new web: http://bdml.stanford.edu/pmwiki

TWiki > Rise Web>TWikiUsers > VirgilioMattoli>SensorFabrication (31 Aug 2004, VirgilioMattoli? )

Rise Web>TWikiUsers > VirgilioMattoli>SensorFabrication (31 Aug 2004, VirgilioMattoli? )

-- MarkCutkosky - 25 May 2004

This will be a new page about sensors and their fabrication.

-- VirgilioMattoli - 02 Aug 2004

Features of the sensor #1 are:

Features of the sensor #1 are:  Features of the sensor #2 are:

Features of the sensor #2 are:

Features of the sensor #3 are:

Features of the sensor #3 are:

Embedded Strain Gauge Fabrication

Intro

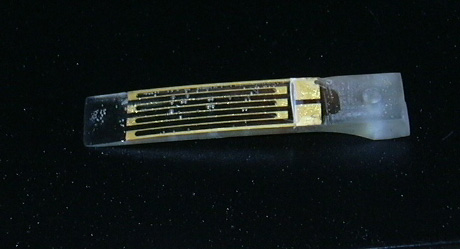

My main research activity at the BDML Lab in summer 2004 is focused in developing of an embedded strain gauge sensor: the should be developed directly embedded in a plastic structure like for example the leg or foot of climbing robot. The idea is to deposit a thin film of metal (in our case gold) onto a plastic substrate (like hard or soft polyurethane), the right shape can be obtained by ablation of the unwanted film of directing controlling the film deposition using a mechanical mask. After deposition the film resistor must be embedded by final casting process. In this way should be possible obtain “artefact” with sensorial capability. Moreover is possible extend this concept to obtain complex and 3-dimensional shape for the sensing artefact. Deposition combined with electroplating could be also utilised in order to provide electric contact and electric wire connection also embedded in the “artefact”. In this way to final vision is to improve technology to obtain smart artefact and in the particular case smart legs and foots for the climbing robot wit capability to feel forces and contact with the surface to climb.Prototypes

In order to investigate the feasibility of the idea discussed above, I developed 3 prototype to test and characterise. All prototype are composed by a plastic cantilever with a thin gold film as strain sensor. The substrate used for the fabrication is a part of leg of the sprolita robot (prepared by some preliminary working).Experimental Setup

The prototype are intensive investigated using an experimental setup developed ad hoc (detail of the experimental setup are reported in GaugeExperimentalSetup ).Prototypes #1

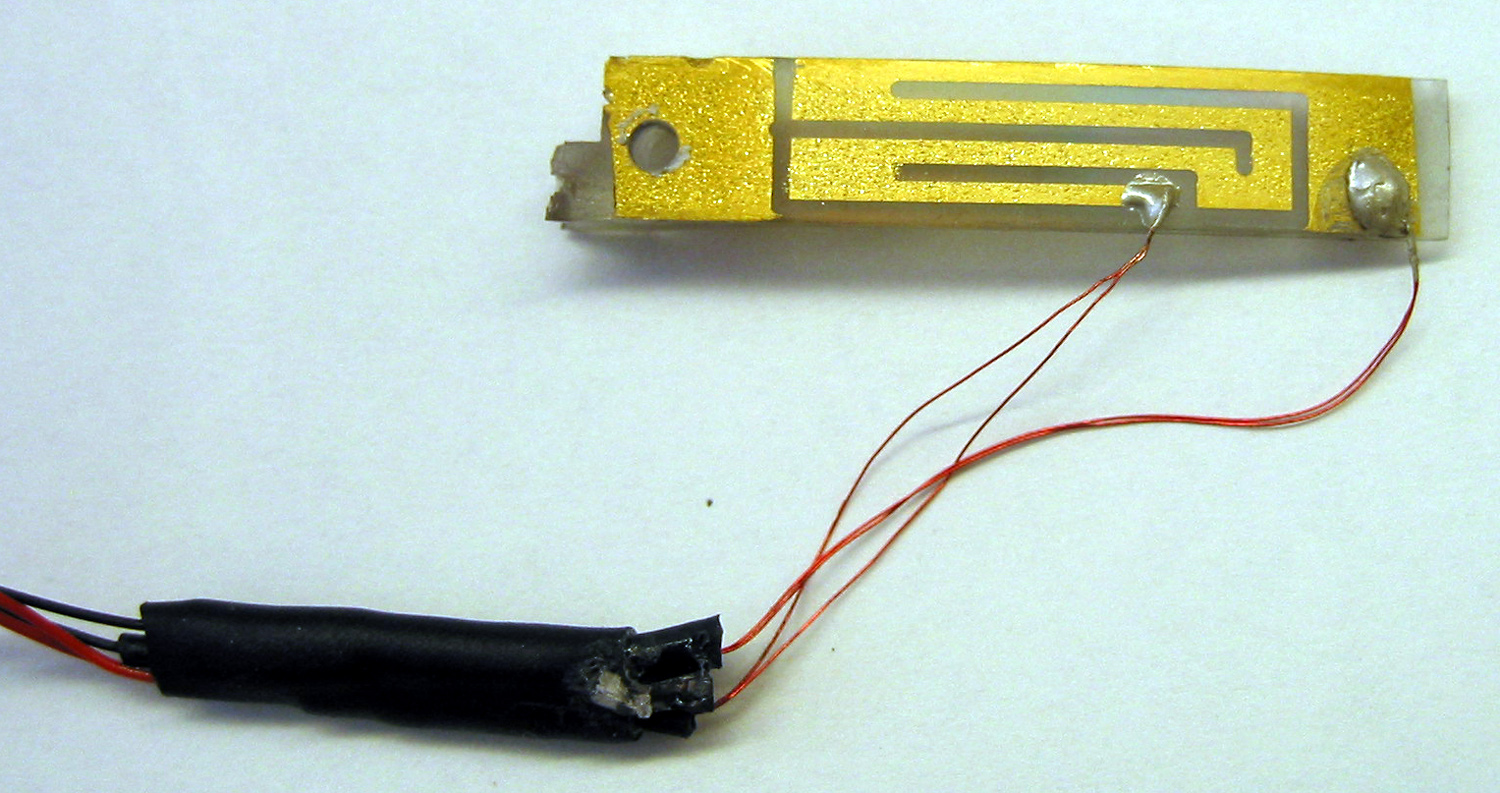

Fabrication Process

The fabrication steps are:- Preparation of substrate by milling in order to obtain a flat and polished surface, suitable for the thin film gold deposition

- Thin gold film deposition by Sputtering machine (parameters of sputtering was set in order to obtain a gold film with 200 nm of thickness)

- Shaping of gold film in order to obtain a suitable strain gauge. This step is accomplished milling out the unwanted gold film surface, by a mill with 1/32 inch diameter

- Creation of contact with wires for measurement tests using conductive epoxy glue

Features of the sensor #1 are:

Features of the sensor #1 are: - Gauge Thickness = 200 nm

- Number of Coils = 6

- Gauge Length = 81 mm (3,2 inch)

- Gauge Width = 0,98 mm (0,0387 inch)

- Gauge Resistance = 9,7 Ohm

Test results

Test completed ! (Sensor broken during tests) Test results are reported on the file: Sensor1.xlsPrototypes #2

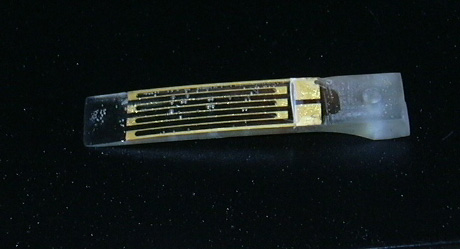

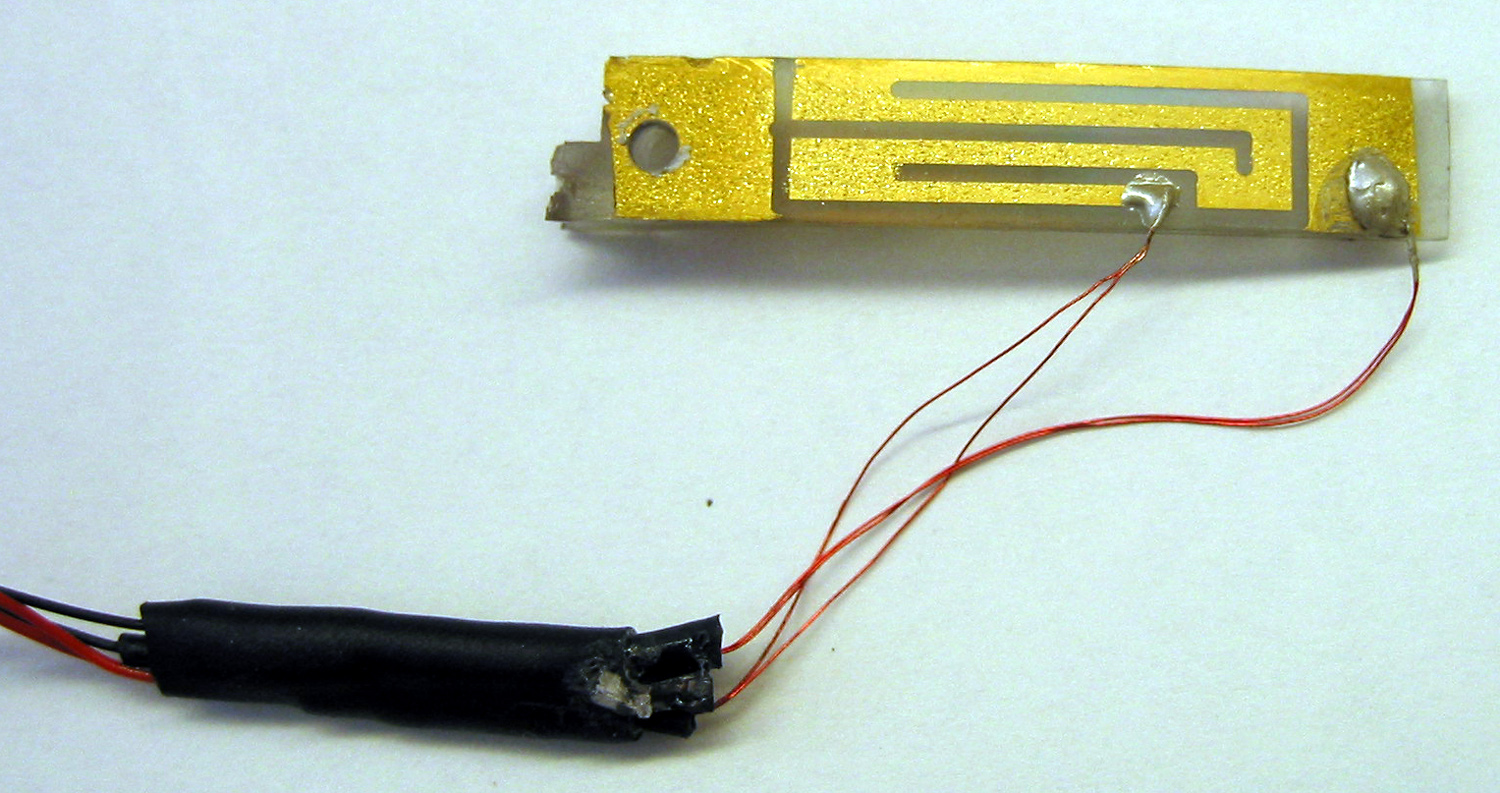

The fabrication steps are:- Preparation of substrate by milling

- Thin gold film deposition by Sputtering machine (200 nm of gold film thickness)

- Shaping of gold film by milling (mill with 1/32 inch diameter)

- Embedding of the film by depositing another layer of hard polyurethane on top sample (only the pads for contact are left uncovered)

- Electroplating of the sensor pads with nickel (5-10 micron of thickness)

- Creation of contact by soldering on pads wires for measurement tests

Features of the sensor #2 are:

Features of the sensor #2 are: - Gauge Thickness = 200 nm

- Number of Coils = 6

- Gauge Length = 99,06 mm (3,9 inch)

- Gauge Width = 0,13 – 0,10 mm (4 - 5 mil)

- Gauge Resistance = 110,57 Ohm

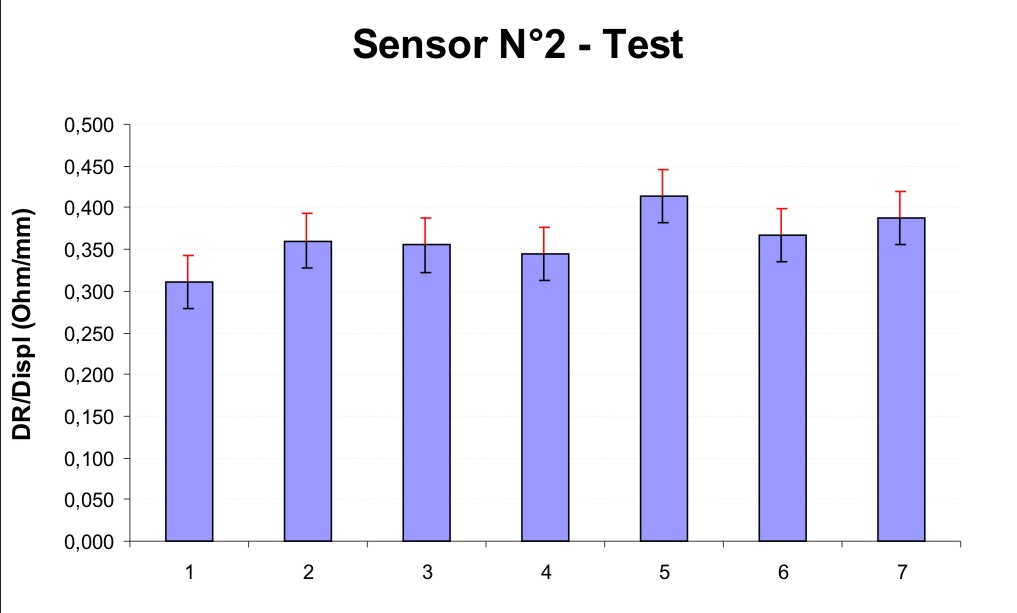

Test results

Test completed ! (Sensor broken during tests) Test complete results are reported on the file: Test_Sensor_2_bis.xls- Sens.2: signal in different experimental condition: sinusoidal excitation at different frequencies and different strength

- Average Sensitivity (DR/R) / Displ = 0,00328 +/- 0,00029 1/mm (Used only results from Sin Excitation )

- Average Sensitivity (DR/R) / Displ (%) = 0,328 +/- 0,029 %/mm (Used only results from Sin Excitation )

- Variation of Resistance due to stress of tests = 0,387 %

Prototypes #3

The fabrication steps are:- Preparation of substrate by milling

- Thin gold film deposition by Sputtering machine (200 nm of gold film thickness)

- Shaping of gold film by milling (mill with 1/32 inch diameter)

- Embedding of the film by depositing another layer of hard polyurethane on top sample (only the pads for contact are left uncovered)

- Electroplating of the sensor pads with nickel (5-10 micron of thickness)

- Creation of contact by soldering on pads wires for measurement tests

Features of the sensor #3 are:

Features of the sensor #3 are: - Gauge Thickness = 200 nm

- Number of Coils = 8

- Gauge Length = 132,8 mm (5,2 inch)

- Gauge Width = 0,13 – 0,10 mm (4 - 5 mil)

- Gauge Resistance = 88,10

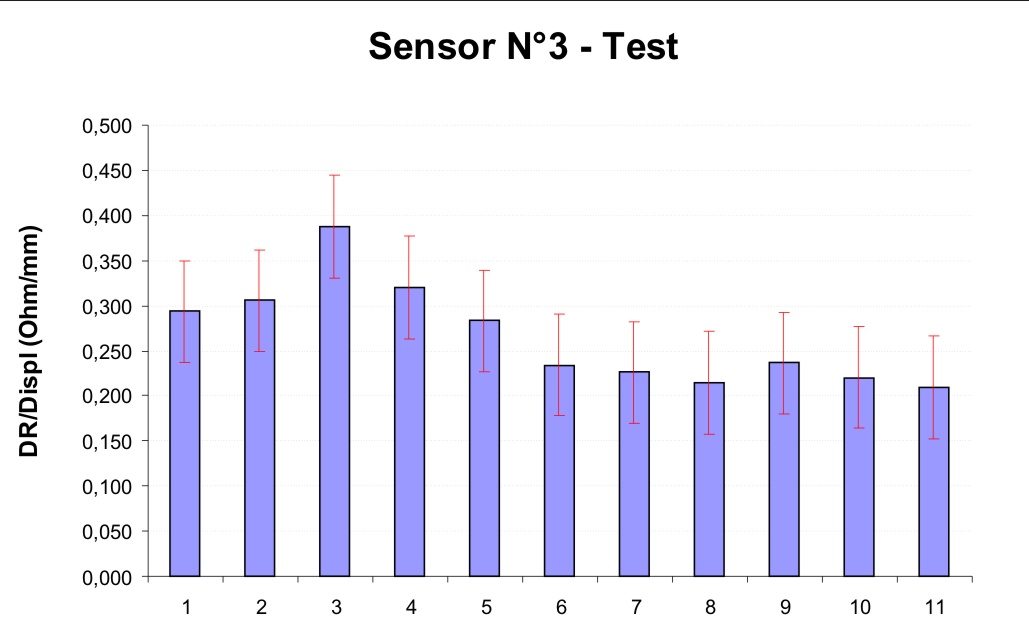

Test results

Test completed ! (Sensor still working) Test complete results are reported on the file: Test_Sensor_3_bis.xls- Sens.3 signal in different experimental condition: sinusoidal excitation at different frequencies and different strength:

- Average Sensitivity (DR/R) / Displ = 0,00302 +/- 0,00064 1/mm (Used only results from Sin Excitation )

- Average Sensitivity (DR/R) / Displ (%) = 0,302 +/- 0,064 %/mm (Used only results from Sin Excitation )

- Variation of Resistance due to stress of tests = 0,560 %

Ideas, requests, problems regarding TWiki? Send feedback