new web: http://bdml.stanford.edu/pmwiki

TWiki > RisePrivate Web>PrivateRiSE > StickyBotPrivate>NewPatchFabIdeasMay (16 May 2007, MarkCutkosky)

RisePrivate Web>PrivateRiSE > StickyBotPrivate>NewPatchFabIdeasMay (16 May 2007, MarkCutkosky)

Tools

Should order some new end mills 250, 200 um. Interested in 45 or 30 deg cutter (carbide). Recall also the shaping tools that Aaron got. Recall also to ask Tom Hasler about his optical collet attachment to help with alignment or registration.Materials

Should different silicone rubbers, polyurethane. Issues include viscosity and wettability of mold by the silicone. Different silicones seem to wet the mold quite differently. Could also try a different mold material (e.g. brass with carbide cutter). If use brass the wetting is probably better but we might need to use a mold release agent... "free machining brass" typically has a bit of lead added -- ask Tom Hasler. Thickness < 2mm. http://www.brass.org/Publicat/pub117/the_brasses.htmCopying DPS idea

Top Cap ideas

Issue: Alignment of compliant top cap and mold is problematic. Misalignment can lead to mold damage and/or improperly shaped stalk tips. Problem: Silicone is more viscous so top cap pressure needs to be higher, making alignment problems worse. Try a stiffer top cap with a thin lower layer of soft stuff? Make dowel pins sticking up from 2 corners of the mold area; cast the top cap around the dowel pins, encapsulating them. Then the dowel pins ensure perfect cap/mold alignment on re-assembly. This would work especially well if the mold is made from brass and the top cap is from a moderately stiff urethane or similar material.Long stalks

Would like to try a slightly longer stalk design with the silicone. Might simplify engagement at the expense of some shear load. Silicone being less sticky may have less tendency to clump.Lamellae

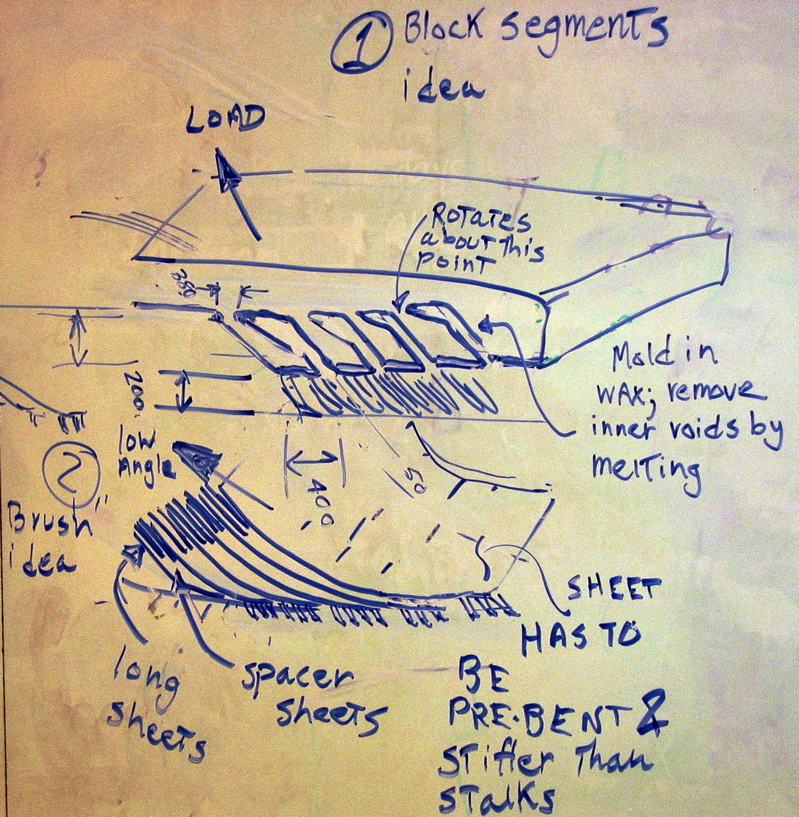

We have an existing lamellar design. Mark has a couple of ideas involving many overlapping sheets or "blocks" of somewhat stiff but flexible material:

(higher resolution version in table below) -- MarkCutkosky - 14 May 2007

Ideas, requests, problems regarding TWiki? Send feedback