Category: TactileSensing

On this page... (hide)

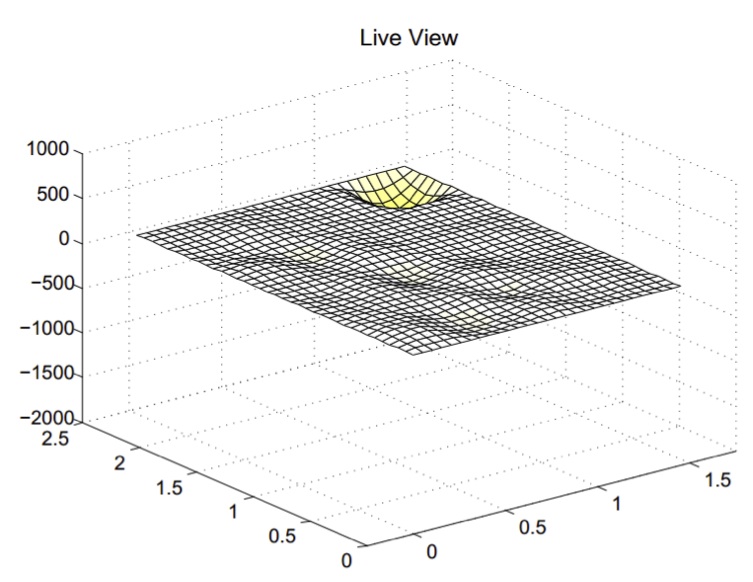

display from dynamic normal force array with 1 gram weight

1. Introduction

While many interesting tactile sensors have been developed over the past 30 years, the focus of the work in BDML is on:

- large arrays for a sensate skin for mobile robots - Challenges include making a robust, flexible and economical array with the ability to address many sensing elements so that robots can become aware of contacts, intentional or accidental, anywhere on their surfaces.

- small arrays for dynamic tactile sensing in manipulation - Challenges include combining normal and shear sensing, in a compact package that can provide dynamic signals for slip detection, etc. The sensors can be applied to under-actuated hands or to the feet of small mobile robots. Other work focuses on bio-inspired signal processing methods to classify contact events.

2. Projects

2.1 Sensors for robotic oceanic oil drilling

This work is in collaboration with Robotics Drilling Systems, AS of Norway. The project is focused on creating a robust method to sense slip events and classify slip interfaces in a large automated robotic drilling system.

- public project page with a description of the project

- Private RDS page with project notes, meetings, details

2.2 Ground force sensors for small mobile robots

Small arrays for dynamic tactile sensing in manipulation present many challenges, including simultaneously measuring shear and normal forces in a compact package that can provide dynamic signals. In particular, very few tactile sensors have the combination of capabilities necessary to accomplish ground force sensing for small legged robots.

Shear and normal force information would be valuable in robotics, enabling small robot locomotion optimization, providing useful tactile feedback regarding motion on various terrains, or applied to under-actuated hands.

2.3 Dynamic tactile sensing for manipulation

Slip Interface Classification through Tactile Signal Coherence.

- Imagine turning a key in a lock. It is trivial for humans to determine whether the key slips in the lock (the environment) or slips out of one’s grasp (the hand)

- Similarly, during robotic manipulation, grasped objects may slip relative either to the hand or the environment with quite different consequences

- Clever signal processing for tactile sensor arrays can be used to distinguish these two events

- Draws upon bio-inspired signal coherence and coincidence ideas

- Measures whether a group of signals samples a single input or a group of incoherent inputs ** Methods developed are able to classify slip interfaces

- Uses a linear system model of the environment, held object, and tactile sensor array of n sensors

- Results indicate that coherence based measures can be used to classify slip type

- Applications:

- RDS automated oil drilling system- classifying slip between pipe handler, roughneck, pipe, and threads

- Seabed Rig Robotic Drilling grasping project

- Mobile manipulation and the mechanics of soft fingertips

|  |  |

| Tactile array sensor with 8 embedded PVDF strips. | Sensor package profile. | Texture boards tested. |

Biologically inspired tactile classification of object-hand and object-world interactions.

- During robotic manipulation, a grasped object may slip relative to either the hand or the environment, with very different consequences

- In humans these events excite the mechanoreceptors differently, allowing event identification and response

- Tactile sensor suite presented

- can produce an array of dynamic signals over a wide range of frequencies

- bio-inspired design criteria combine sensor signals to compare taxel stimuli individiually and as a group

- investigates combinations of sensors and frequency ranges that make it possible to distinguish object/hand slippage from object/world slippage

- tested for a variety of textures and conditions

- Using the ratio of power in individual versus group signals, discrimination between object/hand and object/world slips with ~84% accuracy over all trials was possible

- Method is insensitive to the center and width of the frequency band used

- Does not require precise accounting of taxels in contact

IEEE "Best Paper in Biomimetics"

1/3/2013 things to add:

- a link to the large array sensor we did with Meka for Georgia Tech. (large array sensor for human-safe robotics)

- the ARM-H sensors

3. Recent Developments

We are developing several variations on tactile sensors that take advantage of new chips that have become available for the smartphone industry. These devices simplify the task of monitoring changes in capacitance, providing shielding, and communicating results on a standard bus to minimize wiring. Some recent developments include:

3.1 Tactile sensing for underwater hands

Suction pressure measurement for proximity sensing

- Given that we have used suction on the fingers, we could put a pressure transducer on the suction line. This would not even have to be very close to the orifice. What kind of pressure transducer? Looking for something small and robust. Maybe from automotive industry?

- A barometric pressure chip modified for the Takktile sensor: http://www.takktile.com/ -- they filled it with soft silicone rubber

- Otherwise just Google "miniature pressure sensor" and we should find some things. Easiest quick test might be with a T fitting on the line.

- Example: http://www.omega.com/googlebase/product.html?pn=PXCPC-004WCDV&gclid=COGI0IO55LkCFSU6QgodPjQAlA -- this one would need to be filled with silicone grease or something like that for protection from water.

- Another, example, perhaps more suited to the environment: http://www.meas-spec.com/product/Pressure/EPL.aspx

- Could also see what pressure transducer they use for the BioTac tactile sensor (actually, the entire BioTac sensor would be relatively OK under water because it has no air spaces). Barrett knows these people.

We have one TakkstripDemonstrator board which is useful for experiments where one needs pressure only for 5 taxels, a little under 1cmx1cm each.

Encapsulated PVDF

See the PVDF examples above on this page

Encapsulated opto-mechanical

We could adapt the design from the Sandia hand. We have the circuit design courtesy of Kurt Salisbury.