new web: http://bdml.stanford.edu/pmwiki

TWiki > RisePrivate Web>FootDesign? >SeparatedCompliances (22 Sep 2005, MattSpenko? )

RisePrivate Web>FootDesign? >SeparatedCompliances (22 Sep 2005, MattSpenko? )

- See FootDesign? for other foot designs.

Movie of Hard Pieces of Toe * demoofseparatedcompliances.mov:

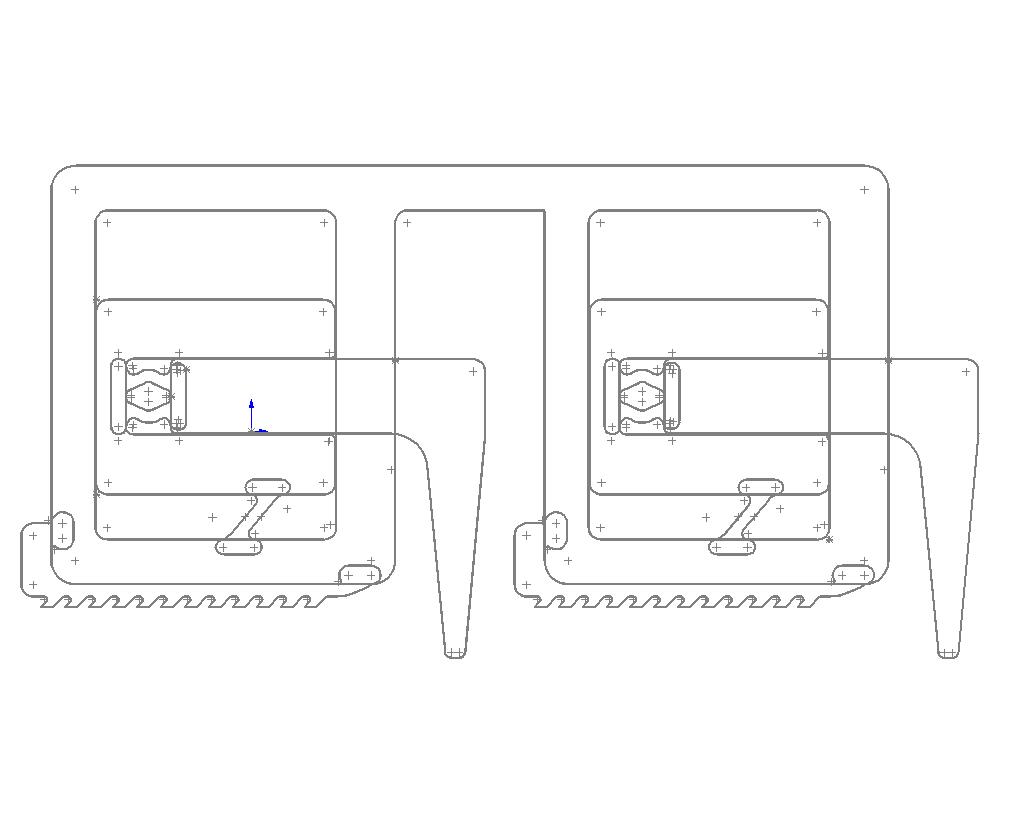

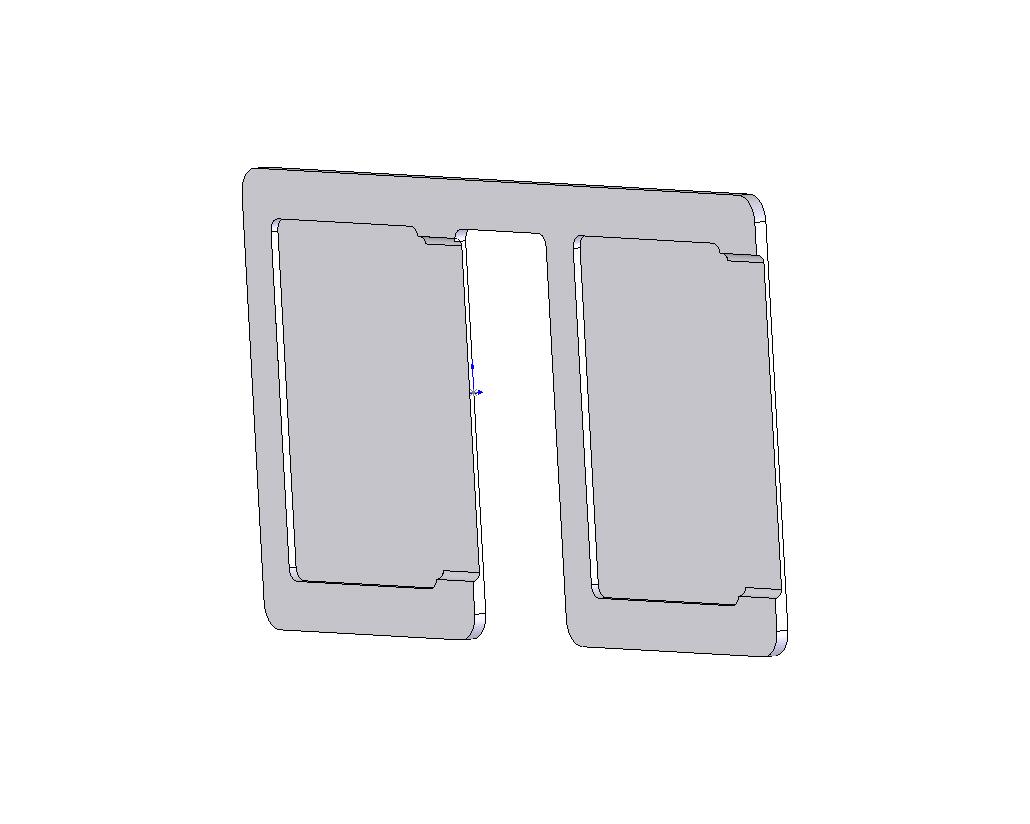

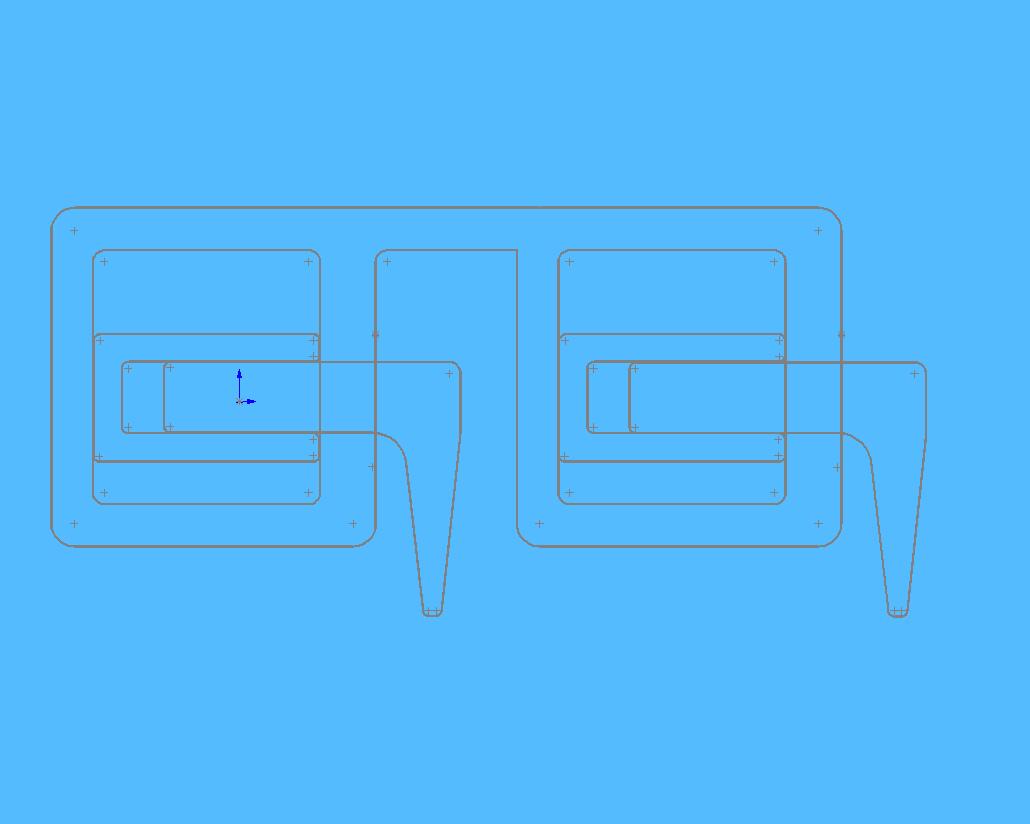

Picture of design at present * newfootwithflexandstick.jpg:

* newfootouter2withbacking.jpg:

* newfootouter2withbacking.jpg:  * newfoot.jpg:

* newfoot.jpg:

Plan for Manufacture

- Separately mold and pour all hard pieces of toe (5 total-case, 2xslider, 2xtoes w/ spines)

- mill out cavity and fit pieces into place

- fasten pieces either with wax or by some other means

- pour soft flexures

- extract

Notes from Mini-Meeting with Will:

- make slider c channel part taller to decrease likelihood of binding (creates less point like contacts at the walls

- use curved flexures--will provide nonlinear response, but allow for more travel and more compliance

- ensure that the slider radius on the corners is larger than the channel radius, prevent getting stuck

- continue using .05mm gap for sliding--equivalent about .002in

- possibly use a thin backing to separate toes, prevent neighboring toes from interacting, complicates manufacture however

- bench level tests of flexures to test compliance and design with 1,2,3, or 4 small flexures

Ideas, requests, problems regarding TWiki? Send feedback