June 18

Arrived in lab. Received a cursory introduction to the different projects in the lab and met people a bit more formally than during the year. Morgan got me set up on the wiki, yoda, and the lab computers. Eric introduced me to a couple machines and I was able to practice using the mill: I anticipate this to be a very useful skill. Wandered around a bit to get a feel for the different projects.

June 19

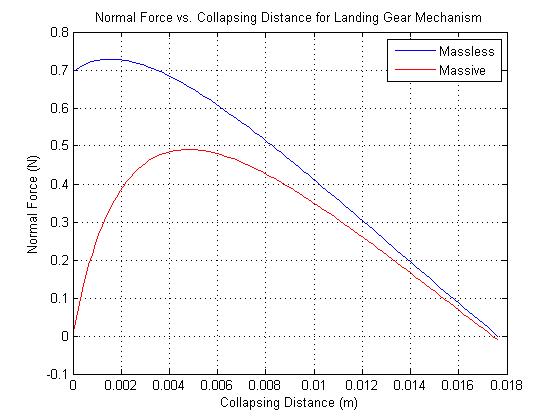

Helped Morgan and Hao sift through the collapsing truss code looking for errors. After some debugging, we were able to get the MotionGenesis output model for the collapsing truss to match Hao's analytical model. We were then able to go through to MATLAB (using code Morgan had previously written) to output graphs of several key elements of the collapsing truss, such as the angle theta vs. time and the normal force acting on the falling truss vs. collapsing distance. Wrote a short bit of code to compare the two graphs, and after some intensive algebra found that we had switched a negative sign; changing this issue fixed the problem and the MATLAB output matched Hao's graph. Ultimately achieved a good model for one half of the collapsing truss for perching.

June 20

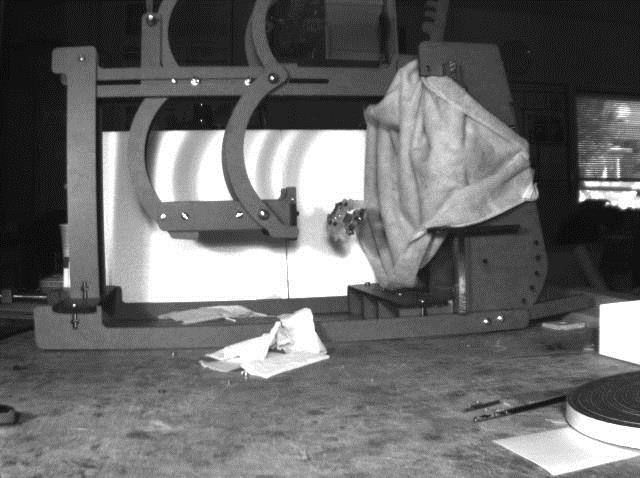

Morgan taught me how to use the high speed camera and Matt introduced me to his quadrotor launcher (intended to help demonstrate/analyze vertical perching). Elliot introduced me to the strain gauges they will be using to test the force distribution on the dry adhesive climbing apparatus. Started thinking about ways to mount 24 strain gauges in order to more effectively collect data from the climbing apparatus. Spent some time fixing the magnets and kinematic couplings on the launcher, ended up settling for quick fixes for the most part (hot glue and more magnets). Ran experiments on the launcher and analyzed with the high speed video camera; substituted a wrench of comparable weight for the quadrotor for the time being. Morgan introduced me to the MATLAB code that allows you to analyze the high speed video. Started playing with the code and analyzing the video I took.

June 21

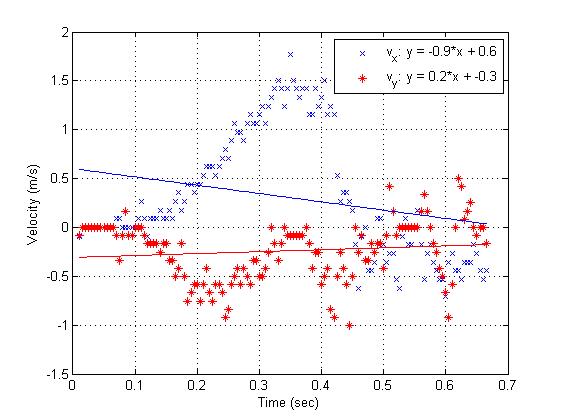

Finished analyzing video data from launcher, sent out summary and baselines to Morgan and Matt. Suggested a few tweaks for launcher. Lab bbq today, got a more in depth introduction to each project and saw everyone's goals for the summer. Very exciting projects, helped cook the food! Attached is an example of the velocity profile for one of the launches.

June 24

Attended morning SURI kickoff meeting. Jon and Richie arrived in lab; joined them on an in depth tour of all the projects currently in development. Started modifying launcher to fix issues with pitch and velocity. (Mostly used rubber bands and new lasercut pieces.) Matt showed us some in depth SolidWorks techniques and walked us through the new design for the kinematic couplings. Taught Jon how to use the high speed camera.

June 25

Worked out a few issues with the Phidget strain gauges and settled on a first possible design. Hao took us over to the TLT to lasercut the new kinematic couplings; it took us a couple tries because we had to slow the speed down more than we originally thought to cut through 1/4" duron. Used the drill press to fit the ball bearings in the couplings: fairly straightforward process. Fiddled with the launcher and attempted to fix the issues that were causing the quadrotor not to perch effectively. Could not fix the launcher in time to get a video to Mark; enlisted Hao to help fix parts of the quadrotor that were deteriorating and eventually took high speed video of the quadrotor perching on a vertical surface after being thrown. Also took video of the quadrotor effectively perching on a slanted surface as well. See attachment.

Attach:SpineLandingVertical.mov

June 26

Modeling day with Morgan, Hao, and Matt. Spent a fair amount of time figuring out how to transfer MotionGenesis code to Adam Leeper's visualization program. Got it working but the model of the collapsing truss didn't follow quite what we hoped: might have to go back to the drawing board on parts of the code. Sat down with everyone involved in perching (Morgan, Hao, Matt, Jon, Richie, myself) and agreed upon a universal model to use for all future problems. Started thinking about ways to modify the lasercut pieces in the launcher in order to rebuild it so it's better suited for the spine quadrotor and successful landings in general.

June 27

Hannah took Richie, Jon, and I over to the TLT in the morning to teach us how to cast plastic in molds (she is using them for different test joints in her finger/hand apparati). Worked on edits to launcher in conjunction with Jon and Richie, make the launcher about 1.5 times taller by CADing up some extra pieces to bolt on, lasercutting them, and replacing two of the "tower" pieces. Seems to be working well so far, will probably test it more tomorrow.

June 28

Completed all the safety and workstation training required by the administrative uppity-ups. Cleaned the lab, had lab meeting, and Alice led tutorial on how to use Eagle (reaffirmed my love for Mechanical Engineering and respect for Electrical Engineers). Worked on reassembling a previously downed piece of dry adhesive perching gear to reattach to the dummy quadrotor for launcher testing purposes. Also worked on next model of the stirrup for Elliot's climbing gear; this one did not fail in the honeycomb aluminum!

July 1

Introduced to possible summer-long projects from Santhi, Hannah, Alice, and Morgan. Spent a while talking with Jon and Richie about the possible projects and where we want to work. Spent the afternoon talking with Eric and working with him to design a prototype piece to hold the strain gauges for the sensor to measure the force distribution on Elliot's climbing apparatus. Drilled and milled a hollow rectangular tube of aluminum to fit the strain gauge correctly. Decided to work jointly with Richie on Morgan's landing envelope project and independently on Santhi's pneumatic brake project for the master-slave MRI manipulator. Introduced to the project by Santhi and took a cursory look at the current pneumatics for the brake.

July 2

Spent the morning working with Morgan learning how to build perching gear: successfully built (/repaired) some perching gear; it stuck to the glass quite well. Went with Richie to lasercut his acrylic pieces for the force sensor. Helped unpack and organize a bunch of new equipment for the lab. We now have a plethora of sharp and organized drill bits! Jon got the launcher working reliably! It's a miracle! See attached videos.

Attach:DryAdhesiveLauncherLanding.mov

July 3

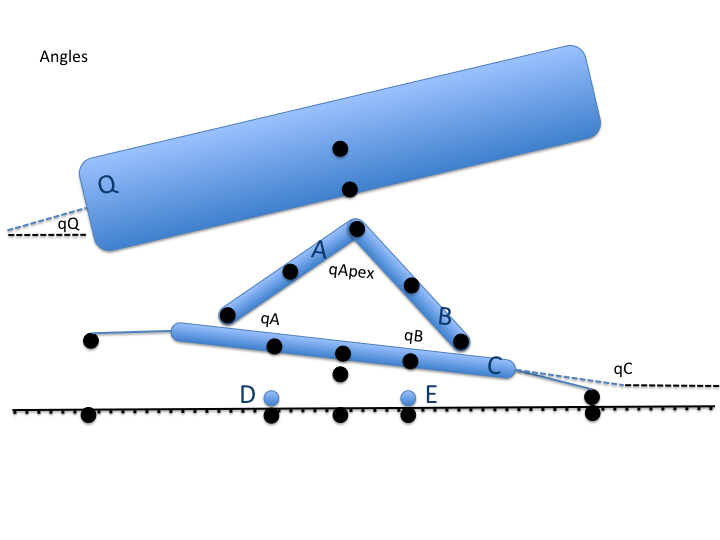

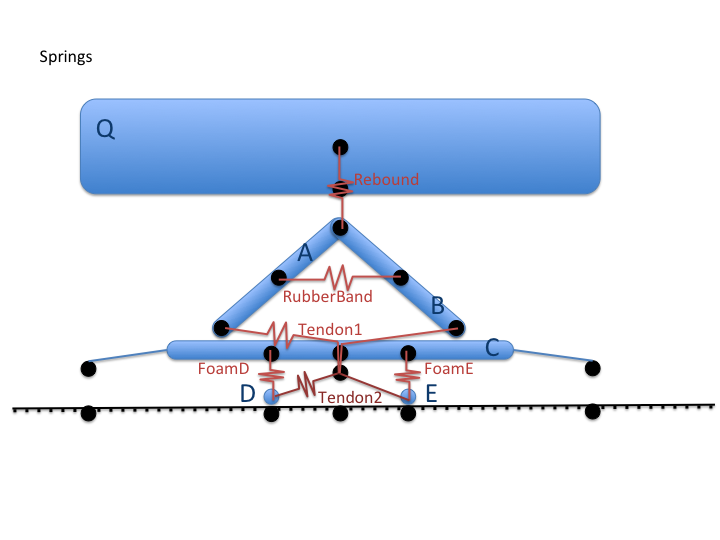

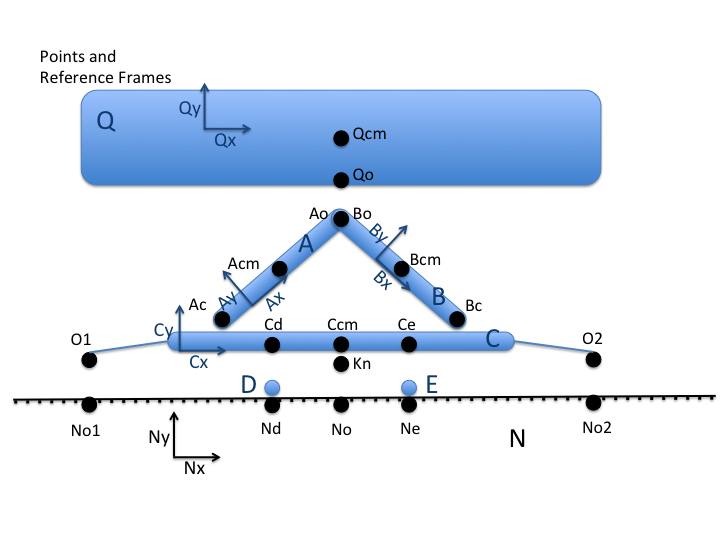

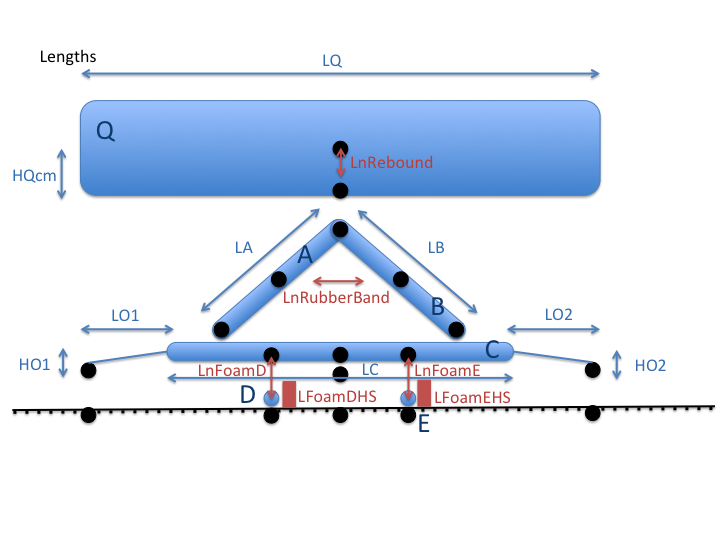

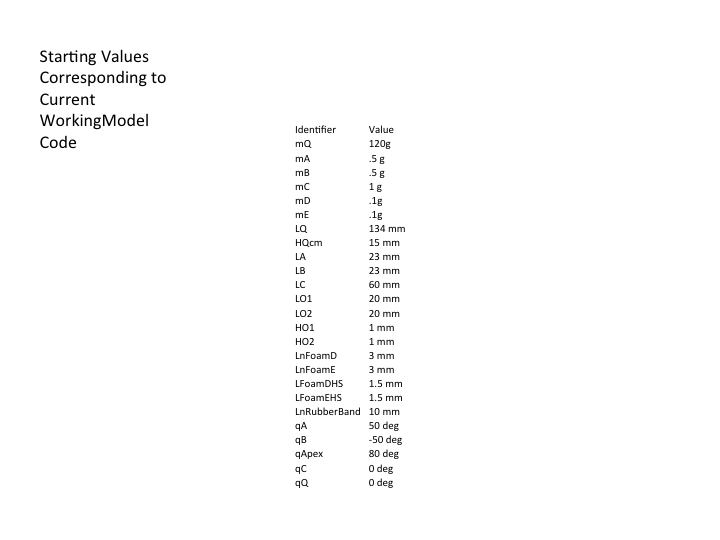

Spent the morning and part of the afternoon going over some of the modeling for the quadrotor with Morgan, Matt, and Hao. Learned a small bit of working model from Hao, finalized model/identifiers for quadrotor model (see attached pictures).

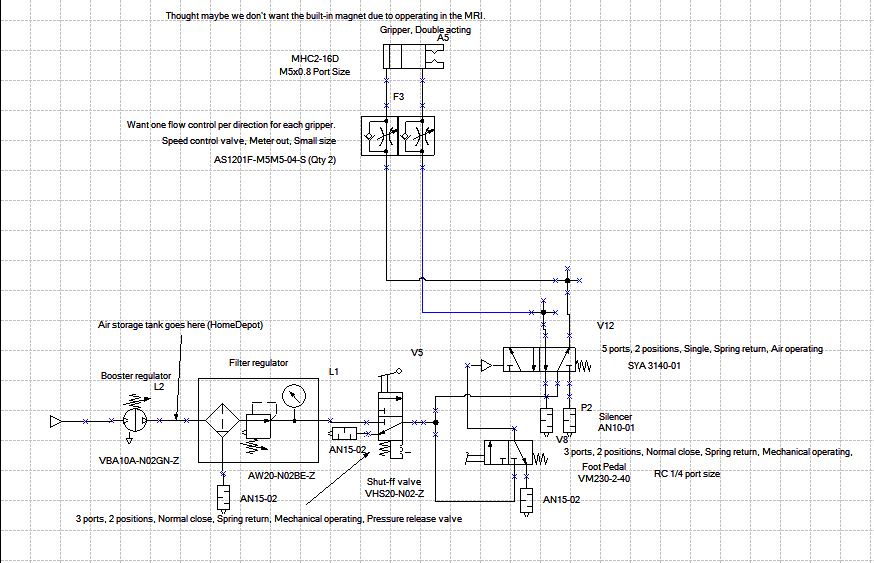

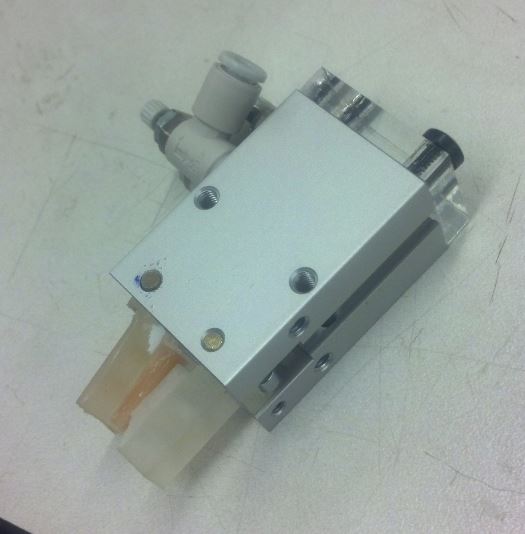

Built the pneumatic brake with the metal pieces for the master-slave manipulator, have yet to test it. Need to jerry-rig a fixture between the air-hoses in the lab and the input hose for the pneumatic circuit. If impossible, need to find part. See attached photo for circuit.

July 4-Happy Birthday America!

July 5

Lab meeting. Spent the afternoon messing with possibilities for a connector from the compressed air in the lab to the pneumatic circuit; got one working reliably. Unfortunately could not get the gripper itself working reliably, will continue to focus on that for the pneumatic brake project. Quadrotor had a couple issues while on the launcher, fixed those and launched once or twice. Will start taking data soon.

July 8

Spent the morning taking videos of the quadrotor perching with the launcher. Richie and I worked together to set it up and start taking data, however we discovered after lunch that one of the tendons had snapped, so the perching gear was no longer working. Perching gear, therefore, needs to be fixed before meaningful data can be taken for Morgan's landing envelope project. To make up for the failure there, however, got the pneumatic brake/gripper working! See attached video.

Next steps: 1) design/prototype several options for non-metallic grippers/brakes that will work in an MRI, 2) test the metallic gripper/brake in an MRI to see if it truly is a viable option.

July 9

Spent almost the entire day debugging the quadrotor/perching gear. Lots of issues came up (thanks to Richie, Morgan, and especially Elliot for helping out) and while most of them were fixable, we ultimately decided that it would behoove us to simply build an entirely new perching mechanism and try to cut some new adhesive as well. Looking forward to seeing if we can build a repeatably reliable quadrotor/perching mechanism that integrates well with the launcher.

July 10

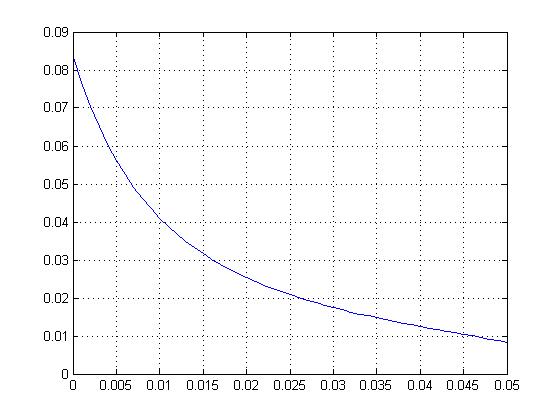

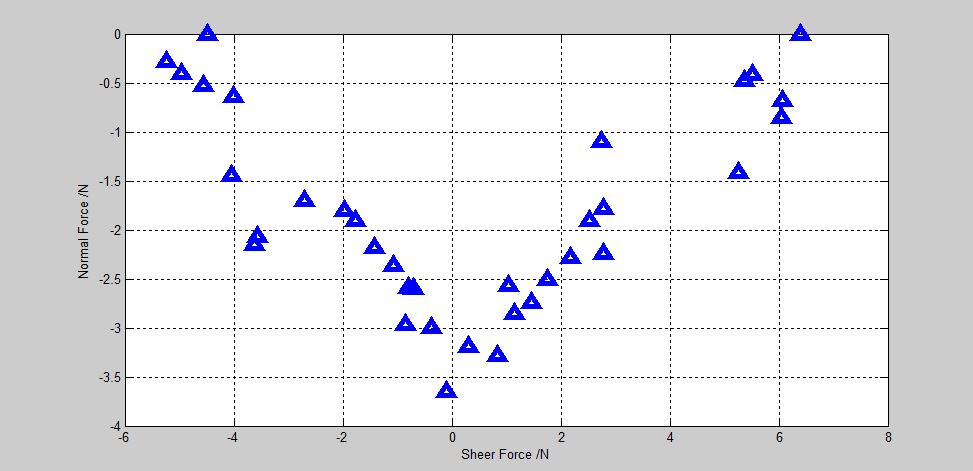

Spent all day modeling/coding with Morgan, Hao, Richie, and Matt. Objective today was to model the quadrotor and perching gear aligning before engaging the adhesive/collapsing the truss due to the outriggers. We were somewhat successful by the end of the day; there's still a problem in the sign for the force. Used Motion Genesis to model and code and MATLAB to numerically compute; learned a bit from just chatting with Morgan and Matt about the process of graduate school and the style of upper level dynamics classes. Looking forward to taking 161 and (hopefully at some point) 331. Should be good classes. Output graph of force on truss during alignment attached. Problem to fix: force should not be positive. Axes are as follows: x axis is time from when the outrigger first contacts the surface/ground (in seconds) and the y axis is the normal force on the truss from the quadrotor (in Newtons).

July 11

Cut new pieces of adhesive in the morning in order to make more perching trusses in the hope that we will have a few that work reliably enough to collect data on the launcher. Made a mistake with the first batch: put the slot on the wrong side. Good learning experience, glad I didn't cut the whole pad on the first go round. Luckily we caught it before we started assembling any perching gear so Richie and I went back to the TLT and cut 7 more pads (with the slot on the correct side this time). With Morgan's help we tested them out and they all seem to be capable of carrying at least 200 grams of weight, so we're good there. Spent the afternoon assembling the trusses and troubleshooting them. Still not working perfectly, but were getting there. Also, helped Elliot and Dave (and pretty much everyone who was in the lab that afternoon, it's a fun project) put up the frame for the glass "climbing wall" outside. Record time to cut through aluminum with a hacksaw: 20.8 seconds held by yours truly.

July 12

Spent the morning debugging the perching pads. Lab meeting at 10:30, heard/learned much more about the variable stiffness project. Incredibly interesting project, hopefully I'll get the chance to talk to Aki and Nick more about it before the summer is over. First MERL barbecue today, seemed to be a success. Took note of areas where we can improve for our barbecue; it's always a competition. Cut some more aluminum for the glass wall, headed out early to spend the weekend in Palm Springs.

July 15

In Palm Springs. Check out the view.

July 16

Back in lab! Richie, Morgan, and I went back and created a force profile for the new batch of adhesive and, after some "angle math" (i.e. trigonometry), adjusted the angle and distance between the pads for the perching gear accordingly. Noticeable difference in adhesion for the perching gear, but still not excellent. Spent the afternoon talking with Santhi about how were going to test the gripper in the MRI on Friday. She introduced me to the physics store where we picked up some tubing and pneumatic connectors that we'll need to interface with the medical air lines. Things starting to look promising! Messed around with some possible coating for the gripper fingers; found this great rubber stuff in lab that works very well. Taped on for the time being, may attempt to epoxy it later if it works permanently.

July 17

Spent some time re-familiarizing myself with SolidWorks. Useful program, but I still have a lot to learn about it. Subsequently made a design to mount the gripper in the MRI (two layers of quarter inch acrylic). Spent a large portion of the afternoon debugging the perching gear and creating force profiles for the gear that we created (continued failure of our landing gear is starting to get frustrating, but were making enough progress to keep me motivated to lick this problem). Generally a day for continuing projects.

July 18

Lasercut material most of the day today including the acrylic pieces for the pneumatic brake mount, larger pads from the old adhesive batch for the perching gear, and acrylic pads for the ATI (Jon). Things generally turned out well, had one snafu with the acrylic at first where my dimensions were all halved, but ended up working out on the second try. Plastic screws came in as well. Put the new, larger pads on the perching gear.

July 19

Lab meeting in the morning, MERL barbecue at noon, testing in the MRI after lunch. Made some significant discoveries in the MRI: need non-ferrous fingers for the brake/gripper (expected), the latex tubing is a no go (unexpected), and the circuit itself will work well for the future minus the gripper (exciting). Met Juan in the med school, got to see a bit more of Santhi's work: interesting stuff. Hopefully I can learn more about human biology by working around and on her projects this summer.

July 22

Spent the day brushing up/learning new things on SolidWorks. Looking forward to the day when CAD is intuitive and straightforward. Borrowed a great textbook from a friend that helps you learn more advanced techniques, started working my way through that. Hope to be done with the majority of it by the end of the week.

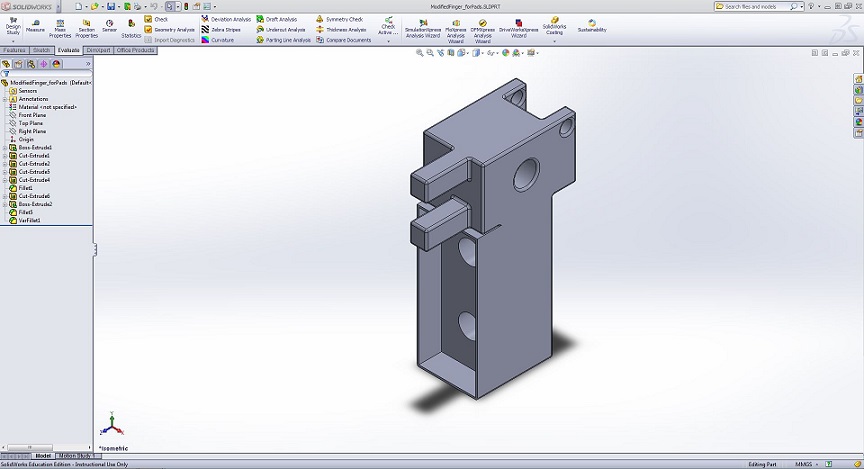

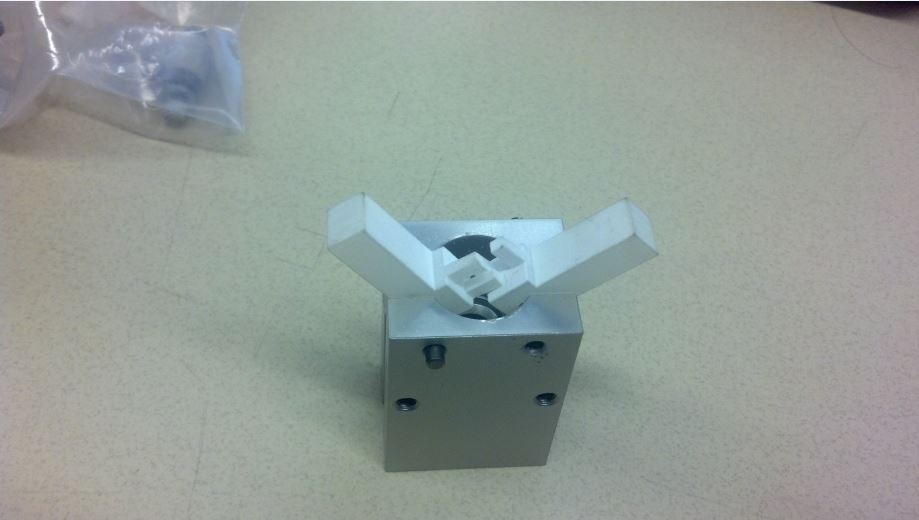

July 23

Took apart the gripper, was a bit more challenging than it initially looked. Continued learning more about SolidWorks, also started to CAD up some potential replacement parts for the gripper. Would love to be able to use the aluminum housing that the gripper came in: would be robust and save time. Talked to Santhi and plan on 3D printing the new parts that we need.

July 24

Finished up the finger piece for 3D printing, hopefully first iteration will be a success, but expecting that some tweaks will need to be made in the long run. Santhi had a great suggestion that we put a slot in so we can cast a urethane right into the finger instead of having to attach gripping material later for the break. She added a couple pieces to the finger as such: look forward to seeing how it works! Continued working through some SolidWorks exercises. Attached the new larger pad perching truss to a mock quadrotor, Hao built a magnetic hinge for the same and helped me troubleshoot it (all credit to Hao on the excellent design and reliability of the hinge). Hopefully we'll be able to get back to testing the landing gear next week.

July 25

Played around with the completed 3D printed fingers: found a couple of issues. Most notably, they can't close (awkward). They do fit in the housing though so I should be able to simply change a few parameters around. Also finished the first big project in my SolidWorks textbook/learning initiative: all practice parts and the final assembly are under //yoda.stanford.edu/users/cparlier/SolidWorks/Practice. Attempted to CAD up another one of the pieces to replace for the gripper: definitely going to take me a bit longer on this one; it's the piston guide piece. Some fairly complex parts in it.

July 26

Made changes to the CAD model of the 3D printed finger for the gripper. Went with Santhi to watch how to work the 3D printer: such a cool device. Lab meeting: Dave practiced his presentation and Eric/Elliot presented their current work. Excited to see them start climbing. MERL BBQ! Vyta30 cured in the fingers: the large walled ones seem to be quite viable if implemented in the new finger design (Stonehenge?). Went back and quickly revisited the strain gauge sensor apparatus for Elliot's climbing gear. Will have to work on that as soon as they start climbing.

July 29

Made some last minute changes on Friday to the fingers with Santhi, went home excited to have them printed by Monday. Unfortunately the 3D printer was on the fritz all weekend, ergo no fingers. Worked on a bit more SolidWorks practice, also Richie and I got tasked with a new project by Morgan: build an apparatus that will allow/force the jump glider to launch at a 55 degree angle (plus or minus 5 degrees). Started working/designing/doing math for this idea.

July 30

Completed a working prototype for the jump glider "truss." Messed around with it quite a bit to get the optimal configuration, think we figured it out by the end of the day. See attached video for design/operation. Landing envelope project has been put on a bit of a hold on account of trying to get these other papers done by the end of the summer. Looking into magnetic latch options for the jump glider truss.

July 31

Spent the morning working on the truss, tuning and seeing if there were more optimization possibilities. Practiced a bit more SolidWorks as well, had to leave early for an optometrist appointment, learned that I have astigmatism, but got new contacts!

August 1

Can't believe it's already August! Spent the morning catching up on where the climbing project is at. Brought Jon along to help with the strain gauge apparatus: props to him, he assembled everything and got it working on his computer in no time. Looks like there are some advantages to the mac interface and some to the PC; it will behoove us to see if we can get both in conjunction. 3D printed fingers came out, casted vyta 30 in them in the TLTL, should be ready in 24 hours. Also had a long talk with Morgan about his jump gliding project. It looks like he has some small design things to tweak, nothing big, but we discussed the pros and cons of using the ballistic trajectory versus the already proved carbon spring method. It will be interesting to see what happens with this considering the time constraints; it's going to be a cool final product no matter what though.

August 2

3D printer on the fritz again. Somewhat less than stoked about this machine currently... Lab meeting in the morning, MERL barbecue during lunch. Climbing may happen soon! Very excited about that; when people ask what I did this summer I want to show them a video of Elliot climbing glass.

August 5

Back to perching! Yay! With Mark back in town, the perching folks had a meeting with him that outlined the plan for the rest of the summer. Developments: Hao is pretty much taking over the landing envelope project and Morgan is exclusively focusing on jump gliding for at least the next few weeks. Richie and I sat down with Hao and basically hashed out all the experiments we need to do (starting with "floor" perching). Rigged a little mount to the ATI and started taking a bit of data; had some issues with the perching gear, sat down with Hao and debugged in the afternoon.

August 6

Spent pretty much the whole day taking data/working on the perching gear with Richie and Hao.

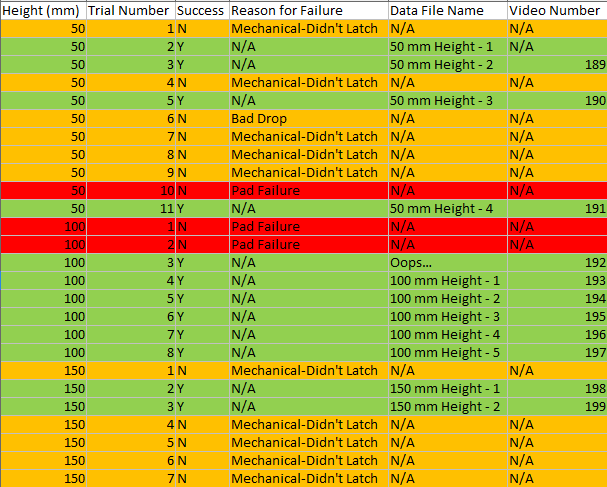

August 7

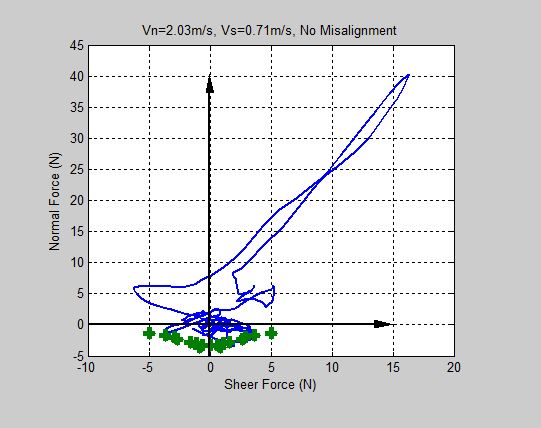

Lab cleanup in the morning! Things are looking spiffy now. Thanks to Mark for the pizza for lunch, it was delicious. Spent the entire afternoon with Hao and Richie taking data for the quadrotor landing on the floor. We determined the upper limit to be a 700 mm drop, or about 3.7 m/s. This is... a bit more than we expected, but we'll find out about why when we look at the model and analysis. Hao started doing some testing on angular floor and angular vertical and straight vertical landings. Data is hard to get, but interesting when we get it. Also, Yoda still hates us apparently (actually it's just the network, but it means we can't connect to Yoda). Ergo, attached is only data taken on the 7th (which looks better than the data from the 6th anyhow). Edit: This is actually the original data because Mark et al got Yoda working.

August 8

Super busy day. Started by looking over the data Hao had analyzed over the previous day or so. It's looking good, this landing envelope paper may become a reality soon. Then talked to Santhi about the state of our gripper: 3D printer back online! Assembled everything we have so far for the gripper: it's all fitting/working so far, but made a couple tweaks and designed another piece in SolidWorks for the top gasket. This thing is definitely coming together, hopefully it will be finished by the first animal testing. Also met Dr. Bruce; nice guy, had some great comments. Brass pegs working well, 3D printed parts working well, everything going right! Spent the afternoon shopping for the BBQ: wow. Lotsa food. Pictures forthcoming.

August 9

Spent the entire morning on the BBQ; it was a huge success! (Pictures forthcoming). Helped Hao take some limit curve data for the perching gear (picture also forthcoming). Took our new parts out of the 3D printer; excited to put them in the gripper next week!

August 12

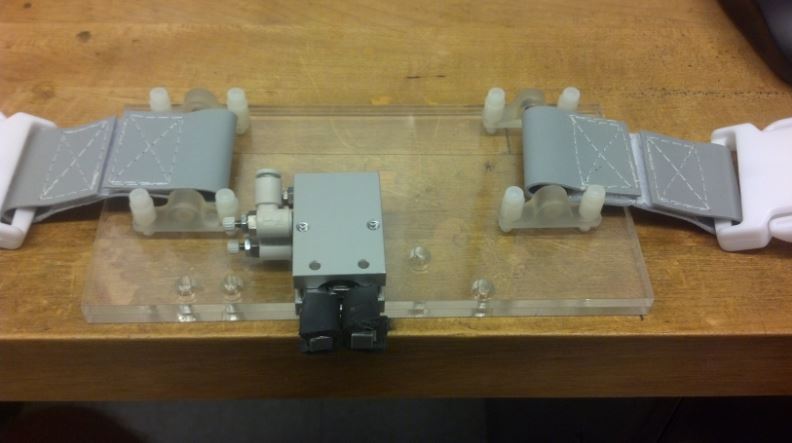

Perching meeting in the morning. Heard about where everyone's at in their project; definitely think we're going to get all the perching data before Hao leaves at the end of the week. The perching gear has a very high success rate on the vertical wall: as such it allowed us to take a large amount of data for the quadrotor with and without auxiliary foam. Put together the pneumatic circuit with all of the 3D printed parts and tested the gripper! The good news: the plastic pieces don't break. The bad news: the gripper doesn't work particularly well. This is due to a leak on the front end on account of the fact that the piston guide piece I built has too much movement in it. Thus the gripper opens quite well, but it takes a while to close and does not do so reliably. I also had to add a small piece on the top to keep the top gasket in. That part was straightforward and worked well.

August 13

Went to the MRI in the morning and tested the gripper in the 3T bore. It seems to be very slightly magnetic: i.e. not enough to worry about and probably due to eddy currents. Just to make sure we ran a test and it did not affect the image at all, so we're good on that count. Spent afternoon taking data for perching with Hao and Richie.

August 14

Spent the majority of the day taking/analyzing perching data.

August 15

Designed and lasercut a mount for the break, didn't have a chance to test it. Generally just spent the day preparing for testing tomorrow; did a lot of lasercutting in the TLTL, cast some urethane for new gripping fingers, dremeled new brass pins for the other grippers, and assembled a test (without the new piston pieces). Also took a bit of spine perching data for Hao.

August 16

Morning: MRI tests! Brought a bunch of equipment over tot the Lucas center and started setting up around 8 in the morning. Tested the new piston guide piece for the first time: it works! The mount however did not; Santhi had changed the spacers on the manipulator and so my first design didn't quite fit. (In retrospect this was a blessing as we thought of a couple new ideas for a mount design.) Headed back for lab meeting and was able to catch at least the 2nd half of it. MERL BBQ and more perching data in the afternoon.

August 19

Cleaned up a bit of the perching data that Richie and I took with Hao, took care of some administrative stuff. Spent the afternoon casting plastic in the new fingers.

August 20

Designed and CADed a few different mounting options for the break. Spent the afternoon lasercutting them, picking up my new fingers, putting new grippers together and trying out the mounting pieces. Looks like theyll work in general with just a few modifications to the manipulator.

August 21

Mounted and tested 1st gripper. It works! Woot!

August 22

Finished cutting/creating the rest of the mounts and tested all 3 grippers. Project outcome:

SUCCESS

August 23

Spent the morning before lab meeting getting the presentation together with Richie and subsequently presented. Feel that it went over well, everyone had some great points. Now on to the poster! MERL BBQ after meeting, after which Dr. Bruce came in and tested out the manipulator with brakes. Fixed a couple small things in the grippers and sent the SolidWorks designs to Santhi. She printed a couple pieces to try on the MRI in Monday including a new mount design. Looking forward to hearing how the brakes work in in the animal test.

Final Week

In lieu of posting a day by day blog post for the final week, I will simply attach the posters that Richie and I presented at the SURI poster session on Friday. Thanks to the entire BDML for a great summer!