We have been making various capacitive tactile sensors over the last couple of decades.

Schmitt oscillator (2008-2010)

One of the earlier designs was from John Ulmen, using a Schmitt inverter for each taxel to give a frequency ~ capacitance. This sensor used a thin sheet of silicone foam rubber (McMaster Carr 8785K821 or similar depending on desired thickness) for the dielectric, wrapped around the inner sensing electrode. Some details are found here including a clever design for making an array of elements with row/column addressing and an explanation for why long leads can be made relatively resistant to noise:

- http://bdml.stanford.edu/twiki/bin/view/HSPrivate/CapacitorArray.html

- Ulmen & Cutkosky, "A robust, low-cost and low-noise artificial skin for human-friendly robots," IEEE ICRA 2010

Pressure sensor with pillars (2013-2018)

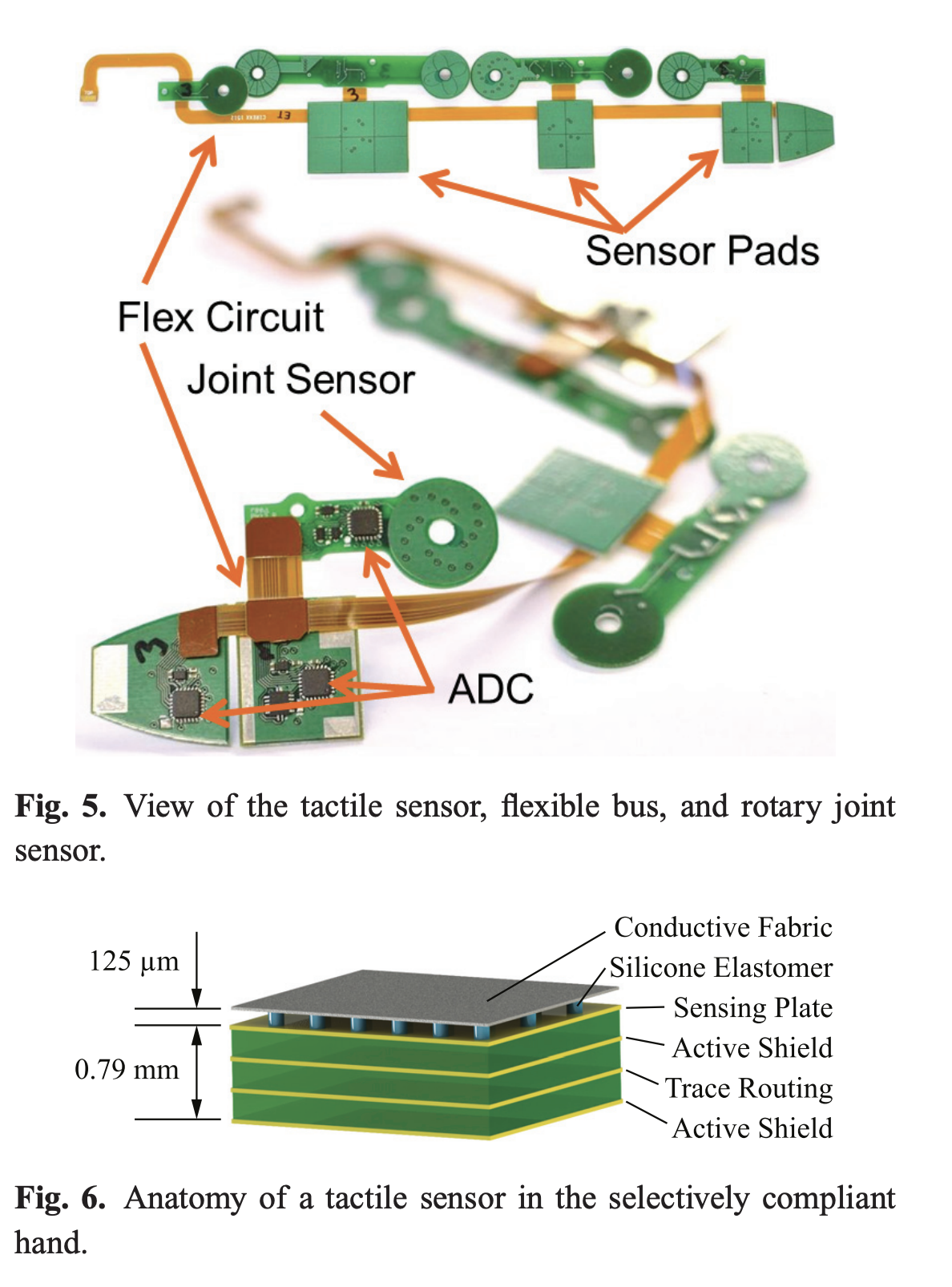

We susequently have used designs that do not require a surface-mounted device (however tiny) at each site. The design is similar to that used by the iCub robot tactile sensors, except that it uses a custom-fabricated array of pillars instead of foam for the dielectric. (Note: a new multiaxial design uses miniature Hall effect sensors: Tomo, et al, 2018).

A first description for the of the sensor on a hand is here:

"The dielectric is a dense array of silicone rubber posts, 200 Ám (8 mil) in diameter, with a fill ratio of 0.25, created using a perforated laser-cut mask. The bottom layer is a printed circuit with pads, active shielding and trace routing. A soft (shore 15A) urethane pad covers the outer surface to distribute loads and provide abrasion resistance."

For several projects, starting with the "selectively compliant" hand cited above, we made tactile sensors with molded arrays of small (100-200um diameter) pillars of TAP blue silicone rubber to create a dielectric with even lower hysteresis than the foam used in 2008-2010, and with tunable stiffness as a function of pillar density. The pillars were created by lasercutting a thin sheet of plastic to create an array of holes. John Ulmen had discovered that if one asks the laser for a "gray scale" pattern, it automatically creates a halftone image of small holes. We applied silicone through the holes, let it cure, and lifted the sheet off, leaving the array of pillars behind.

Then we spun a thin layer of silicone on the mating surface and bonded this to the pillars to create a sandwich. We used the Analog Devices AD7147 chip for sampling the taxels and communicating.

Essentially the same design was used for Barrett Heyneman's work:

- Heyneman, Barrett, and Mark R. Cutkosky. "Slip classification for dynamic tactile array sensors." The International Journal of Robotics Research 35, no. 4 (2016): 404-421.

- Heyneman, Barrett. Heyneman, Barrett. Classifying Object-Hand and Object-World Interactions Using Dynamic Tactile Array Sensing. PhD Thesis, Stanford University, 2013.

Some of these sensors remain attached to the Robotiq 3-fingered hand. They used rigid PCBs for the bottom layer to reduce cost and simplify fabrication. Some are starting to delaminate -- this is an issue that has been addressed in newer sensors with improve bonding methods including primers and Oxygen plasma treatment.

Multiaxis and flexible sensors (2014-2019)

Subsequent versions of these sensors were expanded to 3-axis sensing and flexible circuits to wrap around small robot legs:

- Alice Wu, Srinivasan A. Suresh, Hao Jiang, John V. Ulmen, Elliot W. Hawkes, David L. Christensen, and Mark R. Cutkosky. Tactile sensing for gecko-inspired adhesion. In 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), pp. 1501-1507. IEEE, 2015.

- Wu, X. A., Huh, T. M., Mukherjee, R., & Cutkosky, M. (2016). Integrated ground reaction force sensing and terrain classification for small legged robots. IEEE Robotics and Automation Letters, 1(2), 1125-1132.

- Wu, X. A., Huh, T. M., Sabin, A., Suresh, S. A., & Cutkosky, M. R. (2019). Tactile sensing and terrain-based gait control for small legged robots. IEEE Transactions on Robotics, 36(1), 15-27.

Reprogrammable sensors (2016-2019)

At some point we switched to using Cypress PSoc 4200 L chip, based on advice from Jean Phillipe Roberge, who had used it for his tactile sensors ( Maslyczyk2017, Rana2016 ). In addition to being able to monitor more sensors more rapidly this chip is more programmable. It allows us to "time slice" background jobs that read an entire large array with higher frequency jobs that read a few sensors in a particular pattern to detect particular events.

- Huh, Tae Myung, et al. "Dynamically Reconfigurable Tactile Sensor for Robotic Manipulation." IEEE Robotics and Automation Letters 5.2 (2020): 2562-2569.

- Huh, Tae Myung. Robotic Tactile Sensors for Changing Contact Conditions. PhD thesis, Stanford University, 2020.

We are using the same chip for a modified 6-axis force/torque sensor adapted from some of the technology in (Wu, et al. IROS 2015) for multi-axis sensing. We have made steady progress in techniques for leveling and bonding non-uniform patterns of pillars to obtain a sturdy and reliable sensor.