new web: http://bdml.stanford.edu/pmwiki

TWiki > Main Web>ClimbingAdhesion>HierarchicalAdhesionFabrication (17 Nov 2010, MarkCutkosky)

Main Web>ClimbingAdhesion>HierarchicalAdhesionFabrication (17 Nov 2010, MarkCutkosky)

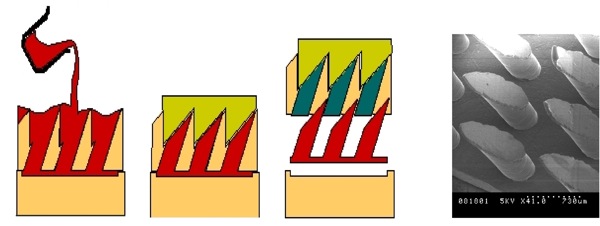

Fabricating Hierarchical, Directional AdhesivesA challenge in creating hierarchical adhesives is that the manufacturing processes used for creating features at the micrometer scale are different from those used at millimeter scales and larger. To create large (e.g. 10cm x 10cm) hierararchical patches, we use two different processes to create molds and we assemble the molded products. The text and graphics below describe the general process as of Summer 2009. We are exploring different materials, bonding methods, and suspension stalk diameters and angles, to improve performance. For details on performance, etc. see the adhesion publications page. |

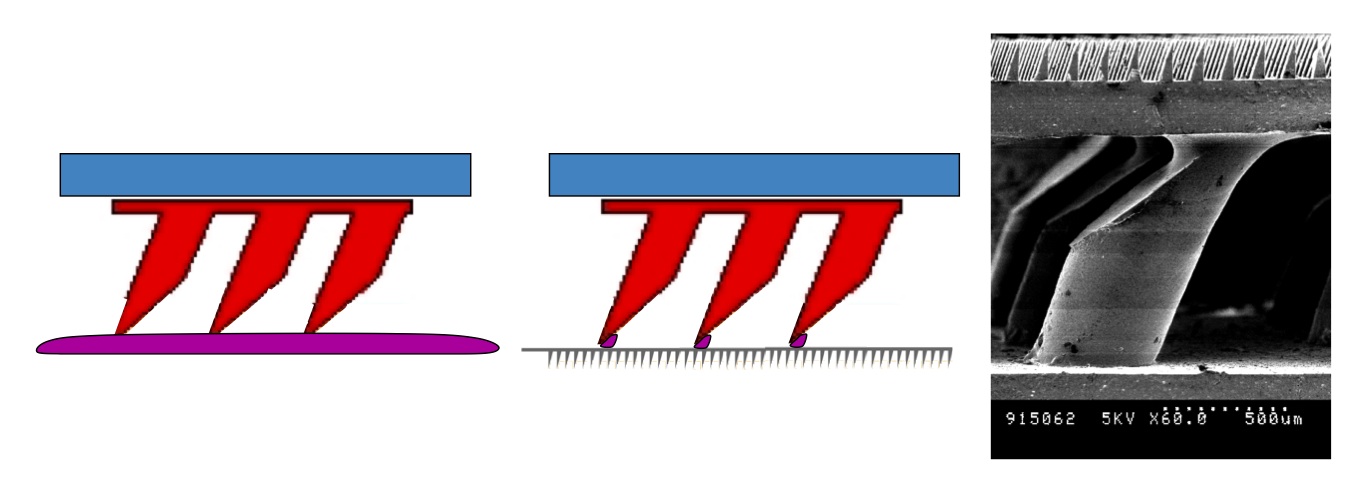

Hierarchical, directional adhesive (version 1) with 0.3mm dia. posts and 20um base-width wedges |

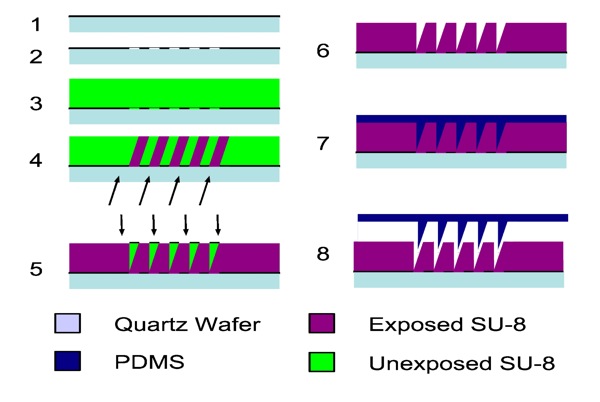

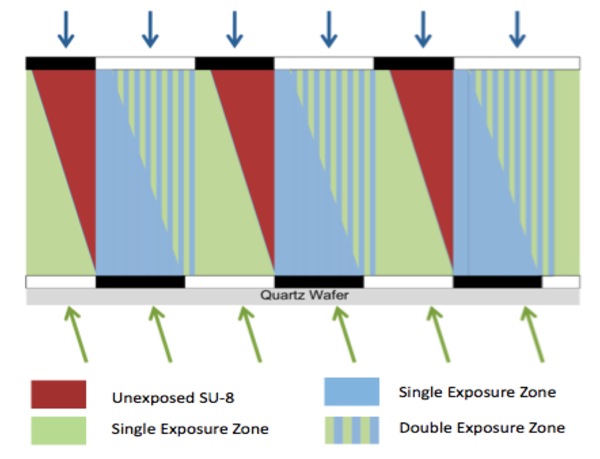

Overmasking with top mask to reduce overexposure. | Overmasking in the top exposure helps to ensure that triangular cavities will have sharp tips and crisply defined surfaces. The microwedges are molded from Sylgard 170 PDMS (Dow Corning). The backing layer thickness is controlled by spinning, to between 100um and 400 um thick. |

Assembly

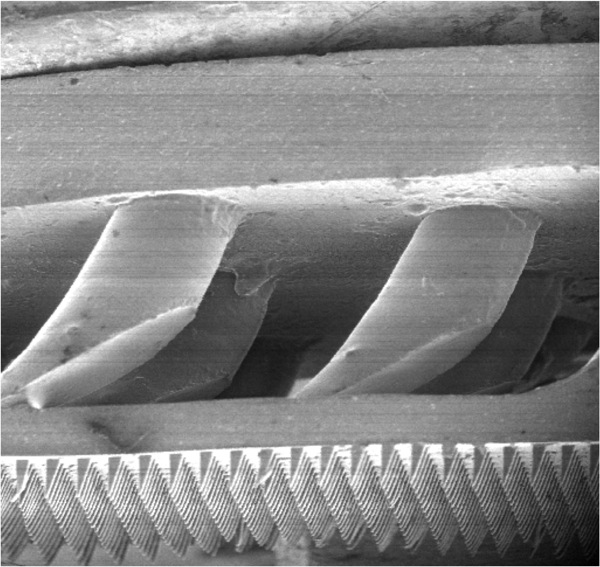

The suspension stalks are dipped in a thin (200-300um) film of Silpoxy or RTV 118 to wet the tips of the stalks, and assembled to the microwedge backing layer with a very light pressure (to avoid deflecting the stalks).

Suspension stalks are dipped in a thin layer of liquid adhesive for bonding to the backing layer of the microwedges

Variations and Optimization

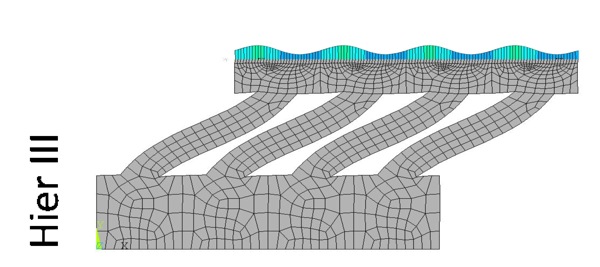

Different combinations of materials and geometries will affect the performance of the hierarchy. Making the suspension stalks slightly longer and more angled than the original DPS stalks on Stickybot results in a softer suspension with a more uniform pressure:

Large-strain ANYSYS model of the suspension, with wedges approximated by a contact model having similar behavior, to assess effects on pressure of varying stalk geometries, stalk-web connections, etc. |

If the stalks get too long, they will stick to each other, or clump; however, there is less danger than with the original DPS stalks because the tips are attached to the backing layer of the microwedges. |

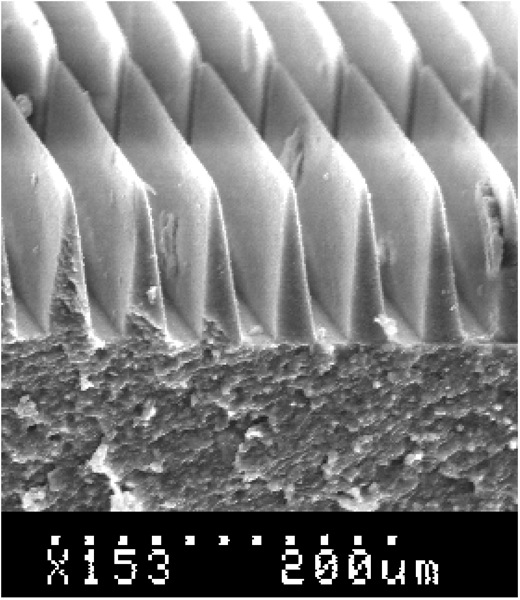

Due to limitations on the double lithography process (underexposure,

overexposure, alignment) there are fewer variations possible at the micrometer scale.

Presently, best results are obtained using 200um long "squeegee wedges" with triangular

cross sections having a 20um base width and 80um height.

PerformanceThe attached video (Quicktime movie) gives an idea of the typical performance of the Hierarchy III patches on a variety of surfaces. For more details see the Climbing Adhesion Publications page. |

"Squeegee" wedges for greater fill ratio

"Squeegee" wedges for greater fill ratio

|

-- MarkCutkosky - started 26 Oct 2009

Ideas, requests, problems regarding TWiki? Send feedback