new web: http://bdml.stanford.edu/pmwiki

TWiki > HSPrivate Web>HumanSafePrivate>ForceSensingResistor (15 Sep 2008, JohnUlmen)

HSPrivate Web>HumanSafePrivate>ForceSensingResistor (15 Sep 2008, JohnUlmen)

Force Sensing Resistor Skin (FSR Skin)

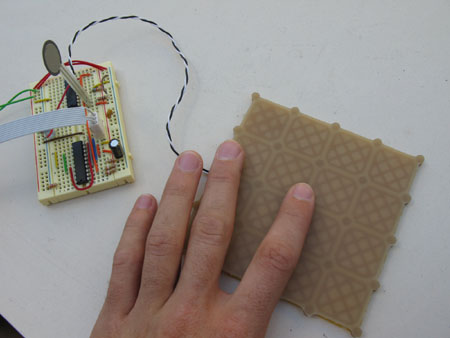

| A flexible, formable skin was designed for use with FSR's to test their viability as low cost force sensors. |

A flexible, formable skin for use with FSR's:

|

Force sensing resistors (FSR's) decrease in resistance as an increasing force is applied. They are great for qualitative measurements of force and are commercially available.

Advantages of FSR's:

|

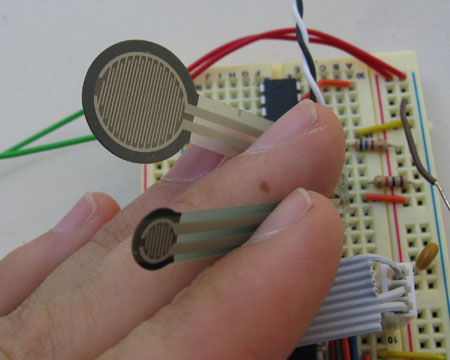

Some examples of FSR's:

|

| The main design considerations for the FSR skin were to create a flexible, soft, formable skin that transfers all applied forces through sensing elements. Transferring all loads through sensors means that there will be no missed contacts. This is a conflicting design parameter with others such as flexibility and formability, but is still highly desirable. FSR's are placed directly below small pegs that protrude from the bottom of the skin. The skin has a structural design with fabric backing to ensure that all applied loads run through the pegs to the FSRs. |

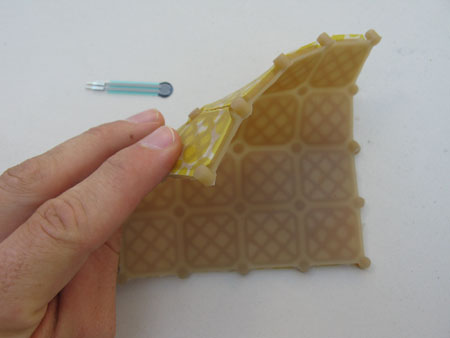

FSR Skin folded back to show FSR sensor below:

|

| The sensor rests beneath the protruding peg. Note the fabric backing that adds strength to the skin and helps route applied loads through the FSR's. |

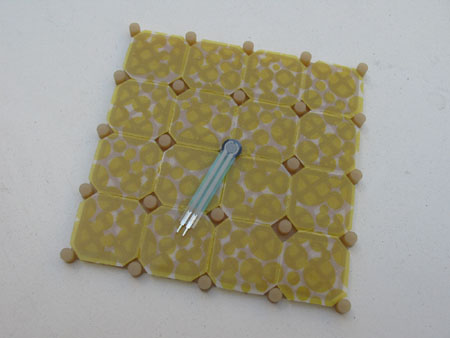

FSR skin showing fabric backing and sensor location:

|

| The skin is made from VytaFlex 40, a soft urethane rubber compound that has exceptional toughness and flexibility. Though the skin has structural elements to transfer loads through sensors, it is still very formable and is not damaged by severe misforming. |

FSR skin compressed to show formability:

|

Ideas, requests, problems regarding TWiki? Send feedback