new web: http://bdml.stanford.edu/pmwiki

TWiki > RisePrivate Web>PrivateRiSE>FiberDrawing (18 Oct 2010, EricEason)

RisePrivate Web>PrivateRiSE>FiberDrawing (18 Oct 2010, EricEason)

Fiber Drawing

Related papers by Nain et al, 2006: In this one they dissolved PMMA in chlorobenzene, drew fibers using AFM and STM probe tips, and pumped the solution through micropipettes. In this one they dissolved polystyrene in xylene and pumped the solution through a micropipette. In both papers, the plastic is dissolved in a solvent instead of melted. The high surface area to volume ratio of the fibers causes the solvent to evaporate very quickly as the solution is drawn.Experiment on 10/12/10 (Eric and Elliot)

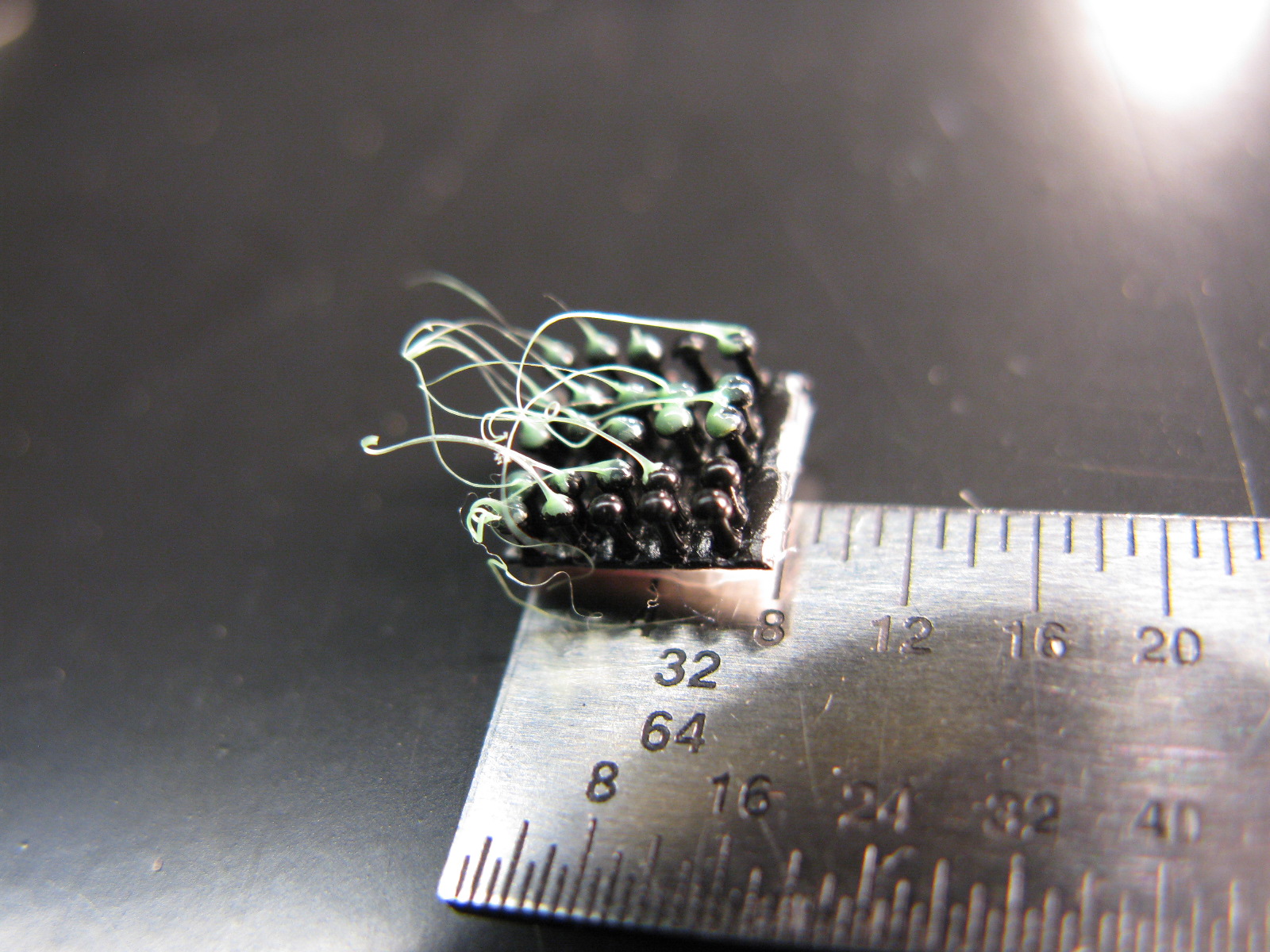

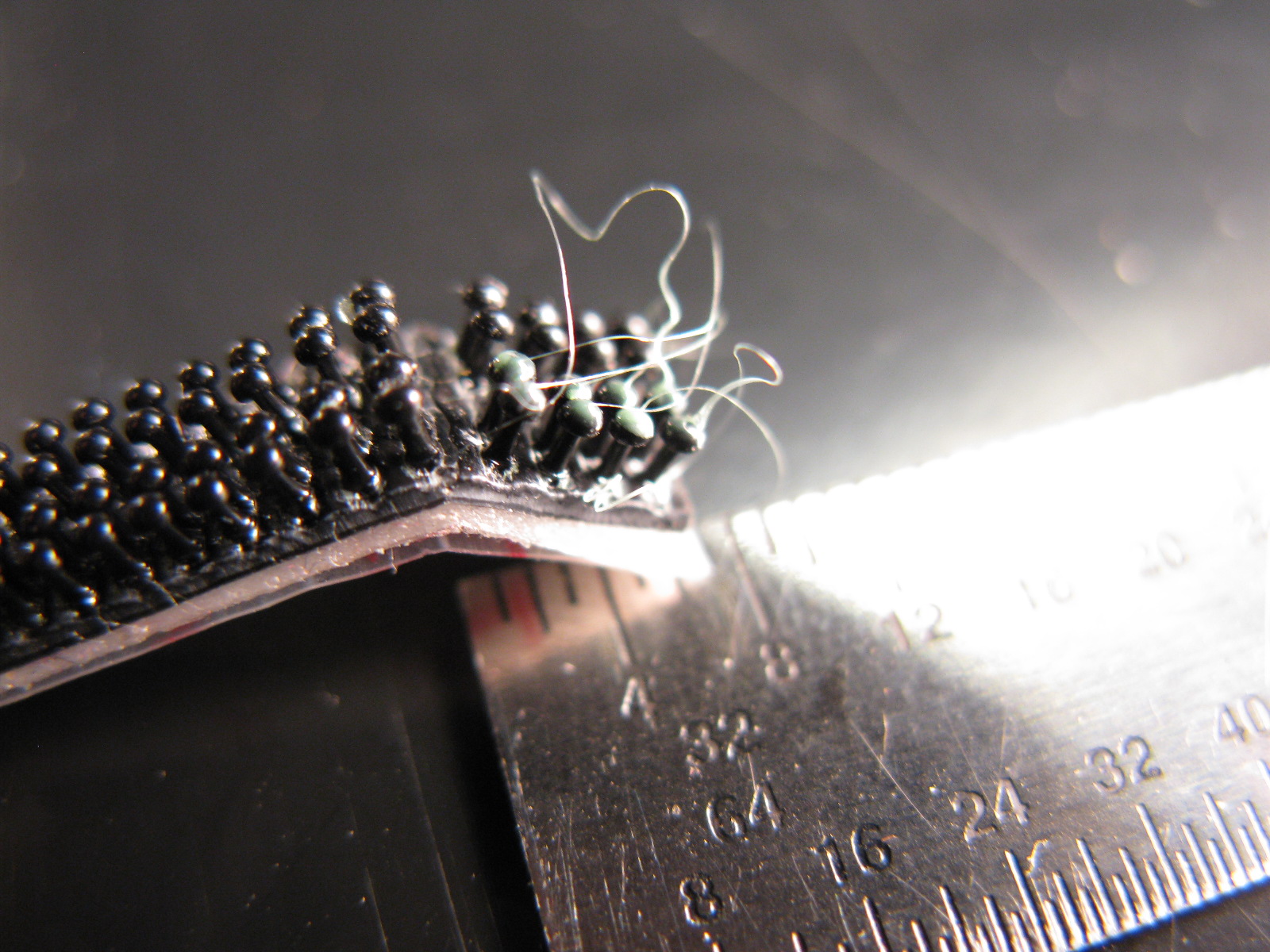

We poured a few mL of xylene into a glass petri dish and then dissolved styrofoam (polystyrene) packing peanuts in it. After dissolving around 20 peanuts in it (we weren't counting) the solution became viscous enough to extrude fibers. For this simple test we dipped pieces of 3M Dual Lock into the solution by hand. Dual Lock is made up of arrays of mushroom-shaped plastic posts. The tips of the posts are about 0.9 mm in diameter and are spaced about 1 mm apart (center to center) at the closest. It was possible to get arrays of fibers using this method. However these fibers are not consistent in their diameter, straightness, or direction. Some fibers became joined during the draw. (The green color is from the styrofoam peanuts, which were also green.)

We will have to control the conditions more carefully to do better. The surface of the solution was not flat or uniformly viscous during the test. We found that fiber drawing was possible only from the most viscous areas of the solution (these areas were of a tacky consistency). Attempting to draw from more fluid areas did not work, as the solution succumbed to gravity faster than the solvent evaporated.

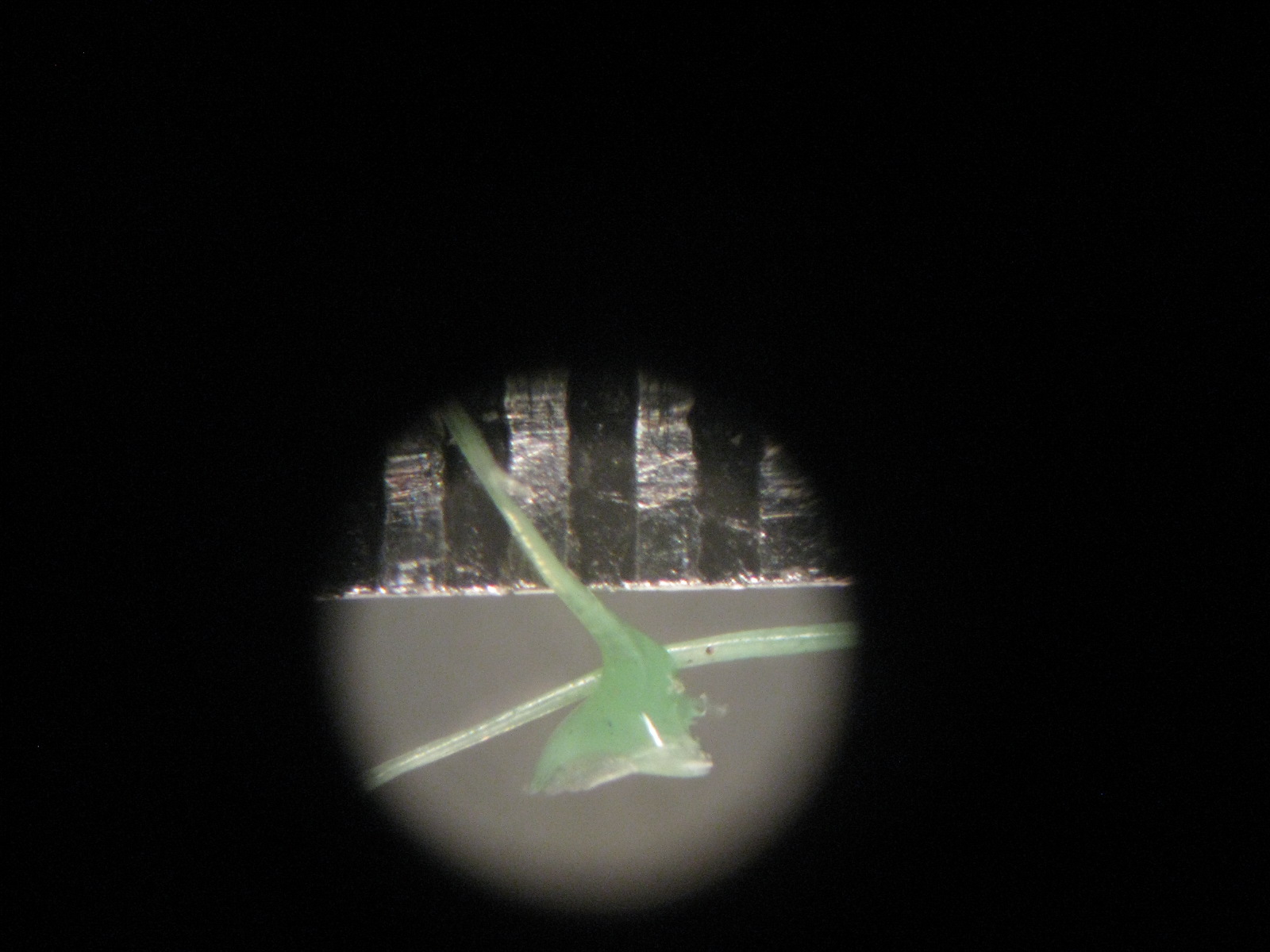

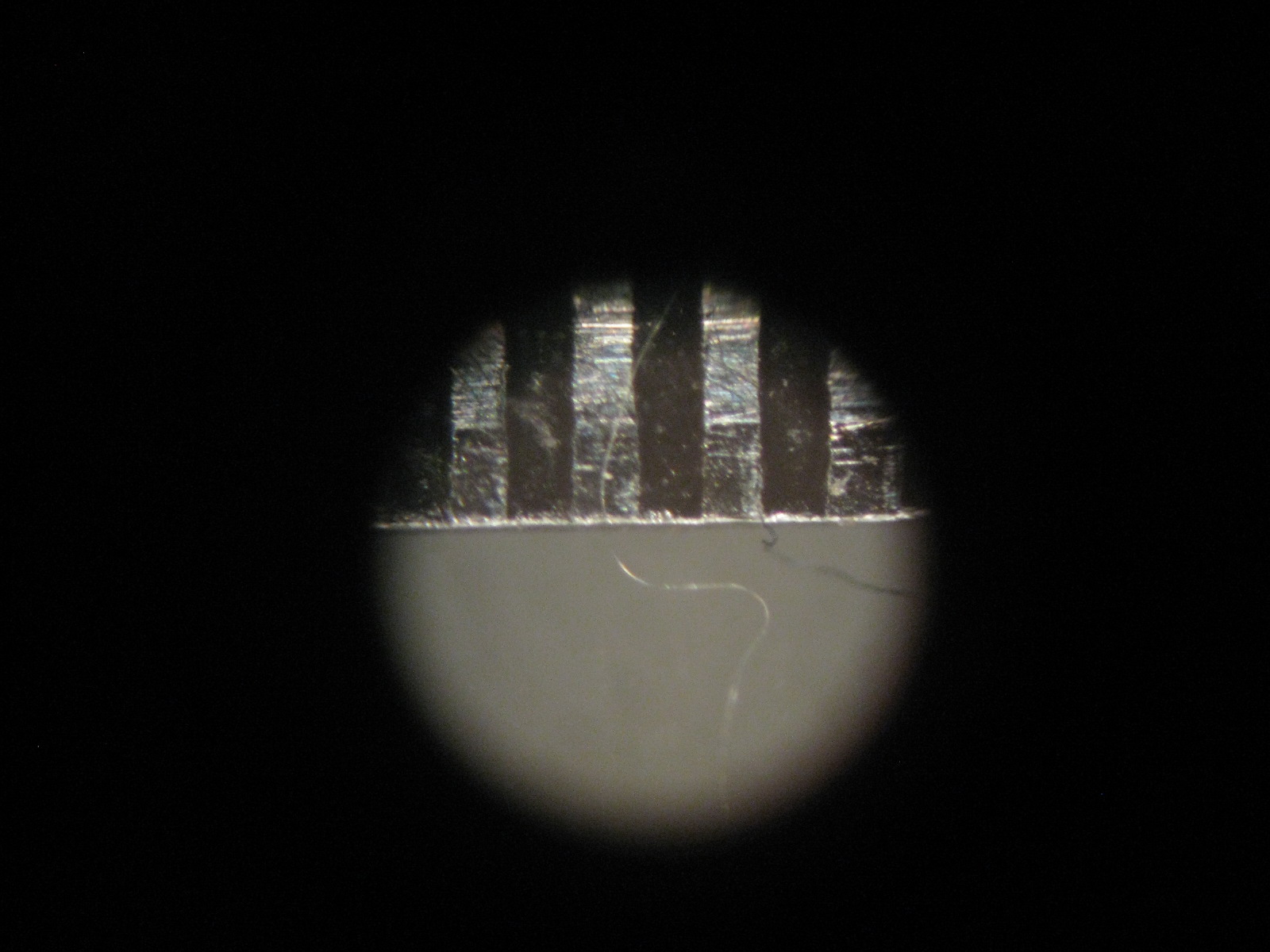

This is a microscopic view of two of the fibers which were detached from the Dual Lock posts using tweezers. The ruler lines are 1/64" apart. The round surface which was deposited on the post's tip adhered to the side of the ruler in the second picture.

We will have to control the conditions more carefully to do better. The surface of the solution was not flat or uniformly viscous during the test. We found that fiber drawing was possible only from the most viscous areas of the solution (these areas were of a tacky consistency). Attempting to draw from more fluid areas did not work, as the solution succumbed to gravity faster than the solvent evaporated.

This is a microscopic view of two of the fibers which were detached from the Dual Lock posts using tweezers. The ruler lines are 1/64" apart. The round surface which was deposited on the post's tip adhered to the side of the ruler in the second picture.

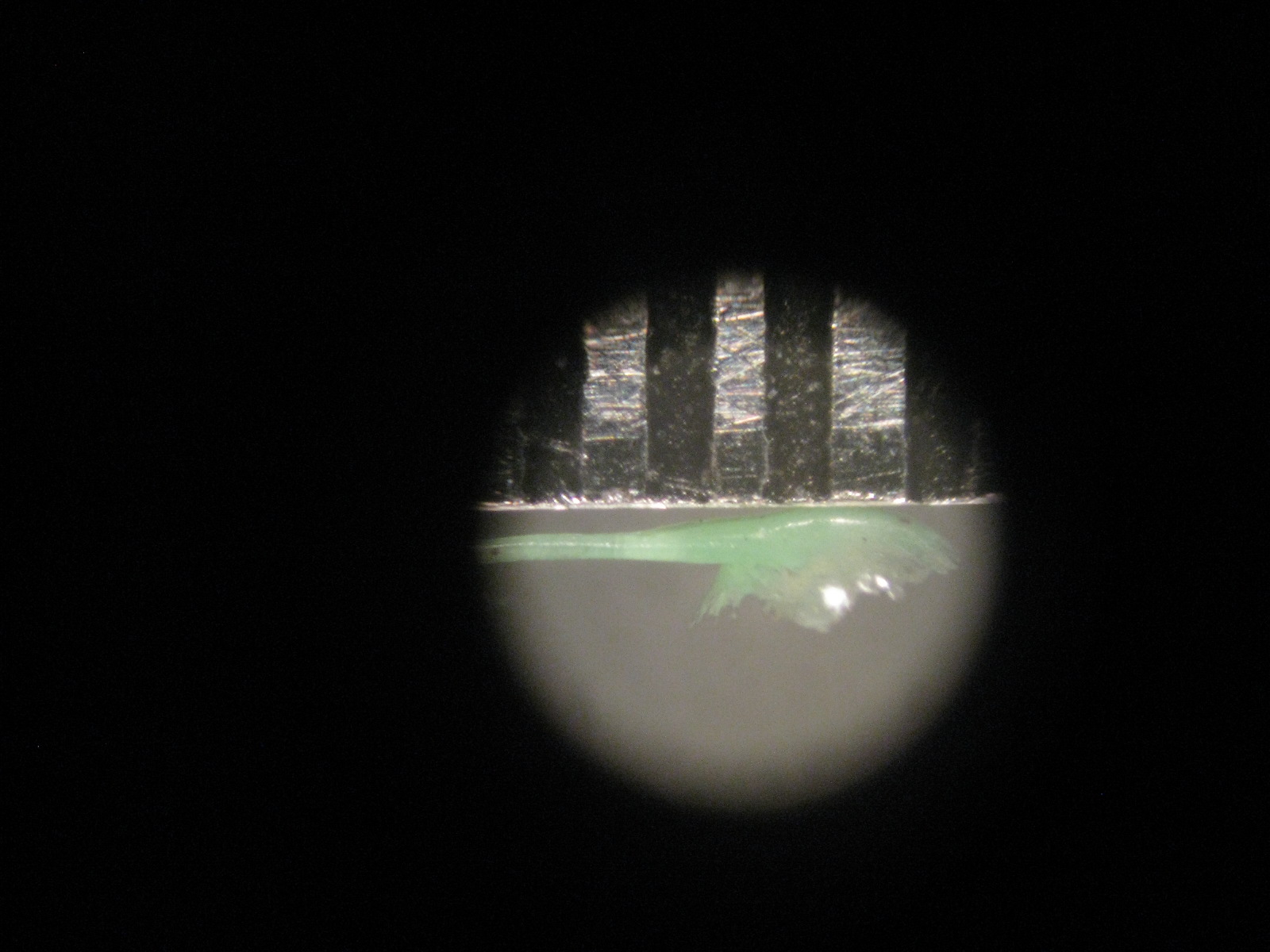

Much smaller fibers were also drawn with this method. The following picture is at the same scale as the previous two (1/64"). I couldn't measure this fiber exactly, but I estimate that it was around 1-3 microns in diameter. Like a piece of spider silk, it exhibited a large amount of static cling.

Much smaller fibers were also drawn with this method. The following picture is at the same scale as the previous two (1/64"). I couldn't measure this fiber exactly, but I estimate that it was around 1-3 microns in diameter. Like a piece of spider silk, it exhibited a large amount of static cling.

The fiber size seems to be a function of the viscosity of the polymer solution and the drawing speed. I suspect that a smaller pattern with sharper features will make it possible to draw smaller fibers from a less viscous solution.

The fiber size seems to be a function of the viscosity of the polymer solution and the drawing speed. I suspect that a smaller pattern with sharper features will make it possible to draw smaller fibers from a less viscous solution.

Experiment on 10/15/10 (Eric)

I tried again using the same polystyrene and xylene but using a different drawing object: A loose bundle of filaments from a piece of "embroidery floss" made of rayon (cellulose, which resists xylene). The rayon filaments were around 25 microns in diameter. The result is that I was able to draw 10 polystyrene fibers of consistent diameters simultaneously from the ends of the rayon filaments. I estimate their diameters at between 2 and 6 microns. The fibers have been trimmed with scissors; they were originally a few centimeters long. Not shown is an additional, larger-diameter fiber that was attached to a group of filaments which touched each other. These filaments were cut away because the larger fiber was in the way of the picture.Ideas, requests, problems regarding TWiki? Send feedback