new web: http://bdml.stanford.edu/pmwiki

TWiki > RisePrivate Web>PrivateRiSE > NewProposals>MicrohairIntegration (09 Mar 2006, MattSpenko? )

RisePrivate Web>PrivateRiSE > NewProposals>MicrohairIntegration (09 Mar 2006, MattSpenko? )

-- MattSpenko? - 14 Nov 2005

This page is set up in chronological order starting with the most recent work at the top of the page.

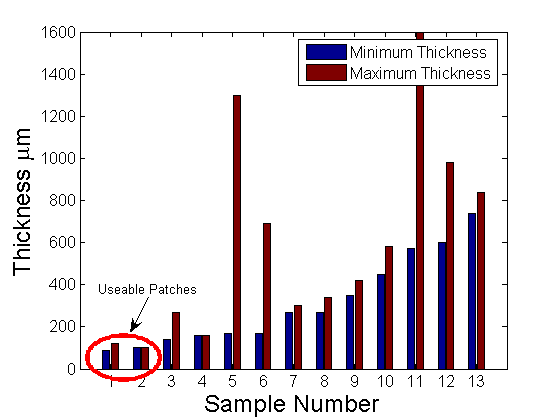

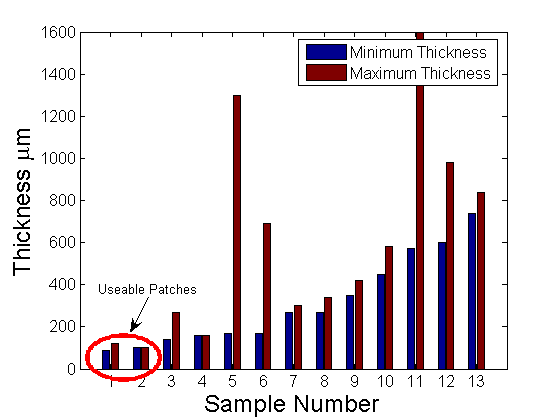

Another thing I learned is that the polypropylene hairs vary too much in thickness. I picked one sample from random (approximately 800 um thick) and found that they are too thick to be used as the lamellar pads because they are too stiff. I then measured the thickness of each one of the polypropylene patches that I received. The results are given below:

Another thing I learned is that the polypropylene hairs vary too much in thickness. I picked one sample from random (approximately 800 um thick) and found that they are too thick to be used as the lamellar pads because they are too stiff. I then measured the thickness of each one of the polypropylene patches that I received. The results are given below:

The patches that Rick gave me before he left on his interview were the best (see my discussion below).

Next step is to try some other methods of blocking off the polypropylene hairs including using glue, sorbothane, or silicone dams. Details and pictures to follow.

2/27/06 - I started experimenting with the thermoplastic (polypropylene) hairs that Rick sent me last Friday. Rick sent me two types of samples. The first was fabricated using the small (1.3 cm diameter) filters. He cut up the resulting patches into shapes that he thought had good results (Rick, did you look at these under a microscope, or can you just tell by the opaqueness?). Most of the patches were around 250 um thick, although some were as much as 490 um thick. Mostly due to the thickness, but also due to the non-uniform size and shape of the patches, I believe that these micro hairs will be difficult to work with. I think that we will end up with feet similar to those that I brought to November SWRI (see bottom of this page). By that I mean that we will get non-uniform patches in both thickness and in shape.

The patches that Rick gave me before he left on his interview were the best (see my discussion below).

Next step is to try some other methods of blocking off the polypropylene hairs including using glue, sorbothane, or silicone dams. Details and pictures to follow.

2/27/06 - I started experimenting with the thermoplastic (polypropylene) hairs that Rick sent me last Friday. Rick sent me two types of samples. The first was fabricated using the small (1.3 cm diameter) filters. He cut up the resulting patches into shapes that he thought had good results (Rick, did you look at these under a microscope, or can you just tell by the opaqueness?). Most of the patches were around 250 um thick, although some were as much as 490 um thick. Mostly due to the thickness, but also due to the non-uniform size and shape of the patches, I believe that these micro hairs will be difficult to work with. I think that we will end up with feet similar to those that I brought to November SWRI (see bottom of this page). By that I mean that we will get non-uniform patches in both thickness and in shape.

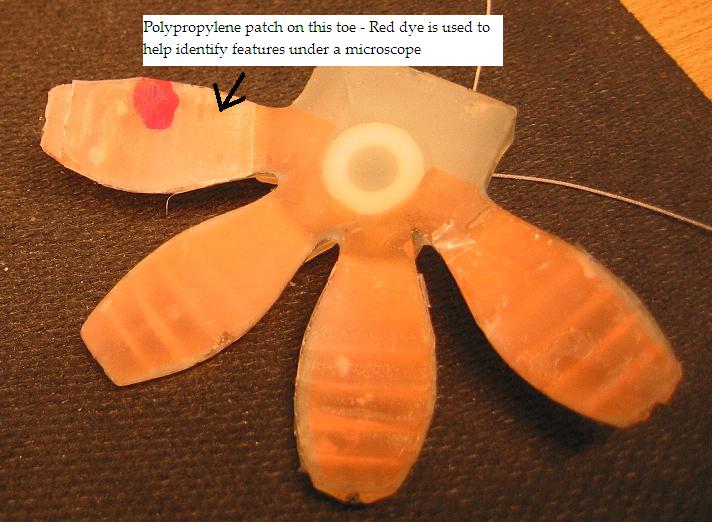

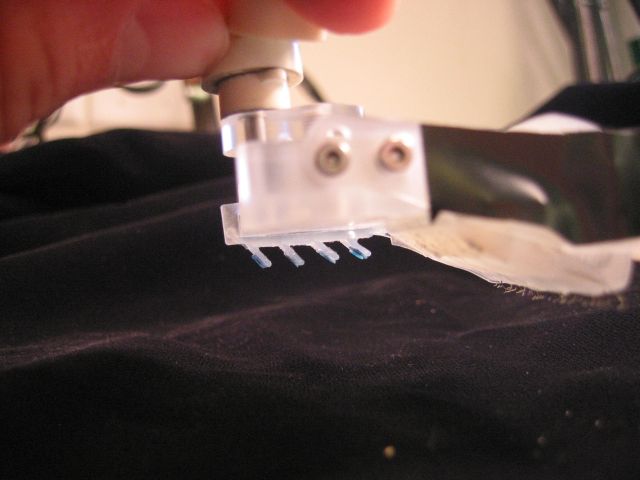

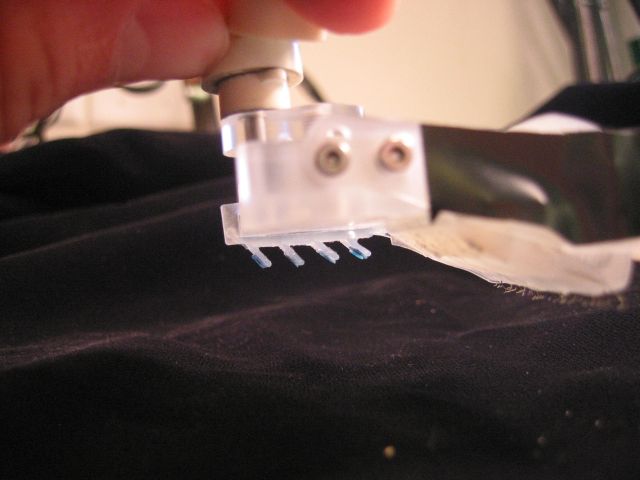

Rick also sent me a one thin polyproplene patch fabricated using the larger (~3 cm diamter) filters. This one is 100 um thick and looks much more promising. Along with the sample you see in the picture below, he sent another piece that didn't have any hairs on it. I used this piece as my first test piece. I placed it on one of Stickybot's toes (attached with thin tape). There is a slight difference between the compliance of the two with the polypropylene and that without.

Rick also sent me a one thin polyproplene patch fabricated using the larger (~3 cm diamter) filters. This one is 100 um thick and looks much more promising. Along with the sample you see in the picture below, he sent another piece that didn't have any hairs on it. I used this piece as my first test piece. I placed it on one of Stickybot's toes (attached with thin tape). There is a slight difference between the compliance of the two with the polypropylene and that without.

The patch is attached with Scotch 467 Hi Performance adhesive which is a very thin tape. I like the tape much better than glue. Those of you who saw the hairs brought down to SWRI can see the difficulties of working with glue (It overflows into the hairs easily).

Next Steps

The patch is attached with Scotch 467 Hi Performance adhesive which is a very thin tape. I like the tape much better than glue. Those of you who saw the hairs brought down to SWRI can see the difficulties of working with glue (It overflows into the hairs easily).

Next Steps

After thinking about it some more, I don't think the glue is going to cut it. Glue has the possibility of running too much.

After thinking about it some more, I don't think the glue is going to cut it. Glue has the possibility of running too much.

Polypropylene

3/9/06 - This past week I looked into integrating the polypropylene pieces into a substrate of 72DC to create a structure that used the polypropylene as a cantilever beam. Rick orginally proposed this idea sometime late last year. The original results were not that good, but I learned some things from it. Procedure - I cut the mold, placed strips of polypropylene into the proper slots in the mold, and then attempted to block the flow of polyurethane from interfering with the polypropylene strips with clay. There were several problems. First, the clay did block the flow of polyurethane; however, it also prevented the polypropylene strips from properly being anchored in the 72DC. Second, the clay is difficult to remove. The patches that Rick gave me before he left on his interview were the best (see my discussion below).

Next step is to try some other methods of blocking off the polypropylene hairs including using glue, sorbothane, or silicone dams. Details and pictures to follow.

2/27/06 - I started experimenting with the thermoplastic (polypropylene) hairs that Rick sent me last Friday. Rick sent me two types of samples. The first was fabricated using the small (1.3 cm diameter) filters. He cut up the resulting patches into shapes that he thought had good results (Rick, did you look at these under a microscope, or can you just tell by the opaqueness?). Most of the patches were around 250 um thick, although some were as much as 490 um thick. Mostly due to the thickness, but also due to the non-uniform size and shape of the patches, I believe that these micro hairs will be difficult to work with. I think that we will end up with feet similar to those that I brought to November SWRI (see bottom of this page). By that I mean that we will get non-uniform patches in both thickness and in shape.

The patches that Rick gave me before he left on his interview were the best (see my discussion below).

Next step is to try some other methods of blocking off the polypropylene hairs including using glue, sorbothane, or silicone dams. Details and pictures to follow.

2/27/06 - I started experimenting with the thermoplastic (polypropylene) hairs that Rick sent me last Friday. Rick sent me two types of samples. The first was fabricated using the small (1.3 cm diameter) filters. He cut up the resulting patches into shapes that he thought had good results (Rick, did you look at these under a microscope, or can you just tell by the opaqueness?). Most of the patches were around 250 um thick, although some were as much as 490 um thick. Mostly due to the thickness, but also due to the non-uniform size and shape of the patches, I believe that these micro hairs will be difficult to work with. I think that we will end up with feet similar to those that I brought to November SWRI (see bottom of this page). By that I mean that we will get non-uniform patches in both thickness and in shape.

- Use quicktime 7.x with H.264 compressor to view GeckoFootwithThermoplastic.mov.

- Receive next batch of hairs from Berkeley, integrate into foot - got them!

- Manufacture 4 more feet (Should take about 5-6 days) - Finished.

- Send feet to Berkeley for testing - still working on it...

Nickel Masters

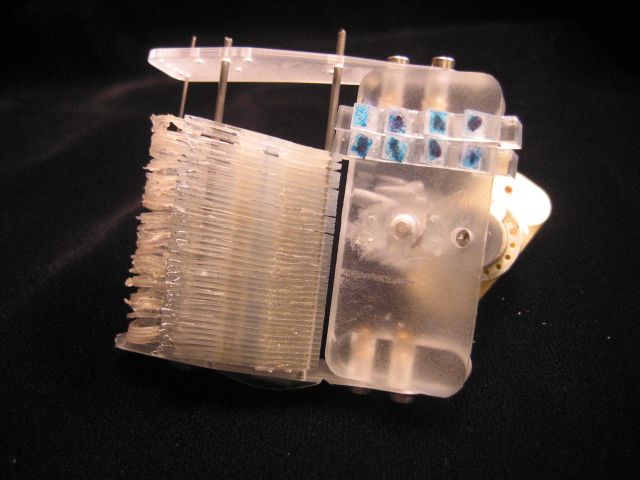

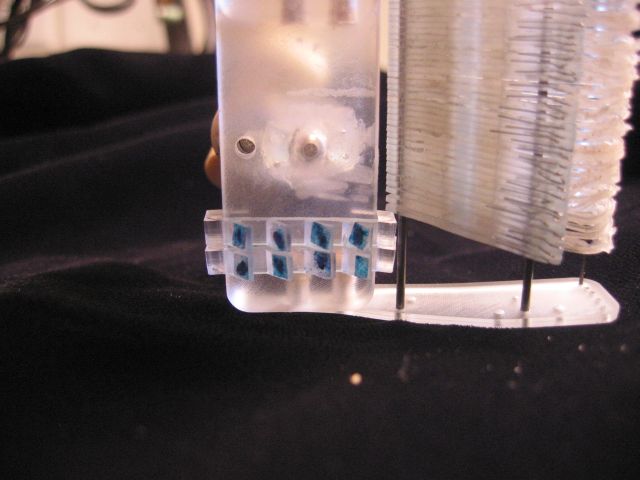

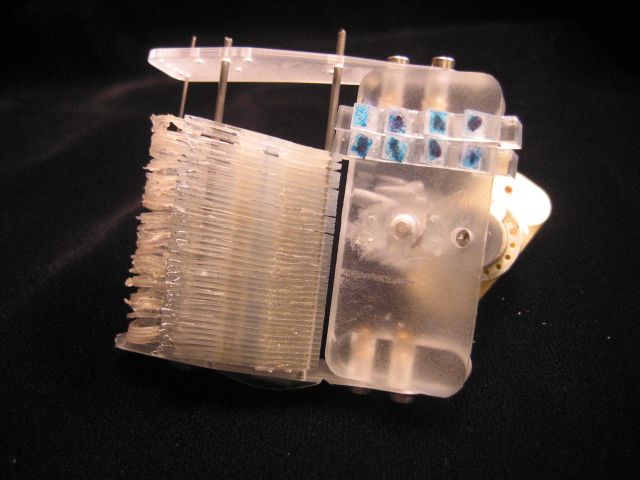

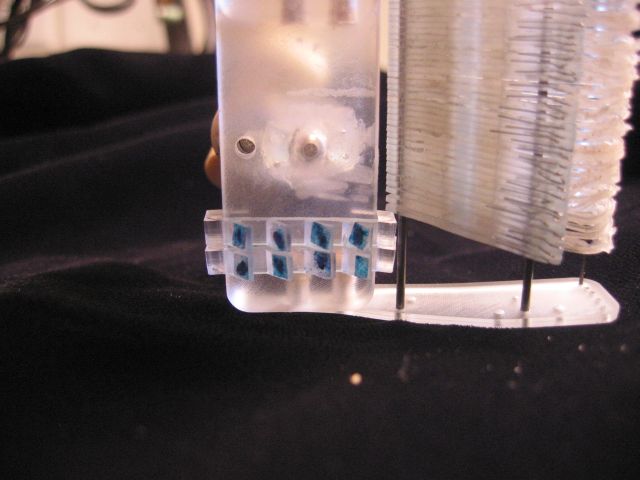

This is my first prototype of lamellar structures with microhair patches on it. I used the procedured outlined in ... to fabricate the patches. There are a few shortcomings of this design.- The microhairs are not dense enough

- The lamellar substrate interferes with the rear of the toes

- The top part of the hard material located at the ends of the suspension structure will interfere with the ankle flexure. This can probably be taken care of by simply removing the top part of that structure

- The attachment process is messy and leads to glue being placed in positions I don't want it.

After thinking about it some more, I don't think the glue is going to cut it. Glue has the possibility of running too much.

After thinking about it some more, I don't think the glue is going to cut it. Glue has the possibility of running too much. Ideas, requests, problems regarding TWiki? Send feedback