new web: http://bdml.stanford.edu/pmwiki

TWiki > Haptics Web>StanfordHaptics > ArmTwister>TimingBelts (28 May 2007, MelodyWu? )

Haptics Web>StanfordHaptics > ArmTwister>TimingBelts (28 May 2007, MelodyWu? )

Making Timing Belts

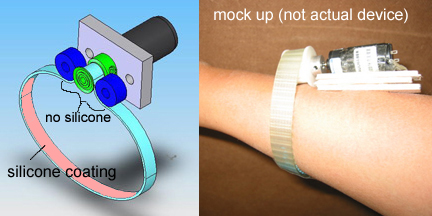

Our current design for a skin stretch device uses a belt that wraps around a subject's arm (very similar to Grigori's device in Tampere). The main difference is that we are attempting to apply static skin stretch, rather than the continuously moving band from Grigori's device. We want the band to maintain contact with the skin in order to be able to apply skin stretch by twisting the belt. After preliminary testing using the sorbothane belts, we decided to experiment with timing belts in order to get smaller, even spacing between the contact points (teeth). Unfortunately, the belts do not have the desired adhesive properties to adhere and apply static stretch skin. Through some prototyping and testing, we've found that softer silicones work well at adhering to skin. The silicones were tested earlier in skin stretch device designs (Karlin's device), but the contact area was too small for the silicone to be useful. With this new device that wraps around the arm, there is increased contact area that allows silicone to be a viable option. Another benefit of using silicone is that the belts can be re-used, unlike the tape currently being used in Karlin's device. The double-sided sticky tape used in Karlin's device also does not stick very well to some timing belts, especially those with pitch smaller than 0.2". Also, silicone appears to work well with hairy skin- it is able to apply skin stretch yet does not hurt when removed from hairy skin.

After preliminary testing using the sorbothane belts, we decided to experiment with timing belts in order to get smaller, even spacing between the contact points (teeth). Unfortunately, the belts do not have the desired adhesive properties to adhere and apply static stretch skin. Through some prototyping and testing, we've found that softer silicones work well at adhering to skin. The silicones were tested earlier in skin stretch device designs (Karlin's device), but the contact area was too small for the silicone to be useful. With this new device that wraps around the arm, there is increased contact area that allows silicone to be a viable option. Another benefit of using silicone is that the belts can be re-used, unlike the tape currently being used in Karlin's device. The double-sided sticky tape used in Karlin's device also does not stick very well to some timing belts, especially those with pitch smaller than 0.2". Also, silicone appears to work well with hairy skin- it is able to apply skin stretch yet does not hurt when removed from hairy skin.

Manufacturing silicone

Manufacturing parts with silicone can be challenging though... with our current design, we would like to coat a timing belt with silicone and still have it driven by a motor.- Neoprene belts have some coating that may be reacting with silicones, preventing the silicone from curing properly- Polyurethane belts do not have this problem

- silicone does not stick to anything except itself - so hard to coat the urethane timing belt

- silicone mold of timing belts, casted timing belts out of dragon skin

- dragon skin ended up sticking to the silicone mold, and the dragon skin timing belt was too soft and stretchy, as expected, but did adhere to the skin well

- pouring silicone over belts and letting it ooze - silicone doesn't conform to the teeth/grooves well, so you end up with a belt with almost uniform thickness

- dipping belt in silicone produces about the same effect

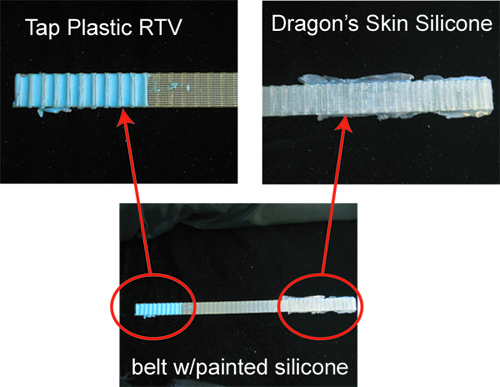

- painting on silicone with a paintbrush seemed to work quite well in creating a thin layer of silicone around the entire belt

- best with the dragon skin (relatively viscous)

- not as good with the blue RTV silicone

- I coated regions of the belt with a thin layer of silicone glue beforehand, and the dragon skin stuck to these regions but not really to the uncoated regions

Melody's notes

- 5/10 - making a mold for the timing belts

- I taped timing belts from Stock Drive to the bottom of a lid and poured RTV-627 silicone over it

- 5/11 - would like to coat a timing belt with softer polyurethane or silicone to do some testing on how that feels on the skin

- probably not possible to make an even layer on the top of a belt

- better idea to make my own timing belts using SDM

- talked to Sangbae, should probably embed some fabric in the part so that it is stiffer and won't stretch as much in tension

- make a cavity and pour in layers of silicone and/or polyurethane

- try out different pitch and widths easily

- need to CAD up some designs for wax blocks, etc.

- 5/15 - make a thin layer on top of the belt (mill out wax block cavity):

- 5/16 - tried out double sided sticky tape, various spray-on adhesives

- double sided sticky tape has problems conforming/sticking to 0.08" pitch belts -- teeth are too small!

- ok for 0.2" and 0.375" pitch belts

- doesn't stick to neoprene belts - might be because of the silicone residue or some sort of protective coating

- aerosols aren't sticky after drying

- 5/17 - tried pouring/dipping belt into dragon skin and blue RTV

- doesn't conform to teeth; fills in dips such that you can't feel the teeth anymore

- 5/18 - used a paintbrush to paint on a thin layer of dragon skin and blue RTV silicone to the belt

- 5/19 - I checked and it worked pretty well! -- conformed to teeth and still very bendable and hard like a timing belt, but adheres very nicely to the skin.

- really not "accurate" but quick prototype

- Dragon's skin sticks really well to skin- slightly easier to paint on belts

- siliconeBelts.jpg:

- 5/18, 5/19 - started machining wax block mold to hold belt in place and accurately apply a thin, even coat of silicone to encase different regions of the belt

- had to divide the part into 3 sections -- Haas threw error 'bad number' probably because code too long

- 5/23 - poured dragon skin -- belt turned out very nice!

Ideas, requests, problems regarding TWiki? Send feedback