new web: http://bdml.stanford.edu/pmwiki

TWiki > Rise Web>MicroAdhesives? >PDMSProceSS (30 Jun 2008, MarkCutkosky)

Rise Web>MicroAdhesives? >PDMSProceSS (30 Jun 2008, MarkCutkosky)

PDMS Process Notes

This page contains about PDMS property & PDMS molding procedure. -- SeungBum? - 12 Sep 2006 Contents:What is PDMS?

Definition

PDMS is polydimethylsiloxane (PDMS), silicone elastomer. PDMS was developed at Whitesides lab at Harvard. It is available from Dow Corning and distributed through KR Anderson. (http://www.kra.com) Most commonly used are Sylgard 182 and 184.- 182: High-temp cure, 45 min at 100C, better for thin coats (down to about 10m)

- 184: Room temp cure, 48 hours

PDMS Property (Reference: ME342 Slide)

PDMS exhibits excellent adhesion to many surfaces (single crystal silicon, silicon dioxide, silicon nitride, glass, and other PDMS).- Young’s modulus near 1.2 MPa. It varies with: 1. base:curing agent ratio 2. Curing temperature and time

- Density (SG = 1.03) does not vary much.

- Can be made hydrophilic by surface oxidation. (it is naturally hydrophobic.)

- Optically clear (varies with PDMS number. ex. Sylgard 172 has black color.)

PDMS Process

PDMS Molding Procedure

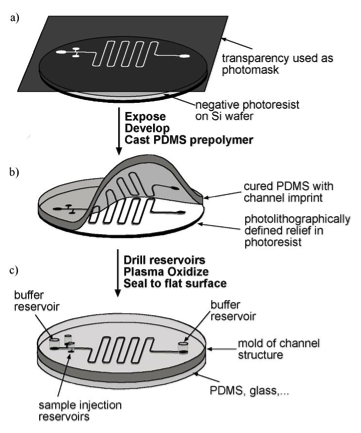

PDMS process is a one of micro mold technique using PDMS for stamp material. It can be molded directly from lithographic master. (usually SU-8)

PDMS Fume hood is in MERL Clean Shop. Inside it, there is vacuum chamber and oven. (Vacuum chamber in MERL clean shop is very weak. Maybe it is better using RPL's vacuum chamber than using it.)

- Mix well 1:10 ratio by weight curing agent: polymer (ratio differs by PDMS number.)

- Do surface treatment if master mold has high aspect ratio or small features less than 50um. (* See surface treatment below explained)

- Degas in vacuum chamber (3 cycles, to remove bubbles)

- Pour onto mold. Put foil under wafer may be helpful when peeling off.

- Cure, e.g. 60 C oven for 1 hr (* See manual or description on PDMS bottle)

- Allow to cool, if using Sylgard 182

- Peel off mold

Surface Treatment (Optional)

If master mold has high aspect ratio or small features, PDMS can be broken when peeling off process. In this case, surface treatment is very helpful to peeling off process.- Find small box in MERL clean shop hood. (This box has warning message on the top. Like this: TOXIC DO NOT OPEN)

- Inside box, there is small cap. Pouring chlorotrimethylsilane into this cap & fill it.

Chlorotrimethylsilane is very toxic & corrosive. Do not touch it and exhale it. Always working in hood. - Close box and wait 5 min.

- Open box and put wafer in the box. There is wafer holder. Close box and wait more 5 min.

- Take out wafer. Close box and leave chlorotrimethylsilane there. It is volatile so that it will evaporate.

PDMS Datasheet (PDF File)

- PDMSdatasheet.pdf: PDMS datasheet

Ideas, requests, problems regarding TWiki? Send feedback