Andrew's Summer Log Book (Summer 2017)

Pinned First Blog Entry

Tuesday, June 20

Welcome to my blog! I think the way I will organize this blog is by writing at two different points in the day. I will write when I come in the morning and again in the evening. In the morning, I will detail my goals for the current day and I will discuss any reflections from the previous day that may have formed while I slept or completed more work that evening. In the evening I will discuss the work that was completed that day and things that still need to be completed.

Morning:

Today, is my first official day in the lab. It has been a crazy last couple of days with graduation happening and family members being in town. But I'm excited to get started! I will be working on the SuperSCAMP project this summer. This is basically a revamp of the SCAMP project to create a more robust MAV that will fly, perch and climb as the original SCAMP did. Our goal is to make SuperSCAMP less "fuzzy" and more reliable, although that may mean adding a little more weight than the regular SCAMP had. From our morning meeting, I think I will be focusing on the perching and crawling mechanism design as well as just helping out when I'm needed. Below are my goals for the day (in no particular order):

- Begin reading and tinkering with the Crazyflie documentation/software.

- Create a four-bar linkage design that we can propose to Mark for the design of SuperSCAMP's legs/feet.

- Solder broken components that Alessandro gave me.

- Continue reading papers about SCAMP.

Edits/updating after a later meeting with Mark, Alessandro, and Will (3:00 pm):

In order to make sure that we have everything we need for a demo at Living Machines (July 25th) and the big DARPA demo in August, we've decided to work in parallel to create both the same perching and climbing mechanism for SuperSCAMP as SCAMP, as well as begin to think about ways to develop a more robust mechanism for it. For the next few weeks, we will be focusing our efforts on re-building the old SCAMP climbing mechanism. We will begin construction once Drew gets back on Monday, but for now, I will be doing some preliminary work, so we can hit the ground running when he returns. I will, then, be focusing on the following tasks for the next few days, in addition to working on the tasks above as time permits:

- Dimensioning the new carbon fiber parts that will go onto the SuperSCAMP

- Looking into the specs of the motor we are currently using in comparison to other servo motors in the lab to see if it can be improved.

- Developing a more robust mechanical takeoff mechanism. Alessandro might also try to figure out a way to do this with a software strategy.

In the back of my mind, I will also be thinking about the "inchworm" wall climber. This might be something we work on later in the summer.

Evening:

I completed a preliminary drawing with dimensions of what SuperSCAMP's crawling mechanism will be. I also began looking into the servo motors and decided I want us to try the HS-45HB, that is in the lab instead of the already used HS-5035HD. The reason for this change is that the HS-45HB has a higher rated maximum torque range (14-17 oz/in) when compared to the HS-5035HD (11-N/A oz/in) (see datasheets). From what I've learned in the short time talking with Mark and Will, more torque seems to be needed from the motor, as well as more robust turning, which we hope a higher voltage supply might address. I also began looking into the Crazyflie documentation. I kind of want to buy one for myself and I probably will.

I have not began to think about the takeoff mechanism yet, nor have I soldered the parts for Alessandro (one of the parts needs Molex connectors that I was unable to find so I will revisit this tomorrow). I've begun working on everything else.

I will not be in the lab for most of the day tomorrow but will continue work remotely dimensioning the crawler, reading more Crazyflie things, and reading about the takeoff mechanism in the paper again. I also plan to come into the lab to cut some carbon fiber later in the day. Hopefully, I can get in.

reverse chron order -- newest at top

Week 10

Friday, August 25

Evening:

I am at the airport headed back to Houston from Stanford for what might be one of my last times making this trip. I have a great deal of gratitude for Mark and the rest of the lab for allowing me to be a member for this summer. It was a tremendous experience and I believe that I am better prepared for my PhD program because of it. I can't wait to get to Michigan and begin to work on my research project. I have attached links to view the PDFs of my project summary below.

Thursday, August 24

Morning:

Work has been completed and I will be picking up my poster this afternoon. I am still waiting to hear back from Drew and Will about any comments that they might have on the poster and summary. I will be meeting with Alessandro this afternoon to get his comments and make changes as necessary.

Evening:

Alessandro gave me some very constructive feedback and I have made an effort to make some of those changes on the poster and project summary. I will attach the final versions of both tomorrow morning.

Wednesday, August 23

Morning:

I completed the project summary yesterday evening. I will use it as a basis to create my poster for the poster session today. I hope to have the poster finished early in the day, so I can have Alessandro, Drew, and Will take a look at it before I send it to be printed. I also plan to put the finishing touches of the feet today and attach it to the Super SCAMP robot. I will take pictures that I will put on the poster for presenting, as well as in the project summary.

Evening:

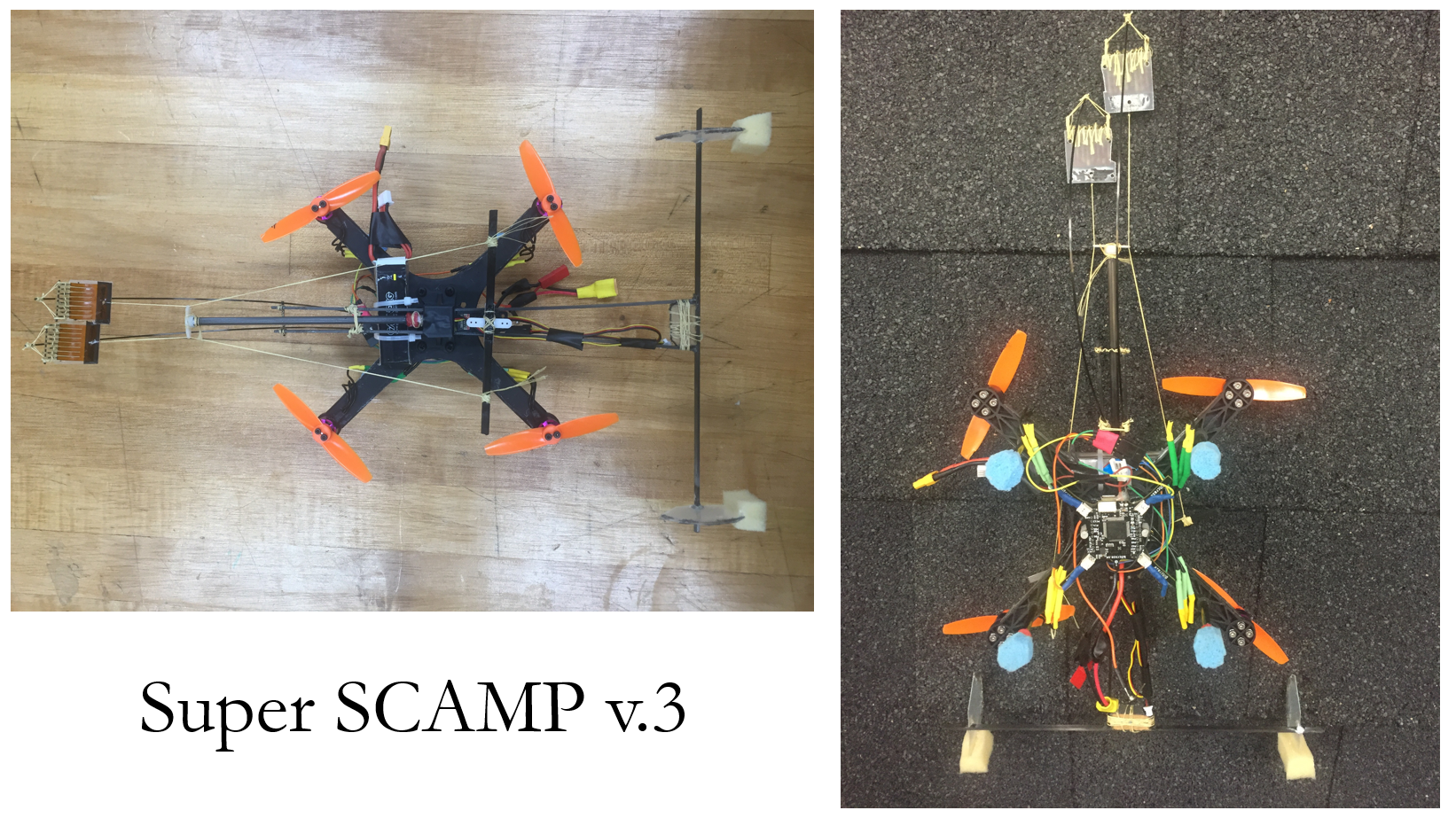

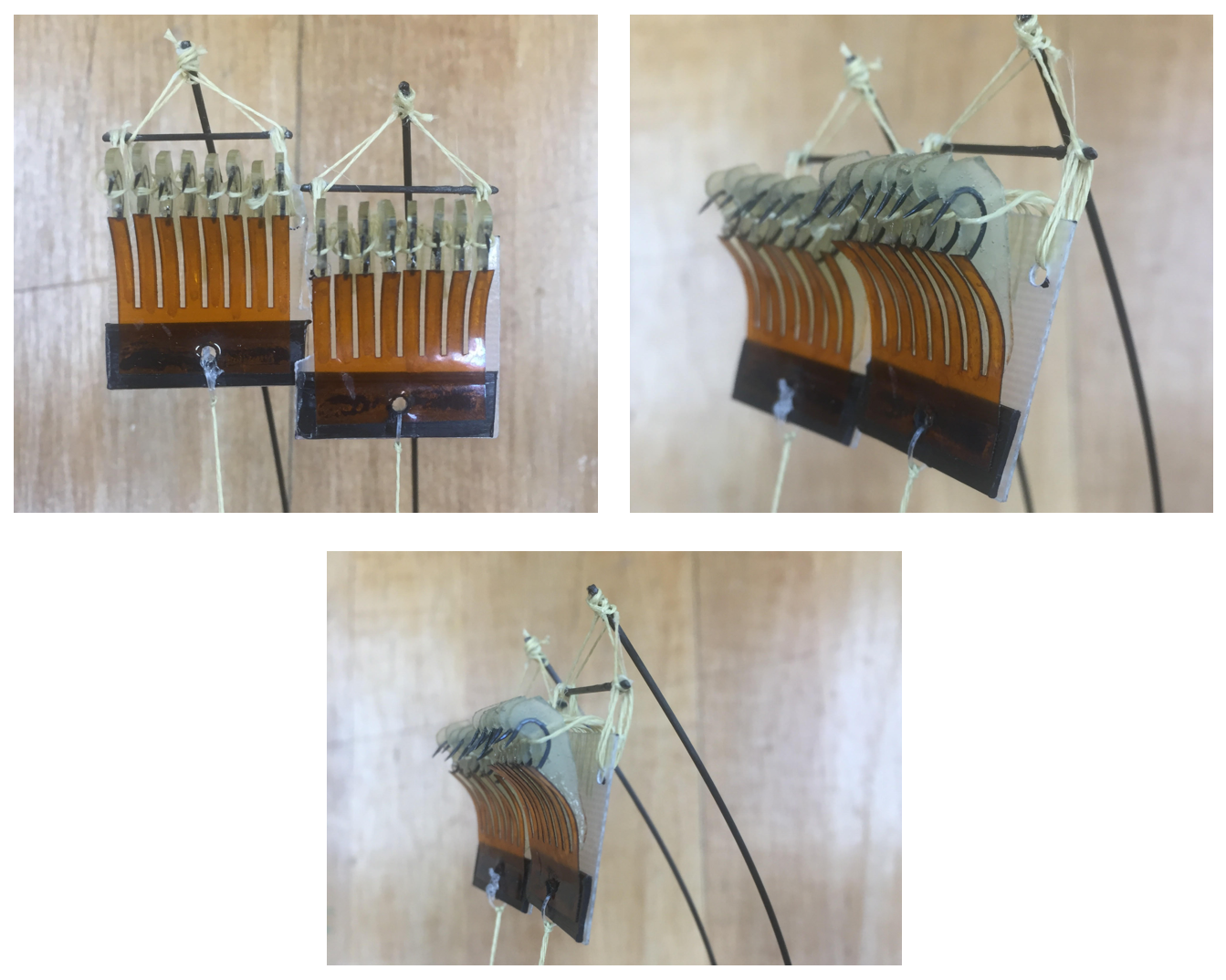

I was able to finish the feet for the Super SCAMP. Please see photos of both the final Super SCAMP and the final iterations of the Super SCAMP feet below:

The poster has also been completed and been sent for printing. I should be able to pick it up tomorrow afternoon. I wasn't able to send it to Drew and Alessandro to get feedback before I sent it out to be printed but I think it is pretty good. I will still send the poster to Drew, Will and Alessandro to get some feedback and I will put try to attach a PDF of the final poster and final reports to this blog.

Tuesday, August 22

Evening:

Today, I continued to work on the project summary and the new Kapton feet. They are both very close to completion. I will likely put the finishing touches on the project summary this evening and finish the Kapton feet early tomorrow.

Monday, August 21

Morning:

This morning, I want to get a head start on the project summary that needs to be submitted to SURI by the end of this week. I did not have the opportunity to work on it this weekend, unfortunately, but I think it will be essential to collect my thoughts about the project. My plan is to complete the project summary by Tuesday evening at the latest and then create the poster. I believe the poster will be much easier to create once I have collected my thoughts in a project summary. I will be able to use it as a reference. I hope to submit the poster to be printed by Wednesday evening, so I don't have to pay a rush delivery fee and will have it before the presentation on Friday.

I will also continue to put together the feet, probably when I get bored of writing. I will make a concerted effort to make sure it gets done soon because I would like to put some images of it on my poster. So, hopefully it will be done by Wednesday afternoon at the latest. I also need to help Drew by ordering some materials that he will need to continue the project when I leave and contacting a vendor for a quote on Water-jet cutting some material for the Super SCAMP frame.

Evening:

I made progress on all the tasks that are discussed above. I was able to order Drew's parts and get in touch with the vendor. I also made tremendous progress on the project summary, although there is still a lot to be done. I will continue working on it tonight and tomorrow. I also made progress on the new Kapton feet. Dividing my time between these tasks has been an effective way for me to remain focused on the tasks that I am working on.

Week 9

Friday, August 18

Morning:

Today, I plan to continue working on the new feet for Super SCAMP. The goal is to try to get the Kapton laser cut in CHARM lab. I also want to begin working on my presentation materials for the SURI poster session that will take place next Friday. We need to write up a summary of our research project as well as create a poster that will be on display for the poster session.

Evening:

Although Jada wasn't around today Alessandro and I were able to get into the CHARM lab and give Jada a call to step us through the process of laser cutting the Kapton. It took a little while, but we were able to get the Kapton sheets cut and I began assembling the new feet for Super SCAMP. I wasn't able to start working on the poster and project summary today, but I will likely work on them this weekend when I have a little more down time.

Thursday, August 17

Morning:

This morning, I've spent some time updating my blog and catching up on sleep from the last week. I will spend the afternoon working on the Super SCAMP platform. Hao gave me some bigger spines that I can use to make reliable Kapton spine feet. He also gave me some tips for making the feet with their ability to climb in mind. I think his advice will help a lot.

I plan to get on the laser cutter in CHARM lab to cut the Kapton this afternoon and then begin constructing the feet. My goal now is to get the Super SCAMP platform working before my last day of work next Friday.

Evening:

This afternoon, I wasn't able to get on the CHARM laser because Jada, the visiting researcher that usually helps me out with the laser cutter, wasn't around to help. Instead, I took some time to cut out the spines that I plan to use for the new Super SCAMP feet. I also made some changes to the CAD files that I used to cut the Kapton feet initially to utilize the features that theses new feet allow and their slightly different dimensions.

Monday through Wednesday (August 14-16)

(Updated Thursday, August 17)

During the weekend, we had a setback to the SCAMP platform we were working on. Once we began to get it climbing fairly well (but not perfect), the extend/retract servo motor began to vibrate and jerk during movement. I suspected that one of the gears in the servos was broken. I imagine it broke at some point when we were testing climbing and a spine got stuck, stalling the motor. This jerk during the movement was not good and had a detrimental effect on climbing. But, at this point, we also felt pretty good about our ability to fly, perch, and climb after several hours fine-tuning the parameters to get SCAMP working fairly reliably. We had also exhausted our supply of carbon fiber and we were unable to rebuild the platform on Saturday (8/12). Thus, we decided that we would wait until Monday when ACP Composites would be open and we could purchase some carbon fiber.

On Monday, after the carbon fiber was purchased, we quickly put together a new SCAMP platform in a few hours and began testing and fine-tuning. Testing and changing parameters took us up until Tuesday evening. At that point, we had a fairly reliable platform. Hao (the original spine expert in Mark's lab) came in on Tuesday evening to help us out. We were able to get some five-spined feet from him that he kept in a secret stash in his office. We speculated that these five-spined feet would be better than our current four-spine configuration, since it increase the likelihood of a some spines engaging with the wall in each step. Our original intention was to build two versions of the SCAMP platform so we have a reliable back-up for the demo. So we decided to use the five-spined feet to build the second platform to see the effects it would have on the system before changing our platform that was working well at the time.

Wednesday morning was largely filled with building this second platform and the afternoon was filled with tuning the platform for climbing, By the late evening, we were feeling pretty good about the reliability of both platforms flying, perching and climbing. The five-spined platform seemed to indeed work more reliably than the four-spined platform. We asked Drew to test these again when he gets to Maryland and add the five-spined feet to the first platform if he deems it necessary.

Week 8

(Updated Thursday, August 17)

Drew is leaving town today, heading to Maryland for the ARL Demo. He will arrive tonight and get some sleep and then have tomorrow (Friday), Saturday, and Sunday to test some more and practice for the demo. We (Alessandro and I) will be in constant communication with him and will try to address any concerns or problems he has remotely. If need be, we will be able to send something to him via FedEx Next Day Air or via Mark, who is flying out to the ARL site on Monday morning. The last few weeks have been a mad dash to prepare for the ARL Demo, hence why I haven't updated this blog in some time. We've been working day and night to prepare. I will try to recall the most important milestones from our work and discuss them here.

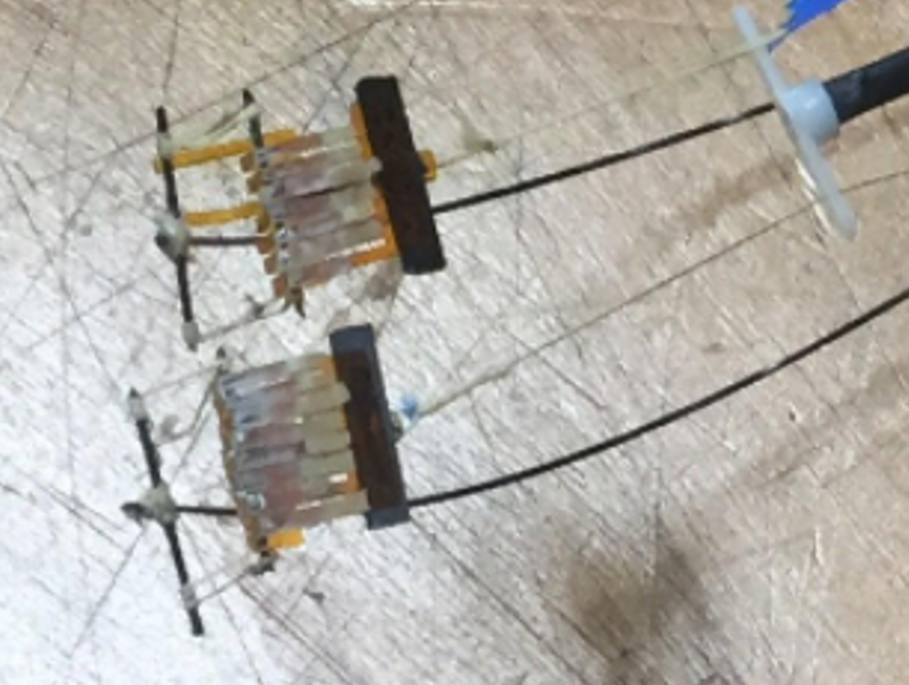

When I arrived from my weekend trip, we found that Alessandro had been doing some work on a smaller SCAMP platform and he had been able to get it to fly with really good control, something we hadn't been able to do on the original SCAMP platform. He had an intuition that the original platform was just a little too massive and had an inertia imbalance that prevented it from flying, so he created a new platform that was slightly less massive and smaller, placing most of the mass closer to the center of gravity. To our surprise, this worked fairly well. He was able to fly it with great control. This revelation shifted our plans a little bit. We then began to work on both this lighter SCAMP and the Super SCAMP platforms to get them to fly, perch, and climb.

At some point in the process, probably around Thursday or Friday last week (~8/11), we decided that it seemed to be more difficult to improve the Super SCAMP platform than the SCAMP due to the mass difference. At around the same time, the SCAMP platform was beginning to look more and more promising, so we made the decision to devote at least the next few days to the SCAMP platform. We hoped that we could be able to get it completed by the beginning of Week 9 and then we would have a few days to see what would be possible to show on the Super SCAMP platform for the ARL Demo.

Alessandro and I began to work on the SCAMP platform and making tweaks to the spines to improve the climbing into the weekend.

Week 7

Thursday, August 3

Morning:

Today, Drew and myself will be flying out of town until Monday, so I won't be in tomorrow morning. We had some issues with 3D printing yesterday and this morning--we continue to have filament jams hours into a print job and it's unclear what we can do about it. We have contracted Alex, one of the members of the lab to use a Formlab 3D printer to print our parts over the weekend, so we can at least have something to work with on Monday. Hopefully, that goes well.

I will be leaving at noon and will update this blog as necessary when I land in Houston. I plan to do some reading on the plane of the scaling paper.

Wednesday, August 2

Morning:

This morning, Alessandro reminded us that we have a presentation to give at our lab meeting and we need to get ready for it. Although neither Drew or myself will be around, we need to prepare slides for Alessandro to present about our portions of the project. We are presenting what we learned from the first Super SCAMP iteration and how that informed our changes. I think I will also work on trying to connect the climbing mechanism to the computer and run the code on the servos to be sure that it is working as we expect.

Evening:

I was able to prepare the slides for Alessandro to present and sent them over to him. I also wired up the servo on the climber and tested them to ensure climbing. They seemed to work fairly well. There was a small piece of carbon fiber that was colliding with a separate piece of carbon fiber, but it was a piece that I could cut off without changing the mechanism. I cut it off after testing, so we are all set for testing on Monday.

Tuesday, August 1

Morning:

Today, I want to glue on the supports to the crawler, fix any last detail flaws, and CAD the attachment mechanism. If all goes well, I plan to test the crawler on the shingles in d'Arbeloff.

I'm also going to set aside an hour this morning to actually read the scaling paper (finally). I will attach my notes here.

Evening:

We had our weekly meeting today and talked through our progress on all fronts. It seems like we're planning on doing climb testing next Monday so I have a little more time than we initially anticipated. I finished the mechanism and the CAD but held off on printing because I want to make sure the holes are compatible with the drone body that Drew is designing. I also read some of the scaling paper and it didn't seem to apply directly to our work right off the bat but I think there might be ways for us to contribute to it. The drone won't be ready until the end of the day tomorrow so I won't be able to test climbing with it. I'm not sure if the best course of action tomorrow is to begin work on a crawling mechanism replica, since our goal is to have two for the demo. I may also try to get the mechanism crawling without the drone body, but I'm not sure if that's more effort than its worth. I could also start working on my poster for the end of summer SURI presentation.

Monday, July 31

Morning:

Today, I want to finish making changes to the crawler. I will need to:

- Make sure the servos are in the correct orientation.

- Glue down shafts/rods connected to the servos.

- Change the connectors on the servos to the light weight electrical connectors we want to use.

- Take the crawler to d'Arbeloff and test it on the shingles to determine how high the supports need to be.

I also want to place an order for the micro fishing hooks and order any other epoxy that we might need to make more spines.

Evening:

All done. I completed all the tasks above for today and I am feeling good about having it ready to go by the end of the day on Wednesday. All that is remaining to do tomorrow is to glue on the supports (add foam if necessary), CAD a new attachment mechanism, 3D print it and test the crawler with the previous Super SCAMP attachment.

In other news, Drew has been spending a lot of time trying to figure out how we can develop a graceful takeoff strategy. Our primary approach was to reverse the rotors in a way that allows us to create a moment away from the wall. Today, he experimented with the motors we currently have and has figured out a way to get them to run in reverse. This is exciting news!

Week 6

Friday, July 28

Morning:

Last night, I actually decided to spend some time looking for the micro fishing hooks and the epoxy. I emailed Matt to get some insight on the micro fishing hooks that I found and he gave me some advice. This morning, he also gave me some invaluable advice. He suggested that since I want to make a foot with 8 spines, I could just glue two four-spine feet together to get an idea of how it might work at the very least.

So I think I'm going to try to do that today. Create feet with 8 spines from the four spine feet. We could use this while we wait for the micro-fishing hooks to be delivered.

Evening:

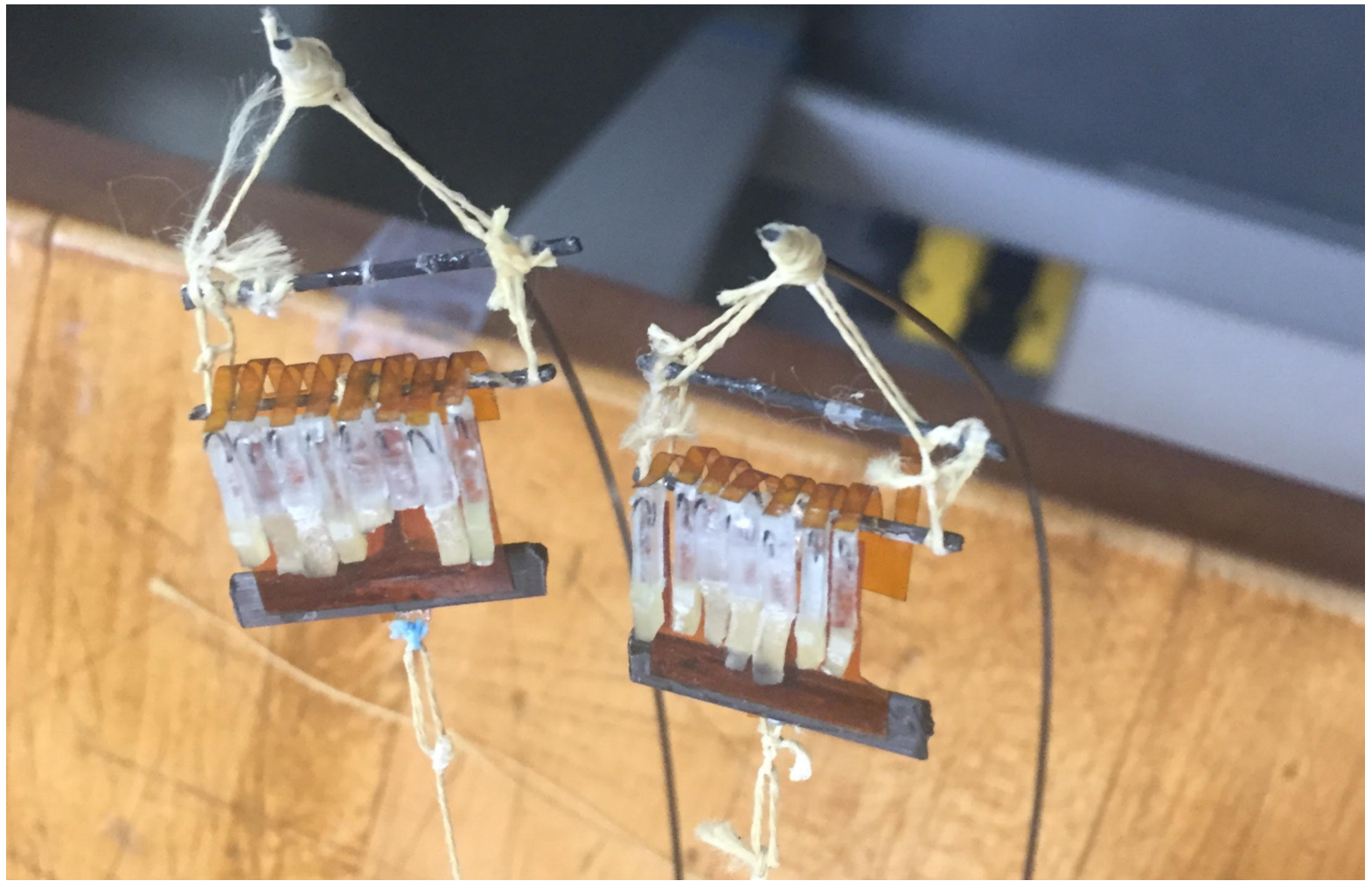

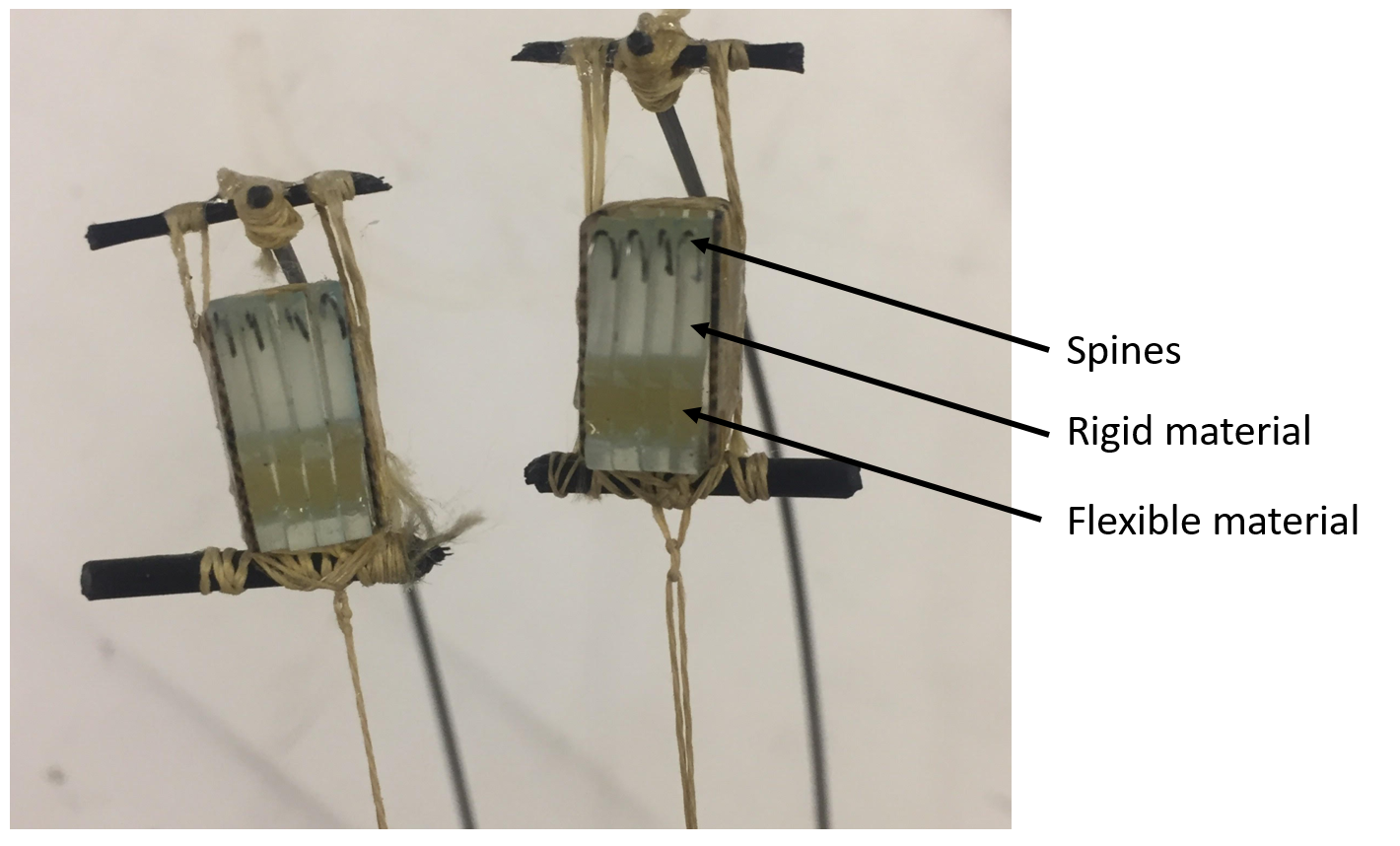

I was able to make the 8-spine feet and I made them to be pretty durable without permanently gluing them together. Here is a look at the spines:

Alessandro was very happy to see these and he hopes we can start testing them soon. He also would like me to continue to pursue manufacturing new spines with Capella, which seems like a good idea since we don't have any usable the spines left at all.

Thursday, July 27

Morning:

Today, I will continue building v2 of the mechanism and I hope to complete it today so we can test it tomorrow. I hope to get it crawling on the wall with some weight attached. One of the things I am trying to remain conscious of is the fact that we want to keep the weight of the entire system down so I am aiming to keep the weight of the mechanism under 25 g.

Evening:

I completed constructing the mechanism with the exception of attaching the feet. Alessandro advised me not to do this because he doesn't believe the new Kapton feet work very well in perching and climbing. He wants to create a version of the old SCAMP's epoxy-cast feet with 8 spines instead of 4 and more rigid epoxy at the front of the feet. I like this idea but I won't be able to get help creating this until next week due to the conference, which is pushing close to the August 4th deadline. I think I'm going to attach the feet that are available tomorrow and attempt to climb while I wait for Capella and gather materials to build new feet. We can't afford to wait.

On that note, Capella noted that we will need to use SDM manufacturing to do it and the materials we will need are micro-fishing hooks (sold for a Japanese hobby sport) and different grades of epoxy. I will also try to look for these tomorrow.

Wednesday, July 26

Morning:

Today, I will be building out the second version of the Super SCAMP crawling mechanism. My goal is to get it the body be more rigid than the body of the first version, while maintaining enough compliance to get it to reliably perch. I think we can get it to perch reliably on the wall and climb successfully.

Evening:

I didn't finish the construction of the mechanism and will continue working tomorrow. I have also been taking pictures of the process and I hope to create some documentation for this work later.

Tuesday, July 25

Morning:

Today is the beginning of the Living Machines Conference and we will be starting with a Bio-inspired Flight Workshop all day today. We worked on our demo a little this morning and we feel pretty confident about it being reliable for the demo this afternoon. I'm not sure how much, research-wise, I will be able to accomplish today and for the rest of the week but I plan to begin designing a new climbing mechanism so that we can begin testing for the ARL demo as soon as possible.

On a slightly unrelated note, I would really like to take some time to read the SCAMP Scaling paper. I feel that we have learned a lot in designing Super SCAMP that could be contributed to the paper before it is published.

Evening:

The demo went really well this afternoon and we are feeling optimistic about the future of SuperSCAMP. After the demo, Drew, Alessandro and I talked through the next steps of the project and developed a timeline on what needs to be completed in order to complete the project on time. We plan to have a new SuperSCAMP built by the weekend of August 4th to give Alessandro the chance to work on the takeoff control and refine the current control for 2 or so weeks before Drew has to leave.

I didn't get the chance to read the SCAMP scaling paper yet, but I think if all of my work is done by August 4th then I will have a lot of time to read the paper and possibly make contributions. I should probably read it earlier rather than later, though so I can start suggesting edits to Mark.

Monday, July 24

Morning:

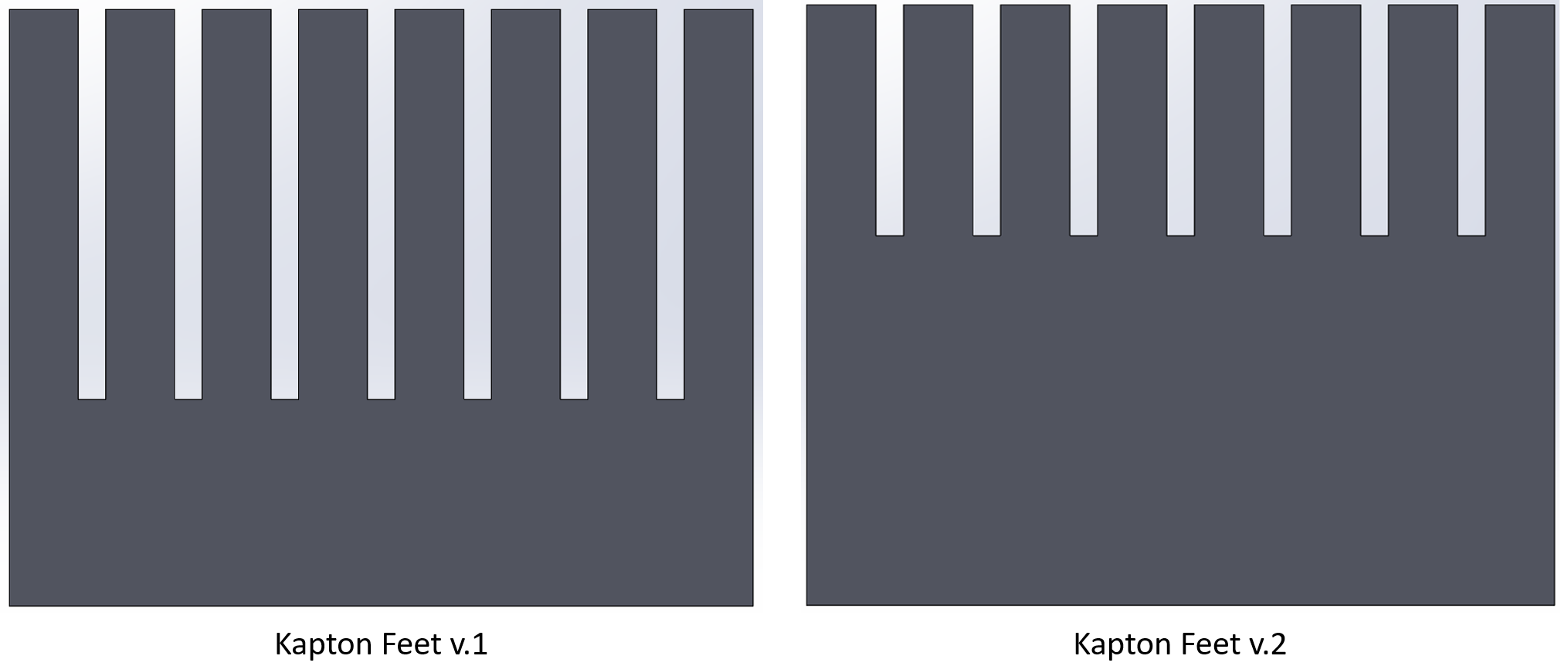

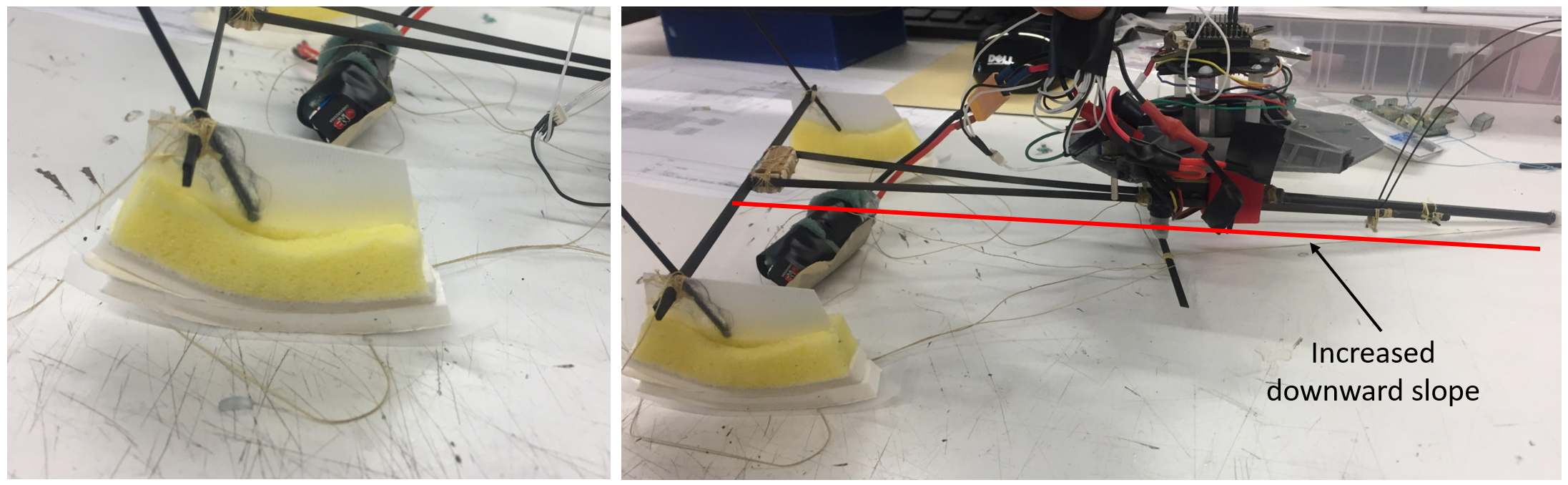

After some more testing this morning, we found that although Super SCAMP is perching reliably, some improvements could be made to the feet to make them more robust. In particular, the a few of the spines have been braking off the feet and I believe that this is because there is too much stress on each spine at the joint where the spine meets the Kapton. I plan to make more feet that will allow the feet to be able to move freely but also have a more secure attachment to the Kapton. This means making the slits in the laser cut Kapton shorter than the previous feet. To clarify, the slits are the same width but shorter in length (see image below).

Evening:

Here is a close image of the Kapton feet attached to Super SCAMP. As you can see one of the spines broke off so we are still having a little bit of trouble but we feel that it will be good enough for the demo tomorrow.

In testing, we had to cut the slits down a little with scissors (so the slits aren't as wide after the laser cut region). This seemed to give us more flexibility without compromising too much rigidity in each spine. We also changed the way the spring loaded foot guide was attached to give the foot more rotational compliance, which helped a great deal with reliable perching (compare the above image with the below image -- above image reflects the changes).

For the next iteration of the foot design, we want to try to use the first version of the Kapton laser cut with this foot guide design to see if this will improve the perching and climbing reliability.

Week 5

Saturday, July 22

(Late update 7/25/2017)

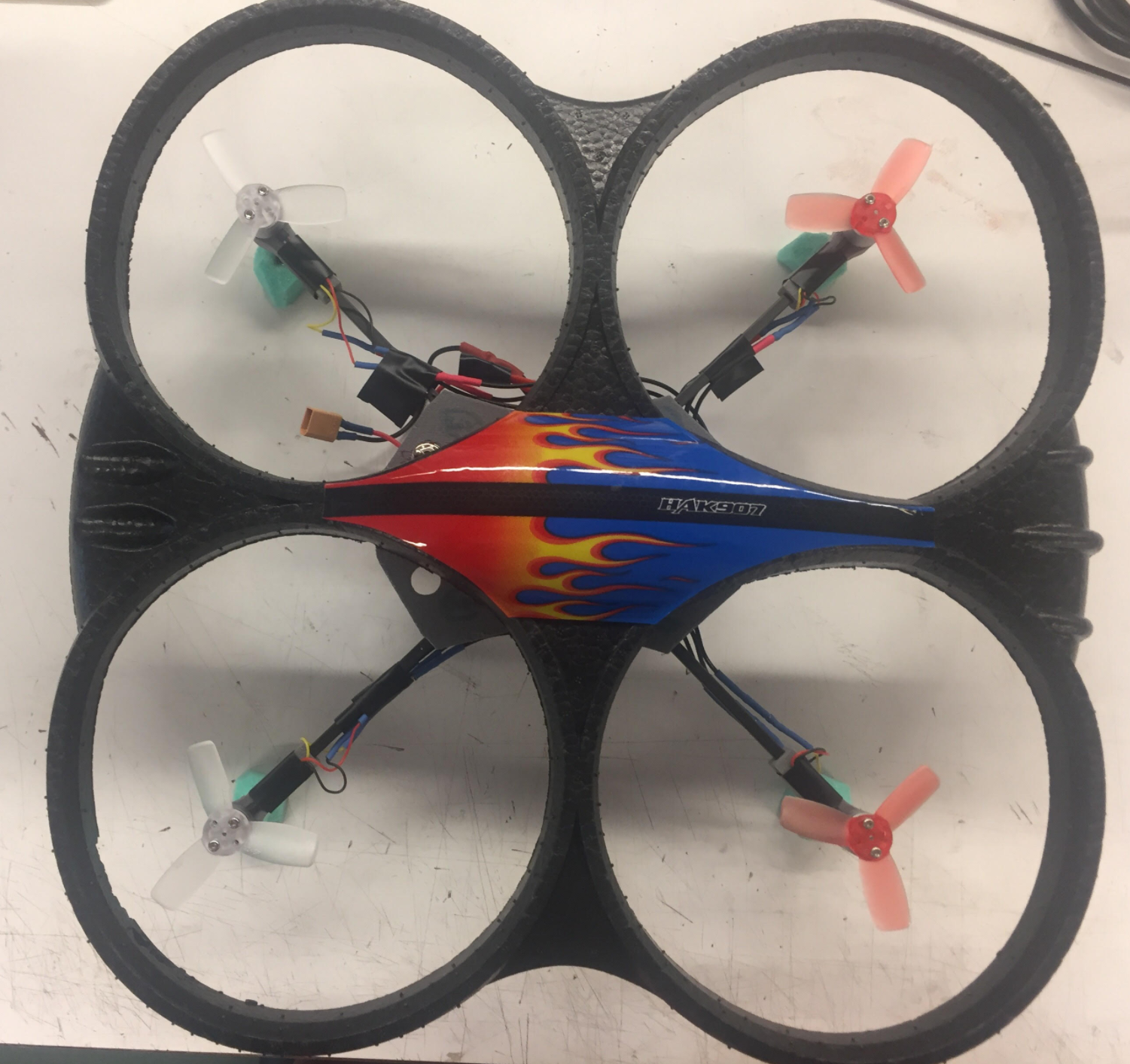

On Saturday, we worked on getting the demo prepared for Living Machines. Our goal for the demo is to show that we can reliably fly and perch, which will be done on our SuperSCAMP platform, and that we can climb up walls, which will be done on the previous SCAMP platform, which doesn't fly very well.

We first noticed that the SuperSCAMP crawling mechanism I created was too large and too flexible for the current quad. We found that the vibrations on the quad were putting in energy into the flexible carbon fiber rods on the crawler and causing resonant vibrations that were making the quad unstable to fly. For the demo, we tried to stiffen the carbon fiber by placing additional carbon fiber rods in the areas that were too flexible. We ultimately ended up cutting down the flexible carbon fiber areas in order to stiffen the structure. This seemed to work fairly well and eliminated the vibration modes that we were seeing. We were then able to successfully perch as can be seem in the following videos:

https://youtu.be/h29chJ2CbZk https://youtu.be/NZswR33dKqU

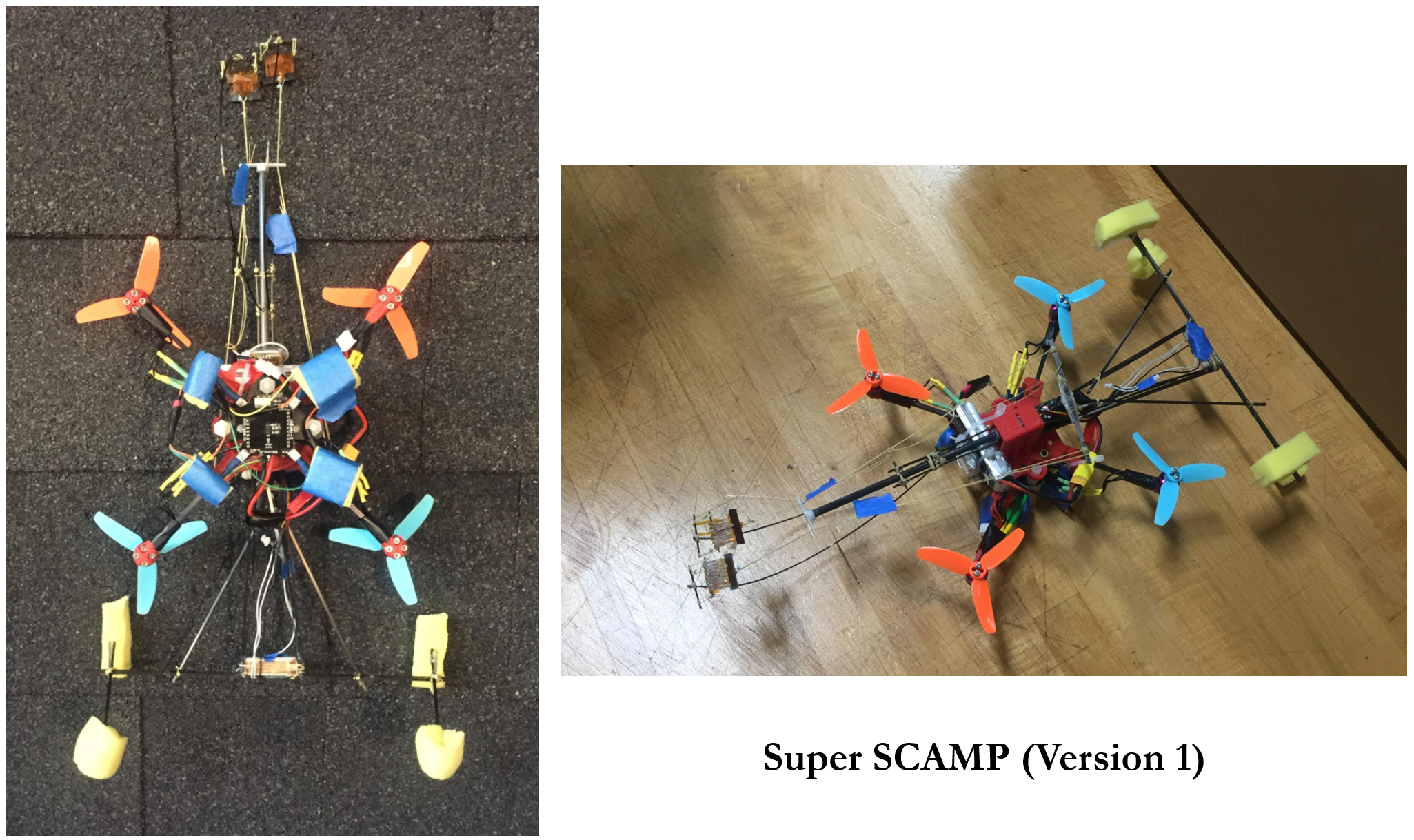

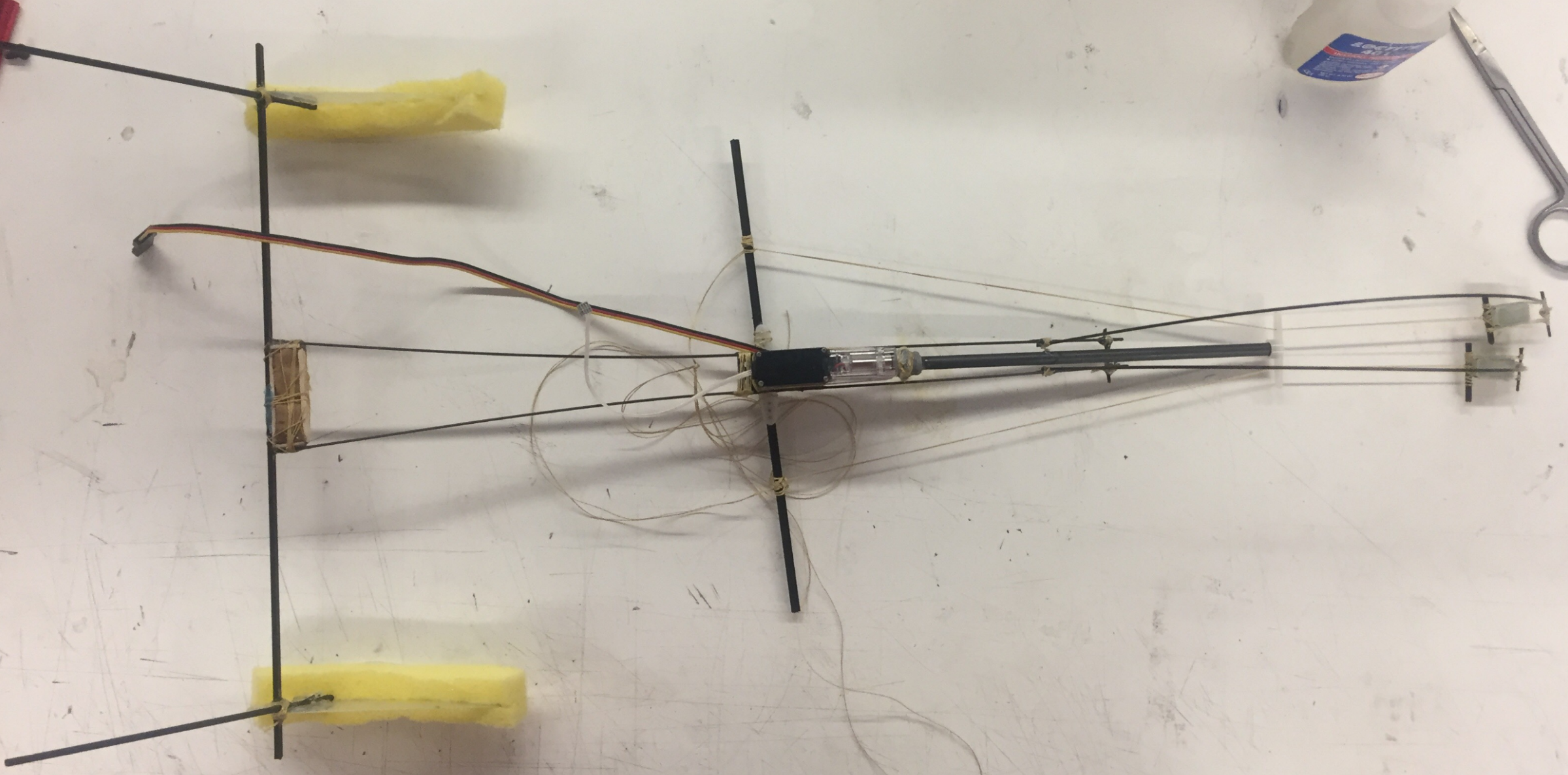

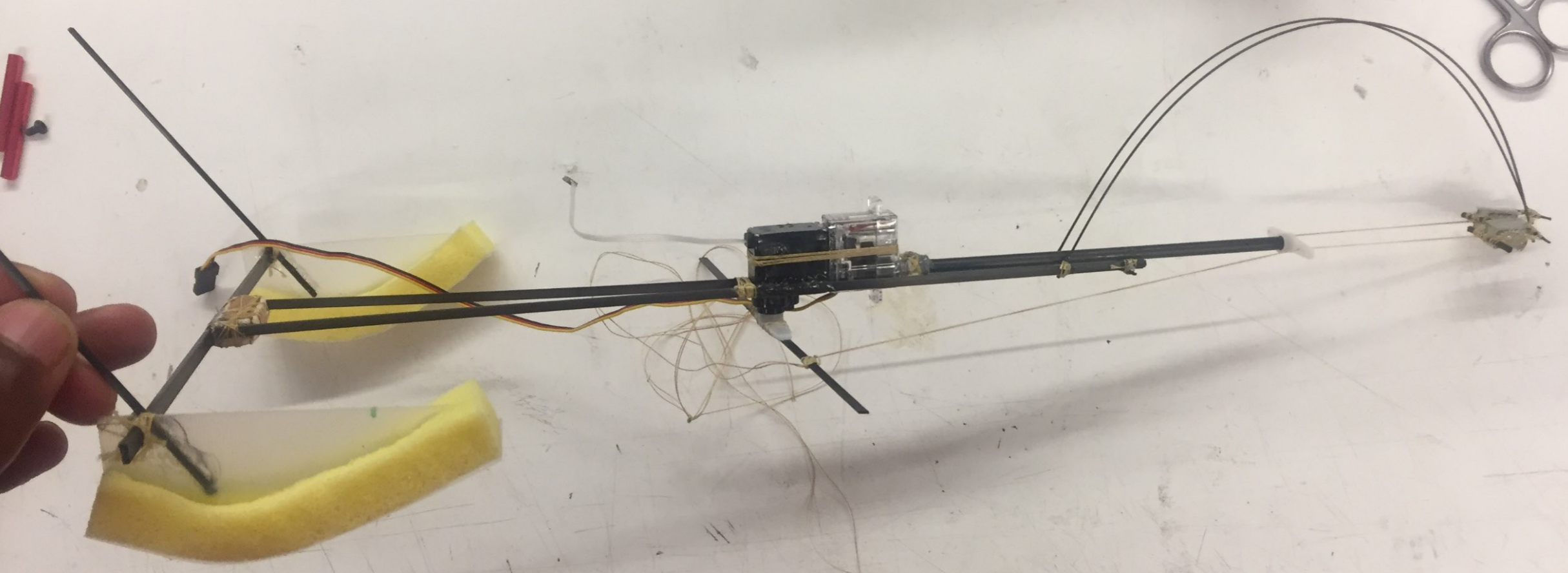

Here are some pictures of SuperSCAMP taken Saturday, July 22:

Friday, July 21

Morning: (Late update 7/25/2017)

On Friday, I was focused on finishing the feet for testing the drone. I came in to some good news to see that the quad Drew and Alessandro were working on the night before was working well and was very stable. I will try to post a video link here so that we can document what the drone looked like when it was initially flying stably. I came into lab a little later on Friday and we had the lab meeting and a MERL BBQ so I wasn't able to get to work until 1 or 1:30 pm. Drew wanted to start a new print for all the parts that we would need to make a new quad and so I helped him get that started while they continued to work on the new quad. My goal for the day was to finish the feet and have them ready to test on Saturday.

Evening:

I completed the feet and the 3D printed parts for Drew. I attached the new Kapton feet to the mechanism and it seemed to work pretty well and was able to perch on the roof shingles fairly reliably before I left the lab.

Thursday, July 20

Morning:

This morning, I will be laser cutting the Kapton to make the feet for SuperSCAMP in the CHARM lab with some help from Jana (one of Prof. Okamura's students). I will then continue putting together the feet. I hope to finish this and get it attached to the SuperSCAMP before the afternoon tomorrow.

Afternoon: (Late update 7/25/2017)

It took some time to complete the feet on Thurdsday and by the end of the day I think I had completed one foot and planned to complete the other foot on Friday. Meanwhile, Drew and Alessandro were working on building the quadcopter and I was helping when I could with things like 3D printing files, etc. Drew completed a version of the drone but ran into some challenges with the motors again. I believe one of the motors was not spinning properly again. It was imperative that we got a quad working for the demo that we plan to do for Living Machines, so Drew and Alessandro stayed overnight to work on the quad. I had outside work to complete that evening so I couldn't stick around to help.

Wednesday, July 19

Morning:

Today, I plan to begin and complete the second iteration of spines that will be modeled after the spines on the very first (or OG) SCAMP. I will create a foot with 8 spines with the body make of Kapton. Let's see how this goes.

Evening:

I began creating the second iteration of the spines by observing the ones created for the first SCAMP and using scissors to cut the Kapton. These cuts weren't very precise and led to poorly a designed foot. After talking with Matt a little bit about how the initial SCAMP feet were made, I learned about the UV Laser cutter in the CHARM lab that can be used to laser cut the Kapton and get mall profiles. I designed the Soldiworks files for the Kapton sheets I want to print and I hope to print them tomorrow morning.

Tuesday, July 18

Morning:

Today will be a big testing and debugging day for the crawler mechanism. Our goal is to get it working as quickly as possible. We are hoping to make quick adjustments to test certain aspects of the crawler that we think may be inhibiting factors to its crawling.

Evening:

We had a pretty good day of testing and there were flashes of a working mechanism from the crawler that were promising. There were a lot of problems that we found and addressed while testing, the biggest of which was the fact that the extend/retract arm continued running into the shingle clearing. To address this, we added some extra foam padding to the lower contact point of the mechanism to increase the slope of the mechanism (see image below). This seemed to fix the problem with the arm getting caught, and the robot began to crawl a bit more reliably.

This still wasn't enough to get consistency with climbing and the robot seemed to just fall a lot from the wall. We began to think that the payload may have just been too heavy to be carried by the few flexible spines that were on the robot. We, thus, began to remove things from the body of the drone and cut apart most of it, but to no avail. We brought it down from ~220 g total to about 150 g and we were still having trouble. In fact, when we just engaged the spines and tried to get the robot to simply perch on the shingles, it was very difficult and apparent that the spines could not withstand the weight. The robot kept falling.

So we decided that we need to make some new feet with more spines that will give the robot a more secure attachment with the wall and hopefully increase its reliability. Alessandro pointed out that we were trying to use the same feet as the original SCAMP which was about 3 times lighter that our current version of SCAMP and it is unlikely that it had a safety factor of 3.

Below are some links to some of the videos we took while testing (thank you, Will!). You can see the spines stretching and being strained during climbing. In fact, one of the spines broke while testing as you may be able to see.

https://youtu.be/7fWzsKHCSQI https://youtu.be/I0tHR9ThqN0 https://youtu.be/RWWJZvDEmk0

Monday, July 17

Morning:

Today, I'm going to help Drew out with some 3D printing of motor mounts and try to get some testing of the crawler going. I will spend the morning getting Drew's prints ready to go and starting them as well as working on making final-pass modifications on the crawler as we are planning to test it with the drone this afternoon. If time permits in the afternoon, I will also begin constructing new parts for the next version of the crawler. I think Drew will need some help today though so this may get moved to tomorrow. I'm excited for the crawling test though and I hope that goes well.

Evening:

I was able to print the parts for Drew without running into too many problems with the 3D printer. And in the afternoon, Alessandro and I began conducting some testing of the crawler mechanism on the roofing shingles. We connected it to the first version of the drone (the one that is ~175 g) using the attachment mechanism and started trying to get it to run. We ran into a few problems while testing that we tried to debug and correct. One of the issues we ran into was mechanical and had to do with how the feet were assembled. Essentially the servo header that was on the in/out servo was not aligned so the feet were running into each other as they climbed up the wall. There were some other problems that were hinted at while testing such as the servo head getting caught on the shingles as well as the extend/retract arm. We want to quickly fix the foot collision problem tomorrow and continue testing.

Week 4

Friday, July 14

Morning:

This morning, after lab meeting, I had a short talk with Drew about out progress. He informed me that he will be attempting to make a smaller quad that was lighter and less bulky. I should take a picture of the bigger quad and attach it here, so that we can see the progression of the quadcopters. The smaller version of the quad means that we would need a smaller climbing mechanism. So I plan to begin working on the next generation of the climber once I get a CAD model from Drew with the dimensions of the smaller drone. While that is happening, I also want to continue testing the current crawler mechanism and trying to see how it works on surfaces.

In other news, Alessandro and Drew are conducting testing of the drone. And there is video evidence that it went pretty well this morning. It seemed like the gains of the control parameters were too high and the quad was jittery but it was stable, which is great progress! So here's what we have today:

- Soldering the wire with the correct connector onto the servo lines on the crawler

- Change the CAD for the attachment mechanism to size down to the smaller motor. Also make changes that we mentioned previously.

- Add holes to the drone body in Drew's CAD and upload to Box folder

- Make a box to add weight to the top of the crawler for testing.

- Prepare to test the crawler mechanism on Monday

Evening:

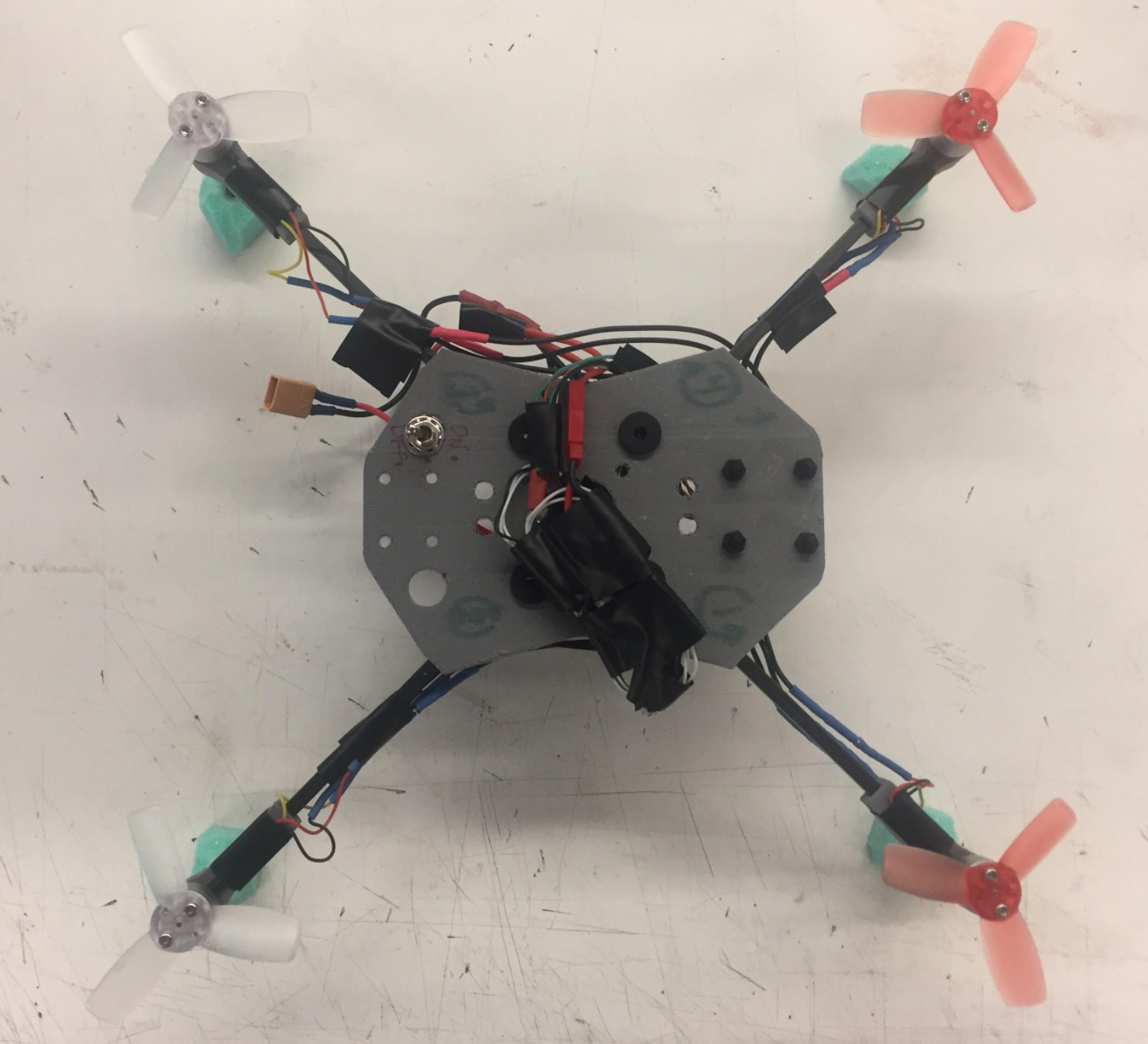

Here are some photos of the current SCAMP drone:

The drone looks great and was well-designed by Drew, obviously. But as I mentioned earlier in this blog, it is quite heavy (~175 g) and will not fit for our application. I believe Drew will be designing another one this weekend and maybe 3D printing them Monday.

I completed soldering wires and changing the CAD to add holes for the mounting device on the drone. This will be helpful for Drew when he begins making the next version to know where other parts will fit in to the assembly.

I'm not quite ready to test the crawler on Monday but I don't think there is much left to be done to be able to test it. I think I would just need to grab the current drone and mount the crawler on it and we can easily use that for testing. Since we are effectively done testing with the drone (since we're creating a new one), I will have the opportunity to use the drone for some crawler testing.

Thursday, July 13

Morning:

Today, I plan to work to address the crawling dilemma by changing the software and hopefully get the mechanism to begin crawling on the wall. I also want to look at the schematic for the D-SUN voltage regulator and integrate it to the schematic made by Drew so we can begin to find space for it on the quadcopter.

Evening:

With a little more testing with the crawling mechanism, we found that we were able to get it working. It turns out that the pins were just in the wrong position and we needed to switch them to get the climbing working properly. Some of the attachments on the foot were running into each other and while the crawler was climbing, but I fixed those short after. A larger problem, that we may need to keep an eye on is that the extend/retract motor kept jamming after some time running. It would get to a point where it required too much torque to turn the gears and get stuck. When this happened, we also weren't able to turn it with our hands. After a few moments of waiting, it would be working again and we could easily turn it. I looked into this a little bit and found this post (https://www.rcgroups.com/forums/showthread.php?1782899-Bad-Batch-of-HiTech-HS-65MG), where someone was having the same problems with the Hitec HS-65MG. The respondents of the post seemed to think one of two things is the culprit: 1) when there isn't enough clearance around the servo case, pressure from the frame will distort the plastic servo case, causing the gears to bind and jam, or 2) the servo may be a fake one/knock off produced by a third party. My inclination is that the former is likely the case. If you scroll down this thread, you can see that where the servo is located, I over-secured it by adding rope in the lateral and longitudinal directions. this may be creating the pressure that is causing the gears to jam after a while as the motor heats up while running and the plastic expands.

I also got a chance to work on the voltage regulator. I soldered the wires of a connector to the voltage regulator. These connectors will supply 5V from the regulator to the servo motors of the crawling mechanism. Drew also needed to use it to supply 5V to the Big Quad Deck so he incorporated it to the drone.

Tomorrow, I need to take a look at some CAD: my attachment mechanism and the drone body. I need to add some holes to the drones body for the attachment mechanism. I would also like to connect the crawler to the body of the drone once testing is complete tomorrow and try to get it to crawl up the roofing shingled wall we created at the back of the lab.

Wednesday, July 12

Morning:

This morning, Alessandro and I spent a little more time looking into trying to get the Crazyflie to work with the servos on the climber. After doing a bit of debugging, we found out that there are problems with a few of the Crazyflies in the lab. Some of them won't turn on when you plug in the batteries and others seemed to be fried (I think I may have fried one yesterday). Furthermore, we found out that there are some problems in the Crazyflie firmware that keep it from uploading the code properly. One of the communication pins to the servo was working but the other was not giving a signal at all. Alessandro is going to spend some time trying to figure out what is wrong. He also wants me to try to figure out what is wrong with the other Crazyflies, especially the ones that are not working and verify that the ones we think are fried are indeed fried.

Along with that, the following tasks are what I hope to do today:

- Finish CAD part - reduce the amount of material needed to print to save weight

- Print CAD part

- Look up voltage regulator schematic and begin to design circuit for the crawler to attach directly to the battery - talk with Drew

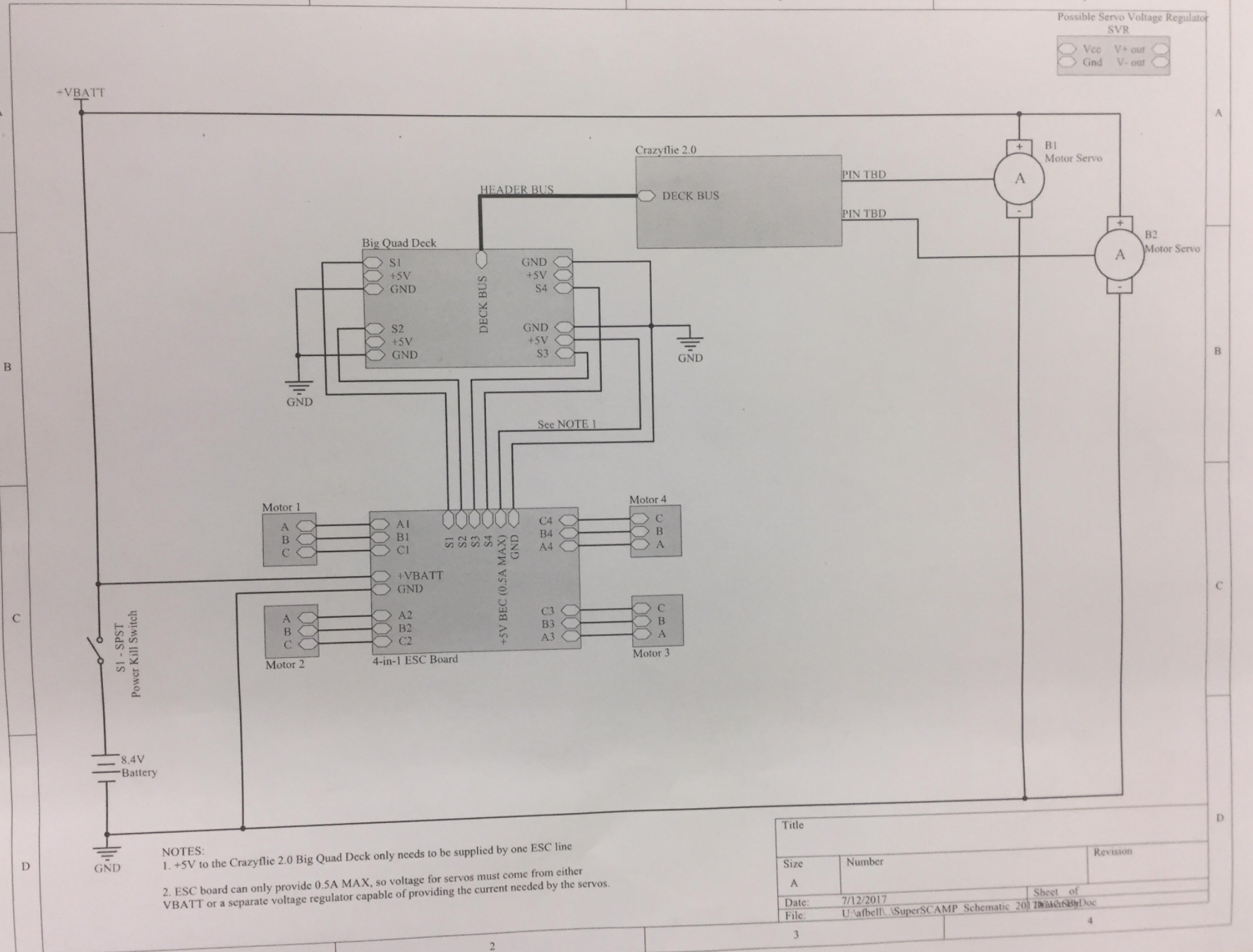

The final task refers to a talk that I had with Drew about the power electronics of the drone circuit. As it turns out, we will be using a 7.4V battery (max 8.4V) that will be connected to the ESC board to control the motors on the quadcopter. The ESC board then has a battery eliminating circuit that will send 5V to the Crazyflie Big Quad Deck. This 5V will then be used by the Big Quad Deck to power all the sensing, logic operations, and computation that are happening to control the quadcopter and the climbing mechanism.

This means that we will not be able to use the voltage that is supplied to the Big Quad Deck to power the servo motors so we will need an alternative way to do so. An immediate thought is to connect the servos directly to the batteries, but given that the battery could output 8.4V, this may not be good for the servos which are rated at 4.8 - 6 V. Thus, we want to include a voltage regulator in the circuit to drop the voltage from 8.4V to around 5V or so to be supplied to the servos.

Evening:

Below is a schematic of the nominal circuit that Drew created. As you can see, the servos are connected directly to the battery's positive lead and ground. What we want to do is include the voltage regulator in between those connections.

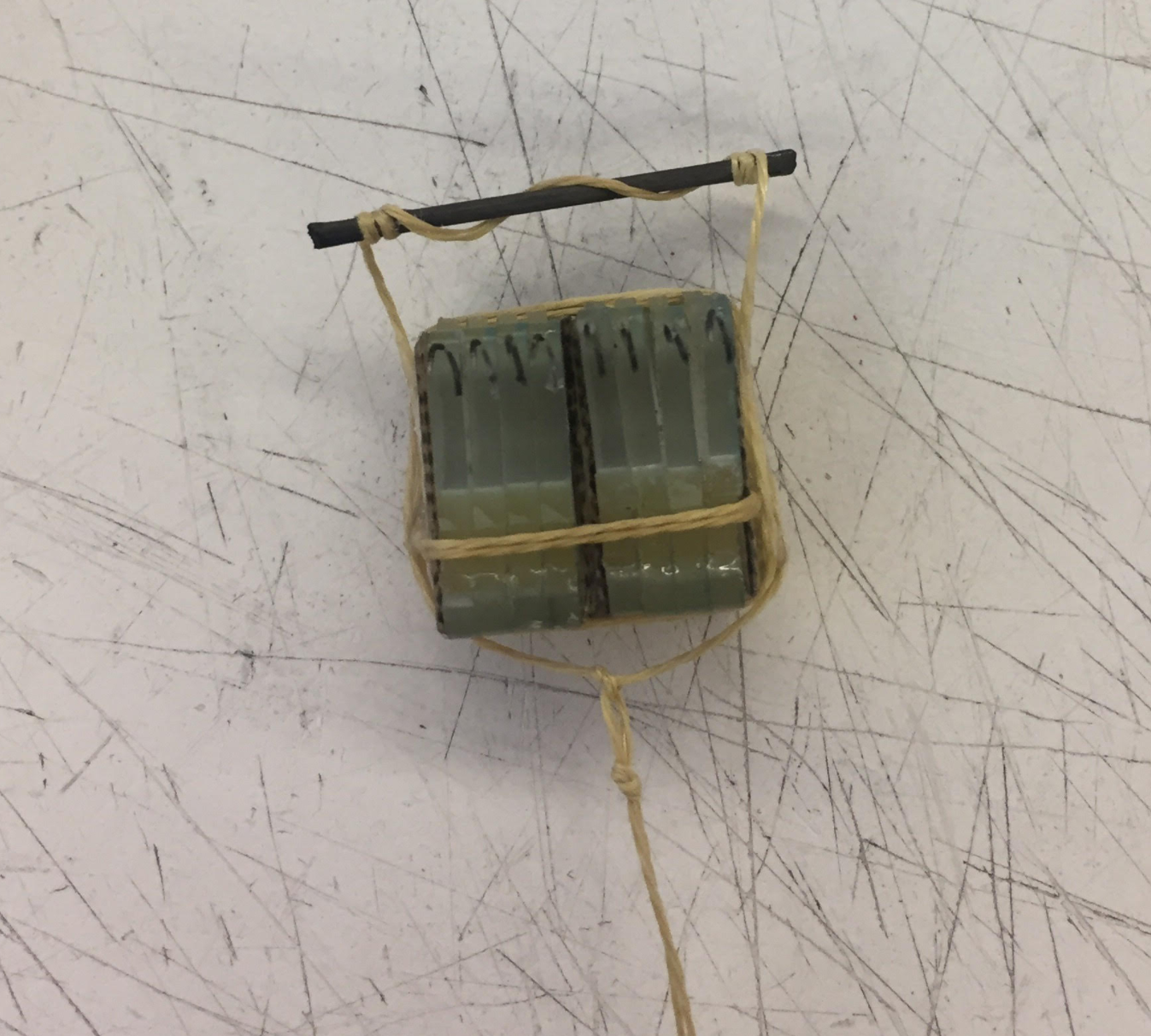

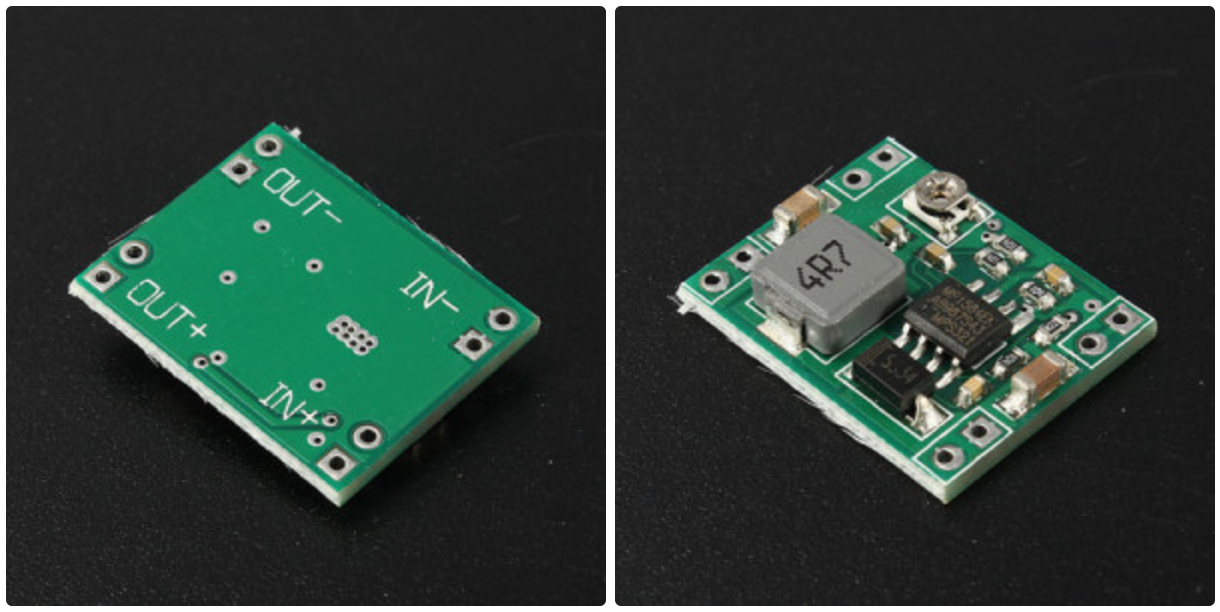

The voltage regulator we plan to use is a D-SUN 4R& Mini Voltage Regulator (pictured below). It can convert 4.5V to 28V (2S, 3S, 4S all the way up to 7S) battery to 0.8V to 20V (which includes the most used 3.3V, 5V, and 12V) by the trim pot. The maximum current it can provide is up to 3A. It is also very light weight (~2 grams). At 5V, our servos seem to be only pulling 0.5A together so using this regulator shouldn't be an issue.

I didn't have enough time to look into the schematic of this circuit today but I plan to do it tomorrow morning. Today, I worked on getting the climbing of the SCAMP mechanism going. After some debugging, we were able to get the servos to work properly and the Crazyflie to supply logic to the servos. I took a rough video showing the work, see it here (https://youtu.be/rKcZAqWTT_k).

As you may not be able to detect at first glance, there is a bit of an issue with the crawling. If you look closely, it looks like the robot would be crawling down the wall rather that up the wall. We will now begin to look into the code to get the crawling going in the right direction.

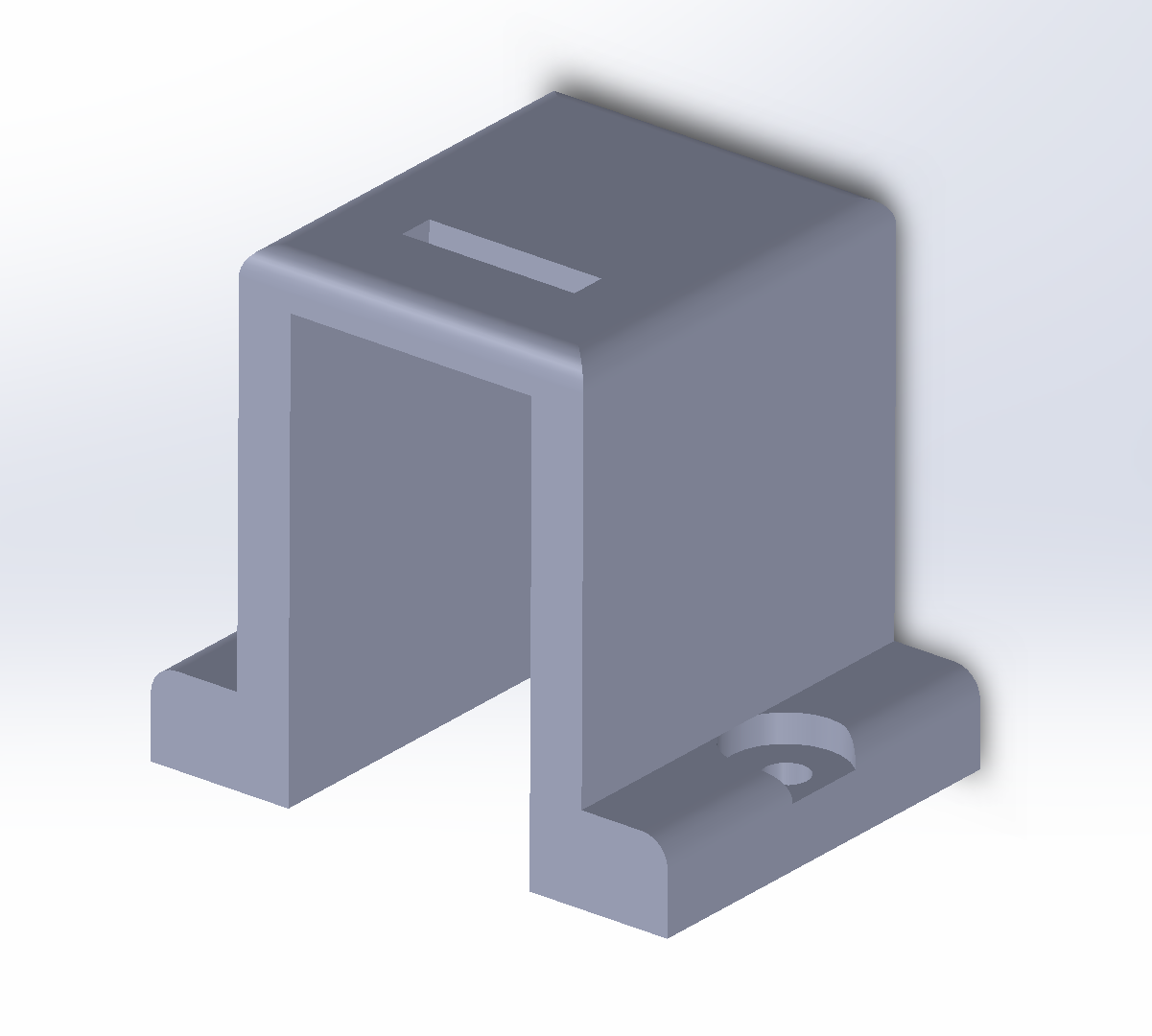

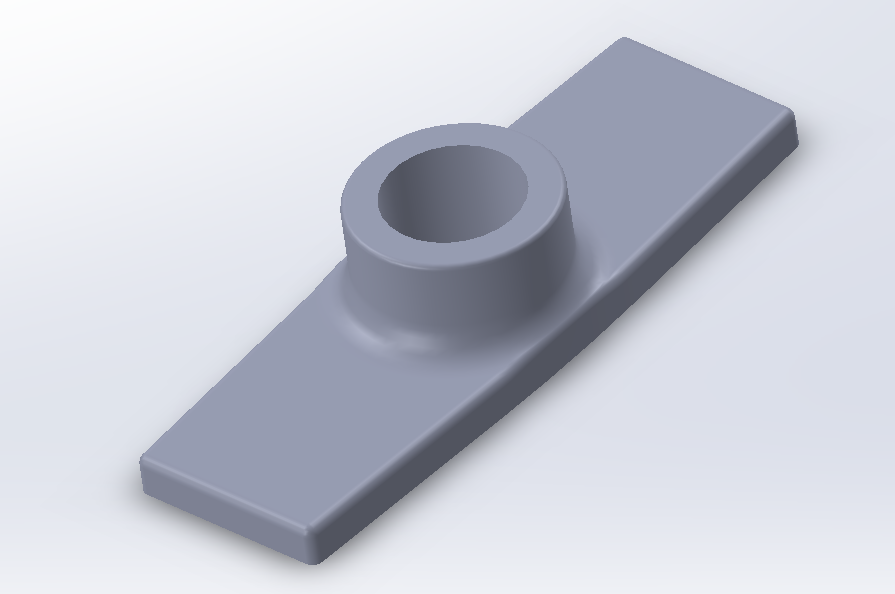

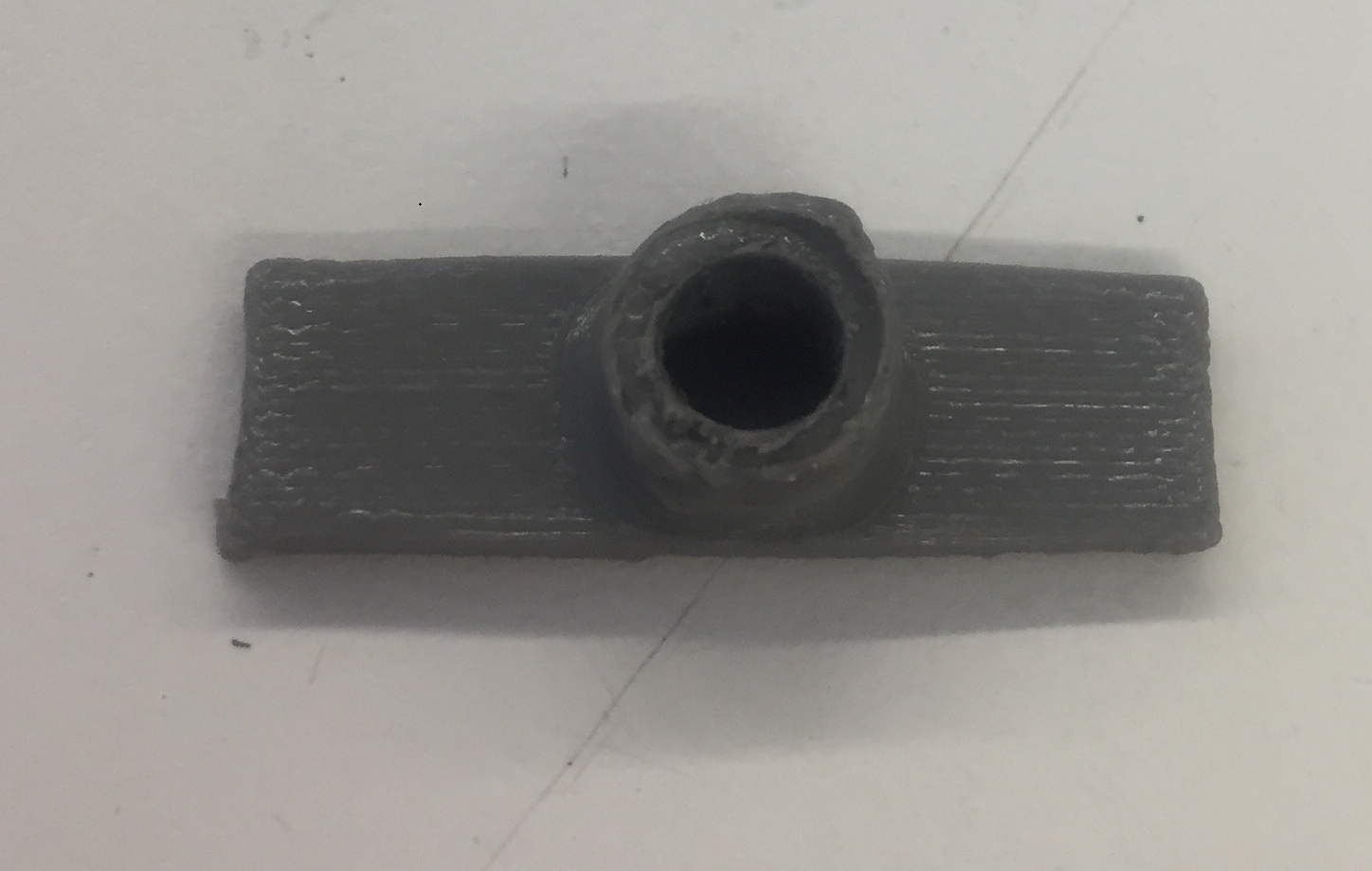

I also completed the CAD model and printed a first version of the attachment mechanism as seen below.

It seemed to fit on pretty well, but there are a few modifications that I would like to make. I would like to increase the size of the slit for the top of the motor slightly; add ribs to the side of the mechanism to make the body stiffer. It is important to keep in mind that this mechanism will change when we change the in/out servo motor since it attaches to it. I will make the adjustments to this one and I believe they will translate to the new mechanism with quite easily with some simple dimension changes.

Tuesday, July 11

Morning:

Today, I am going to continue working on getting the crawler mechanism to crawl. I need to get into the Crazyflie code to understand what is going on with the crawling algorithm. I think I might try to convert the code into Arduino and use the Arduino to control the crawling since I don't have access to all the software required to use the Crazyflie directly. I think it will take less time to convert the code to Arduino than it will to learn the Crazyflie platform.

Evening:

Today, we had a perching meeting and I needed to run to Santa Clara to get some carbon fiber tubing parts for Drew, among other errand, so I didn't have much time to work on the crawling mechanism. I spent a little time in the morning trying to convert the crawling code from the Crazyflie platform to Arduino for testing. But this was a fruitless effort and Alessandro told me in the afternoon that I was free to use the Crazyflie along with the computer that he has been using for the Crazyflie control development. This way I don't need to install the Virtual Machine software in my computer to do this.

Unfortunately, I had a little bit of difficulty getting the Crazyflie code to control the servos. I remembered that the Crazyflie actually can only output a 3.3V and probably doesn't have enough current output to control the servos on it's own. When I tried to control the servos with an Arduino and a power supply, I had a lot of success. I need to figure out a way to get the Crazyflie to control the logic of the servos while I power the servos with a power supply.

Monday, July 10

Morning:

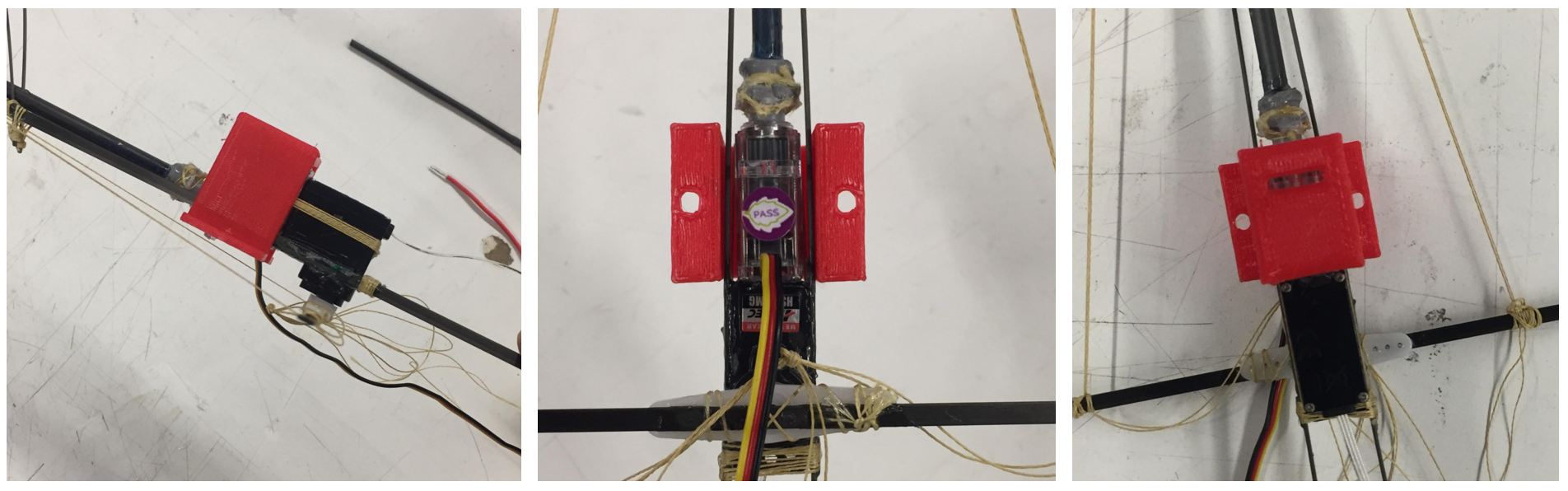

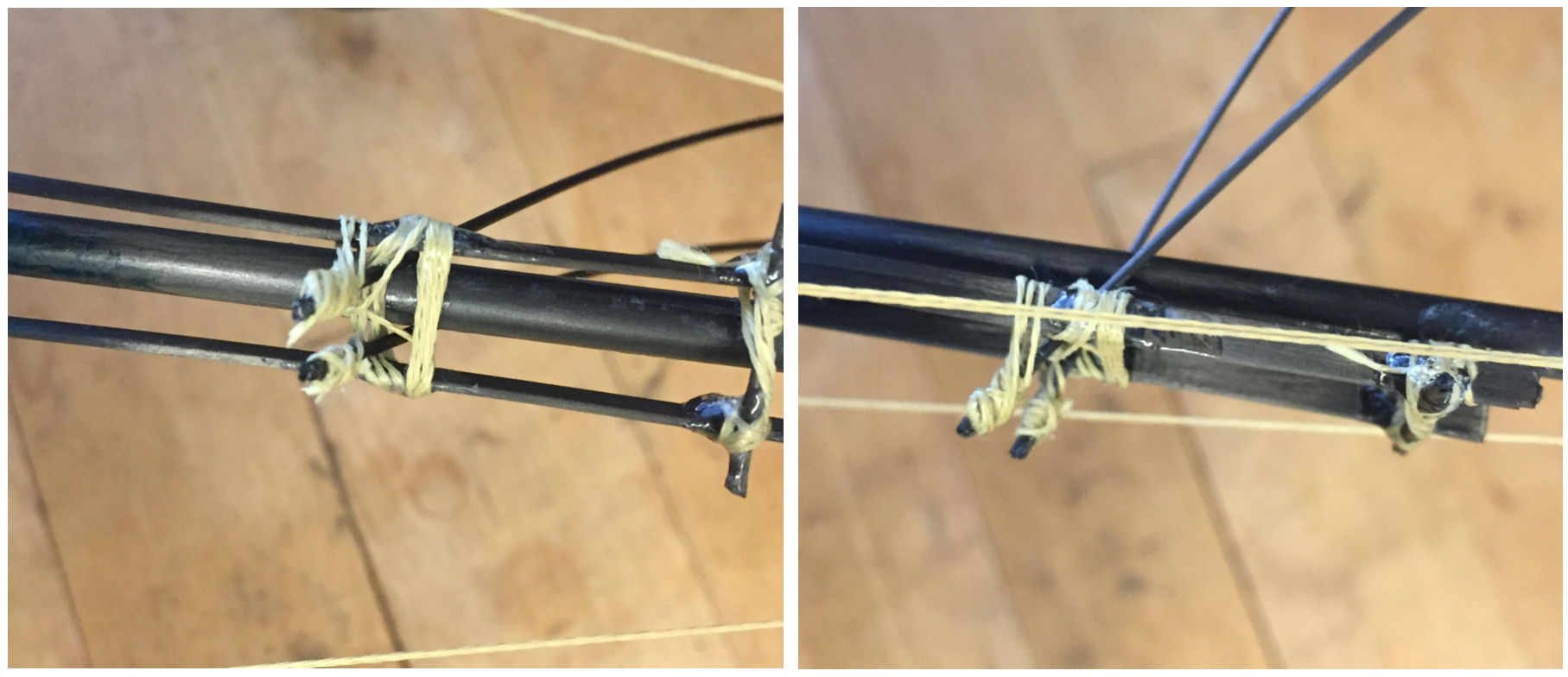

Drew, Alessandro and I came into the lab for some time this weekend to work on the SCAMP robot. I worked on the changes to the foot of the crawler mechanism and I was able to address the issues with the feet of the mechanism pitching up by using the roping in a clever way. I constrained the crawler's legs in the axial and vertical directions using string, as seen below in the figure on the left, while still allowing it the freedom to rotate/extend as necessary, as shown the figure on the right. When the legs were glued to the frame, they were unable to rotate in this way.

Today, I will be cleaning up the changes in the mechanism design and making sure that there are no obvious issues that will come up during climbing. Drew also shared the CAD model of the drone with me, so I also hope to make some additions to my CAD model for the attachment mechanism and add it to the assembly to see how it fits before printing it out. I will also begin working on getting my mechanism to climb independently, so that when the drone is ready, we can attach the climbing mechanism with some confidence that it might climb or that we aren't too far away from getting it to climb.

Evening:

Drew and Alessandro has some setbacks today while testing the drone with the Crazyflie. I believe there was a short somewhere in the circuit that kept one of the motors from working. After a while, they reported that none of the motors on the drone were working at all. This was compounded with the fact that the drone was also heavier than we anticipated, weighing in at about 175 g. We began to discuss ways to reduce the weight of the drone and we feel comfortable that we will be able to do that.

I will also need to reduce the mass of the mechanism in future iterations. Right now, it weighs about 37 g which is way higher than we want it to. When discussing with Mark, he mentioned that we wanted it to be ~20 g. But given that the the extend/retract motor weighs 11.2 g and the smaller in/out motor that will be used for the next iteration weighs 4.5 g, we will already be at 15.7 g with the motors alone. I think it is more realistic to shoot for ~25 g of total weight for the crawler. This gives us ~10 g to make the rest of the crawler, which will be difficult but is more reasonable.

I was able to complete all the changes that I am making to the climbing mechanism (for now) and began to work on getting it to climb. The first step was to get the servos aligned in the correct orientation for the in/out and extend/retract motions. This means that I set the 90 degree point on the servos to be the center of the movement on both servo. I completed this using the servo library on Arduino. I also took some time to attach molex connectors and a new connector onto one of the servos that initially had a non-standard connector. I wasn't able to make too much progress on the CAD model because I think it's more important that I spend time on the climbing right now. I also am not sure if there will be changes made on the drone body that would make my work obsolete in a few days, so waiting a little while will be beneficial.

Week 3

Friday, July 7

note added by MarkCutkosky

- Elastica stuff

- Dan Soto's thesis: https://searchworks.stanford.edu/view/8714770

- Nice python code for tapered elastica: https://github.com/dsoto/modeling (uses notation from thesis)

Morning:

We had a lab meeting and a lab clean up this morning so most of the morning was used to complete those things. But I hope to start working on the CAD and to look through the code for the Crazyflie to see how the servos are controlled. Drew and I may work on some CAD together later and trade CAD files to maintain compatibility while we design. Something to keep in mind when designing is making sure my attachment mechanism is able to be flat against the drone where it will be attached.

Evening:

I designed the attachment mechanism CAD part that would fit over the motor and attach it to the drone using dimensions from the motor's specification sheet as well as measuring the dimensions of the parts on the SCAMP mechanism. A CAD model of the part is shown below.

Towards the end if the day, I began to think about how to improve the SCAMP mechanism. A problem that I noticed was that when the feet reach the limits of their extension, they began to pitch up a non-negligible amount which would cause them to lose contact with the wall while crawling and potentially create a moment that would cause SCAMP to flip. After some investigation, I realized that the reason this was happening was because I glued the "legs" of the robot (the flexible, spring-like pieces of carbon fiber) to the the body of the crawler and this created a reaction moment at this joint, opposing the free motion of the feet and giving it a tendency to pitch upwards. I will address this problem this weekend by detaching the glued feet and placing them in an orientation that allows for free rotation.

Thursday, July 6

Morning:

Today, I will continue building the crawler mechanism. I need to add the feet/tendon mechanism and test how it works. I will also begin to compile a list of good building practices. I might even try to make a step-by-step tutorial on how to build the mechanism when I am building the next version of the mechanism. I didn't take enough during the construction this time, so I don't think this will be possible for this version.

Evening:

I completed the bulk of the construction of the SuperSCAMP crawler mechanism today. What's left is just fine-tuning some components and securing all the tendons once this is complete. An image of the mechanism is included below.

Tomorrow, I will begin to design the attachment mechanism in CAD that will be used to attach the mechanism to the drone. Drew has made a lot of progress and has a body for the drone that will likely be used on the real SuperSCAMP, or a small deviation from it. Thus, I can start considering effective ways to connect/remove the mechanism.

Wednesday, July 5

Morning:

Today, will mainly be a building day. After a valiant attempt to find the motors (calling FedEx, going to the post office, and asking Gosia--the admin--where it might be), I decided to start building the mechanism with the different (larger) motor. So the goal today is just to build as much as possible.

Evening:

As it turns out, shortly after I started building the mechanism, I got a note from Gosia letting me know that the motor was in the adjacent building, CDR (Center for Design Research). It was too late to change what I had already started so I just decided to continue building. My plan is that I can then use the smaller motor to make the second version of the mechanism. I imagine there will need to be a second version as we learn lessons and make changes after testing.

I made a great deal of progress with the crawler. All that is remaining is to attach the feet of the crawler, and it will be completed tomorrow morning.

Tuesday, July 4

I did not go in the lab today, due to the 4th of July holiday.

Monday, July 3

Morning:

Today, I was hoping to start putting together all the parts for the mechanism as soon as I received the motor from Sparkfun. Unfortunately, I can't seem to find the package anywhere although the tracker notes that it has been delivered. Thus, I think I will spend some time doing the CAD for the design. Over the weekend, Arul suggested that I familiarize myself with OnShape and use it for CAD so that the parts will be in the cloud and can be easily accessed by anyone in the lab who might need it at a later time. I also want to spend some time reading the scaling paper that Mark sent me. It is an incomplete paper that details some of the findings of people in the lab previously in regards to scaling the SCAMP platform to bigger drones.

Evening:

I am still motor-less and I am now considering just using the motor that I have here (one of the motors that just so happened to be in the lab - the HS-45HB) so that I can continue to make progress. I made significant progress on the CAD today, but I wasn't able to figure out how to model the flexibility in the real system in the CAD. I am probably going to ask Drew to help me with this. All in all, today was a pretty slow day and I was a little unhappy with my progression.

Week 2

Friday, June 30

Morning:

Today, I have three simple goals, while I'm still waiting on the last motor to arrive. A note to self for future iterations -- use Amazon, even if it might be slightly more expensive. The shipping speed goes a long way! Here are the goals:

- Cut foam for landing damper.

- Continue to CAD pieces that are now on the crawler mechanism.

- Think about how to make the torsional stress piece more robust.

We also have our lab meeting presentation today which should be fun.

Afternoon:

I spent most of the morning preparing for the lab meeting presentation, but it went very well and was very fruitful. A few ideas/notes that came from the presentation was that #) we can't necessarily depend on proportional scaling of the component dimensions from the initial crawler to the one we are making now and #) the in/out shaft that experienced a lot of torsional stress can be made more robust by increasing the diameter of the shaft as well as making the part out of hollow carbon fiber tubing.

In the afternoon, I was luckily able to find a hollow carbon fiber tube that press fit perfectly into the top end of the servo connector that we are using to guide the rope that connects to the feet. To connect this tube to the in/out servo, I designed an adapter that could attach to the servo connector with glue. The other end of this adapter contains a press fitted hole for the carbon fiber tubing. I designed and 3D printed this part as seen in the images below.

Thursday, June 29

Morning:

Tomorrow, we (Alessandro, Drew and I) will be giving a presentation of our progress and our anticipated work for the summer during the lab meeting. Thus, I will be spending most of the morning working on my slides for the presentation. I also need to complete the safety training for the lab before today at 2 pm when the building safety expert is coming in to complete the training. So I will also be doing that this morning. In the afternoon, I hope to continue my work on building the mechanism. Thus, the tasks for today, enumerated, are:

- Create slides for lab presentation tomorrow morning.

- Complete lab safety training.

- Meet with Drew and Alessandro to finalize slides.

- Complete first foot of mechanism and begin creation of second foot.

- If time permits, make adjustments to CAD parts made and build assembly of crawler in CAD.

The goal for building is to be ready for full assembly once the motor arrives.

Evening:

All the tasks for today were completed with the exception building the CAD parts and assembly. I was able to create both feet that will be attached to the mechanism. I also met with Drew and Alessandro for a brief while and we talked about our slides for tomorrow's presentation in addition to SuperSCAMP in general. One issue of contention was that it turned out the motors we were planning to use have different voltage specifications. As you may recall, we were planning to use the Hitec HS-65MG for the extend/retract motor and the HK-5320 as the in/out motor. The HS-65MG's voltage range is 4.8 - 6 V and the HK-5320's voltage range is 2.8 - 4.2 V. Thus, if we wanted to use these motors, we would need an addition to the circuit to send specified voltages to these components. This addition would complicate the circuit, with minimal benefit to the functionality of the drone.

We decided to change the in/out servo motor to the Hitec HS-5035HD, which was the motor that was used for the original SCAMP's extend/retract motor. This motor also has an operating range of 4.8 - 6 V, just like the HS-65MG. Thus, we can supply 5 V to the entire circuit and we wouldn't need additional circuitry to redirect voltage.

Wednesday, June 28

Morning:

Today is a building day. I will continue to work on the SuperSCAMP mechanism prototype and post updates as necessary.

Evening:

I made a great deal of progress today. I finished the frame of the mechanism and began working on one of the feet. I realized that making the feet, which involves creating the tendon and then attaching the foot onto it, is a non-trivial and non-systematic process. It takes a few tries to really understand how I can get it to work properly, but it was an interesting challenge and I feel better about moving forward. My building process will be slightly delayed due to waiting on the in/out servo motor to arrive. I ordered it last Friday and I expect it by Friday or early next week. Waiting will give me some time to really work on the feet and make them as robust as possible. It may also give me time to make progress on my CAD model.

Here are some images of the progression of the frame:

Tuesday, June 27

Morning:

This morning there is some work being done in the lab (on the roof and things) and we are unable to be in the lab to work. I think I will take the morning to try to CAD the crawler mechanism parts. I'm not sure how I will add the flexibility of the carbon fiber into my model, but I am willing to learn. Besides that, I hope to continue construction of the crawler mechanism. I should definitely try to take some more pictures and add these to this wiki this evening...stay tuned. I hope to complete building the frame today. I think that the other parts of the construction, such as attaching the spines will be a little more difficult. So, for today, we have:

- Create a mock-up of the crawler mechanism in CAD.

- Continue construction of the SuperSCAMP crawler mechanism.

- Take pictures of the progress.

Evening:

I began to design the parts in CAD but quickly realized that I wasn't exactly sure about how all the parts would fit together and what the dimensions would be. I decided it best to then continue working on the prototype crawling mechanism. After I finish building the prototype, I plan to then finish the CAD renderings.

Here are some pictures of what I was able to make today: Attach:SCAMP_Crawler1 Attach:SCAMP_Crawler2

It is meant to be the back frame of the crawling mechanism, as seen towards the bottom of this photo of the original SCAMP:

Monday, June 26

Morning:

Today is an exciting day! Drew is back and we will begin the construction of SuperSCAMP! Today my tasks are as follows:

- Cut out pre-dimensioned carbon fiber pieces for the crawler mechanism on SuperSCAMP.

- Build out as much of SuperSCAMP as is possible without receiving all the parts that were ordered on Friday.

- Talk to Drew and Alessandro about the timeline for the project, prepping for ICRA and getting ready for the Living Machines demo.

Evening:

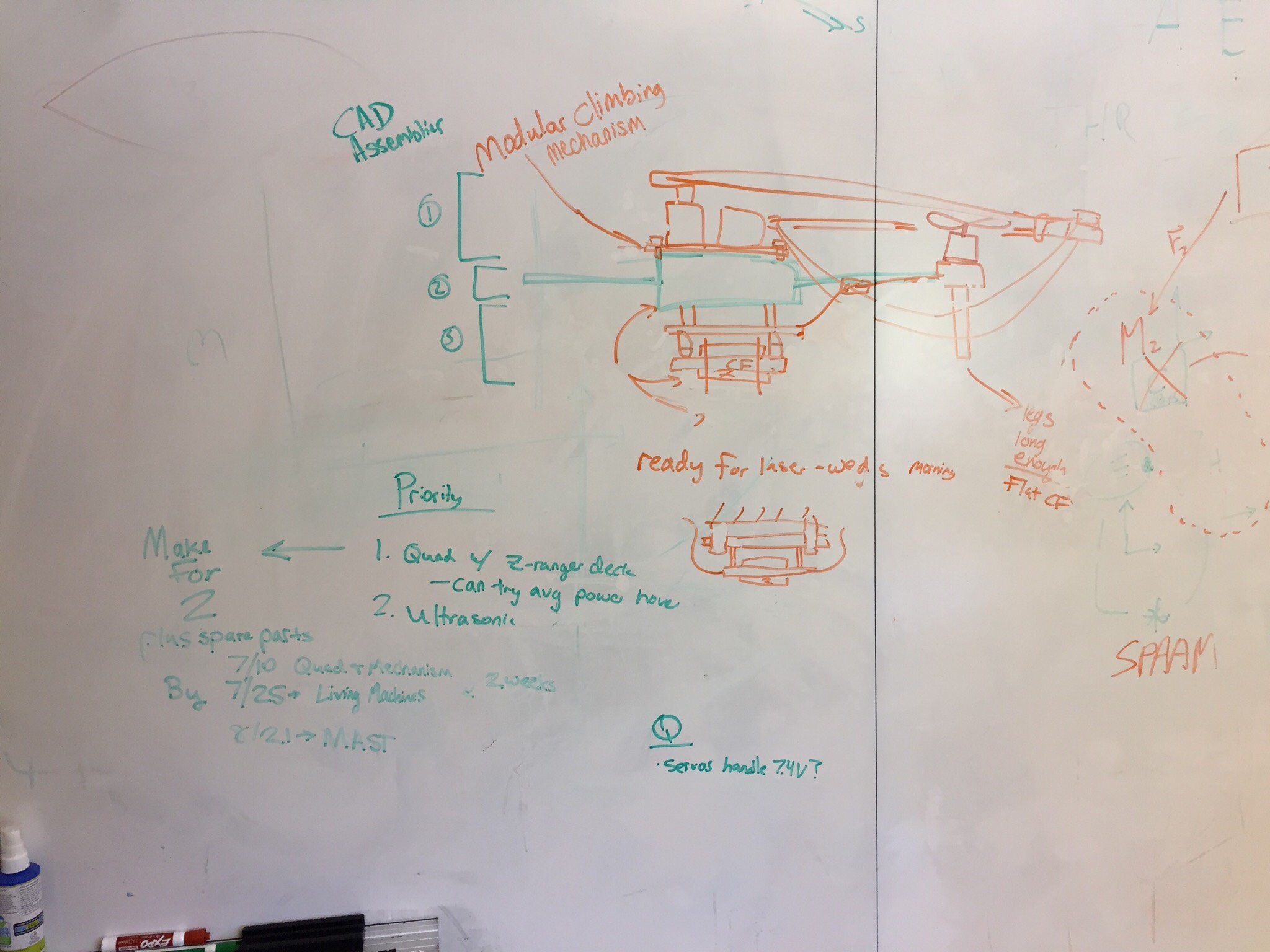

I talked with Drew and Alessandro for about an hour after lunch and it was a very productive meeting. We are meeting with Mark tomorrow to discuss our progress so we wanted to be ready. We also just wanted to have a good idea of what our next steps were. Drew got up and drew a fairly detailed schematic on the board (see figure below). From the schematic, we found that the construction of SuperSCAMP would boil down to 3 essential parts:

- The chassis, which was bought and is basically already complete, pending some designed and 3D printed motor mounts that Drew will make soon.

- The crawler mechanism, which will be attached to the chassis on the rotor side.

- The Crazyflie and its supporting materials such as dampers, batteries, and z-ranger (distance sensor).

Alessandro has done a remarkable job with the software implementation to control the Crazyflie and will continue to work on improving it, as well as beginning to design the takeoff approach. Drew will develop a CAD model of the chassis, the motor mounts, and the Crazyflie attachments. This will give us the ability to estimate the inertia in CAD and use it as an input into Alessandro's control model. I will be working on the construction of the crawler mechanism. I will be basing the design on previous crawler designs and simply scaling it for the SuperSCAMP's dimensions.

Today, I sized a new motor for the extend/retract motor that is used to move the spines up and down enabling SuperSCAMP to climb. Since SuperSCAMP is about 6 times the mass of SCAMP, we felt that it would be necessary to change motors to get the desired torque. After some torque analysis and motor selection (luckily one of the servos in the lab worked perfectly [Hitec HS-65MG]), I continued building the mechanism frame with carbon fiber. I plan to continue work in this frame tomorrow. One of the points that came up in our meeting was that we wanted this frame to be modular and be able to be detached from the drone. I also hope to develop a CAD model of the frame to complement Drew's work. The construction will be held up by the in/out motor, which we are expecting later this week.

We are also presenting what we are working in this Friday at the lab meeting, so I hope to have some good materials by that point.

Week 1

Friday, June 23

Another late entry (Mon. 6/26):

Friday was a good day. We had a lab meeting and it was good to hear Mark talk about our goals for the summer because it gave me a concrete vision for the SuperSCAMP project. Here, I will write out some of my notes from the meeting. One of our goals is to get a paper written for an ICRA conference. The deadline to submit a paper for review for the conference is September 15th and the deadline to submit for RA letters is Sept 10th. Thus, we want to have a drafts for RA letters ready by September 2nd and drafts for ICRA ready by September 7th to give Mark enough time to review them and make edits.

For the paper, we want to focus on SCAMP's failure recovery on outdoor surfaces. The idea is that we want SCAMP to be able to detect when it doesn't have a successful perch on a surface and be able to recover from that. So, SCAMP might fly to a wall and attempt to perch. If it is unable to perch immediately, it will try to provide more power to it's rotors in an attempt to engage the spines. After a specified amount of unsuccessful attempts, SCAMP will then disengage from the wall/takeoff and hover by the wall, waiting for the next command.

We want to get this working by the end of July in order to collect some data for the paper. We need to get some data that answers some of the following questions that reviewers may have: How does SCAMP detect that it failed? What is the state machine? How many times is it good for SCAMP to try to perch before it takes off?

An idea for the data representation in the paper was that we could create a plot with lines for each of the different surfaces that graphs the probability of SCAMP's success as a function of the number of trials it tried to do so. I thought it would also be a good idea to explain our algorithm in detail.

Lastly, I purchased the parts that we needed to build the crawling mechanism for SCAMP: Loctite, accelerator, in/out climbing servo motor (HK-5320), and the extend/retract motor (HS-5035HD). They should be here hopefully by the end of the week and next week at the latest.

Thursday, June 22

Late entry (Mon. 6/26): I didn't do too much on Thursday. I was in staff training again but spent a little time in the evening emailing Will and Drew to continue to get oriented to the lab. I got a few housekeeping things done like getting after hours access to MERL and finding out which parts we needed to purchase, after talks with Will and Drew. I also continued to think about the takeoff mechanism and I'm convinced that it will be difficult to develop a reliable takeoff approach that isn't software implemented. That being said, it will be difficult to develop the software approach but I am up to the task.

Wednesday, June 21

Morning:

Today, tomorrow, and possibly Friday, I will not be in the lab because I am in a training session for my role as an RA in one of the campus dorms over the summer. I am working remotely here while we are in the sessions and I will continue working remotely tonight. I will also try to see if I can get into the lab to experiment with cutting the carbon fiber later. Thus, goals for today are:

- Transfer money into my account to purchase Crazyflie (personal goal).

- Continue reading about Crazyflie and the documentation.

- Continue reading about SCAMP.

- Brainstorm ideas for the takeoff mechanism after reading part of SCAMP paper about current takeoff mechanism.

Evening:

I ended up choosing not to purchase the Crazyflie right now. I think I will just send an email to Alessandro to see if he can give me a Crazyflie to work with this summer. I think that it will be very important to get some hands-on experience with the Crazyflie while I'm learning about it in building SuperSCAMP. I read some more documentation for the Crazyflie and I am becoming more confident with what I'll be able to do with it.

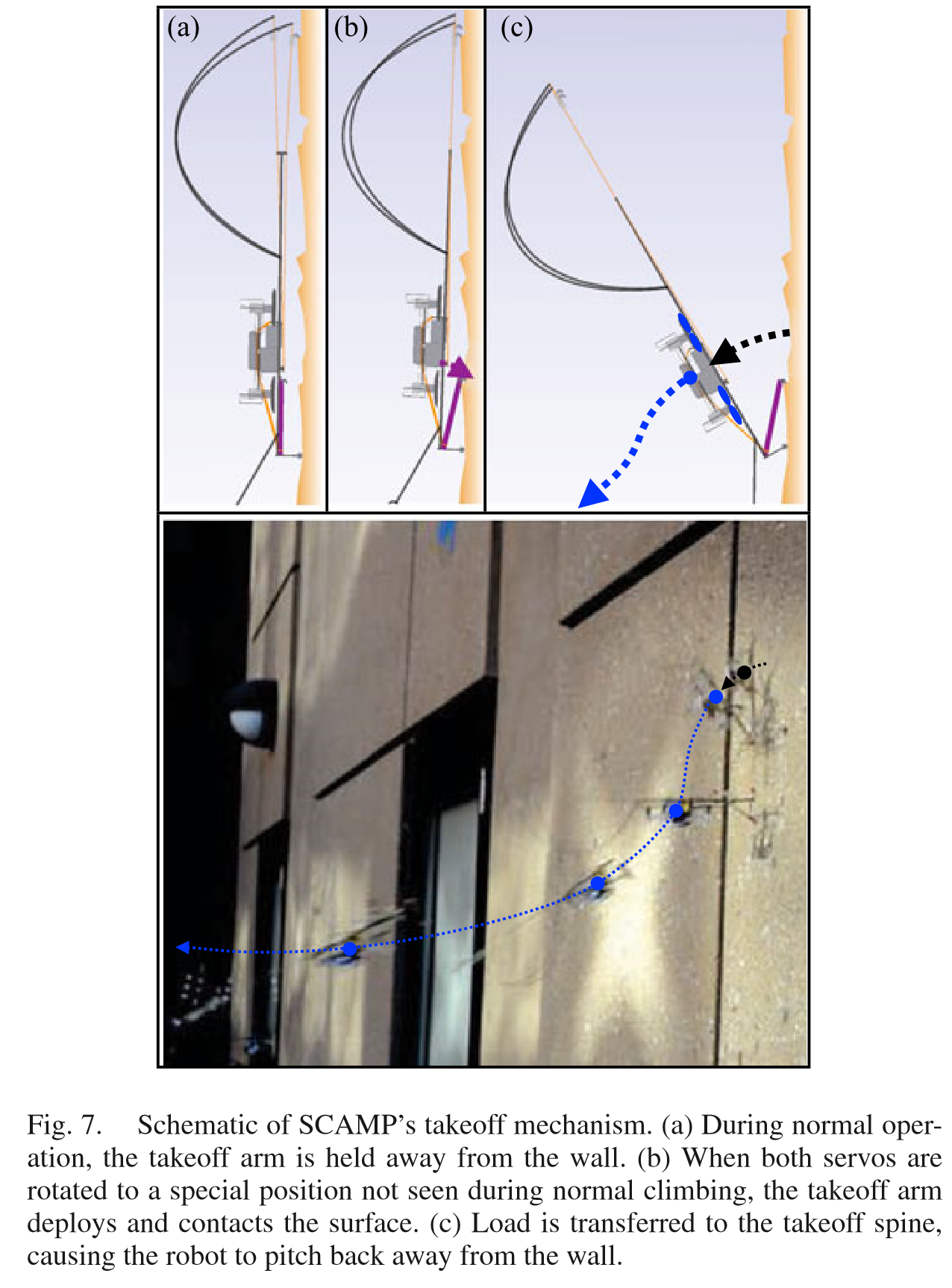

I continued reading the original SCAMP papers, and gained a lot of insight about the takeoff mechanism. The original takeoff mechanism for SCAMP included a takeoff arm with a single spine. This takeoff arm can be seen in the figure below derived from the SCAMP paper ("A Multimodal Robot for Perching and Climbing on Vertical Outdoor Surfaces"). The mechanism operates by releasing this takeoff arm when the climbing motors are in a certain orientation and once the climbing spines are released, SCAMP begins to fall until the spine on the takeoff arm engages an asperity. This causes the robot to pitch backward from the wall.

After thinking about this more, I believe that a software/hardware approach in altering the motor circuit to allow for driving the rotors in reverse for short periods of time would be the best way to develop a takeoff strategy. I will begin to look into ways that we can rewire the the Crazyflie to run it in reverse. In the worst case scenario, we could easily add a mechanism that pushes out an arm that creates a moment in order to get the robot to pitch backwards.

Tuesday, June 20

Welcome to my blog! I think the way I will organize this blog is by writing at two different points in the day. I will write when I come in the morning and again in the evening. In the morning, I will detail my goals for the current day and I will discuss any reflections from the previous day that may have formed while I slept or completed more work that evening. In the evening I will discuss the work that was completed that day and things that still need to be completed.

Morning:

Today, is my first official day in the lab. It has been a crazy last couple of days with graduation happening and family members being in town. But I'm excited to get started! I will be working on the SuperSCAMP project this summer. This is basically a revamp of the SCAMP project to create a more robust MAV that will fly, perch and climb as the original SCAMP did. Our goal is to make SuperSCAMP less "fuzzy" and more reliable, although that may mean adding a little more weight than the regular SCAMP had. From our morning meeting, I think I will be focusing on the perching and crawling mechanism design as well as just helping out when I'm needed. Below are my goals for the day (in no particular order):

- Begin reading and tinkering with the Crazyflie documentation/software.

- Create a four-bar linkage design that we can propose to Mark for the design of SuperSCAMP's legs/feet.

- Solder broken components that Alessandro gave me.

- Continue reading papers about SCAMP.

Edits/updating after a later meeting with Mark, Alessandro, and Will (3:00 pm):

In order to make sure that we have everything we need for a demo at Living Machines (July 25th) and the big DARPA demo in August, we've decided to work in parallel to create both the same perching and climbing mechanism for SuperSCAMP as SCAMP, as well as begin to think about ways to develop a more robust mechanism for it. For the next few weeks, we will be focusing our efforts on re-building the old SCAMP climbing mechanism. We will begin construction once Drew gets back on Monday, but for now, I will be doing some preliminary work, so we can hit the ground running when he returns. I will, then, be focusing on the following tasks for the next few days, in addition to working on the tasks above as time permits:

- Dimensioning the new carbon fiber parts that will go onto the SuperSCAMP

- Looking into the specs of the motor we are currently using in comparison to other servo motors in the lab to see if it can be improved.

- Developing a more robust mechanical takeoff mechanism. Alessandro might also try to figure out a way to do this with a software strategy.

In the back of my mind, I will also be thinking about the "inchworm" wall climber. This might be something we work on later in the summer.

Evening:

I completed a preliminary drawing with dimensions of what SuperSCAMP's crawling mechanism will be. I also began looking into the servo motors and decided I want us to try the HS-45HB, that is in the lab instead of the already used HS-5035HD. The reason for this change is that the HS-45HB has a higher rated maximum torque range (14-17 oz/in) when compared to the HS-5035HD (11-N/A oz/in) (see datasheets). From what I've learned in the short time talking with Mark and Will, more torque seems to be needed from the motor, as well as more robust turning, which we hope a higher voltage supply might address. I also began looking into the Crazyflie documentation. I kind of want to buy one for myself and I probably will.

I have not began to think about the takeoff mechanism yet, nor have I soldered the parts for Alessandro (one of the parts needs Molex connectors that I was unable to find so I will revisit this tomorrow). I've begun working on everything else.

I will not be in the lab for most of the day tomorrow but will continue work remotely dimensioning the crawler, reading more Crazyflie things, and reading about the takeoff mechanism in the paper again. I also plan to come into the lab to cut some carbon fiber later in the day. Hopefully, I can get in.

Monday, June 19

- Look at a couple of other blogs for examples:

- AudreysBlog, ChrisKimesSummerBlog, StickySummer

- Check out features like JuliasFirstGallery (append ?action=source to URL to view syntax)

- Note that you need to resize images (e.g. 800x600) before uploading, else page takes forever to load.