Categories:AdhesiveManufacturing, Manufacturing

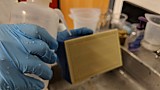

This page describes the process of machining a computed trajectory into a 4 by 6 inch wax block.

You will need:

- Wedge machining fixture (in black carrying case).

- Wedge machining pallet.

- Wax mold block; to prepare a new one, or resurface an old one, see details on preparing wax blocks.

- Automatic soap feed unit from filing cabinet.

- Aluminum foil.

- 5/32" hex key.

- 3/16" hex key.

- Isopropanol in a squeeze bottle.

1. Install the Machining Fixtures in the Mill

- Ensure that no tools or fixtures are in the CNC machine, and then power up and initialize the CNC machine.

- This involves turning on the master power, and then pressing "Power Up Restart" to home and enable the servos.

- Take a small square of aluminum foil and crimp it over the spindle to prevent the flow of compressed air from drying out the micromachining lubricant.

- Locate the blade clamp fixture in its box to the right of the office mill.

- Install the blade clamp by slipping it onto the spindle nose, sliding it up until it hits the reference collar, and then rotating clockwise (as viewed from the top) until it runs up against the reference collar. Hold it firmly with your left hand in this position, and tighten the two screws on the split collar clamp.

- The clamp design has a large mechanical advantage, so they only need to be tightened firmly using the ball end of the hex key, as shown here.

- Locate the wedge machining pallet. This is currently stored under the desk to the right of the CNC machine.

- Install the wedge machining pallet.

- Align the pallet with the pallet chuck with the brush to the left.

- Support the weight of the pallet while depressing the chuck disengage foot pedal, then gently set down the pallet.

- Release the foot pedal. The pallet should now be firmly locked into the machine.

|

|

2. Clamp the Wax Block and Set Coordinates

- Clean any silicone from the bottom and sides of the wax block.

- Place the wax block on the machining pallet with the marked block number facing forwards.

- Slide the block back and left to meet the reference surfaces.

- While applying downward pressure to hold the block flat against the pallet surface, tighten the two edge clamps.

- These are plain carbon steel and can rust a little, so the screws tend to be a bit sticky. Tighten firmly until the block is solidly held in place.

- The coordinate system used for machining is

G154 P57. Jog the tool until you're at approximately Y0 in this coordinate system.

- Bring the tool down until it's near the top surface of the block.

- Using a flashlight or the machine light, slowly jog the tool down by

0.001 increments until the light visible through the gap between the blade and the just disappears.

- Set the

Z origin by pressing PART ZERO SET.

- Lower the coordinate system to ensure planing off the old surface, by typing

-0.005 ENTER with the Z offset highlighted.

- This is necessary because the machining toolpaths put the final reference surface at

Z0, and we want to ensure that the reference surface is defined by machining operations performed as part of this setup.

|

|

3. Install the Automatic Lubricant Feeder

- Locate the lubricant feed unit, currently located in the second drawer of the file cabinet.

- Attach the unit to the spindle housing using the magnets. Place the lower edge just above the screws on the housing and pivot up until the magnets hold it in place. The screws provide stability and prevent the unit sliding off of the spindle housing.

- Place the bottle of soap mixture in the holder.

- The soap is a 10:3 mixture of Ajax orange dish soap and water.

- Place the intake hose from the pump into the bottle and screw on the cap to retain the hose in place.

- This cap should always remain on the hose when installing/uninstalling/storing the lubricant feed unit.

- Plug in the USB cable into the power bank.

- Insert the rigid tube at the end of the output hose into the corresponding socket on the blade clamp.

- Set up the lubricant feed unit.

- Press the lower button once to go from red blinking to active.

- Press the upper button to cycle through feed rates. The regularly used ones are single blink (slowest, for machining) and solid (continuous, used for priming the system).

- Press the lower button to toggle between rate selection (blue) and feeding (green).

- Prime the system using continuous feed, then set the rate to single blink. Leave the unit in rate selection mode while setting up the program.

|

|

4. Run the Machining Toolpath

|

Time Estimate:

| 5 min. for setup

|

|

| Varies for machining, depending on toolpath.

|

- Press

LIST PROG and navigate to find the toolpath folder generated by the MATLAB script.

- Select the initial planing operation by highlighting the file names "S_...", which is the setup toolpath.

- Put the machine in single-block mode, with rapids set to

5%.

- Step though the first few lines of code to verify that the coordinate system has been set correctly. Keep a hand on

FEED HOLD while doing this to catch a potential crash before it happens.

- Once the

Z offset is confirmed to be correct, open the door and turn on the lubricant feed. Turn off single block mode, and set rapids to 25%.

- Press

CYCLE START once more to continue with the machining operation.

- As machining progresses, verify that the old wedge features have been planed off.

- Turning on

OPTION STOP will cause the machine to pause after each planing operation, to allow for opening the door and checking the just-planed surface.

- If wedges from a previous operation can be seen or felt after the full block surface has been planed to depth, press

RESET to halt and jump to the beginning of the program, then adjust the Z offset down by -0.005 inches and run the "S_..." program again.

- Repeat until a clean flat surface is established by the planing operation.

- Once the setup program has finished executing, open the door an make sure there are no wax chips on the mold surface; if there are, gently wipe them off with a finger or a Kimwipe, taking care not to drip soap into the machine. At this time, also ensure that any previously machined features have been planed off.

- Close the door, select the wedge machining program ("E_..."), and run. Since these use the same offset, the step-though in single block is not necessary for this step.

|

|

5. Wash the Mold

- Wipe any wax chips which have accumulated on the left edge of the block towards the left edge of the pallet.

- Unclamp the two edge clamps holding the wax block in place.

- Slide the wax block to the right, and then gently pry up to remove it from the pallet. The surface tension holding the block in place can let go suddenly, so take care not to lose control of the block or splash soap everywhere.

- Tilt the block to pour most of the soap off near the brush side of the pallet.

- Taking care not to drip soap in the rest of the machine, remove the wax block and take it to the sink.

- Turn the cold water on until you have a gentle laminar stream.

- Gently run water across the block parallel to the wedges until the soap is all removed. Typically, the block will transition from hydrophilic to hydrophobic when this happens, although the transition can be more or less clear depending on the wedge geometry.

- Once all soap has been washed from the block, gently rinse the mold surface in isopropyl alcohol.

- Set the block on edge on a paper towel to dry in the top drawer of the file cabinet.

|

|

6. Clean Fixtures

- Flush the lubricant feed unit by running it continuously with plain water from a beaker. Flush with approximately 50mL or until the outflow is not soapy.

- Remove the blade clamp from the machine.

- Wash the blade clamp in hot water, focusing on the blade and the internal soap channels.

- Briefly rinse in isopropyl alcohol to draw water from crevices.

- Dry off with compressed air, and store in the padded box.

- Remove the pallet from the machine, and scrape as much of the wax as possible into a trash can.

- Rinse the pallet thoroughly in the sink.

- The flange around the edge is only held in place by epoxy, so as much as possible avoid supporting the weight of the pallet by the flange and avoid impacts to the flange.

- When rinsing the pallet, make sure to clean the brush thoroughly, as it tends to retain soap.

- The edge clamps are plain carbon steel, and so tend to rust from the soap/rinsing cycles. To mitigate this, once the block has been cleaned, add a small amount of WD-40 to each set screw in the edge clamp blocks to prevent rusting during storage.

- Store the pallet.

|

|