new web: http://bdml.stanford.edu/pmwiki

TWiki > Rise Web>NewFootDesignsApr05 (09 Dec 2005, MarkCutkosky)

Rise Web>NewFootDesignsApr05 (09 Dec 2005, MarkCutkosky)

New Foot Designs Apr05

- See FootDesign for other foot designs.

Contents:

Uberfoot: April 25, 2005

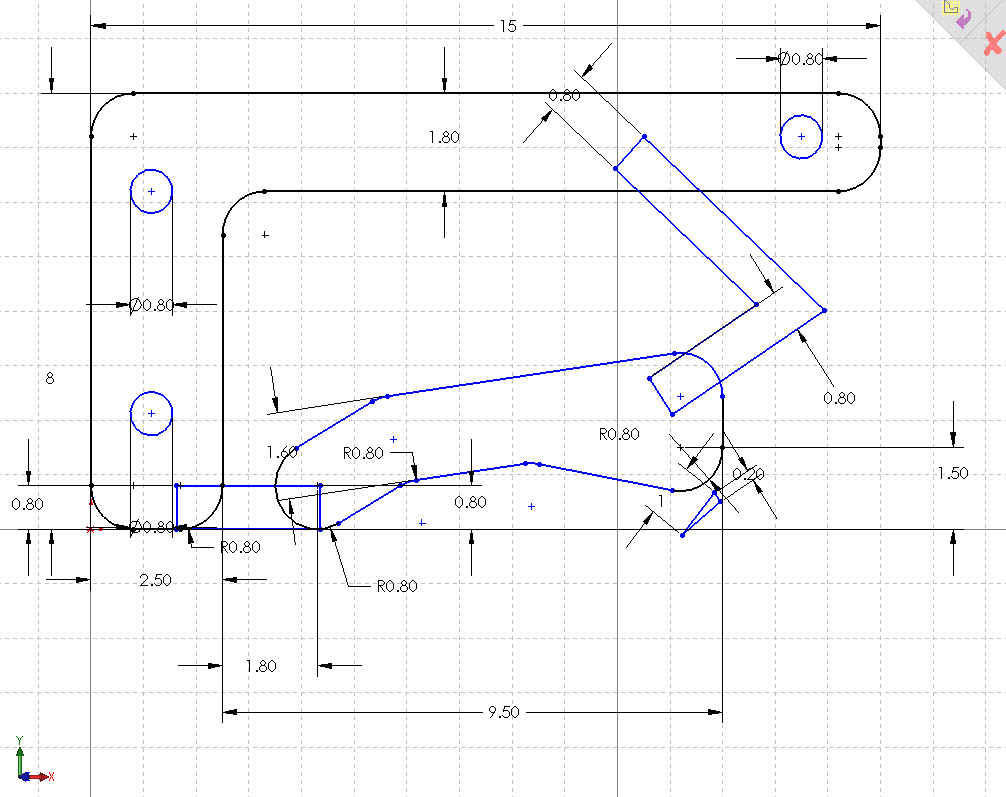

This is one toe for a sub-foot for Alan's latest design. Several sub-feet will be made by putting these slices together (like the normal way we make feet), then the sub-feet will be connected together through a larger-scale compliant structure and cables enabling the sub-feet to share the load. Note that the entire foot is 1.5cm long, the light lines in the picture are every millimeter. -- AlanAsbeck - 25 Apr 2005- First pass in

Solidworks showing the general form:

- Iso View:

- Side View:

- Bottom View:

- Toes (in the sub-feet) are way too stretchy in the axial direction, stretching for over a centimeter and well beyond the other un-stretched toes. Also, each toe supports 45g before breaking. This should be increased to support

RiSE.

- Toes tangle easily, partially as a result of stretching too far.

- Spines were stuck into the wax too far on embedding, requiring them to stick out of the hard plastic a ways before being bent downward. This leads to spines getting stuck in some surfaces such as felt.

- The dactyl should be stretchy, to prevent the situation where it briefly catches a bad asperity, then suddenly releases, which causes the foot to slip downwards a ways without additional toes catching on the wall. This over-extends the (few) toes that have already caught when the dactyl slips.

- Toes should be made to automatically pop off the wall if they are over-extended. This will prevent problems in the situation when just a few toes catch and have to support the full weight of

RiSE; since RiSE is heavy either the spines themselves would permanently bend or become dull, or the flexures would break.

- The top piece of 20A supporting the sub-feet is too stiff, and the sub-feet need to be down (towards the wall) more to begin with.

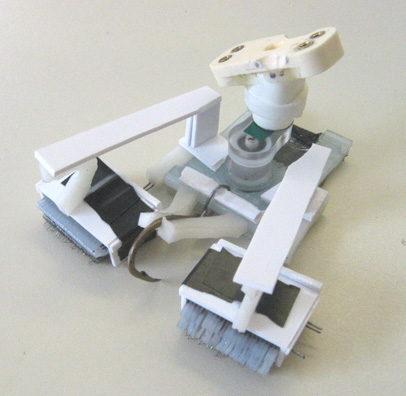

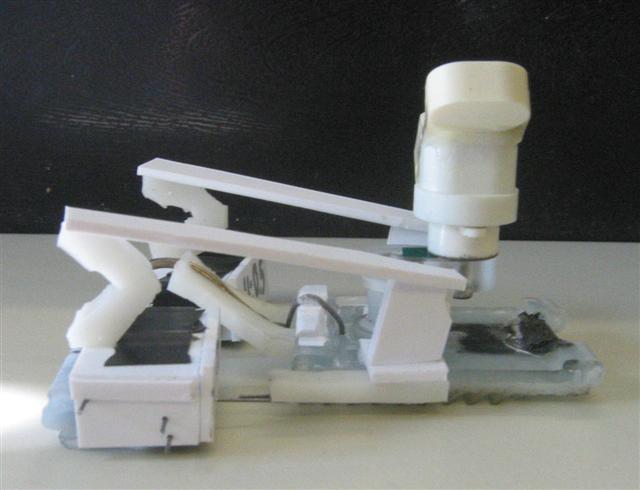

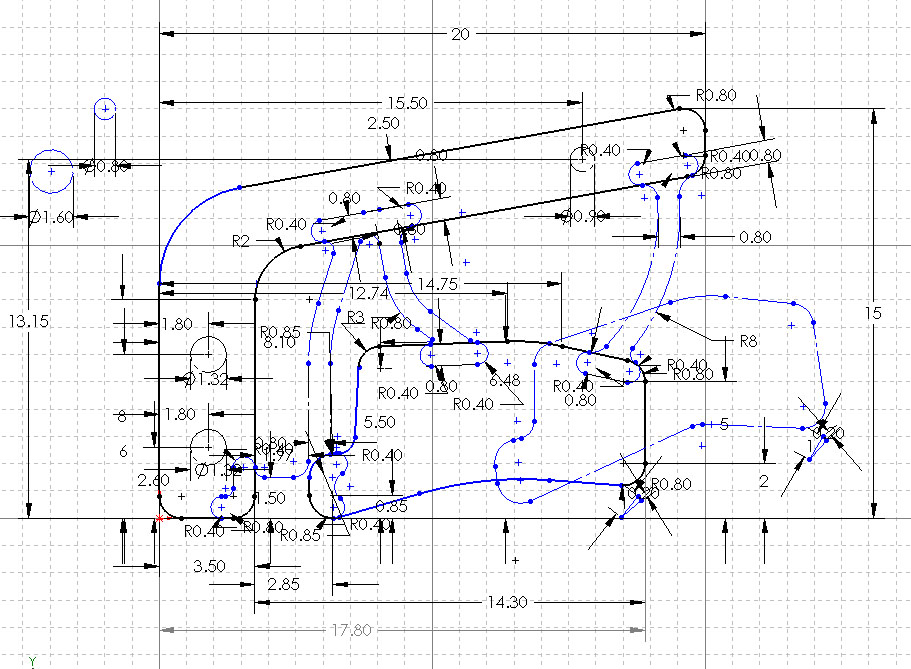

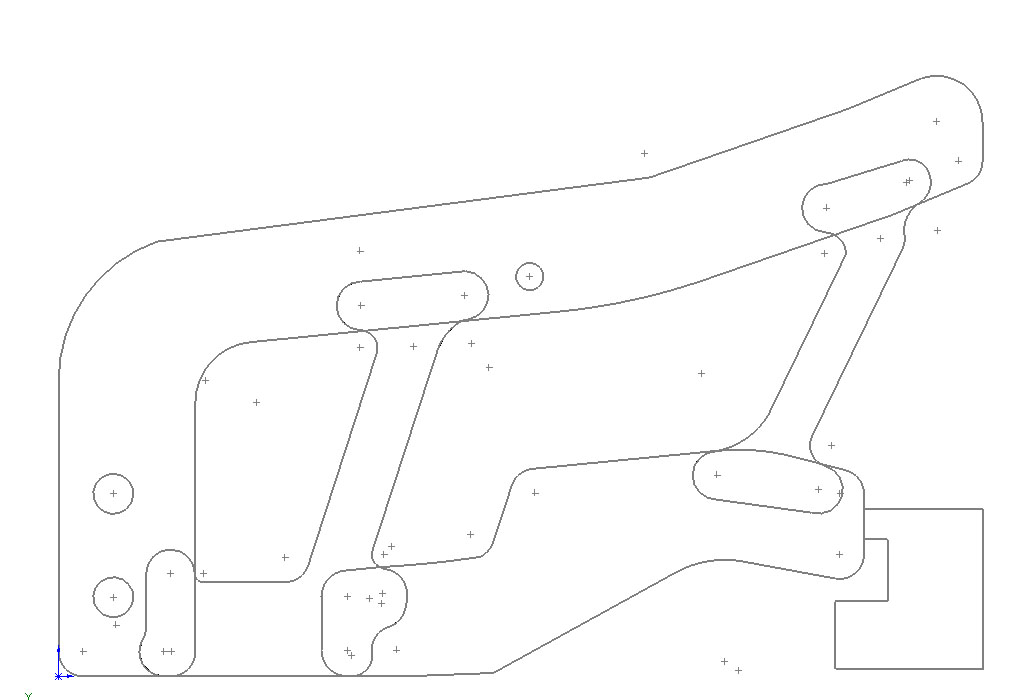

Robust RiSE foot: June 15, 2005

The latest design has 4 variations which are pretty similar to this one, differing in the back flexure dimensions and the position of the middle top flexure. Each toe is designed to hold about 300g before breaking, and should stretch about 8mm. (these vary with the different designs).

-- AlanAsbeck - 29 Jun 2005

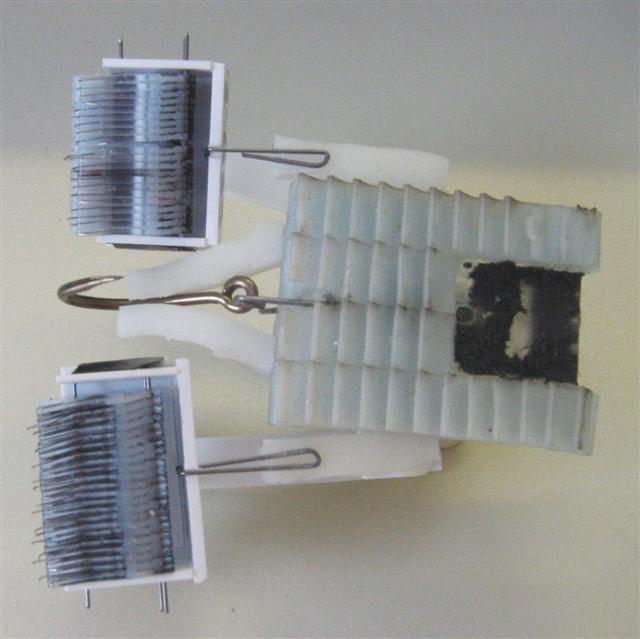

Aaron Private.BigToe: June 25, 2005

- Toe with large claw for

RiSE:

Ideas, requests, problems regarding TWiki? Send feedback