new web: http://bdml.stanford.edu/pmwiki

TWiki > Rise Web>TWikiUsers > MattSpenko>RiSESpaceDesign (12 Jan 2006, MattSpenko? )

Rise Web>TWikiUsers > MattSpenko>RiSESpaceDesign (12 Jan 2006, MattSpenko? )

-- MattSpenko? - 19 Dec 2005

Nylon

Acetal

PVC

Polypropylene

Fluoropolymers

Polyethylene

I remember working with polypropelene and I don't think it is suitable. I'm leaning towards the acetal or maybe nylon. I don't have a good feel for acetal, but it appears to be easily machined, relatively hard, with good impact and tensile strength. Any suggestions??? Acetal is Delrin, if I remember rightly. Super machinable. Strong. Stiffer than Nylon I think. -mrc The more I thought about it, I figured it would be easier if I just sent this thing out to be manufactured instead of making it myself. Thus, I might as well make it using the holes already in place. I received the measurements of the module, and came up with the following two designs. We were thinking of making the design with a small amount of yaw compliance in it. That is why the design narrows in the middle. The main difference between the two designs is that one is lighter than the other (~270g to ~100g). The lighter one may be more expensive to manufacture. The extensions will give us 50mm of clearance between two of the body segments.

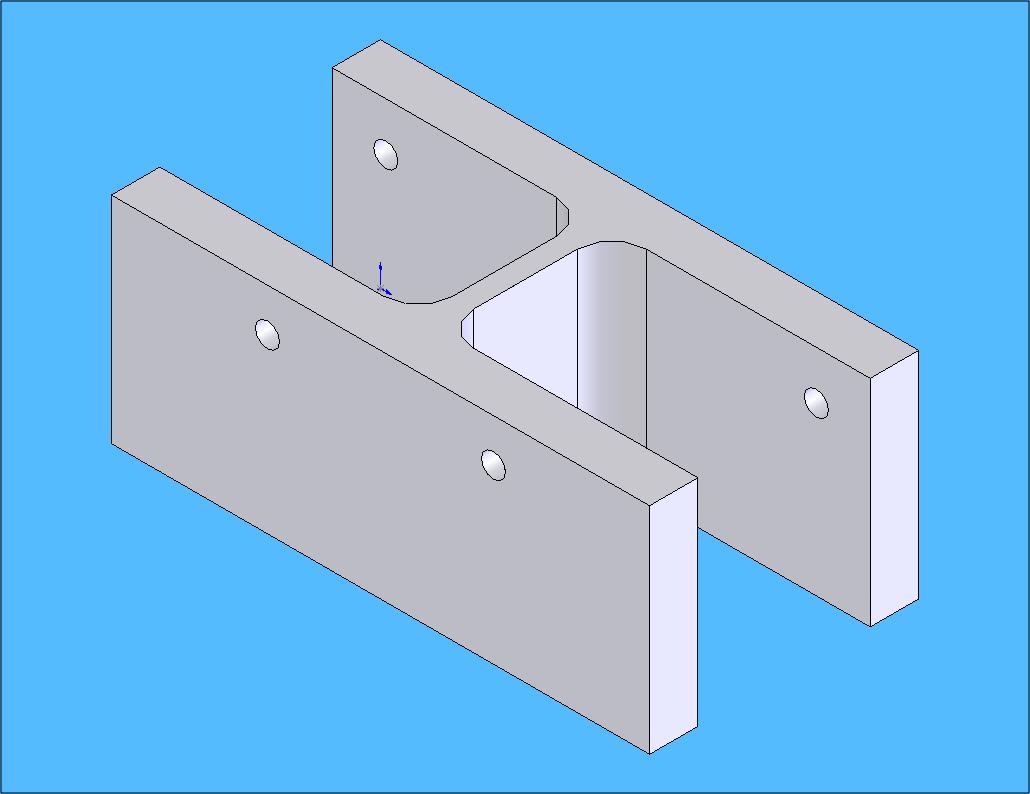

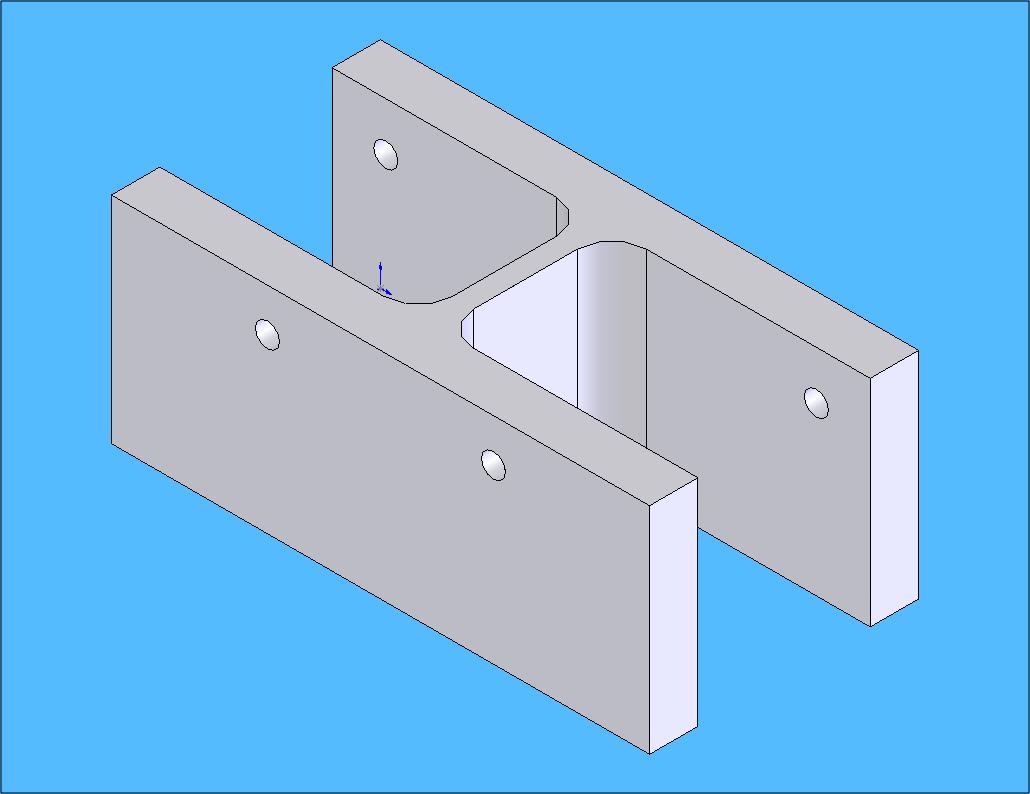

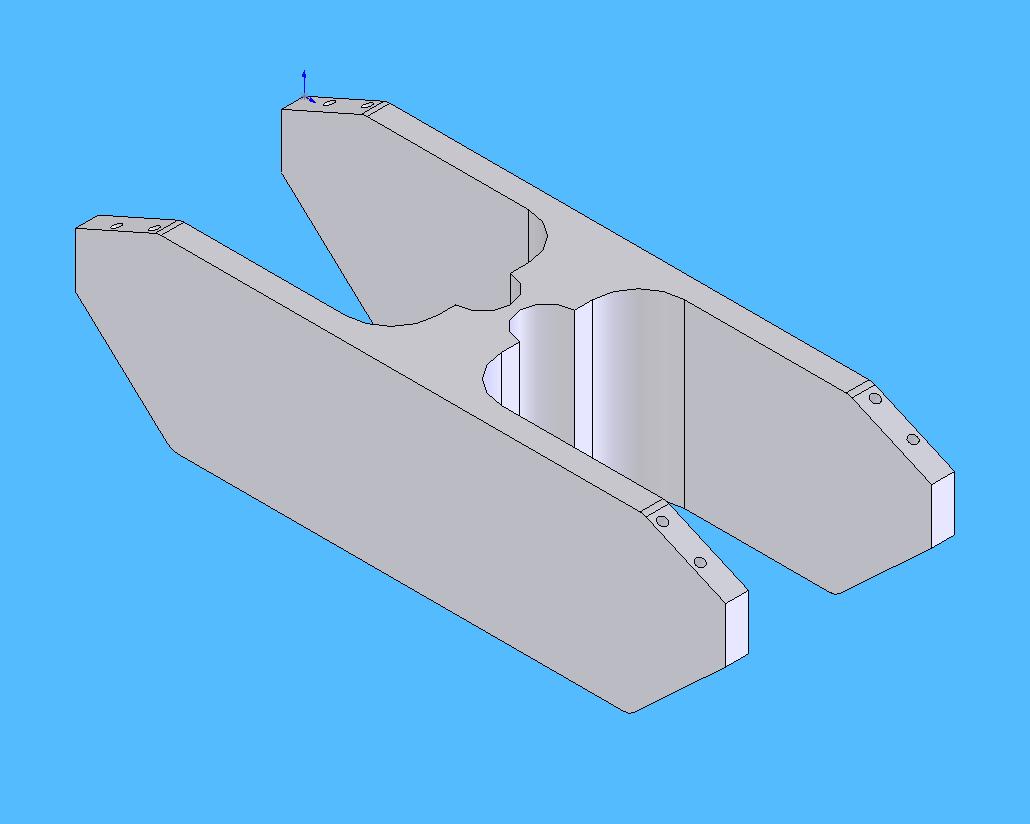

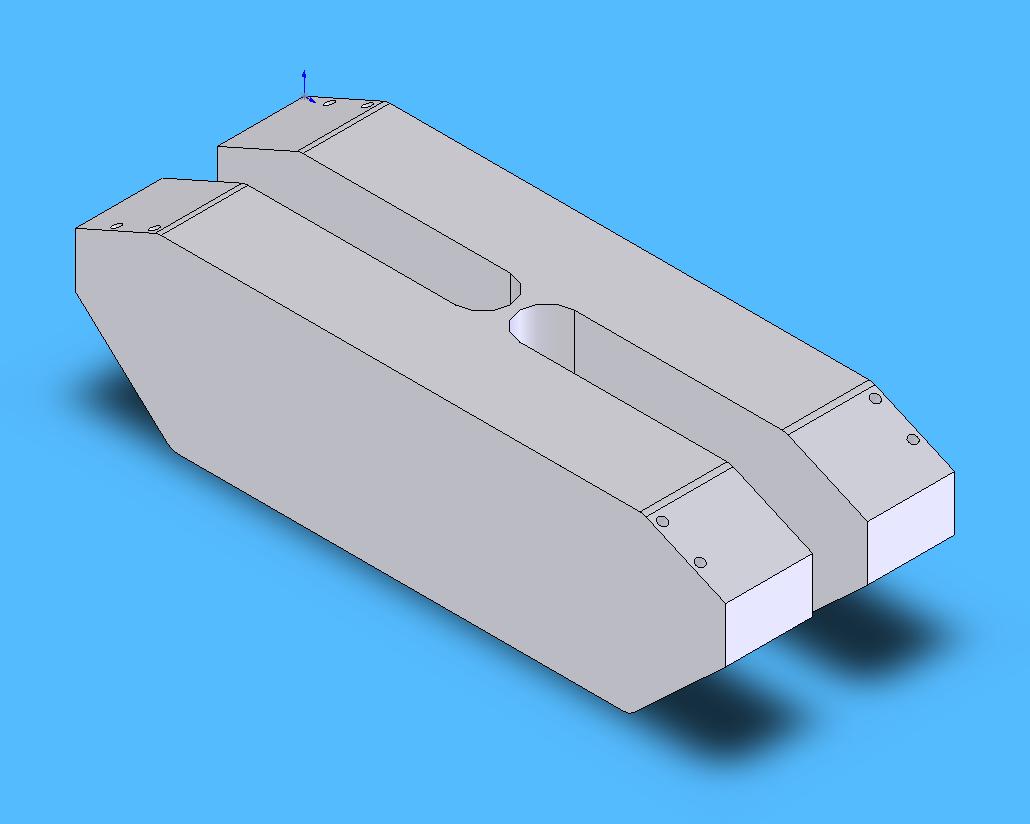

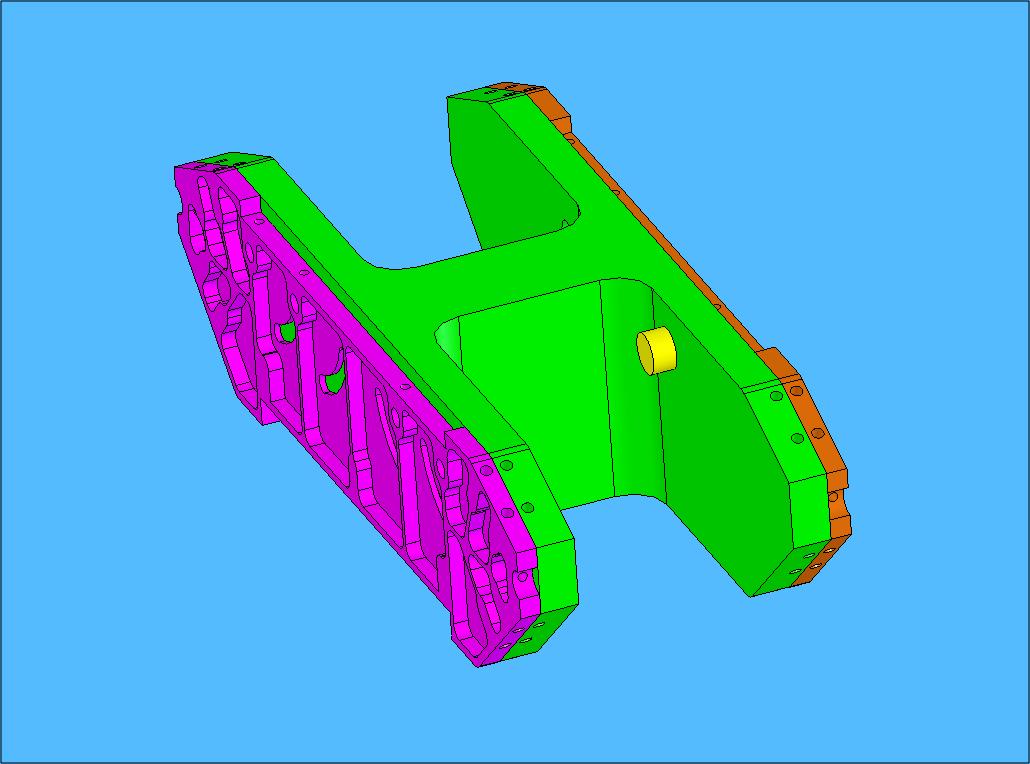

The more I thought about it, I figured it would be easier if I just sent this thing out to be manufactured instead of making it myself. Thus, I might as well make it using the holes already in place. I received the measurements of the module, and came up with the following two designs. We were thinking of making the design with a small amount of yaw compliance in it. That is why the design narrows in the middle. The main difference between the two designs is that one is lighter than the other (~270g to ~100g). The lighter one may be more expensive to manufacture. The extensions will give us 50mm of clearance between two of the body segments.

- extension_v2.jpg:

Nylon

Acetal

PVC

Polypropylene

Fluoropolymers

Polyethylene

I remember working with polypropelene and I don't think it is suitable. I'm leaning towards the acetal or maybe nylon. I don't have a good feel for acetal, but it appears to be easily machined, relatively hard, with good impact and tensile strength. Any suggestions??? Acetal is Delrin, if I remember rightly. Super machinable. Strong. Stiffer than Nylon I think. -mrc

- Ensinger_Delrin.pdf %ENDCOMMENT%

The more I thought about it, I figured it would be easier if I just sent this thing out to be manufactured instead of making it myself. Thus, I might as well make it using the holes already in place. I received the measurements of the module, and came up with the following two designs. We were thinking of making the design with a small amount of yaw compliance in it. That is why the design narrows in the middle. The main difference between the two designs is that one is lighter than the other (~270g to ~100g). The lighter one may be more expensive to manufacture. The extensions will give us 50mm of clearance between two of the body segments.

The more I thought about it, I figured it would be easier if I just sent this thing out to be manufactured instead of making it myself. Thus, I might as well make it using the holes already in place. I received the measurements of the module, and came up with the following two designs. We were thinking of making the design with a small amount of yaw compliance in it. That is why the design narrows in the middle. The main difference between the two designs is that one is lighter than the other (~270g to ~100g). The lighter one may be more expensive to manufacture. The extensions will give us 50mm of clearance between two of the body segments.

- extension_v3.jpg:

- extension_v3a.jpg:

- riseextentioncheckv3.jpg:

Ideas, requests, problems regarding TWiki? Send feedback