Gaining Access to Equipment

Equipment Location: SMF Shriram Center, Rm 099

General Training

Trainer: Dr. Jeffrey Tok (jbtok [sticky] stanford [bot] edu)

- Set up your Badger Account (Instructions) before attending the orientation

- Sign up for the general SMF training(60min): SMF training sign up

|

|

Instrument Specific Training

Trainer: Yuran Shi (yuran [sticky] stanford [bot] edu)

- Subscribe to the Rheometer-DMA mailing list (link)

- Watch the two required videos and read the document covering the chiller and rheometer instructions.

- For DMA mode operation, watch the additional TA Instrument Tech Tips videos regarding different clamp geometries.

- Read the chiller instruction document

- After reviewing the materials, complete the quiz: DMA Training Quiz

- The quiz contains a question asking whether you have any questions about setting up your experiment. This is a good opportunity to discuss your sample’s material, dimensions, and overall suitability for testing with the DMA rheometer.

- Email the trainer with answers to the following questions:

- Have you completed SMF orientation with Dr. Jeff Tok?

- Do you have a valid Badger account?

- What is your home lab? Are you undergrad,grad,post-doc?

- Sign up for instrument specific training: DMA-Rheometer training sign up

If needed, refer to the official training document for additional information on the rheometer training.

System Preparation

- Turn on the air supply of the rheometer.

- This must be done first before powering on the rheometer.

- The bottom plate should spin freely once the air is on.

- Set up the chiller (if required)

- After powering on, wait 15 minutes for the machine to purge.

- Purge state: chiller off, air on, instrument on, oven closed and in the correct position so that air flows through the chamber.

- Then, turn on the chiller and allow 60 minutes for internal cooling before use.

- Log into Badger and start the PC.

- Launch the control software TRIOS and connect to the rheometer.

|

|

Installing Mount Geometries & Calibration

- Install the upper mount geometry by aligning the grooves of the geometry with the transducer rods, then screw it in securely.

- Install the lower geometry using the same method.

- Insert the rectangular alignment tool between the clamps and set the alignment position.

- In TRIOS, Navigate to Geometries in the left panel → select Tension Fixture (Rectangular) → read the alignment position (do not change the mass calibration).

- You can return to this alignment position anytime by going to the Motors tab and selecting Move to Alignment Position.

- Remove the alignment tool and zero the gap.

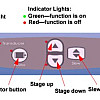

- On the rheometer keypad, press the Stage Down button to move the top geometry down until it is close to the bottom geometry.

- Press the Zero Gap button to zero the gap between the clamps.

- Zero the axial force using the tare function on the machine’s control panel, ensuring no sample is loaded.

- Load the test sample into the clamps, while using the torque screwdriver to apply even clamping pressure. The correctly loaded sample should look like this.

- After the sample is clamped, adjust the gap until the force reading on the rheometer display returns to zero (zeroing the axial force before taking measurements).

|

|

Experiment Procedure Setup

- Set up the sample ID, file name, and file path on the central panel.

- Select the geometry to be used and adjust the corresponding parameters. For the sample length, input the current gap dimension (not the actual length of the sample).

- Configure the experiment and set the test parameters in the Procedure tab.

- Start the test by clicking Start on the top toolbar.

Post experiment

- After completing the test, unload the sample.

- Remove the top and bottom clamp geometries and return them to the drawer.

- Export your data as a PDF if graphs are needed. Use a portable USB drive to transfer data files from the lab computer to your own device. ( PDF files are not exported automatically. Only txt files with the procedure set up and recorded data point values are saved.)

- Close TRIOS, turn off the chiller, and reset the chamber temperature to 10 °C through the Environment tab on the right.

- Disable the tool and Log out of Badger.

|

|