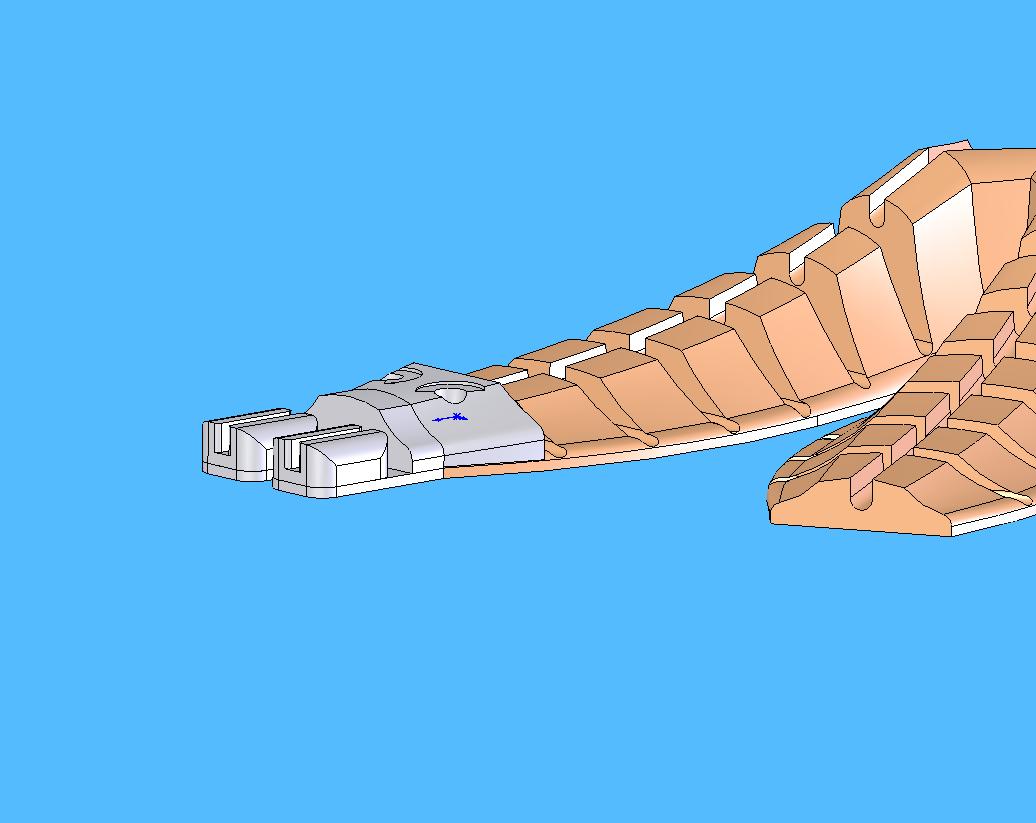

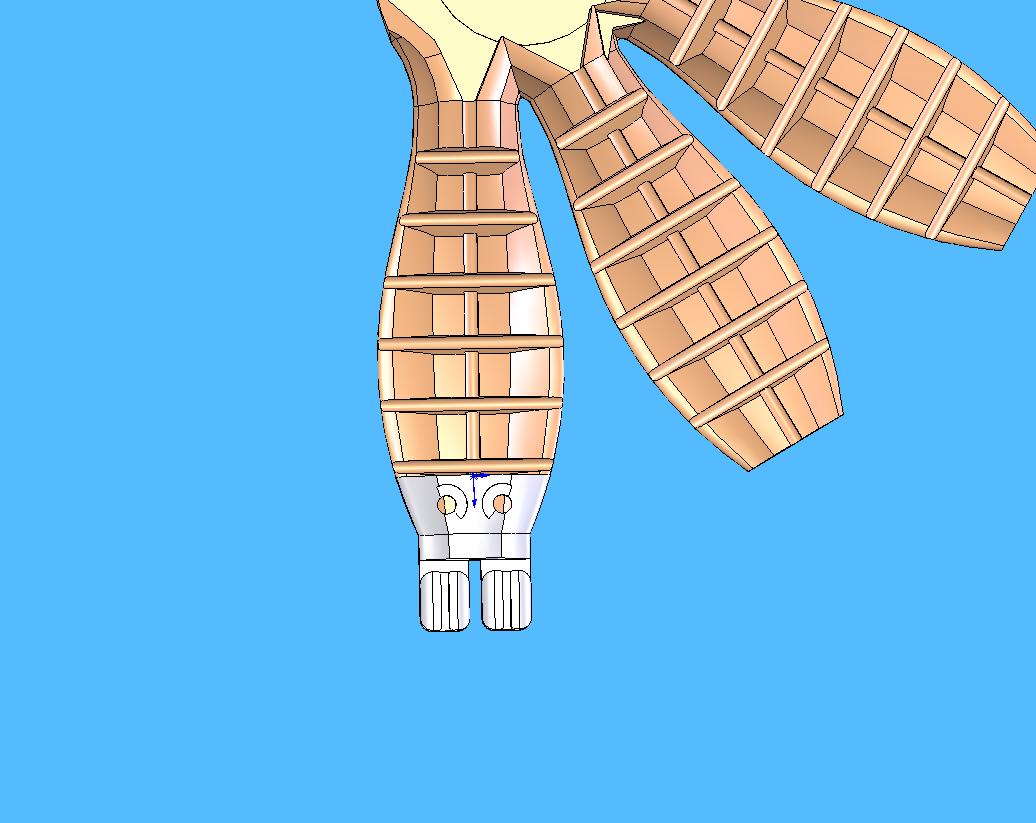

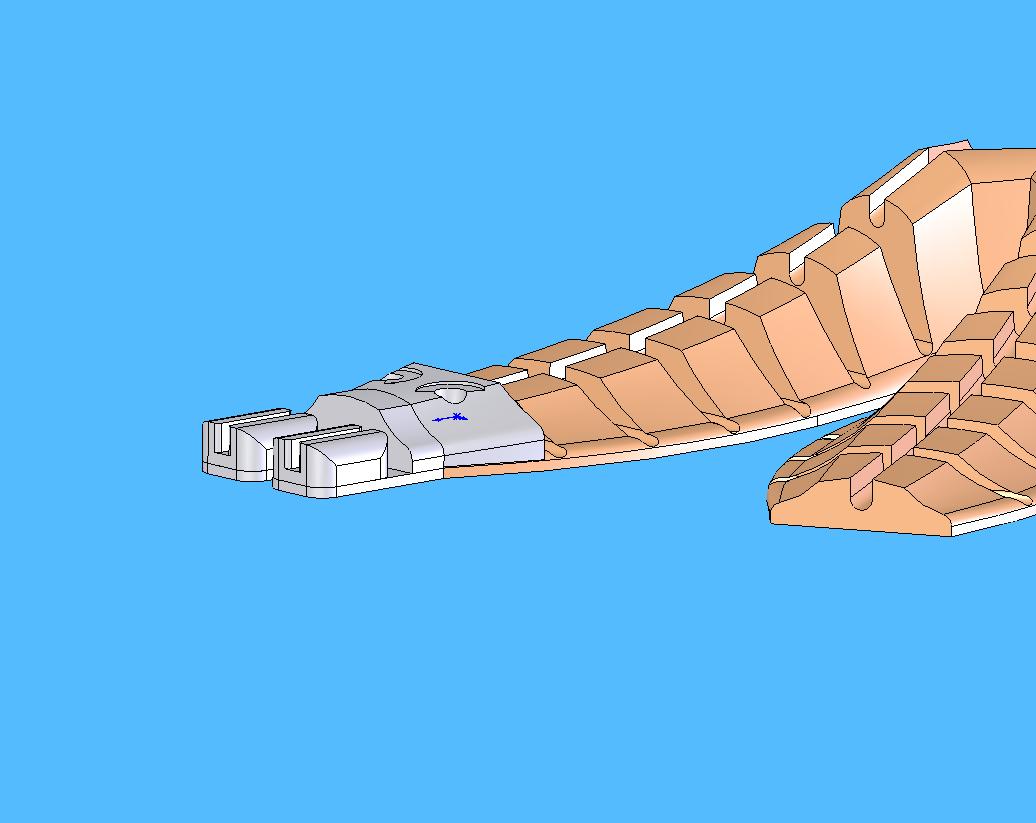

Here are Solidworks models of the toenails actually attached to feet.

Design 2 faces several issues that affect its manufacturability and performance. While applying fabric to allow for stretch and to act as a hardstop allows for added functionality, it is difficult to manufacture and in this case proved inconsistent. Furthermore, while the current design may allow for multiple spines to engage it may not necessarily result in effective load sharing and thus may not actually aid in climbing. Stretchier fabrics (spandex?) are being sought out to ease the manufacturing process and hopefully provide a "softer" stop. Also, the "floppiness" of the spine-holding segments needs to be tuned and created in a more consistent manner. Currently, it is not known what the best starting position for the toenails is. Moreover, each toenail has a varying degree of "floppiness" depending on how it was demolded.

SpinyStickyFoot Design

Here are Solidworks models of the toenails actually attached to feet.

Design 2 faces several issues that affect its manufacturability and performance. While applying fabric to allow for stretch and to act as a hardstop allows for added functionality, it is difficult to manufacture and in this case proved inconsistent. Furthermore, while the current design may allow for multiple spines to engage it may not necessarily result in effective load sharing and thus may not actually aid in climbing. Stretchier fabrics (spandex?) are being sought out to ease the manufacturing process and hopefully provide a "softer" stop. Also, the "floppiness" of the spine-holding segments needs to be tuned and created in a more consistent manner. Currently, it is not known what the best starting position for the toenails is. Moreover, each toenail has a varying degree of "floppiness" depending on how it was demolded.

SpinyStickyFoot Design

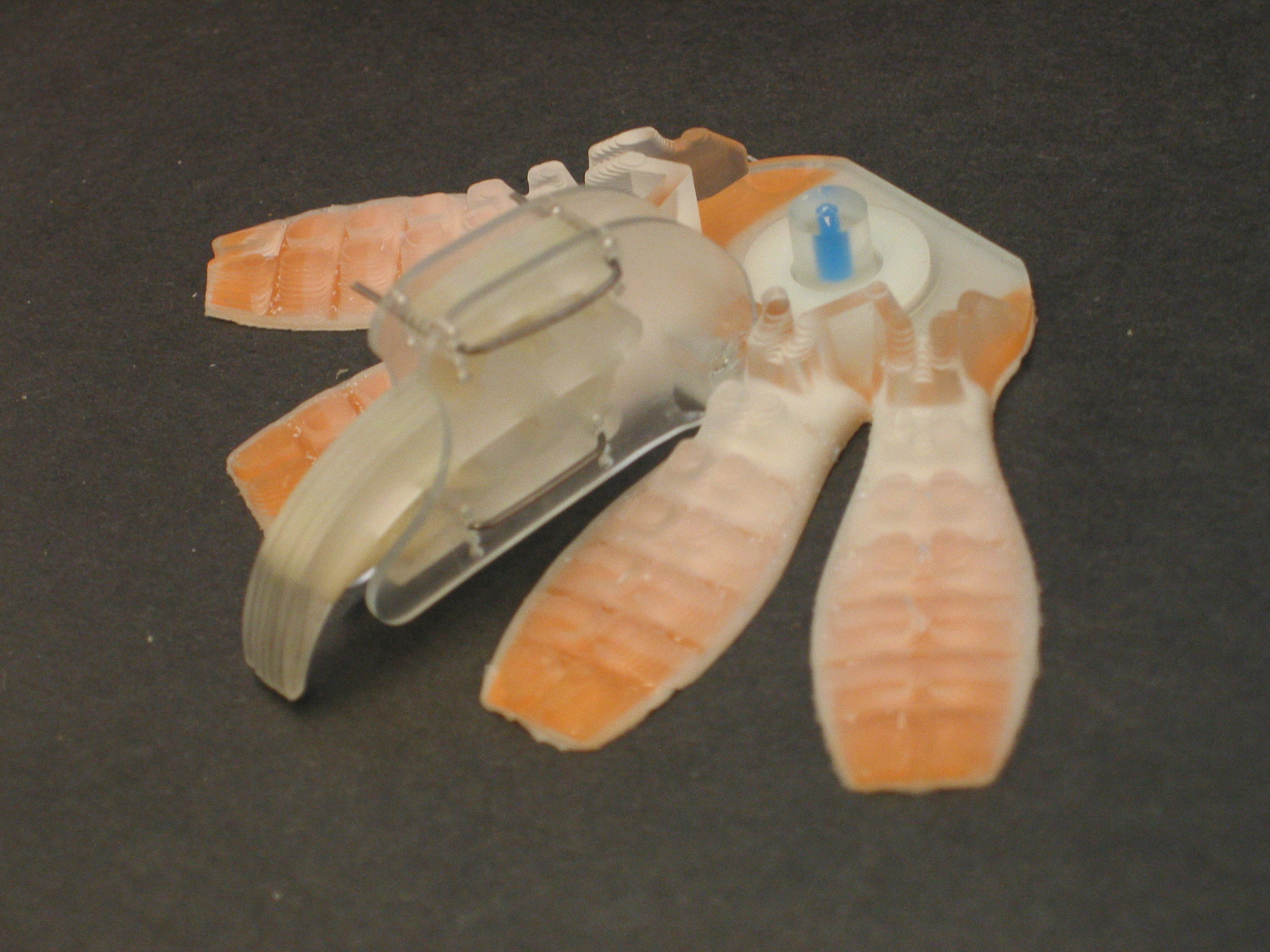

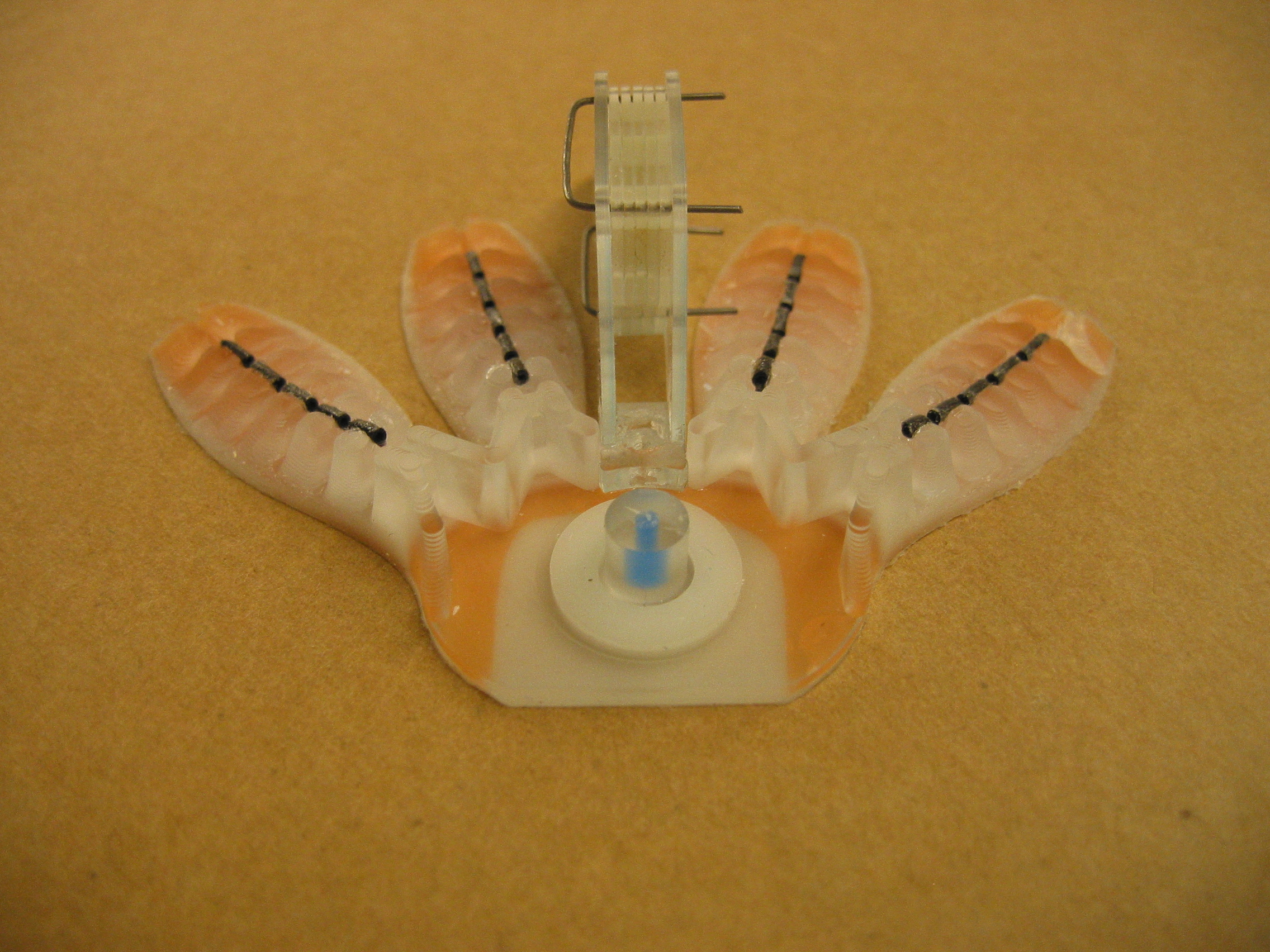

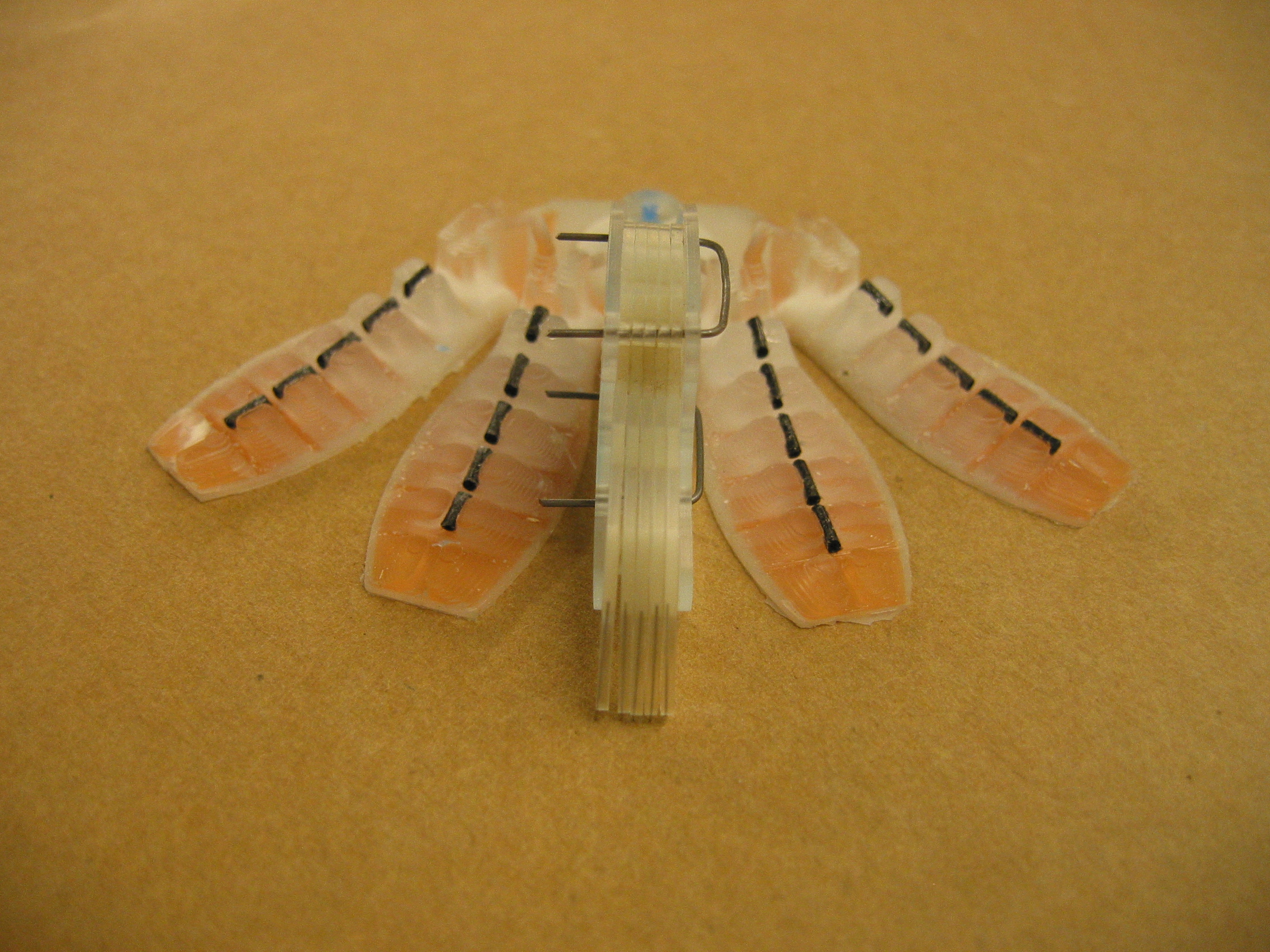

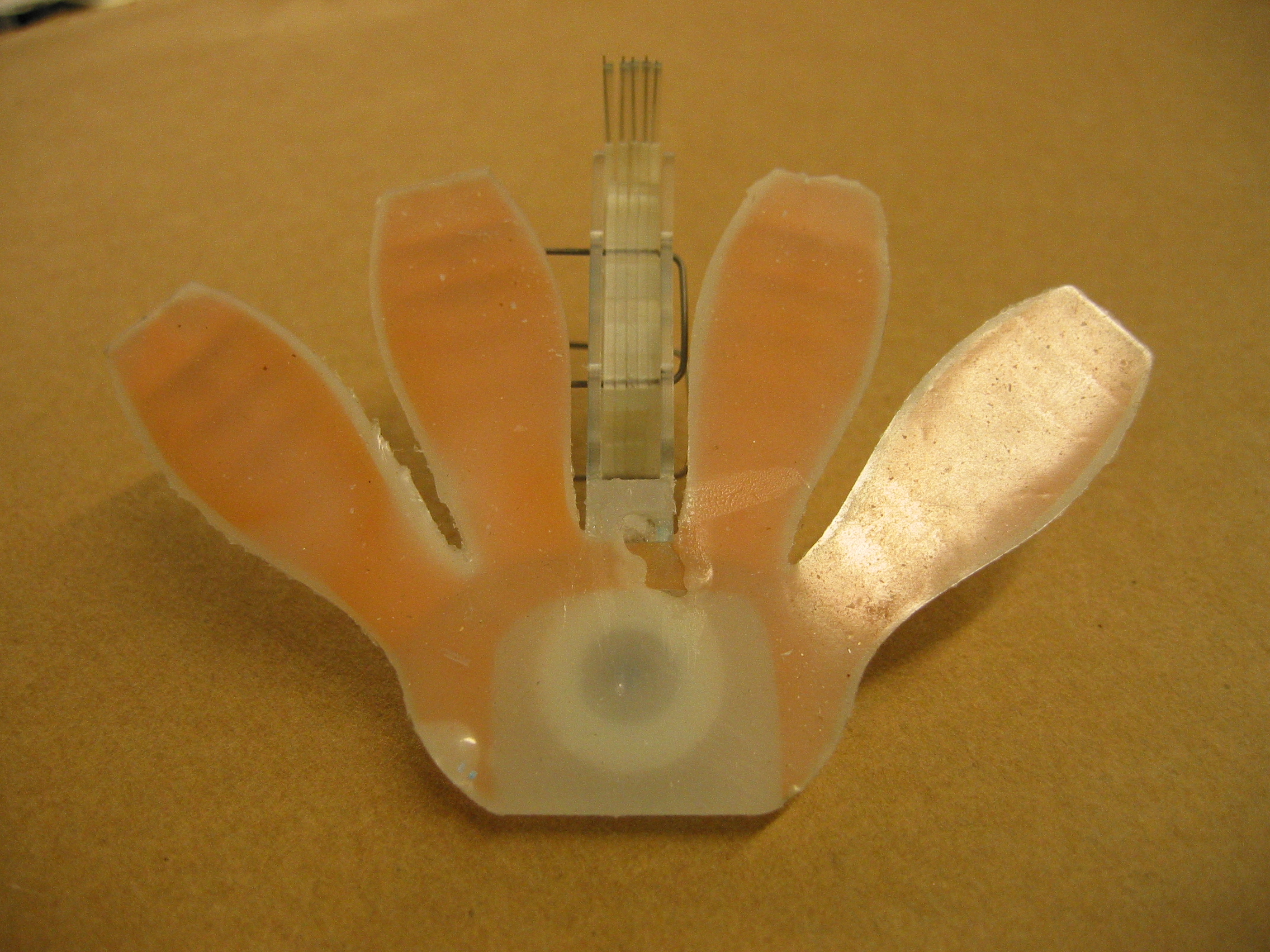

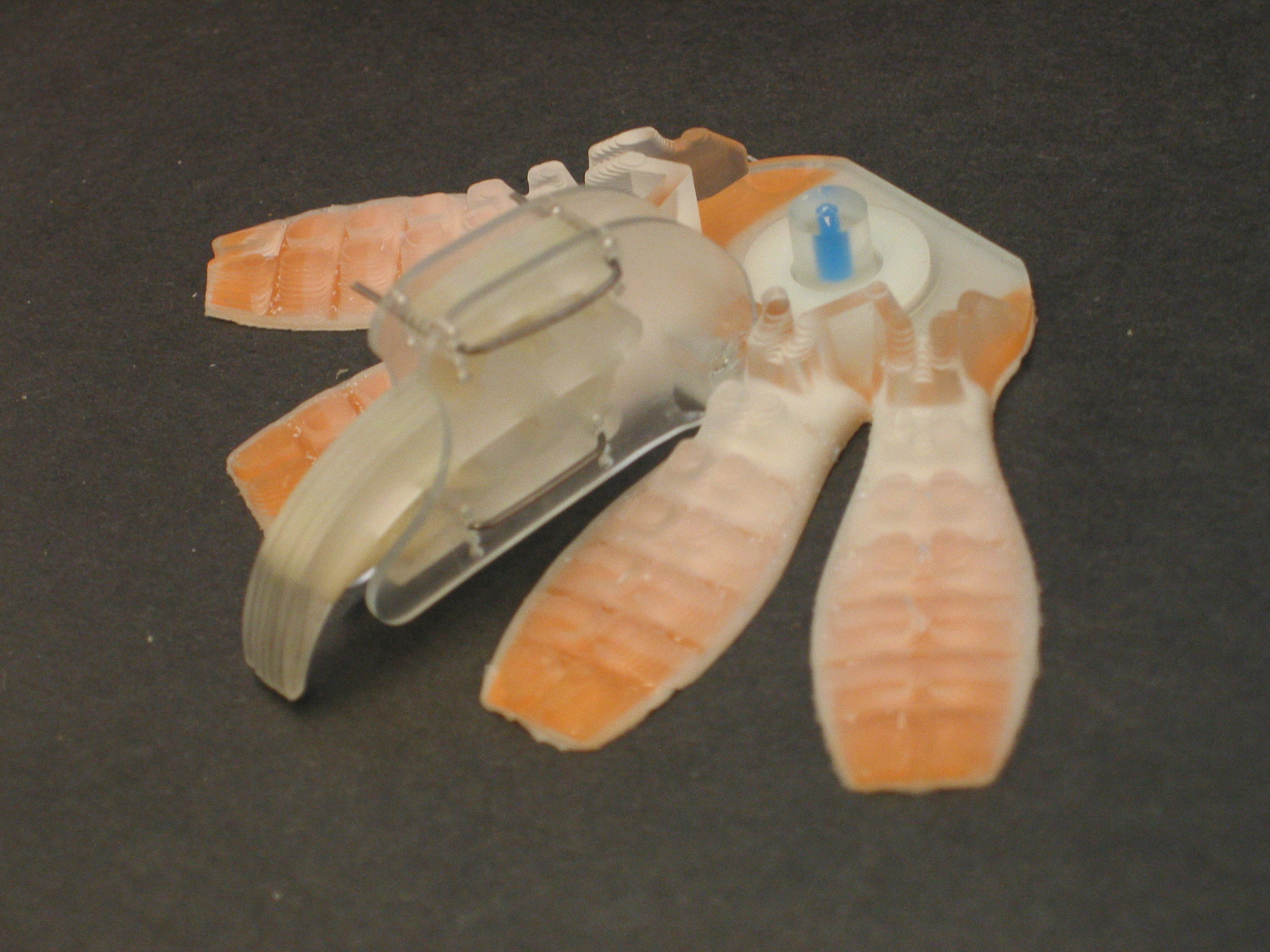

This latest design is essentially a Stickybot foot modified to allow for the mounting of a RISE foot. By combining technologies directly from the two platforms this foot shows promise. Again, modular design has been adopted so that the spines can be mounted and removed without having to recreate an entirely new foot. Without the spines, this foot should perform just as a regular stickyfoot would. Testing of this new foot will focus upon proper integration of the RISE spines with Stickybot stickypads. For testing purposes, variability of spine height normal to the contact wall has been built in. If the spines are placed too close to the wall, they will push the feet back and disengage the stickypads. If the spines are too far away, they themselves will not engage. Preliminary testing of spine height placement and normal compliance (prior to mounting on a Stickybot platform) suggest that the spines are currently too stiff and may have to be redesigned to introduce more compliance in the normal direction.

This latest design is essentially a Stickybot foot modified to allow for the mounting of a RISE foot. By combining technologies directly from the two platforms this foot shows promise. Again, modular design has been adopted so that the spines can be mounted and removed without having to recreate an entirely new foot. Without the spines, this foot should perform just as a regular stickyfoot would. Testing of this new foot will focus upon proper integration of the RISE spines with Stickybot stickypads. For testing purposes, variability of spine height normal to the contact wall has been built in. If the spines are placed too close to the wall, they will push the feet back and disengage the stickypads. If the spines are too far away, they themselves will not engage. Preliminary testing of spine height placement and normal compliance (prior to mounting on a Stickybot platform) suggest that the spines are currently too stiff and may have to be redesigned to introduce more compliance in the normal direction.

Here are more pictures.

Here are more pictures.

As a primliminary test, spines were attached directly to the current Stickybot feet. When tested manually on the walls outside of MERL, these modified feet seemed to gain good holds on the wall with ease and supported approximately 300g mass. However, only a maximum of two spines could engage on the wall on any given time and sometimes only with pitching of the foot.

Design 2:

As a primliminary test, spines were attached directly to the current Stickybot feet. When tested manually on the walls outside of MERL, these modified feet seemed to gain good holds on the wall with ease and supported approximately 300g mass. However, only a maximum of two spines could engage on the wall on any given time and sometimes only with pitching of the foot.

Design 2:

Here are Solidworks models of the toenails actually attached to feet.

Design 2 faces several issues that affect its manufacturability and performance. While applying fabric to allow for stretch and to act as a hardstop allows for added functionality, it is difficult to manufacture and in this case proved inconsistent. Furthermore, while the current design may allow for multiple spines to engage it may not necessarily result in effective load sharing and thus may not actually aid in climbing. Stretchier fabrics (spandex?) are being sought out to ease the manufacturing process and hopefully provide a "softer" stop. Also, the "floppiness" of the spine-holding segments needs to be tuned and created in a more consistent manner. Currently, it is not known what the best starting position for the toenails is. Moreover, each toenail has a varying degree of "floppiness" depending on how it was demolded.

SpinyStickyFoot Design

Here are Solidworks models of the toenails actually attached to feet.

Design 2 faces several issues that affect its manufacturability and performance. While applying fabric to allow for stretch and to act as a hardstop allows for added functionality, it is difficult to manufacture and in this case proved inconsistent. Furthermore, while the current design may allow for multiple spines to engage it may not necessarily result in effective load sharing and thus may not actually aid in climbing. Stretchier fabrics (spandex?) are being sought out to ease the manufacturing process and hopefully provide a "softer" stop. Also, the "floppiness" of the spine-holding segments needs to be tuned and created in a more consistent manner. Currently, it is not known what the best starting position for the toenails is. Moreover, each toenail has a varying degree of "floppiness" depending on how it was demolded.

SpinyStickyFoot Design

This latest design is essentially a Stickybot foot modified to allow for the mounting of a RISE foot. By combining technologies directly from the two platforms this foot shows promise. Again, modular design has been adopted so that the spines can be mounted and removed without having to recreate an entirely new foot. Without the spines, this foot should perform just as a regular stickyfoot would. Testing of this new foot will focus upon proper integration of the RISE spines with Stickybot stickypads. For testing purposes, variability of spine height normal to the contact wall has been built in. If the spines are placed too close to the wall, they will push the feet back and disengage the stickypads. If the spines are too far away, they themselves will not engage. Preliminary testing of spine height placement and normal compliance (prior to mounting on a Stickybot platform) suggest that the spines are currently too stiff and may have to be redesigned to introduce more compliance in the normal direction.

This latest design is essentially a Stickybot foot modified to allow for the mounting of a RISE foot. By combining technologies directly from the two platforms this foot shows promise. Again, modular design has been adopted so that the spines can be mounted and removed without having to recreate an entirely new foot. Without the spines, this foot should perform just as a regular stickyfoot would. Testing of this new foot will focus upon proper integration of the RISE spines with Stickybot stickypads. For testing purposes, variability of spine height normal to the contact wall has been built in. If the spines are placed too close to the wall, they will push the feet back and disengage the stickypads. If the spines are too far away, they themselves will not engage. Preliminary testing of spine height placement and normal compliance (prior to mounting on a Stickybot platform) suggest that the spines are currently too stiff and may have to be redesigned to introduce more compliance in the normal direction.

Ideas, requests, problems regarding TWiki? Send feedback