Category: Adhesion

On this page... (hide)

- 1. Human Climbing

- 1.1 Human Climbing in the News

- 1.2 Publications

- 1.3 Images and Media

- 1.4 FAQ

1. Human Climbing

This work demonstrates a new hand-sized gecko-inspired adhesive device that allows a human to climb a glass wall like a gecko. Previous work on synthetic and gecko adhesives showed that adhesive strength decreased as the size increased. In contrast, this device has the same adhesive strength at all sizes from a square millimeter to the size of a human hand. The adhesive technology was developed in collaboration with the DARPA Z-Man program. These results show that gecko-inspired adhesives can be scaled from laboratory-scale tests to real-life, human-scale applications with little decrease in performance.

|  |

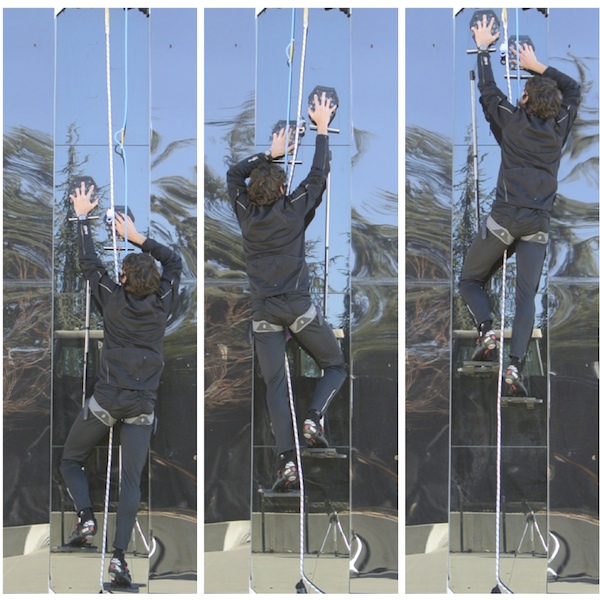

| A 70 kg climber on vertical glass | A climber scaling a 4m glass wall |

1.1 Human Climbing in the News

- Science Mag News

- The Guardian

- Newsweek

- Popular Mechanics

- Stanford News

- Huffington Post

- Washington Post

- BBC News

- Fox News

- MIT TechReview

- Boston Globe

- Cell

- NY Times

- San Jose Mercury News

1.2 Publications

- Human Climbing with Efficiently Scaled Gecko-inspired Dry Adhesives, J. R. Soc. Interface: JRSI Paper

- Other BDML adhesion publications

1.3 Images and Media

Any of these images may be copied and reused with attribution of the source: Biomimetics and Dexterous Manipulation Lab, Stanford University

- Microscope side view of adhesive wedges in unloaded state (0.7MB png image)

- For more background on the adhesives see Day et al. 2013 (DOI:10.1115/1.4023161)

- Back View of Device (2.7 MB tiff)

- View through Glass (2.4 MB tiff)

- Climber on Side of Building (6.7 MB jpg)

- Triptych of Climber Ascending (7.6 MB pdf)

- Video of Climbing (33 MB mov)

- Placing Device on Glass (1.4 MB jpg)

- Microscope views of wedges (0.5MB png): Unloaded wedges from lithographic (a) and micromachined (c) molds. Loaded wedges (b) showing much larger contact area

1.4 FAQ

Figure numbers in the notes below refer to figures in the JRSI publication

How the adhesive works

Interview answering most of the below questions, courtesy of Ethan Allen and Likable Science on Think Tech Hawaii: Likable Science

How does the synthetic adhesive on the pads you use work, and how does the transfer of weight allow adhesion to be switched on and off?-- A good explanation is found in the PBS Nova Series on Making Materials Smarter. Here is a short snippet (copyright PBS): NOVA explanation of microwedges

The adhesive material is an outgrowth of adhesives that we have been using for several years for climbing robots such as Stickybot. It consists of arrays of microscopic wedges of silicone rubber, similar to what you’d find in a cooking spatula. You can see a greatly enlarged view of the wedges in the inset photograph in the lower middle of Figure 1 in the paper, just above “10^-7" on the horizontal axis. A similar detail is shown in the figure at right.

The material is non-sticky when unloaded, because only the sharp tips of the wedges are making contact with a surface (images a and c at right). However, if you gently touch it to a surface and then apply a tangential load the microscopic wedges bend over and form an almost continuous contact (image b at right). The contact area is now large enough for van der Waals forces to produce significant adhesion.

What sort of surfaces and materials could these adhesive pads be used on?-- Any smooth surface such as glass, plastic panels, painted or varnished wood panels, metal… The material chemistry is not particularly important. The tiles will even stick to slippery surfaces like the white dry erase boards used with markers.

Innovation for scaling and climbing

What is new about the system described in the paper?-- The innovation in this paper is a system for loading the adhesive that scales to large areas and large forces without a significant drop in adhesive performance. The trick is to ensure that the overall load is very evenly distributed across the entire adhesive system.

As one can see in Figure 1, even the gecko does not scale particularly well: its adhesion is much lower when measured for an entire toe or foot than it is for a single setal stalk or a small group of setae. Indeed, the gecko’s system, if you extrapolate the diagonal line with square points in Figure 1 to human scale, would not work for human climbing! Perhaps this is why there are no geckos weighing more than a fraction of a kilogram?

In comparison, we start out with considerably weaker microscopic adhesion, but lose very little performance as we increase the area from a single postage stamp-sized tile to a group of tiles and ultimately a large array of tiles. One can see this trend in the lower, dotted line with diamond markers in Figure 1.

Why have there been so many difficulties in scaling up this sort of gecko inspired adhesion in the past?-- Many people have worked on synthetic dry adhesives. The bilbiography maintained by our colleague Professor Ron Fearing at U.C. Berkeley (http://robotics.eecs.berkeley.edu/~ronf/Gecko/gecko-biblio.html) lists over 100 articles on adhesives, adhesion modeling, etc. However, all of these adhesives suffer a substantial drop in performance as areas increase to tens of square centimeters.

The first problem is to ensure intimate conformation to a surface; no surface is perfectly flat. It is for this reason that we divide our adhesive paddles into many postage stamp-sized tiles.

The second problem is to distribute the load evenly. This is where the array of tendons and “degressive” (softening) springs comes into play. As the load increases, the tendons and springs ensure that all tiles converge to the same maximum load. Without this provision, one tile somewhere in the array will become overloaded and will fail. Then its neighbors will fail and so on. The failure proceeds like an avalanche across the entire array.

The load-sharing effect is seen in Figure 4. The red dotted lines show what happens with conventional materials. The blue solid lines show forces that all converge to a common limit of approximately 35N at lower right.

Degressive springs are rarely seen in practice. Elastic materials like rubber bands and even biological tissue generally have the opposite behavior: they become stiffer as you stretch them. But in this particular case softening springs are the solution to load sharing. As a consequence, Elliot is able to get nearly the same adhesive pressure (force per unit area) for an entire hand-sized paddle that he is able to get for a single postage stamp-sized tile. This is unprecedented, and it enables him to climb.

Future Applications

How do you envisage this technology being ultimately used - could we see a generation of "spider suits" or climbing gloves like those in Mission Impossible?-- This goal was explicitly part of the DARPA Zman project, on which we collaborated with Draper Labs in Boston a few years ago.

However the Zman program was set up so that any human testing, and all interactions with the military, were performed by Draper. Most of this work was classified. We and other university partners focused on advancing the underlying adhesive technology and manufacturing processes.

Unfortunately “spider suits” ignore some basic ergonomic issues. People have much greater strength in their legs than in their arms. Therefore we think one needs a system like that shown in Figure 10. The hands are used to gently attach and detach the adhesive tiles. A system of cables and links transfers to the load to the feet. Additional details ensure that Elliot is held stably and controllably against the wall without swaying or lurching from step to step. People are not built like geckos!

Another application is in manufacturing, lifting large smooth objects like windshields, solar panels, and LCD screens. The device does not require power, which could be a benefit over the current technology, vacuum.

Finally, there is a possibility of making gloves that could aid rock climbers in ascending difficult faces.

Have you done any other "human tests" with this material - I'd be interested to know what the team have been getting up to as it sounds like great fun!--The main motivation for this technology was a project that we are engaged in with the NASA Jet Propulsion Lab (JPL). The goal is to gently touch and grasp space junk by attaching to solar panels, fuel tanks, etc. If you’ve seen or heard of the movie Gravity, you will understand the motivation. The project at JPL is lead by Dr. Aaron Parness.

Controllable dry adhesives are one of very few technologies that will work in space: they don’t require suction, they work at low temperatures, and they don’t require external power. So the motivation on our side has been to develop very light grippers that can attach to satellites.