new web: http://bdml.stanford.edu/pmwiki

TWiki > Rise Web>TWikiUsers > GregKatz > GregsSummerBlog>WeekTen (29 Aug 2008, GregKatz? )

Rise Web>TWikiUsers > GregKatz > GregsSummerBlog>WeekTen (29 Aug 2008, GregKatz? )

-- GregKatz? - 25 Aug 2008

Monday, Aug 25

- Finished 4th and final test fixture for force sensing.

- Unfortunately testing is delayed because switching to the new computer has caused problems and LabView won't run.

- The latest casting came out perfect, no bubbles at all. It is about 500 microns thick in the backing layer. I also so a variation of about the hieght of a chisel tip throughout the good quadrant. This is probably flat enough especially if we use small patches.

- Sanjay and I were able to hang 300g in almost pure sheer with just aluminum and either microwedges or plain flat pdms. The area of about 8 square inches of aluminized mylar and less than 1 square inch of pdms. We also held 125g on 5 square inches (slightly different construction and more pitch torque) with plain flat pdms. This brought up the question of whether or not microwedges offer any advantage over plain flat pdms.

- Microwedges may be better for rough surfaces because the split up the surface.

- Directionality of microwedges is not that useful when you can turn normal force on and off as with electroadhesion.

- We were able to see some increaes in microwedge engagement with the help of the mylar backing and electroadhesive force, but it was not extremely effective or robust. Conformation doesn't seem to occur on areas larger than much more than a few millimeters square, nor was it consistent.

Tuesday, Aug 26

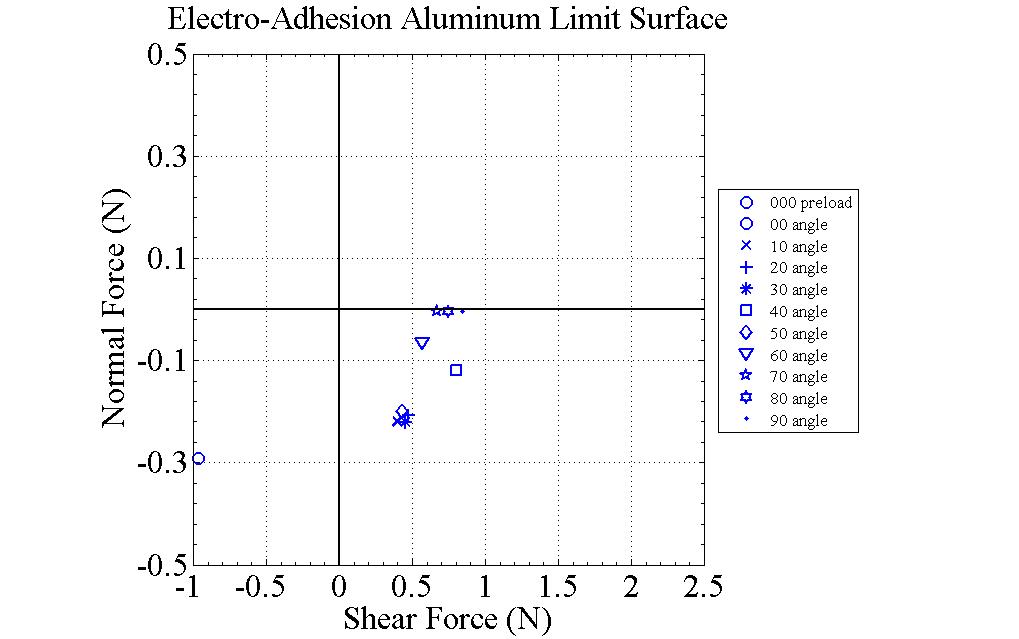

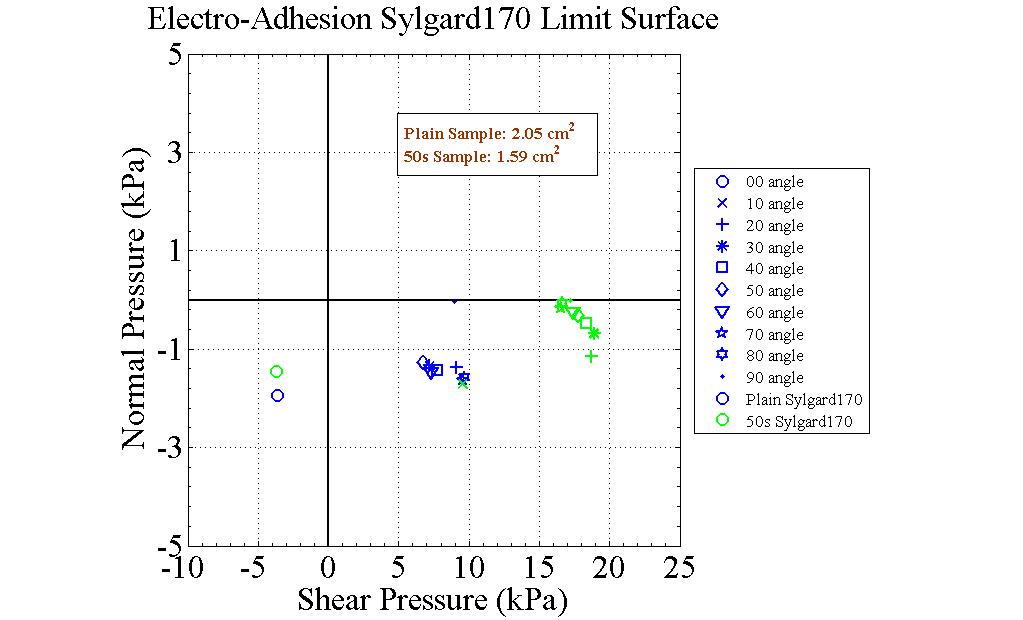

- Did baseline test for three blank aluminzed mylar electroadhesion fixtures (meaning no pdms or wedges). Also attached wedges to one fixture and flat pdms without wedges to another fixture.

Wednesday, Aug 27\

- Made poster for presentation on Friday: suriposter5.pdf

- Finished force tests for electroadhesion with flat pdms and with microwedges.

|

|

Ideas, requests, problems regarding TWiki? Send feedback