new web: http://bdml.stanford.edu/pmwiki

TWiki > RisePrivate Web>FootDesign? >CompliantSpinedFoot (09 Dec 2005, MarkCutkosky)

RisePrivate Web>FootDesign? >CompliantSpinedFoot (09 Dec 2005, MarkCutkosky)

Compliant Spined Foot Development

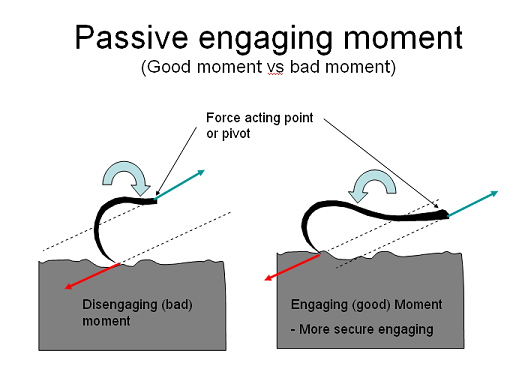

-- MarkCutkosky - 06 May 2004 Key design issues:- Ensure that with N claws you get N times the gripping force from 1 claw

- Try to maximize the reliability so that at least a few claws engage (not just one)

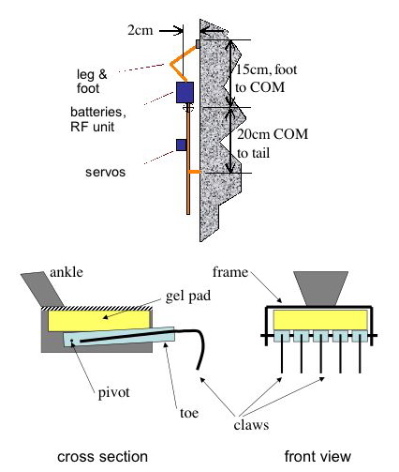

(Click on attachments below to download high-resolution versions of these figures + a CAD solid model rendering). Click here for a short MOVIE of the claws and climber in action. The key message from the video is that strategy and behavior are all-important! Many minor design modifications can be made to the climber. For example, the legs really need 2 DOF so that they do not produce pitching moments when detaching and repositioning. Some quick numbers:

- Weight of the RC climber = 0.1 Kg including 2 RC servos, receiver and lithium polymer batteries

- Distance from wall out to center of mass (COM) = 0.02m (see sketch above)

- So, best-case (minimum) pitch-back moment = 0.02Nm

- Maximum distance from foot to COM = 0.15m

- Distance from COM to tail = 0.2m

- Minimum tensile (adhesion) force per foot in static conditions = 0.08N

, so 0.1 atm would be plenty for just sticking. But this is the best case. Also, the trick is to reliably get 0.1atm over a significant foot area.

, so 0.1 atm would be plenty for just sticking. But this is the best case. Also, the trick is to reliably get 0.1atm over a significant foot area.

- 5-6-04email.rtf: email to RiSE? PIs and Biomimetics May 6, 2004

Ideas, requests, problems regarding TWiki? Send feedback