new web: http://bdml.stanford.edu/pmwiki

TWiki > Rise Web>TWikiUsers > GregKatz > GregsSummerBlog>WeekSeven (19 Aug 2008, GregKatz? )

Rise Web>TWikiUsers > GregKatz > GregsSummerBlog>WeekSeven (19 Aug 2008, GregKatz? )

-- GregKatz? - 12 Aug 2008

Monday, Aug. 4

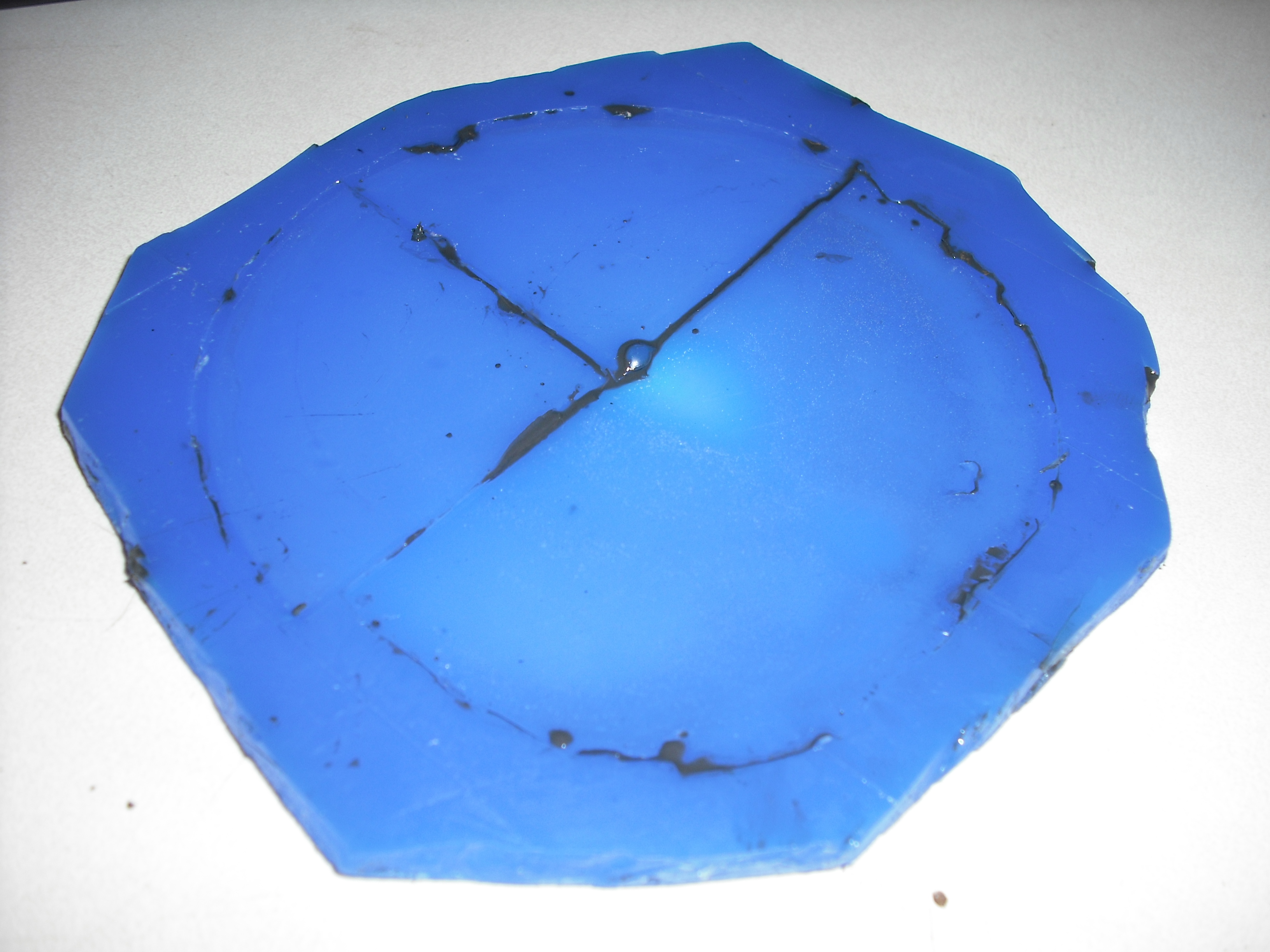

- Took sylgard out of wax mold. It had been curing over the weekend but it didn't fully cure in some of the seams of the mold, along the edges and in between where the different cut-outs were. This is strange because it definitely had enough time to cure. I thought I mixed it well so it seems that something about either the wax or the geometry is causing this.

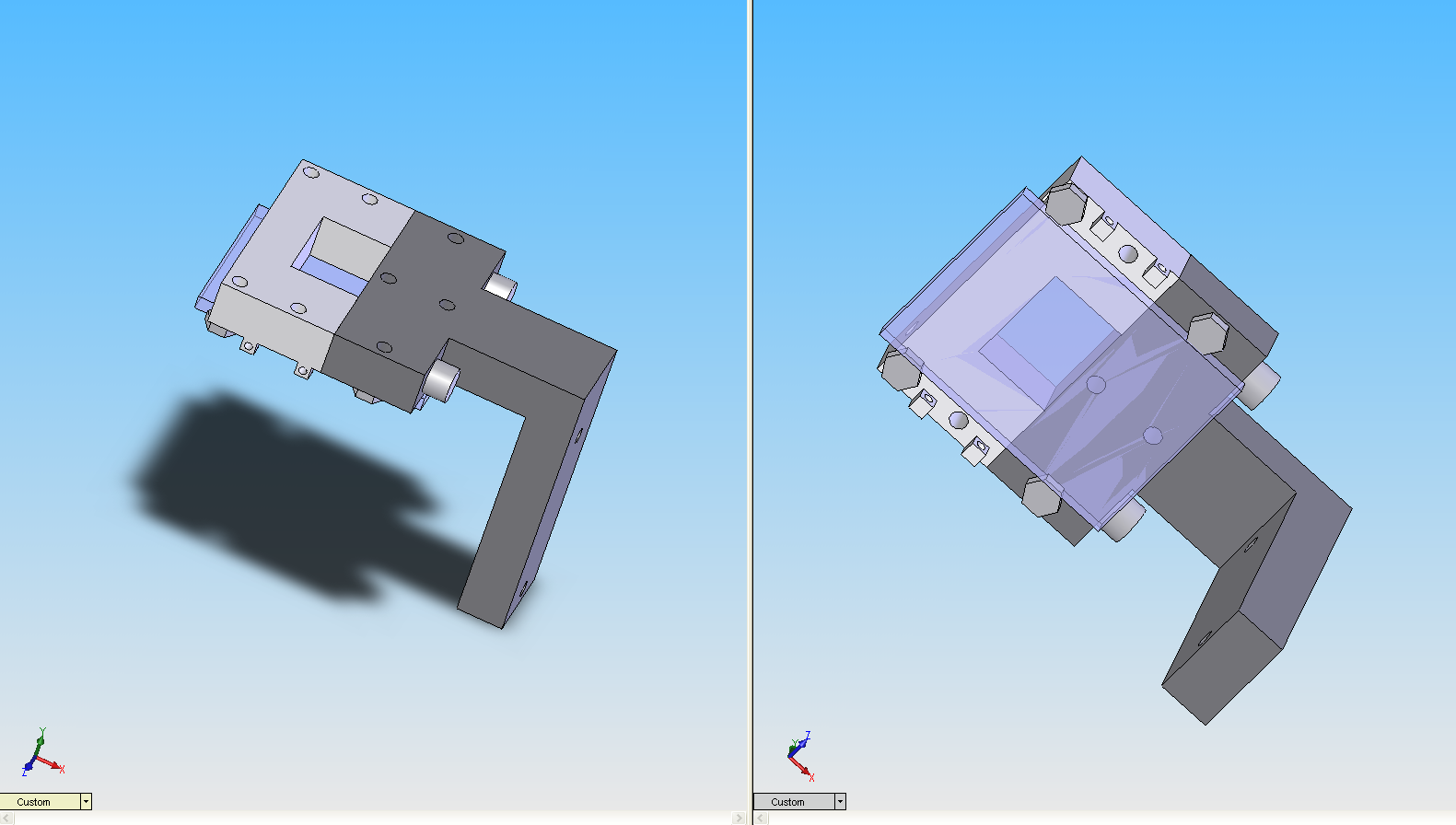

- Worked the end piece of my new arm design with the idea that the end piece could be used alone when the set-up is moved to two axis. Added a place to use set screws as a second shear clamping option. Made the whole arm more narrow. Connected two end pieces to make just one end piece to ensure the end is parallel to the rest of the arm.

| Adhesive Fixture Endpiece | Multi-purpose Clamping Endpiece |

|---|---|

|

|

| adhesivearmscreenshot.bmp: click for larger image | clamparmscreenshot.bmp: click for larger image |

Tuesday, Aug 5

- Looked into low-pass filter for conditioning servo signal for use with electroadhesion. Need to do a simple low-pass filter to convert PWM to analog. Tried to scope the signal to get the frequency but had trouble getting a normal gait back on sticky bot 2. Talked to barret and he fixed it.

- Worked on trying electroadhesion frame on test platform for the first time. Tried first with scotch tape and had trouble because the glass touched other things before touching the sample. Because of the weight of the sample it sags a little and the mylar touches the glass first. Also had a problem because the glass plate could not move low enough to touch the sample. So then I remounted everything with double stick tape and added a couple layers of plastic to raise up the frame. With this second test we were able to align much better, but still had problems with touching the mylar before the sample. So we are going to make a new arm with a much smaller glass piece on the end to make sure we are really just testing the sample and not stuff around it. Despite some uncertainty about exactly what forces we are seeing, we definitely measured .18 newtons of normal force that was due to the electroadhesion. We were happy to discover that the high voltage did not have any unwanted effects on the force plate.

- Test frame on force sensor:

Wednesday, Aug 6

- Used SDM to make a new smaller arm for the force testing platform. We needed a smaller piece of glass to make sure we were only touching the sample and not the mylar or frame around it. Since it would be nearly impossible to get the glass off the current arm we just decided to make a new one.

- Tried mixing carbon and sylgard with the Thinky for the first time. Tried 10% carbon. It came out much smoother than what I had been able to do mixing by hand. Still not perfect on the backing layer, but the wedge surface looks good. It seems that degasing once it is on the wafer doesn't help and might actually make it worse.

Thursday, Aug 7

- Machined and tapped holes for the new arm.

- Got new arm ready to go on force sensor but I made the mistake of making the glass too small so that it doesn't contact both of the electrodes. We could have fixed it but we ran out of time and Noe we won't be read to take more data until Monday because of EPGY and a trip to LA.

- Tried 2% carbon in thinky. It is smoother and easier to flatten than 10%. The question is now how can we tell just how much carbon is enough? Less carbon is better because it is smoother and easier to make flat and thin, but it is also less conductive. So I put together some sheets to try and see if they are clamping ok at 2% carbon.

Friday, Aug 8

- Unfortunately it seems that even at 10% carbon the clamping force is not nearly as strong as simply having an aluminum backing. This is still preliminary as I need to do more tests to determine for sure.

- Tried using the commercially carbon doped silicone that John ordered. It is more conductive than the stuff we make and at first glance it seemed very smooth. It seemed promising, but after curing in the oven at 165C it came out bumpy and didn't fill the wedge side of the mold right. This is puzzling because the under the microscope it seemed smooth when cured on a paper towel rather than a wafer. It is also extremely viscous even at 20% solvent it is not spinable.

Sat, Aug 9

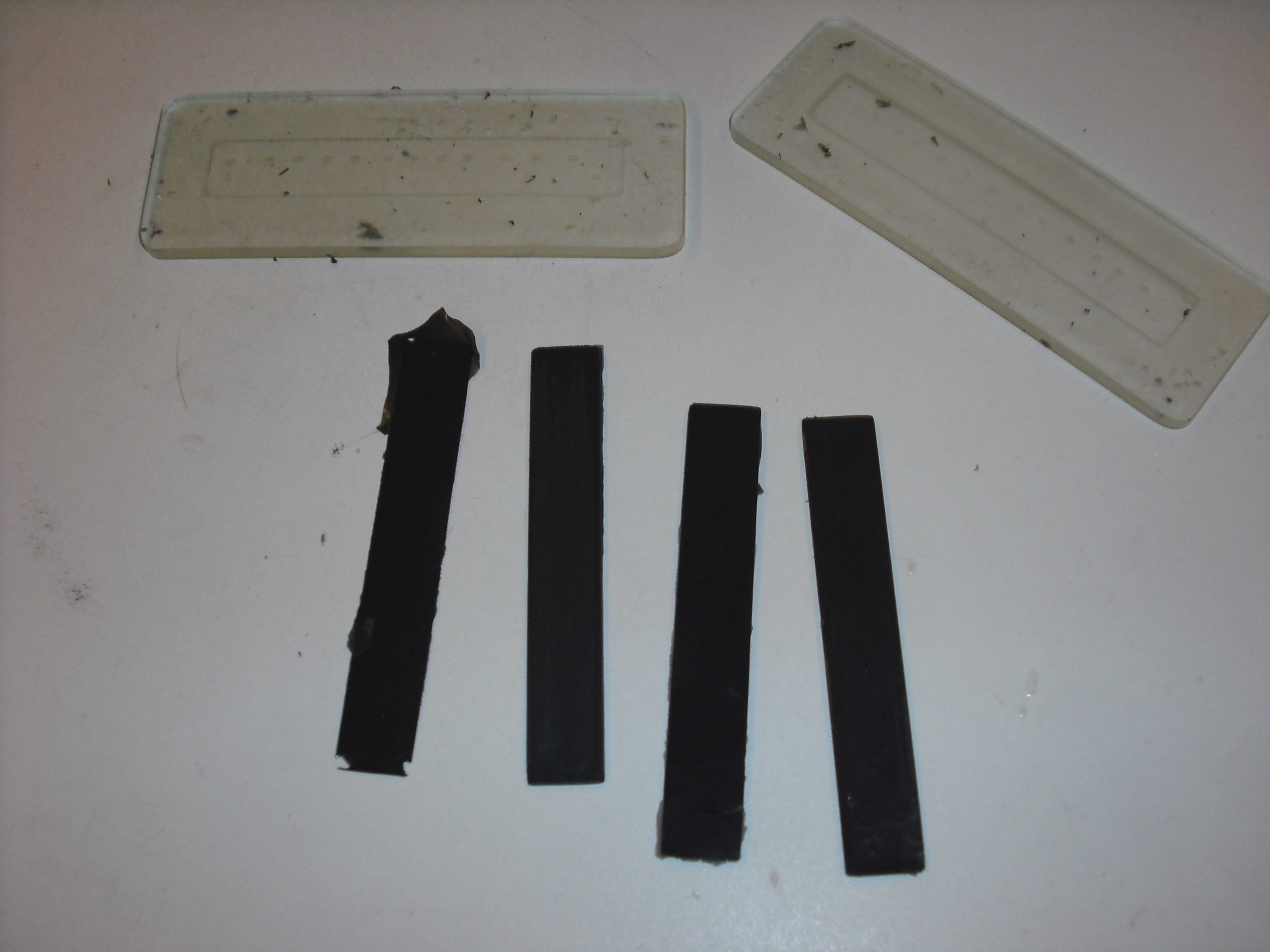

- Made 4 cantilevered tests to isolate pdms from aluminum backing. The performance of the carbon doped pdms was very poor, especially in comparison to aluminumized mylar behind pdms. Even the commercial conductive pdms that John bought performed poorly. It is possible that the weight, shape, and thickness may be having an effect so Sanjay and I decided we should make more standardized cantilevers. To make these I used SDM to make "cantilever molds".

- Sanjay and I played around with measuring resistance. We found that the resistance is highly non-linear with voltage. At 100volts one sample was 1.7MOhms and at 850 volts it was less than 1 MOhm. Despite the promisingly low resistance the performance just wasn't good. There is barely any force detectable by eye/hand with the cantilevered, no backing, conductive pdms.

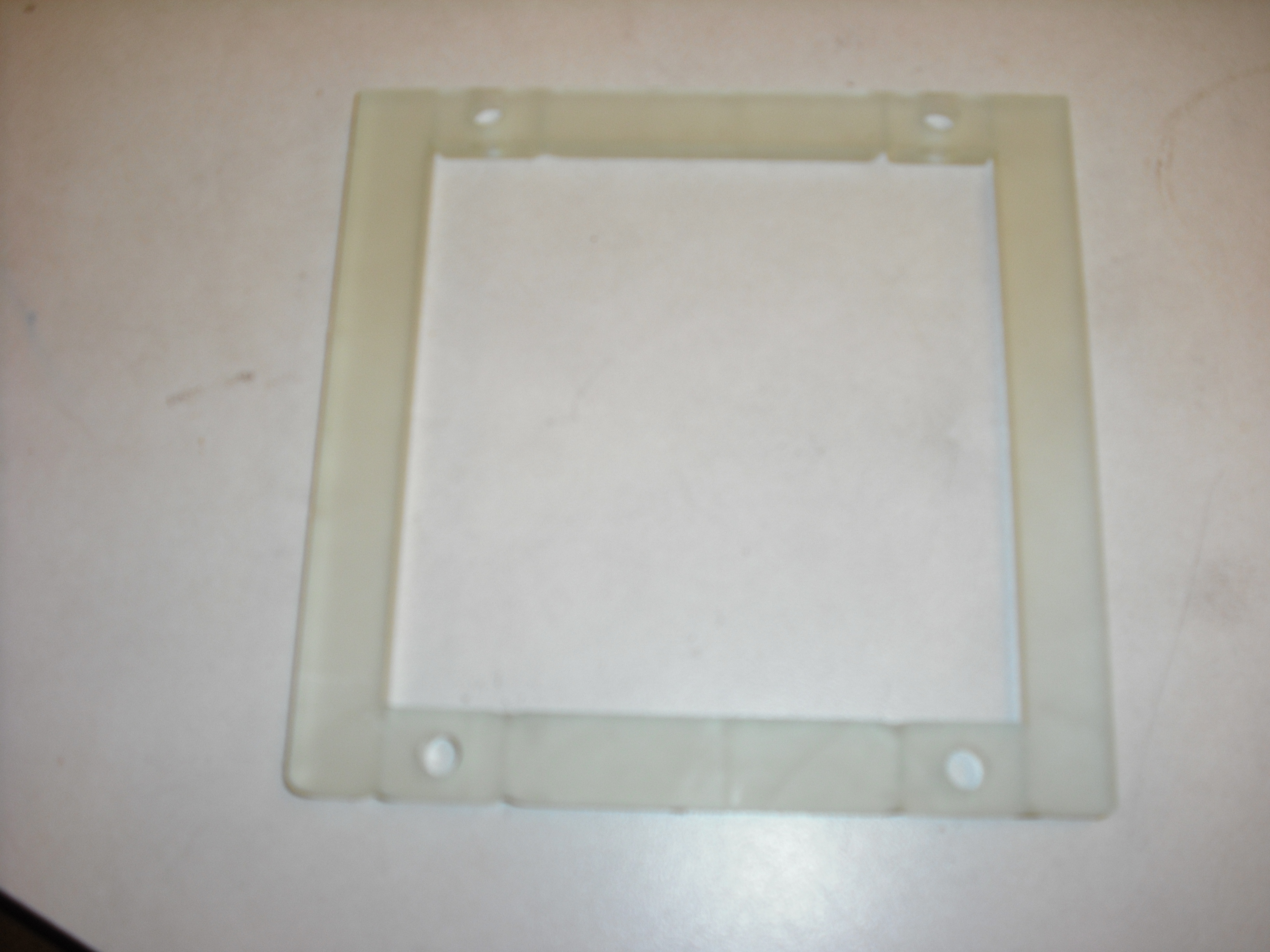

- To improve the force testing set-up I used SDM to make some new frames.

Sun, Aug 10

- Tried carbon with tap blue.

- Made some cantilever shapes with sylgard.

- Tried dipping sylgard in conductive silicone ink.

- Worked on set-up for electroadhesion testing on force plate.

- A "cantilever" test, separating doped silicone from conductive contacts and backings:

- Various electrostatic clamping tests:

- New cantilever shape and their mold for controling size and thickness:

- New repeatable frame with through holes for easy interchangability made in wax block:

- New smaller arm for better stiffness and testing electrostatic clamping forces:

- Wax mold showing cure problems in cracks:

Ideas, requests, problems regarding TWiki? Send feedback