new web: http://bdml.stanford.edu/pmwiki

TWiki > Rise Web>TWikiUsers > WillP > WillsPersonalNotes>ScreenPrintingNotes (15 Jan 2005, WillP? )

Rise Web>TWikiUsers > WillP > WillsPersonalNotes>ScreenPrintingNotes (15 Jan 2005, WillP? )

I've tried had a few decent experiences trying to screen print various items. My first attempt was back in 2000 trying to screen print some conductive traces with conductive silver ink using diazo emultions from an arts store and T-Shirt silk screen supplies. Despite some issues with the solvents in the ink attacking the diazo emulsion, the prints turned out OK, but the ink cracked pretty easily when its flexible substrate was bent.

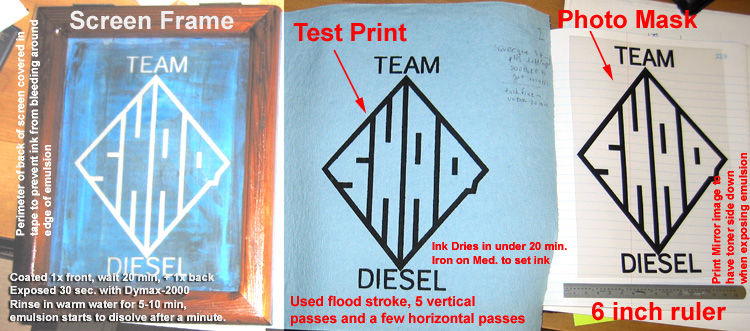

- Initial screen printing (Jan 2004):

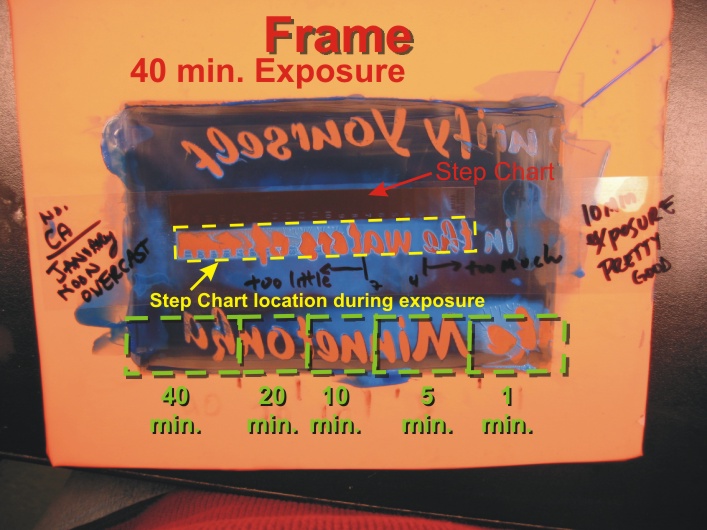

- test exposure screen printing frame (Jan 2005):

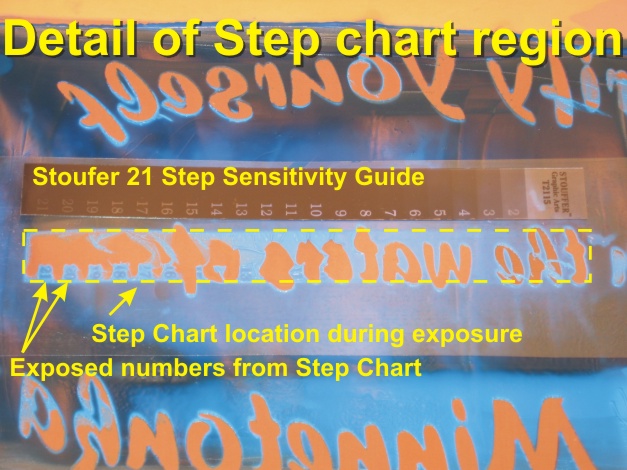

- detail picture of exposure (step) chart:

Ideas, requests, problems regarding TWiki? Send feedback