new web: http://bdml.stanford.edu/pmwiki

TWiki > Manufacturing Web>ManufacturingHome > SDMFabTechniques>GripperFab (31 Jul 2010, DanAukes)

Manufacturing Web>ManufacturingHome > SDMFabTechniques>GripperFab (31 Jul 2010, DanAukes)

My short-term plan is to complete the fabrication of the gripper mechanism I've been working on. The stand-alone version of the gripper should be complete within a week, with a functioning embedded object sensor.

Beyond this, I'm still thinking about what I'd like to work on for CBot. I hope to continue working with SDM, but I'm not sure in what way yet. I will update this once I have a better idea of my plans/goals for the summer.

-- MiguelPiedrahita? - 19 Jun 2003

Suggest to look at possibiltiy of thinner, unjacketed cables. These would be interesting to investigate for future legs (alongside

push/pull cables).

Also check out other polymers (TAP plastics?) that might be less fussy about casting but also adequately tough.

-- MarkCutkosky - 24 Jun 2003

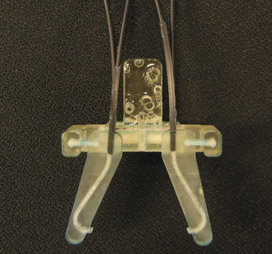

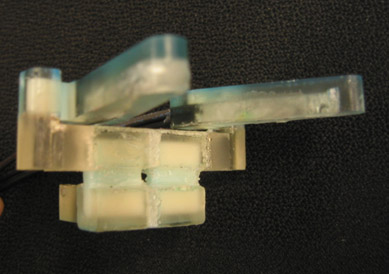

The first prototype of the gripper has been completed. Several problems are apparent:

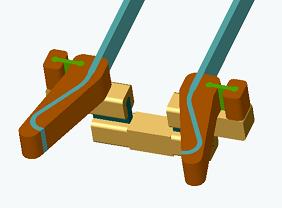

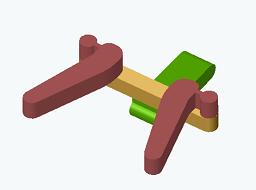

A second prototype has been designed and is being manufactured. Changes include:

A second prototype has been designed and is being manufactured. Changes include:  -- MiguelPiedrahita? - 12 Aug 2003

-- MiguelPiedrahita? - 12 Aug 2003

- a build-up of hard polyurethane on the base flexure, which prevents it from flexing properly.

- the optical fibers were somehow damaged during the casting process; they no longer transmit light! There are a large number of bubbles around the fibers, possibly indicating a chemical reaction with the liquid polyurethane which may have damaged the fibers. Alternatively, the heat from the curing process of the polyurethane could have damaged the fibers.

- overly complex manufacturing process; required many SDM pours.

- poor bonding at several interfaces due to bubbling and hard/soft polyurethane interfaces.

- Streamlined manufacturing process reduces the number of required pours to 4.

- New optical fibers are much thinner (250um diameter), seem to behave well with SDM in a series of tests I conducted.

- Minimized hard/soft interfaces to reduce bubbling problems.

- Building copies using several materials: regular polyurethane; epoxy; rapid-curing polyurethane from TAP Plastic.

Ideas, requests, problems regarding TWiki? Send feedback