category: SummerBlogs

- Rob's Summer Blog

Week 8

The Awesome BDML Crew

- I am truly grateful to Mark, Tony, and the entire BDML crew for opening the doors to their world for me. I'm not sure if they realize how extraordinary the day-to-day work they do here is. As an outsider, I arrived everyday and was awe-inspired every minute I was there. I am struggling to develop an appropriate answer when people back in regular life ask, "Hey, what did you do this summer?" I keep coming back to, "You had to be there, really." It doesn't adequately capture the experience, but echoes at the inexplicable

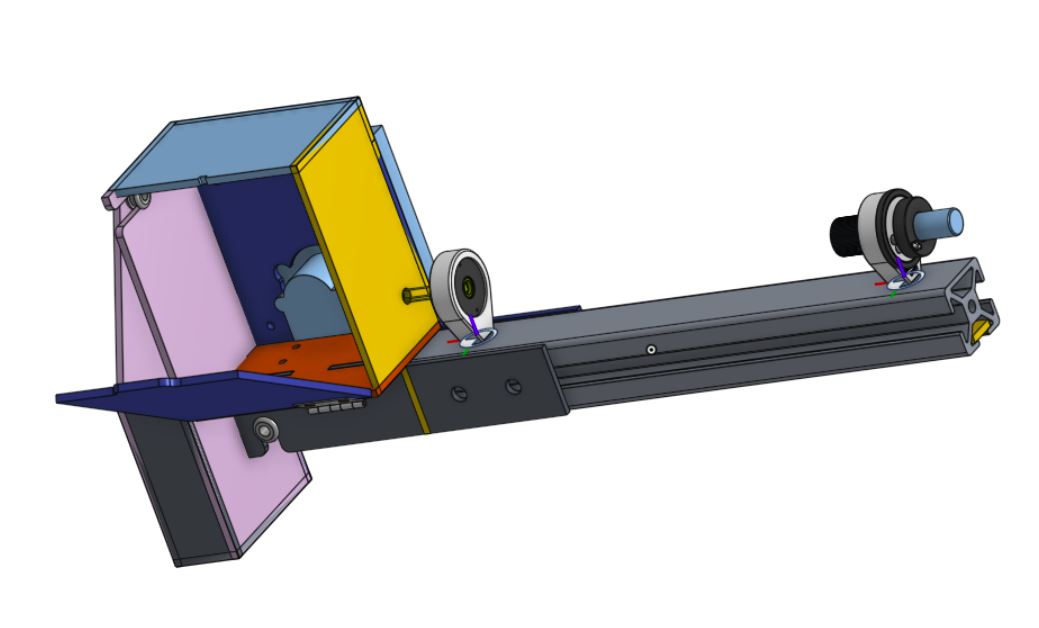

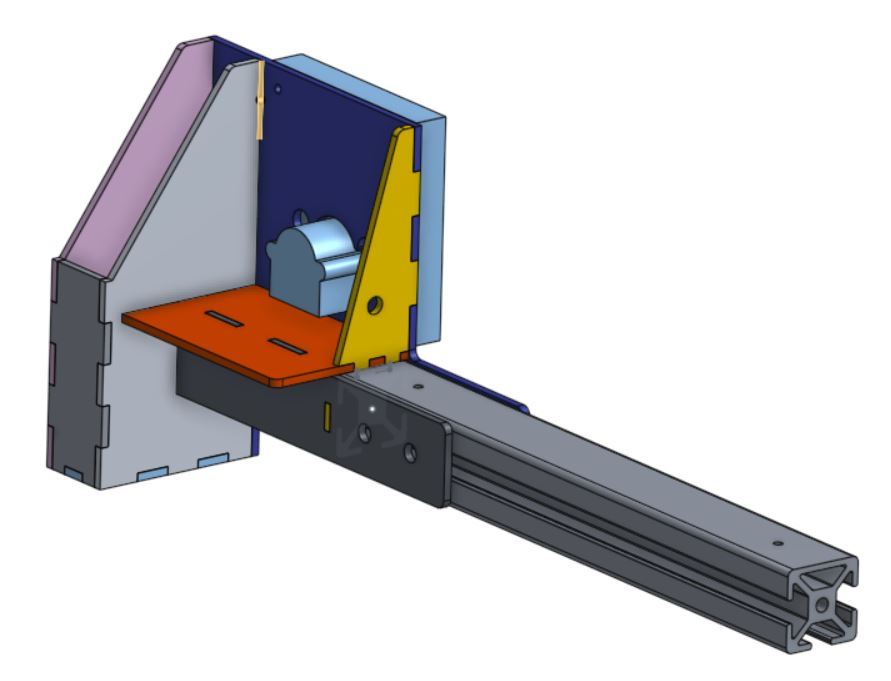

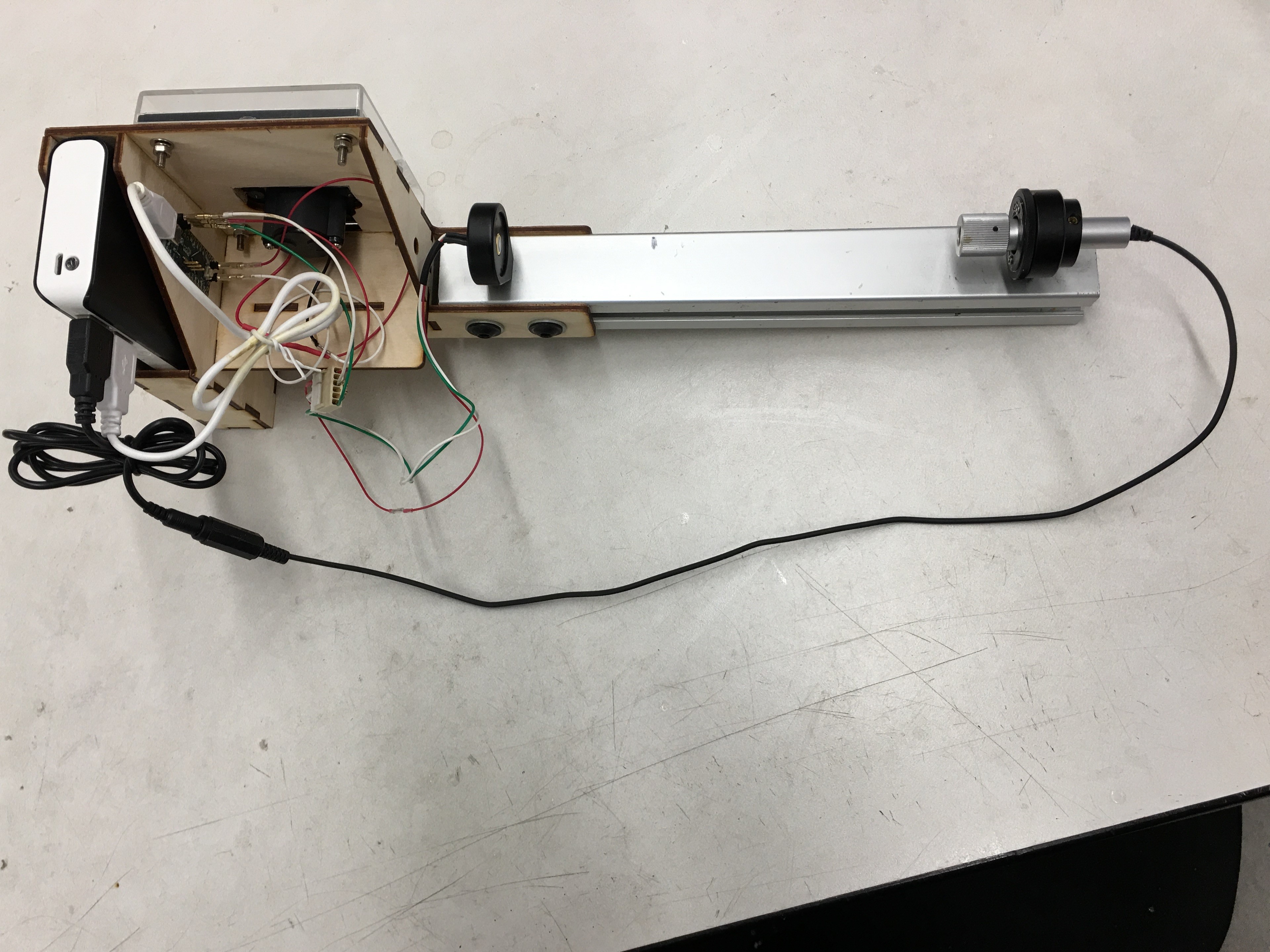

1st Iteration-Laser Alignment Sensor

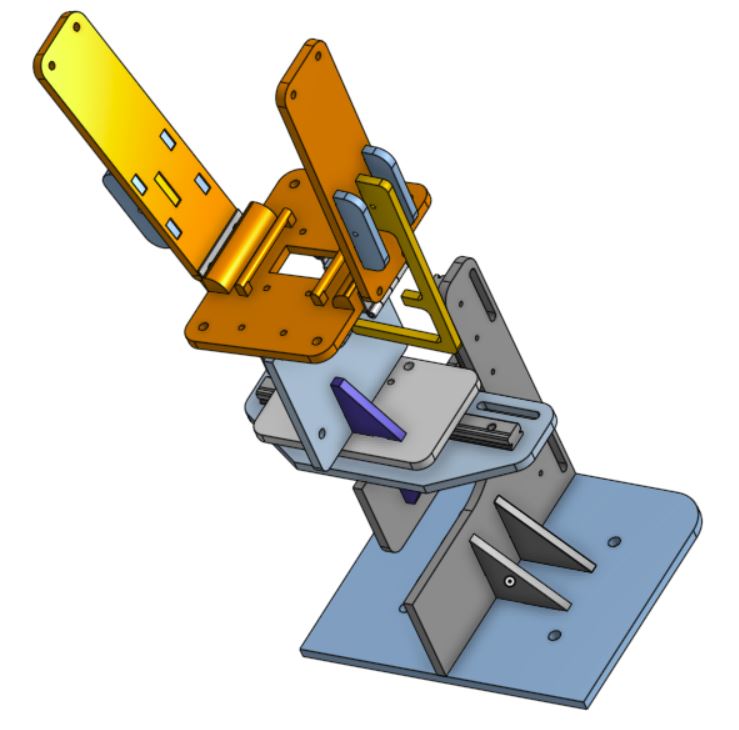

- Worked on multiple iterations on CAD for the Laser Alignment Sensor

- Lowered main wire/electronics compartment box to allow clearance inside CNC mill

- Added wire pass-throughs to connect to battery

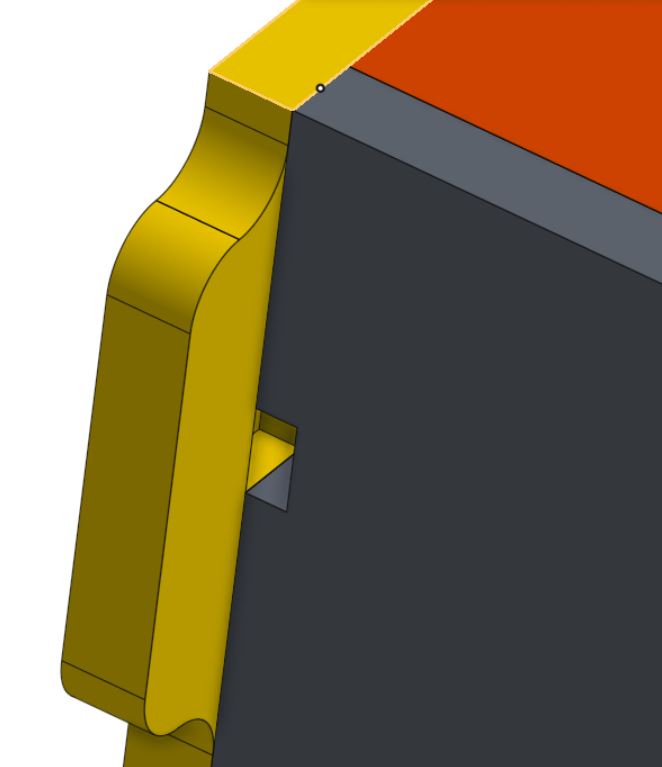

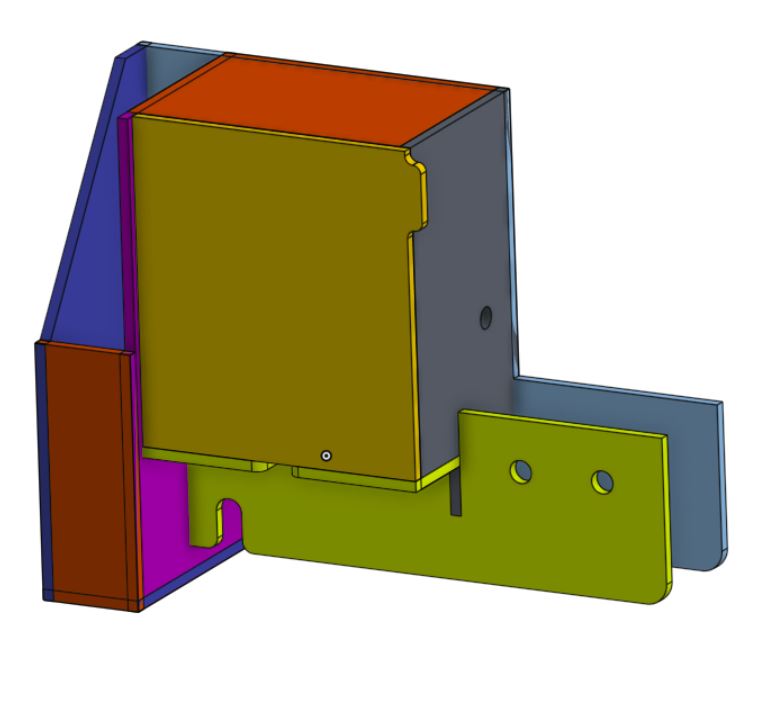

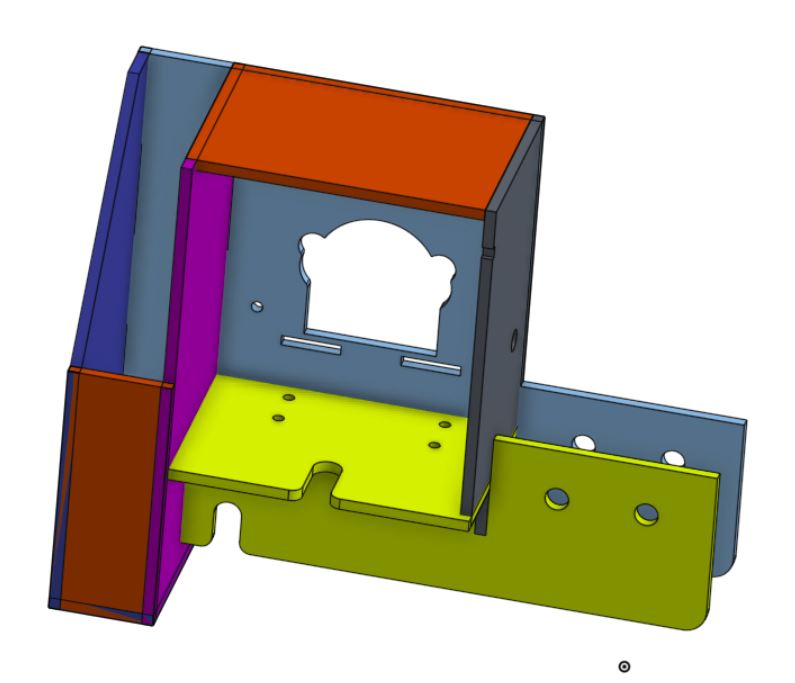

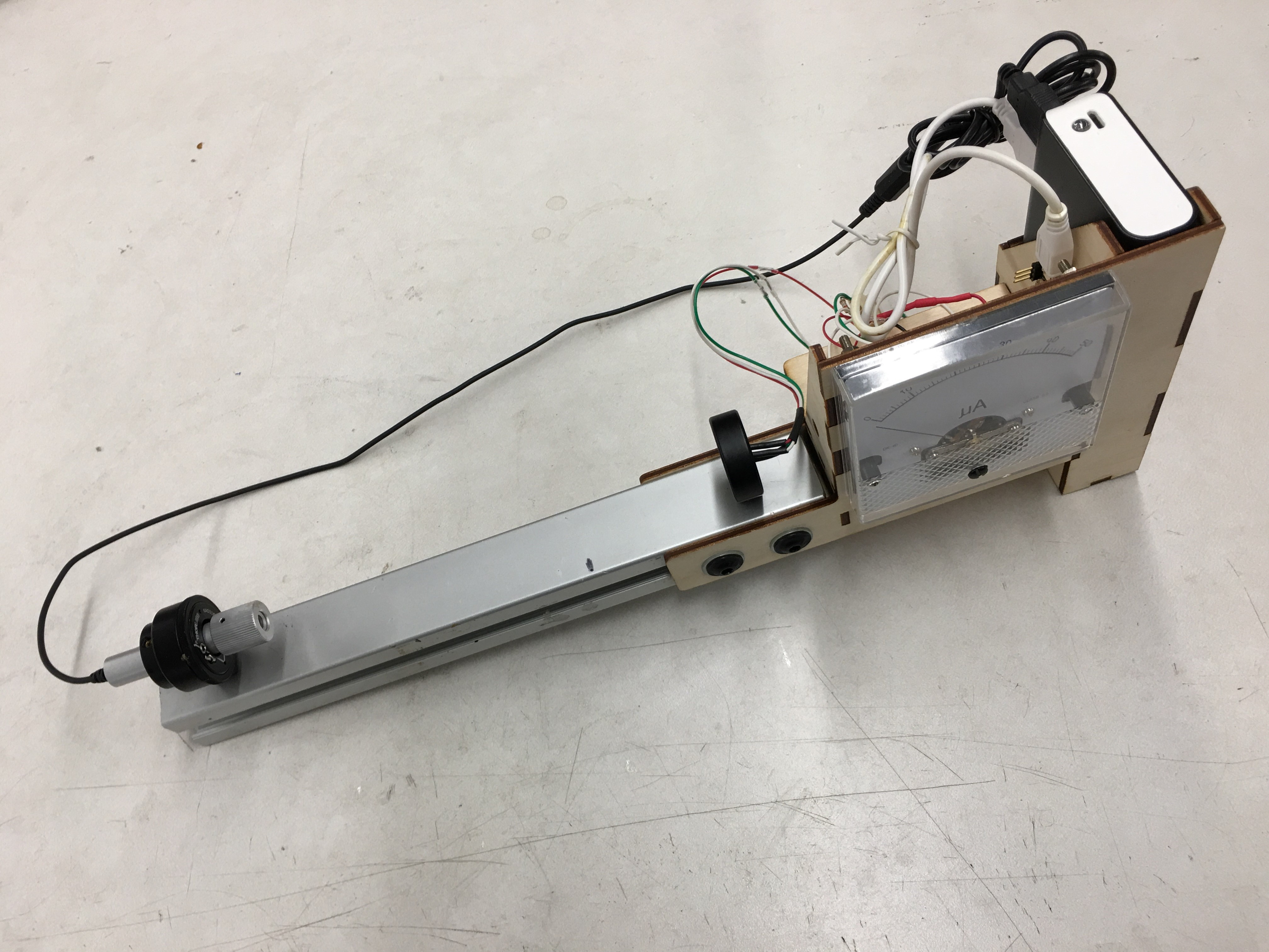

2nd Iteration-Laser Alignment Sensor

Door detail showing magnet cavity

2nd Iteration-Laser Alignment Sensor

Lowered main wire compartment box

2nd Iteration-Laser Alignment Sensor

Interior view

- Completed 36" x 48" poster for the poster session this Friday. 3-1/2 page bibliography, which is not on the poster, is the reason why I tend to lay awake at night pondering the implications. I went for the fabric printing for durability. Now to see how people react...

Week 7

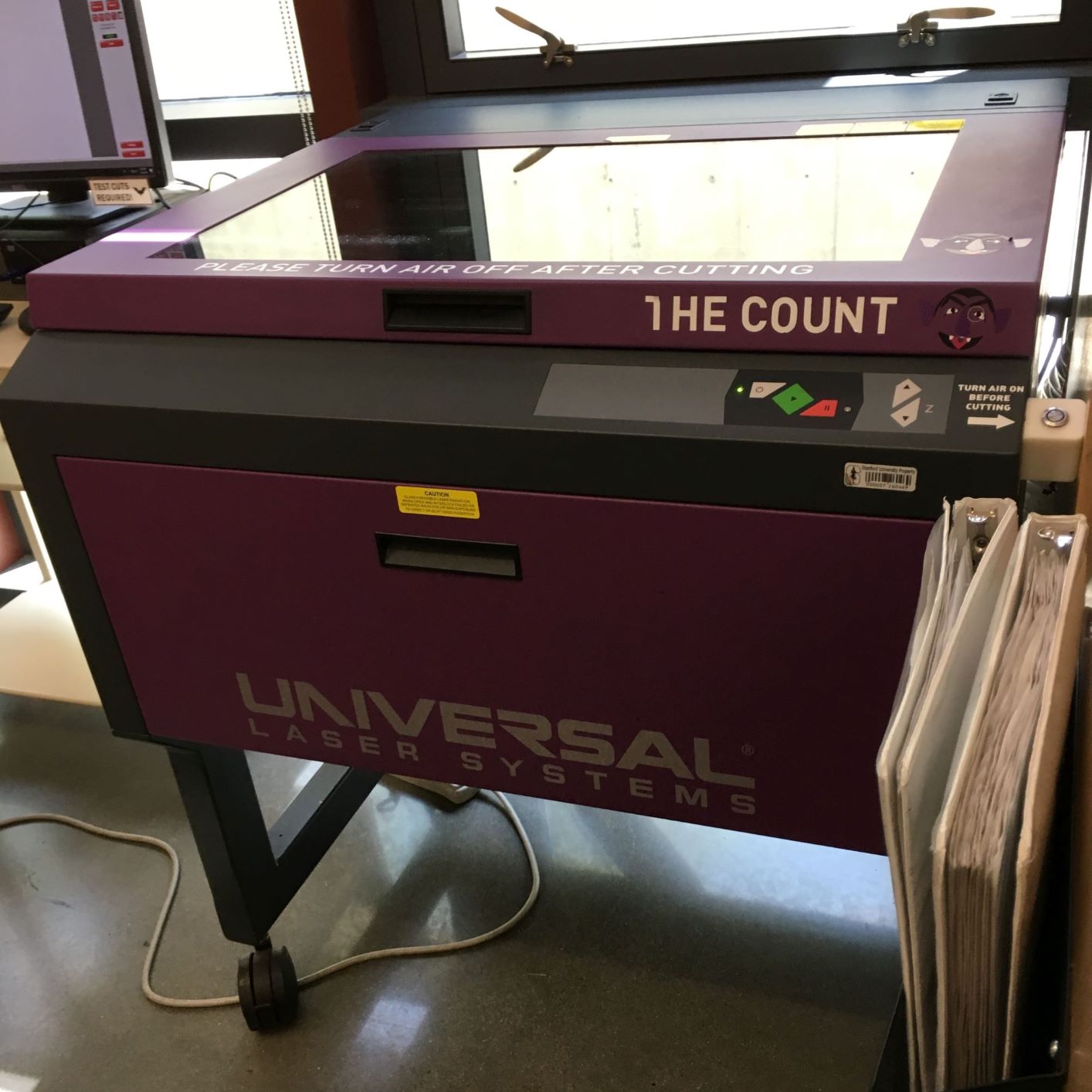

- Took multiple trips to the Rapid Prototyping Lab (Room 36) with Joel to see the laser cutting process

- Spoke with Dan Somen, manager of Room 36 about laser cutter maintenance and process, as well as effective teaching approaches

- Amar showed Joel and I how to set up and operate the Haas CNC

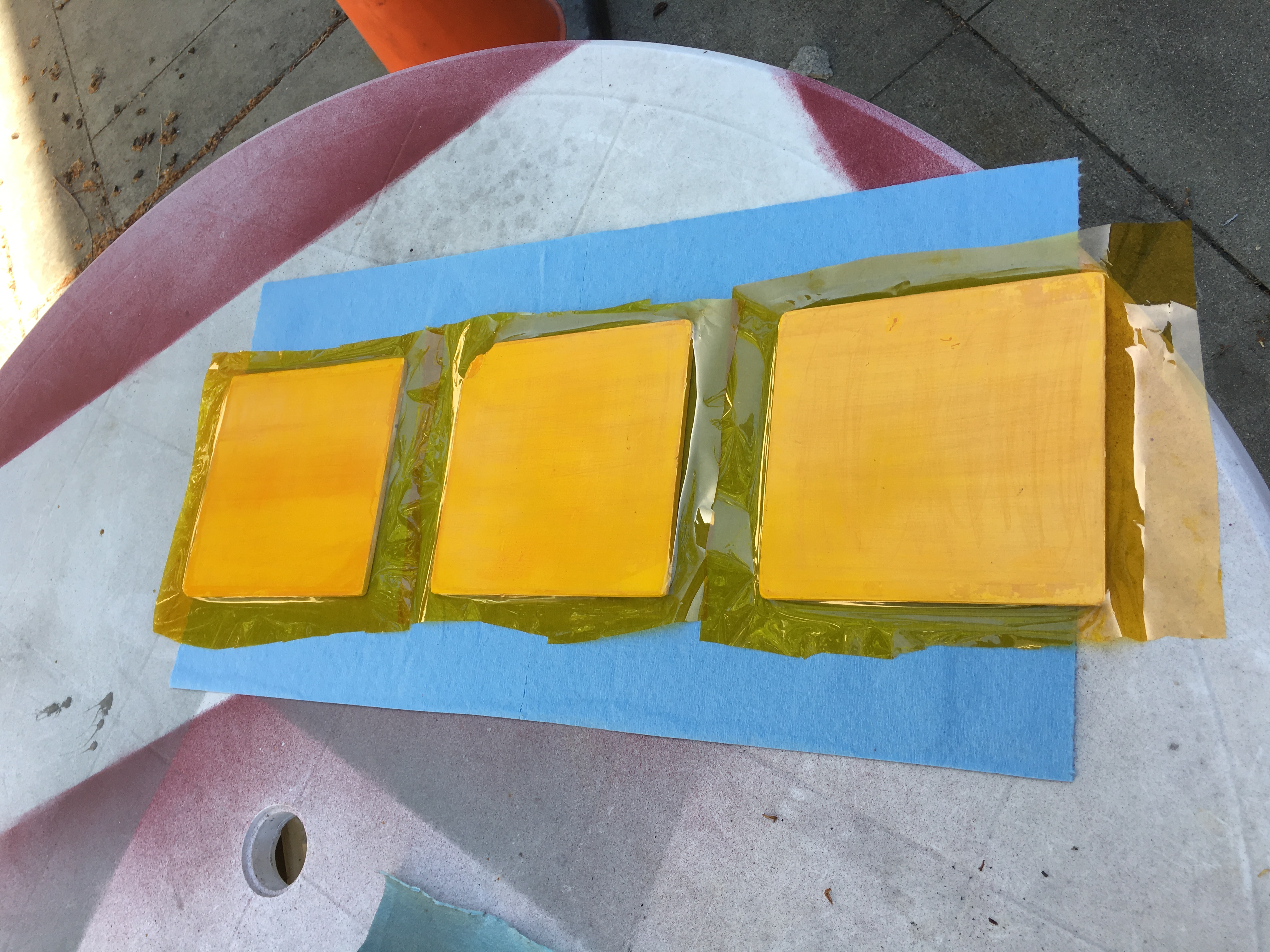

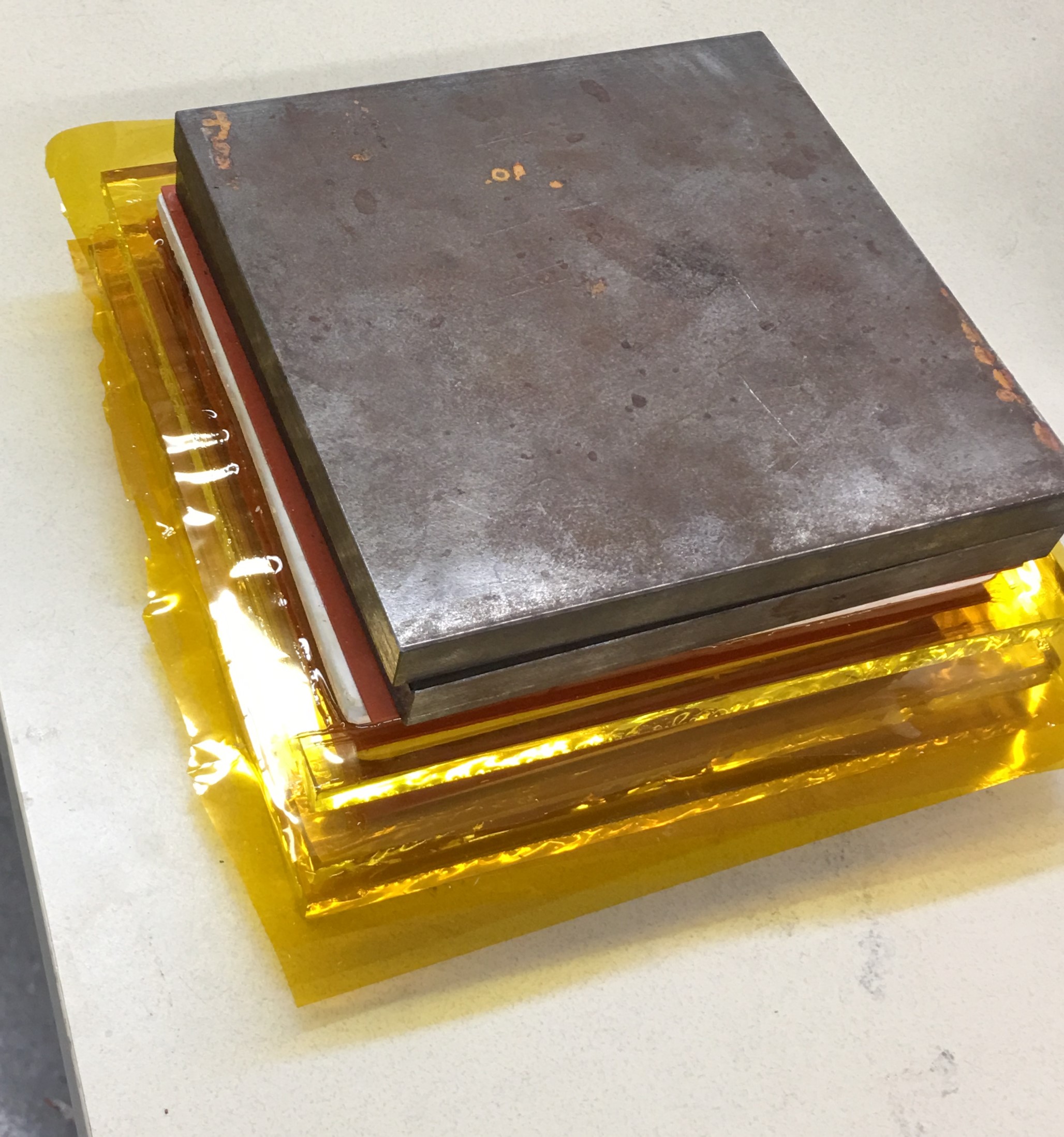

- Amar completed resurfacing and milling 5 Gecko adhesive molds

- I helped refill the Sylgard 170 silicone and casted 2 flexible-backed and one rigid-backed Gecko adhesive strips

Room 36 Laser Cutter

Amar aligning microtome blade with

Laser Alignment Sensor on CNC

Aligning microtome blade to wax on CNC

- Worked on the Ignited poster for our poster session on August 2nd

- Continued modeling the Laser Alignment Sensor

- Encountering challenges making the modifications robust and ready for laser cutting

- Wilson offered some excellent CAD strategies:

- Building outward is usually easier

- Focus on key dimensions

- Have a good vision of its entirety

- Plan for future modifications so geometries and symmetries are not compromised when size changes occur

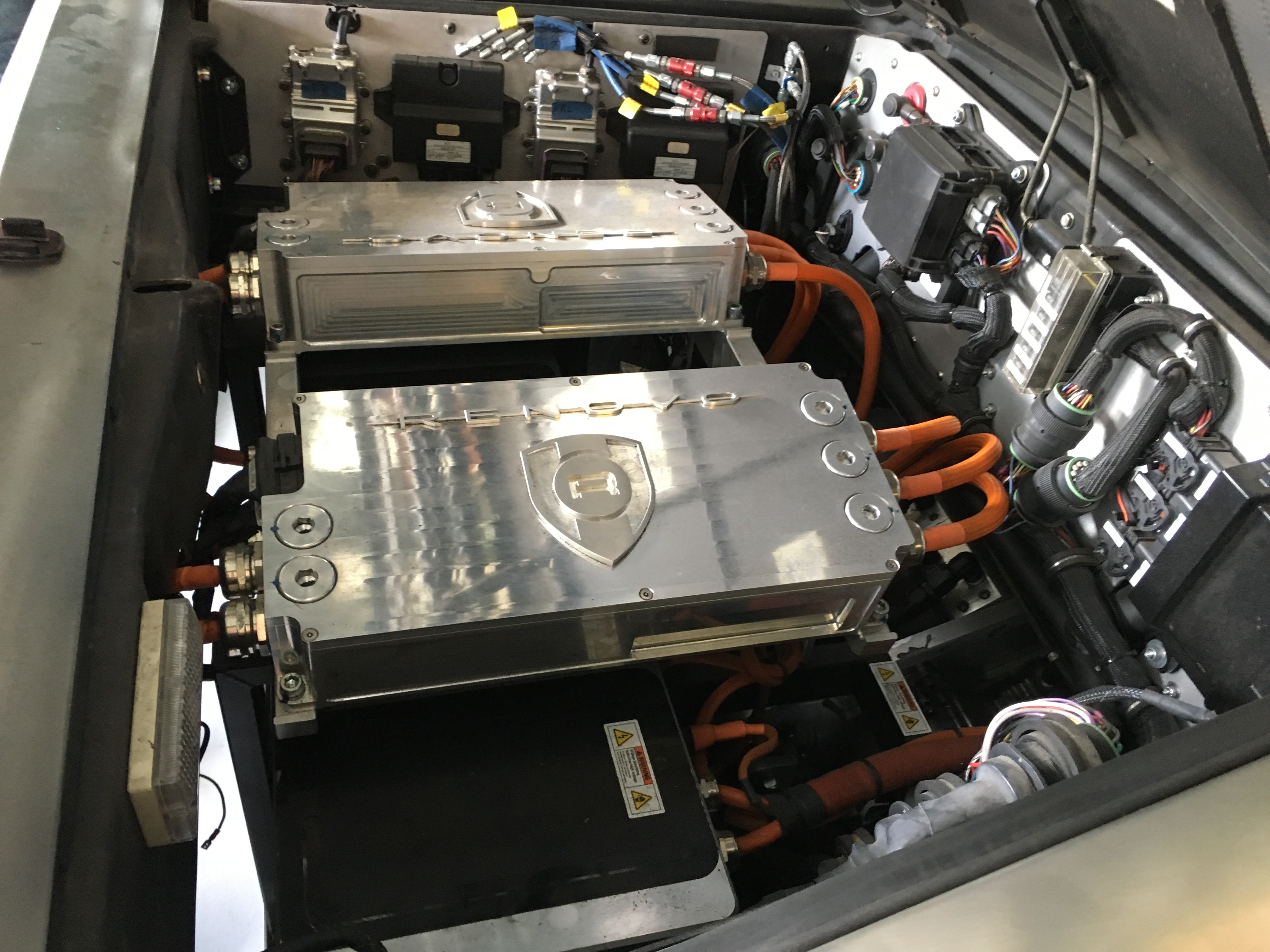

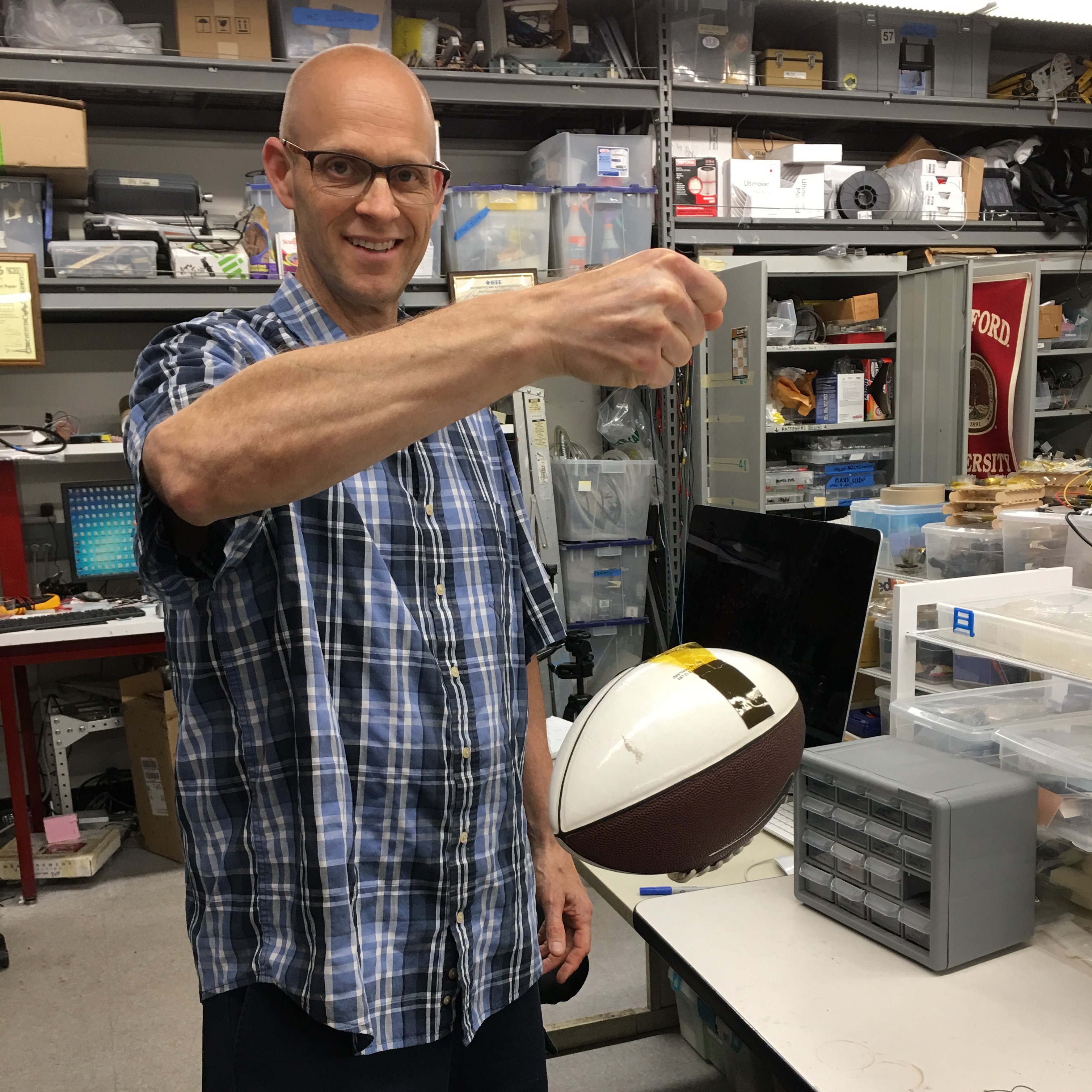

The Marty autonomous vehicle

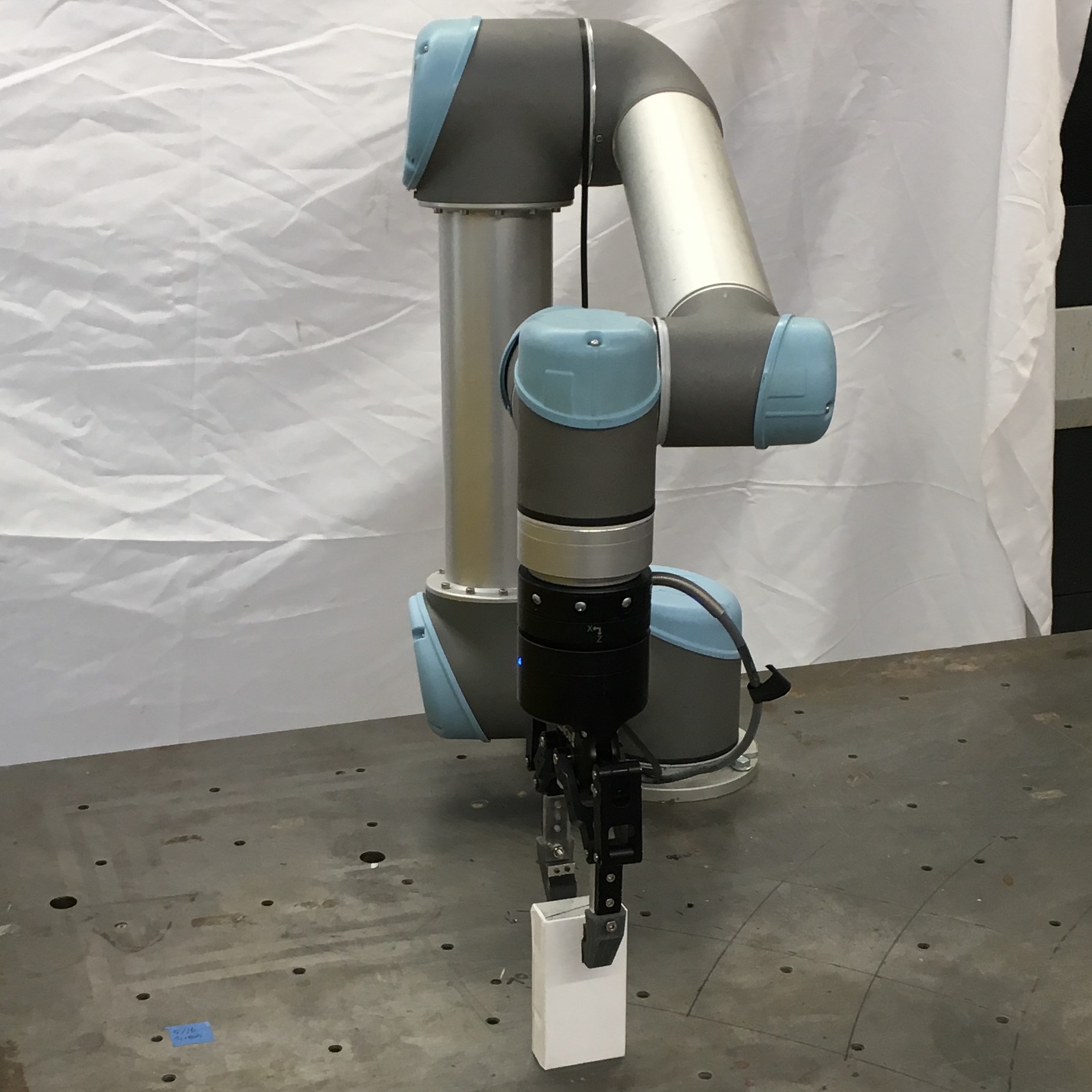

The Robot testing arm

- Jeff O'Connell, a math teacher from Ohlone in the Autonomous Vehicle Lab arranged a tour of their garage. Awesome!

- Helped Amy set up for photo shoot with the robotic arm. She is testing 1,000 grabs using the Gecko adhesive to measure material degradation

Week 6

Current Laser Alignment Sensor modeled by Arul

- Began work on Onshape creating an electronics enclosure for the Laser Alignment Sensor

- The Laser Alignment Sensor allows for proper alignment of the Microtome blades on the Haas CNC mill

- The gecko adhesive molds are manufactured on this mill

- Observed an awesome presentation by BDML crew to the ~30 high school students in the Stanford Stars summer program that has a biology focus

Current Laser Alignment Sensor back

Current Laser Alignment Sensor front

Haas CNC Mill

Week 5

- Removed excess Kapton tape from demonstration devices to improve functionality

- Additional training on Onshape

NASA Bi-Stable Gripper on Onshape

Demonstrating Gecko Adhesive

Excess Kapton tape removal

Week 4

- Finalized assembly of NASA Bi-Stable Gripper

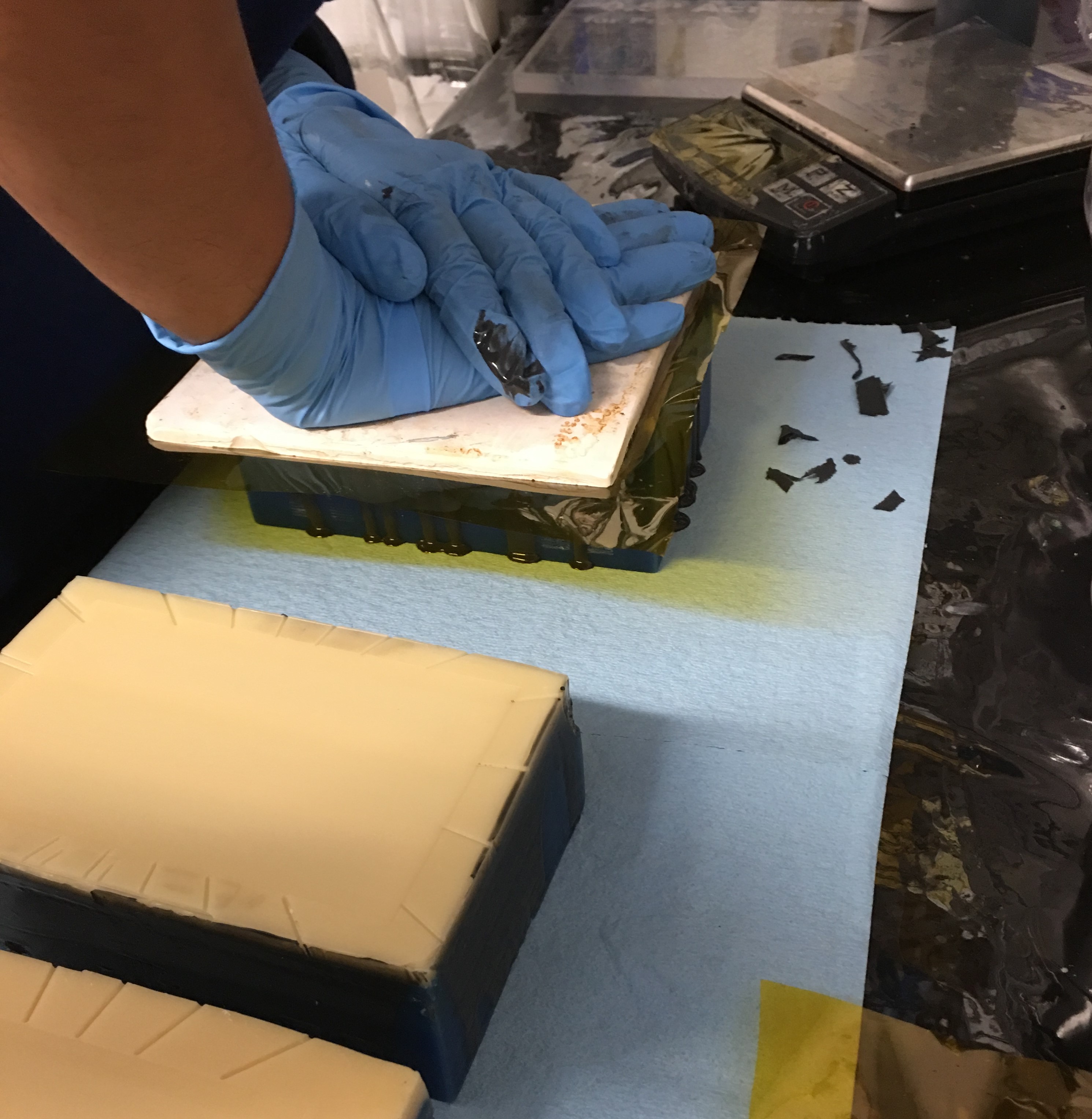

- Amar taught me how to create the backing for the Gecko adhesive

- Tony showed me how to remove Gecko adhesive from the mold and make the demonstration devices

9. Making demonstration device

8. Gecko adhesive trimmed

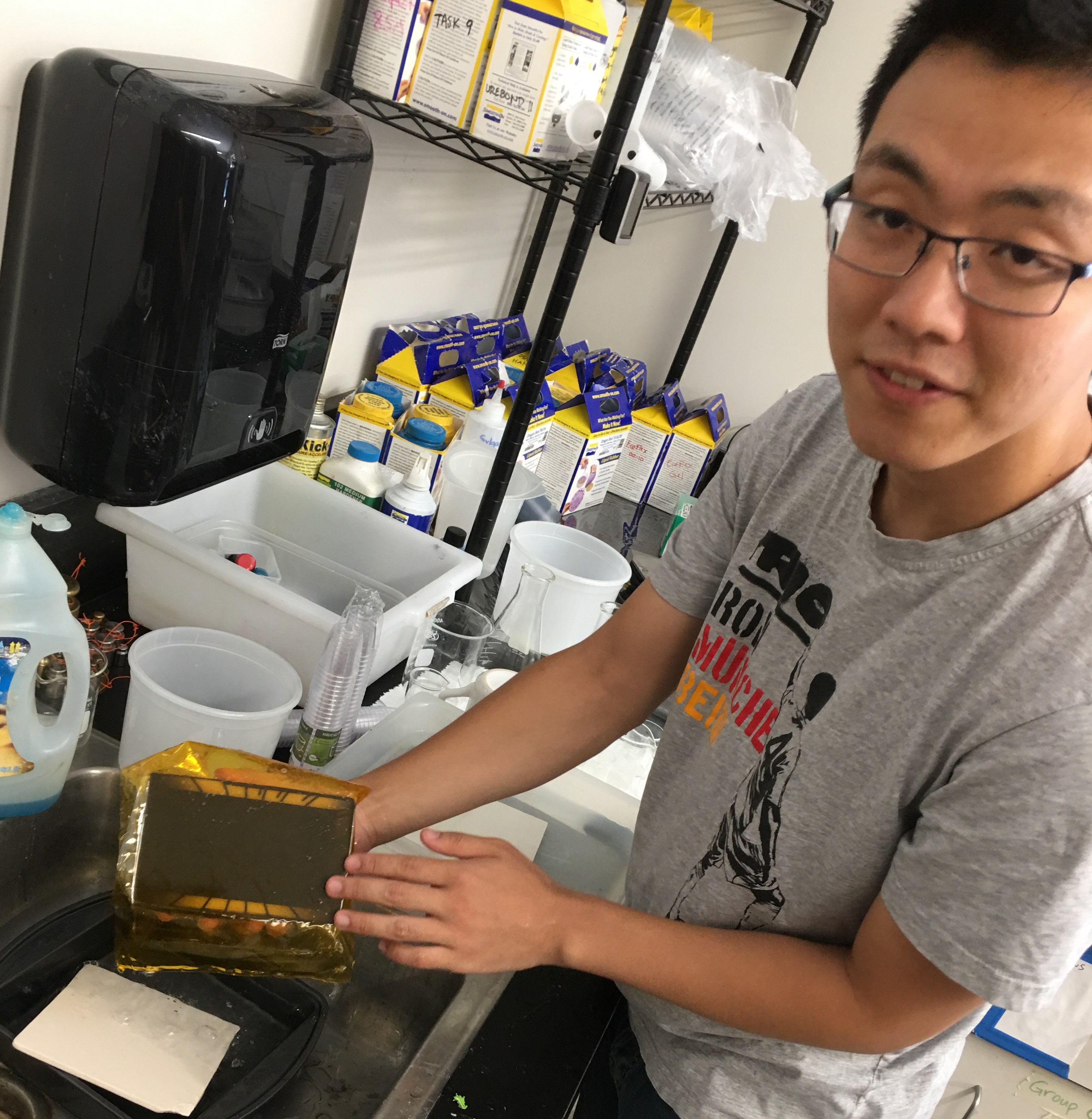

7. Tony Chen demonstrating the process

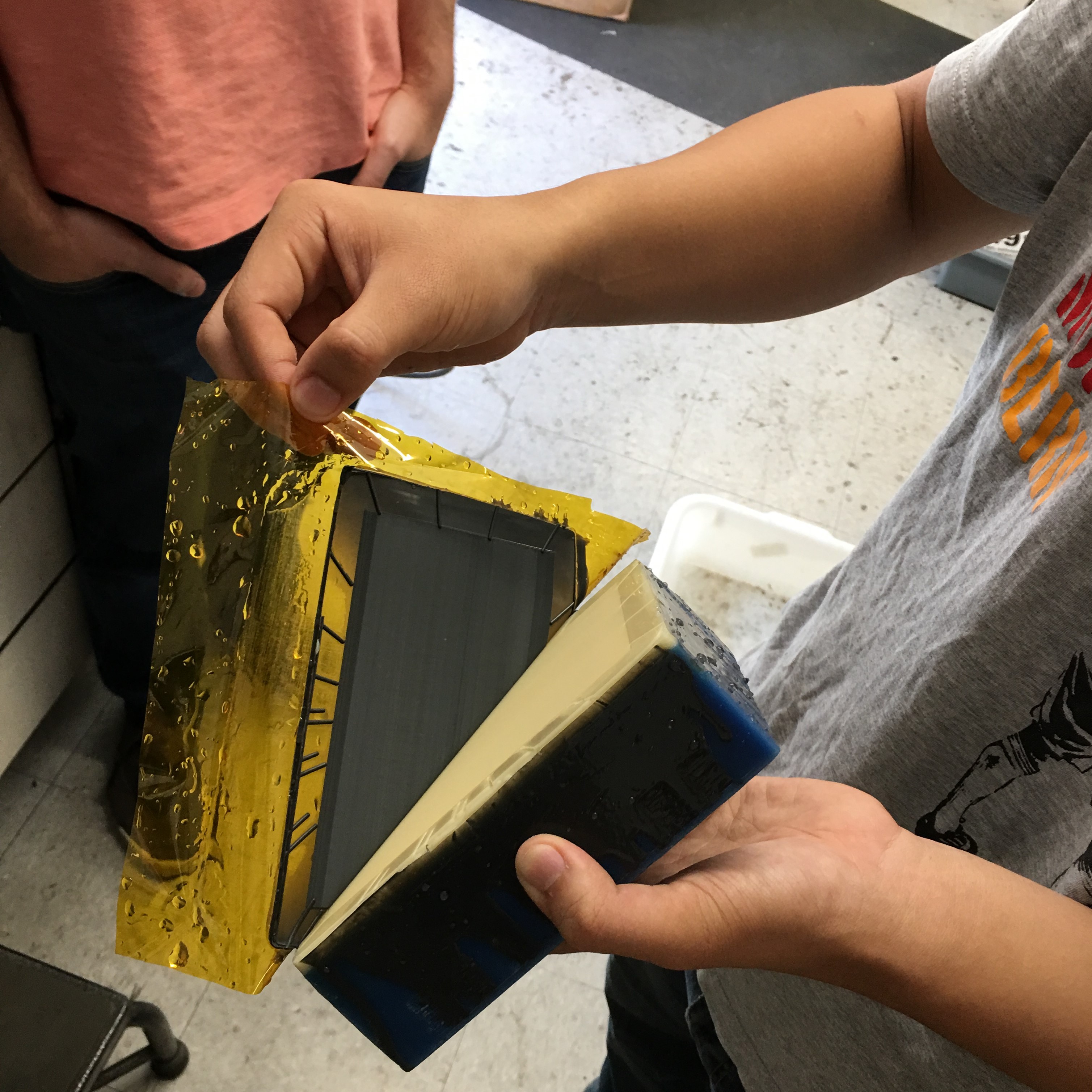

6. Peeling the Gecko adhesive from mold

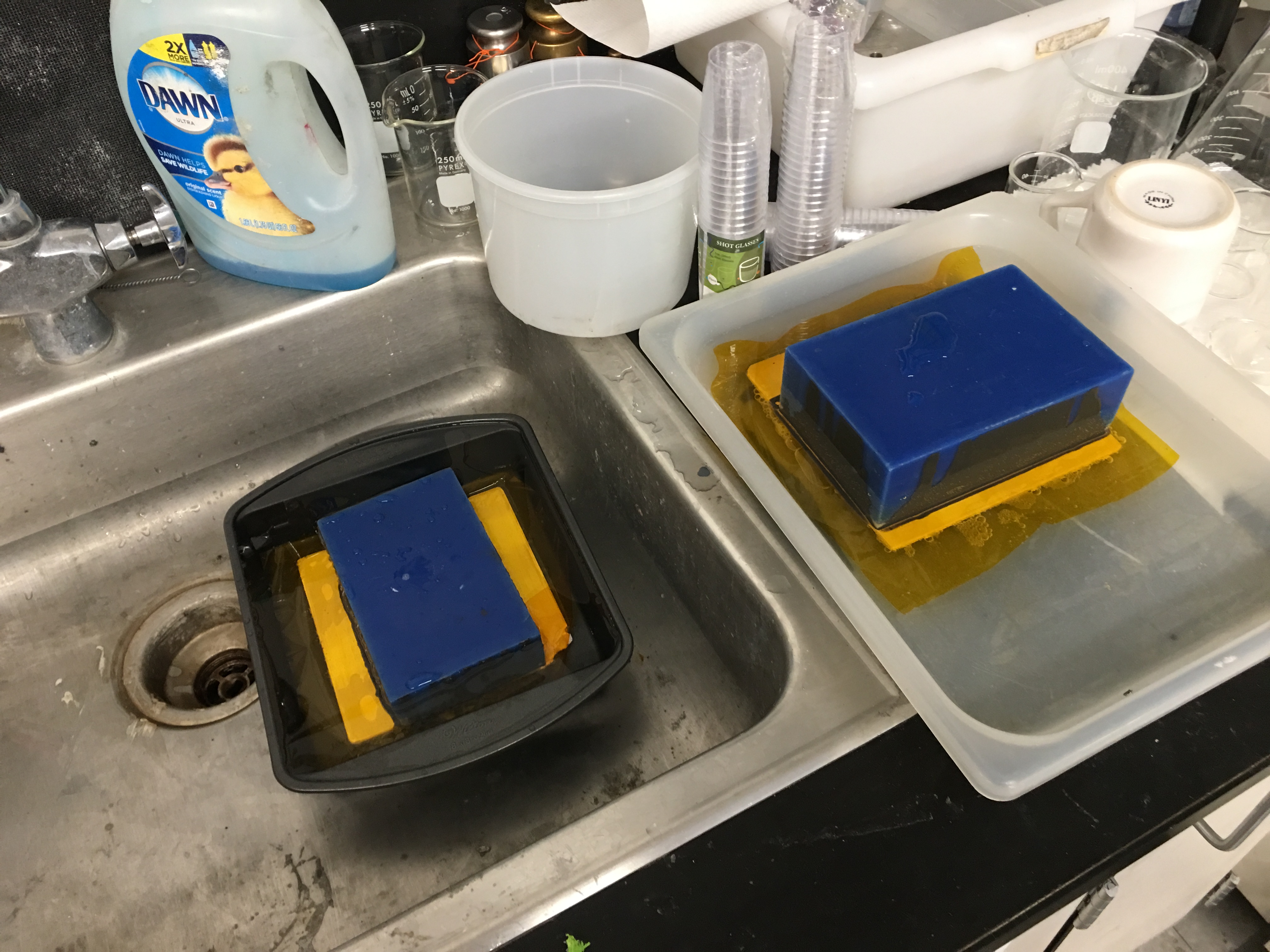

5. Soaking to remove water-based adhesive

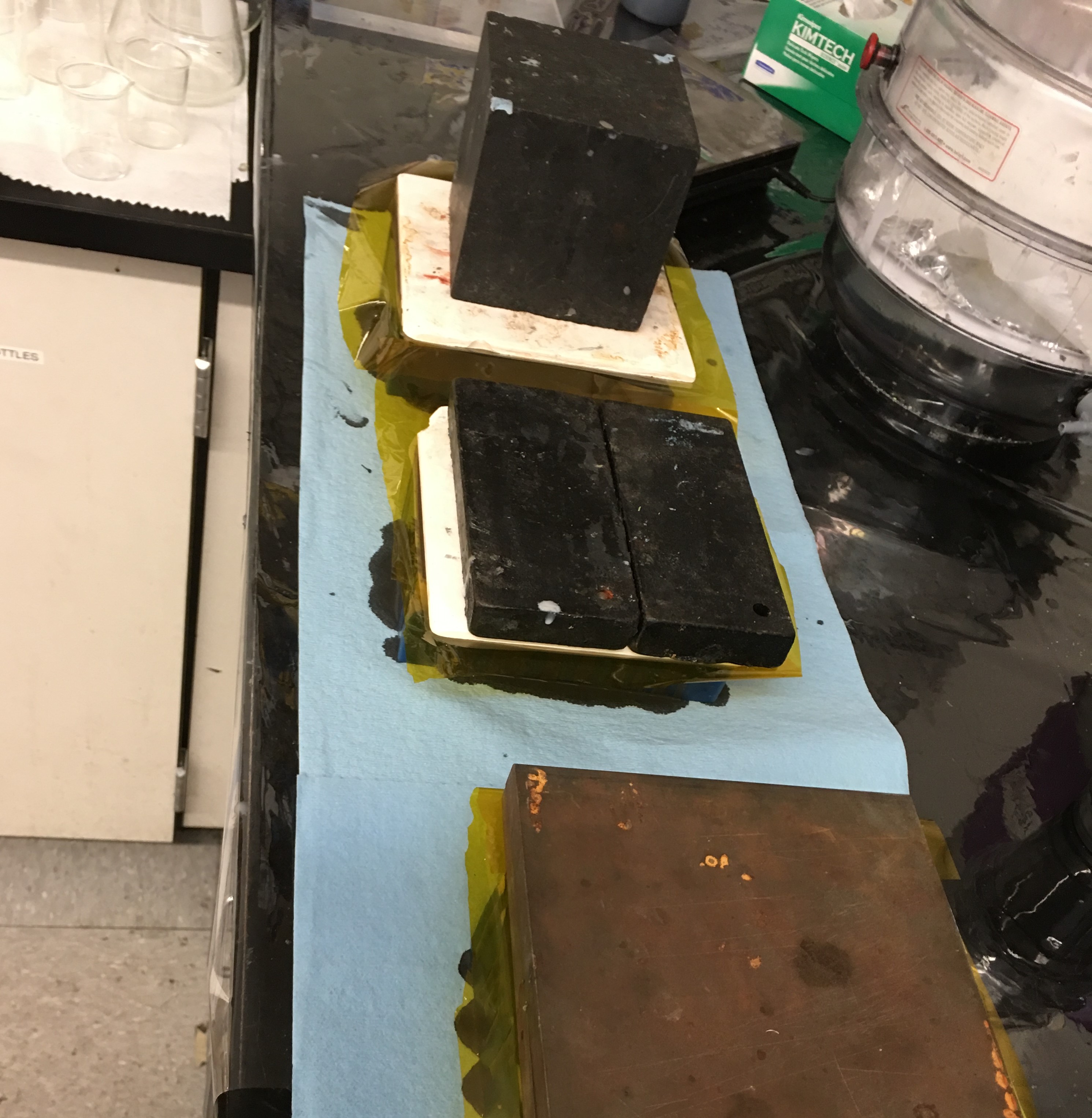

4. Applying weight during cure

3. Removing silicon bubbles

2. Priming the Kapton film

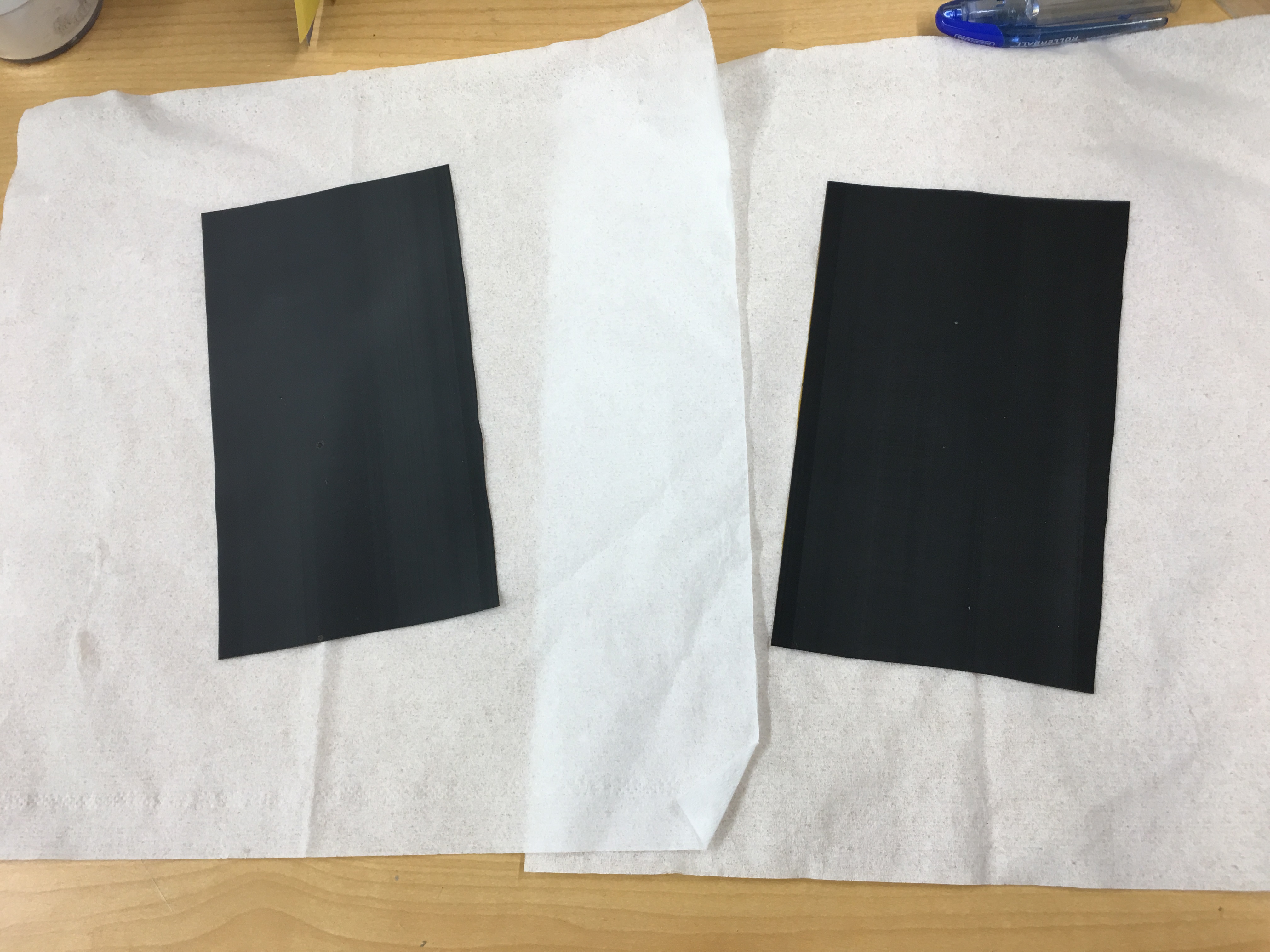

1. Fixturing the Kapton film

Week 3

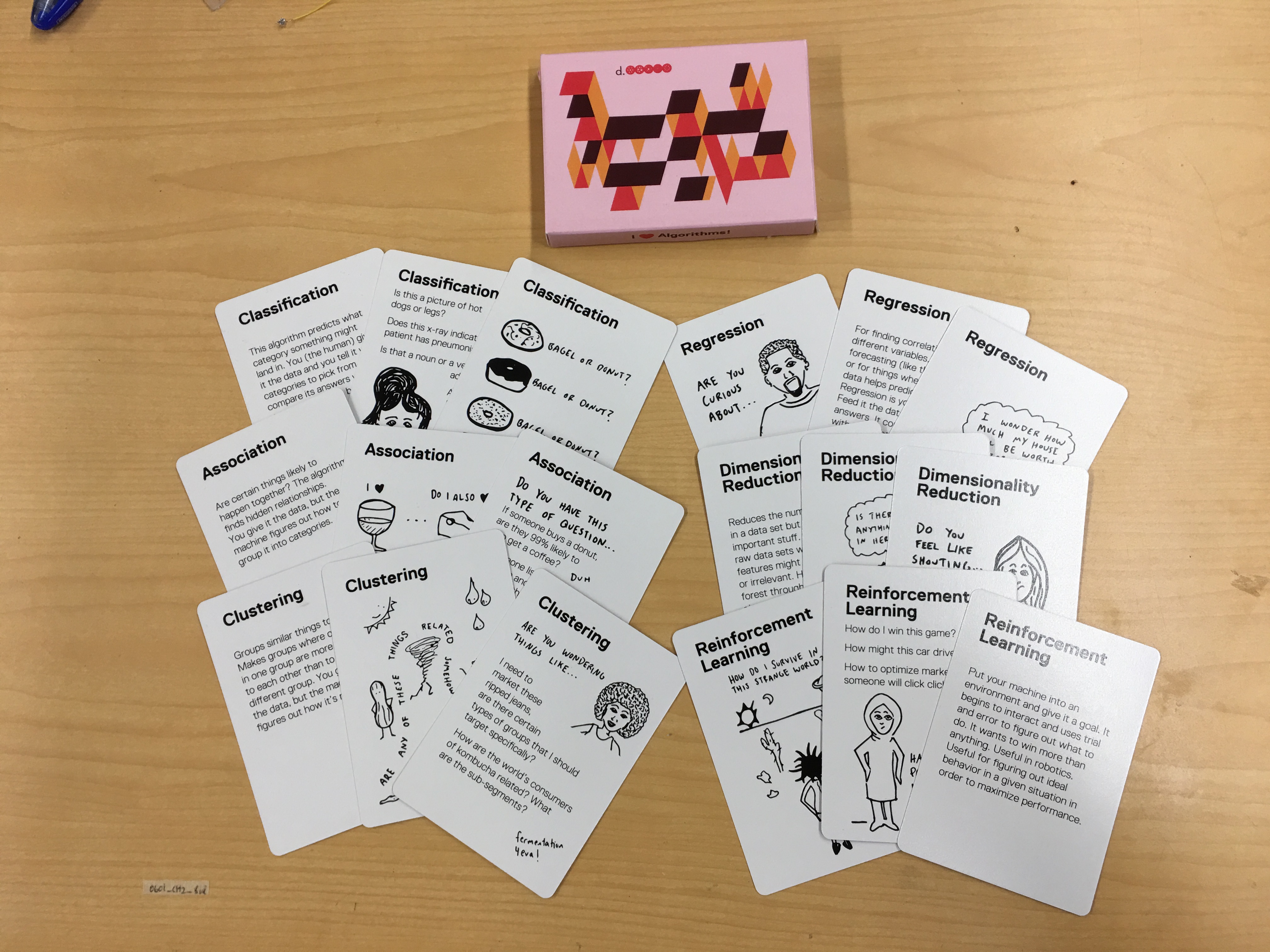

d.school's I Love Algorithms card deck

- Assembled NASA Bi-Stable Gripper parts in Onshape

- Worked on putting NASA Bi-Stable Gripper parts in Onshape

- Attended d.school's Machine Learning Workshop

- They want as many people as possible to be involved in the conversation regarding Machine Learning algorithms

- Machine Learning simulations need to be done ahead of time to make sure unintended, negative, or dangerous results do not effects users

- Their I Love Algorithms card deck explains six common machine learning algorithms: Classification, Clustering, Reinforcement Learning, Dimensionality Reduction, Regression, and Association. Each algorithm is explained in three ways: (1) Cartoon, (2) Simple text description (3) Styles of questions you might ask that the algorithm might service.

Week 2

- Completed Onshape self-paced courses:

- Navigating Onshape

- Intro to Sketching

- Part Design Using Part Studios

- Multi-Part Part Studios

- Onshape Assemblies

- Learning how to use Wiki for my BDML page

- Attended Silicon Valley Energy Summit 2019 at the Arrillaga Alumni Center, Stanford Environmental & Energy Policy Analysis Center on Friday

Takeaways:

James Sweeney, professor, Management Science & Engineering Dept., Stanford

- The issues are morfing, but not going away

- Energy Security was original issue, now Risk issues:

- Consequences of fire, autonomous vehicles, & new utility supply growth

Phil Sharp, former U.S. Member of Congress; president emeritus, Resources for the Future

- How to deal with the social cost of carbon? Carbon tax?

- To diminish worry in the populous, there is less reporting on climate change

- Federal climate action back in the spotlight:

- Bringing urgency

- Equity concern

- You can have strong climate action & prosperity

- Trends in debate:

- Move away from specific renewable energies to new possible technologies, toward "carbon-free"

- Alternative fuels and cars

- Focus on electrification

- Zero emissions vehicle

- Emphasis on the importance of civic engagement

Startup founders and Cyclotron Road fellows are using advanced technologies aimed for positive societal change:

Adrian Albert, Terrafuse

- Physics-enabled AI for climate risk

- Increase in wildfires due to climate change will double in next few years

- Ice caps are melting faster than anticipated

- Less snow pack in Sierras

- We are unequipped to handle these problems

Cara Beasley, Aligned Carbon

- Single-walled carbon nano-tubes are enabling 1000x increase in computing

- Solved monolithic 3D integration

Cody Finke, Brimestone Energy

- Co-generating hydrogen from cement manufacture

Jill Fuss, CinderBio

- Enzymes are the apps of the biological world

- Using bacteria and yeast as production hosts

- Archaea, (domain Archaea), any of a group of single-celled prokaryotic organisms (organisms whose cells lack a defined nucleus) that have distinct molecular characteristics separating them from bacteria. Archaea live in the extremes of life: hydrothermal vents (235o F), acidic soils-most acid-tolerant organisms known-able to grow in about pH 0, marshes, hot springs, and guts of animals, including humans.

- Some current applications:

- Industrial biotech

- Cleaning in dairy industry

Kate Gordon, director, Gov. Newsom's Office of Planning & Research

- 2019-2020 budget

- $250 million for climate-related programs

- $235 million wildfire protection & recovery

- Big Issues

- Fires-put carbon in atmosphere

- Climate change makes fires more sever & frequent

- Population growth & living in dangerous (due to fires) areas

- Utilities (PGE bankruptcy)

- Housing & Transportation

- Need communities and transportation to be planned together

- Need more walk ability-obesity on rise in CA

- 80,000 drive over Altamont pass/daily

- Car rebates for electric vehicles and retiring vehicles

- 25% of vehicles in downtown SF are Uber and Lyft

*Thanks Capella for the event recommendation!

Week 1

- Met with Tony and a lot of the amazing BDML crew, who helped me get situated

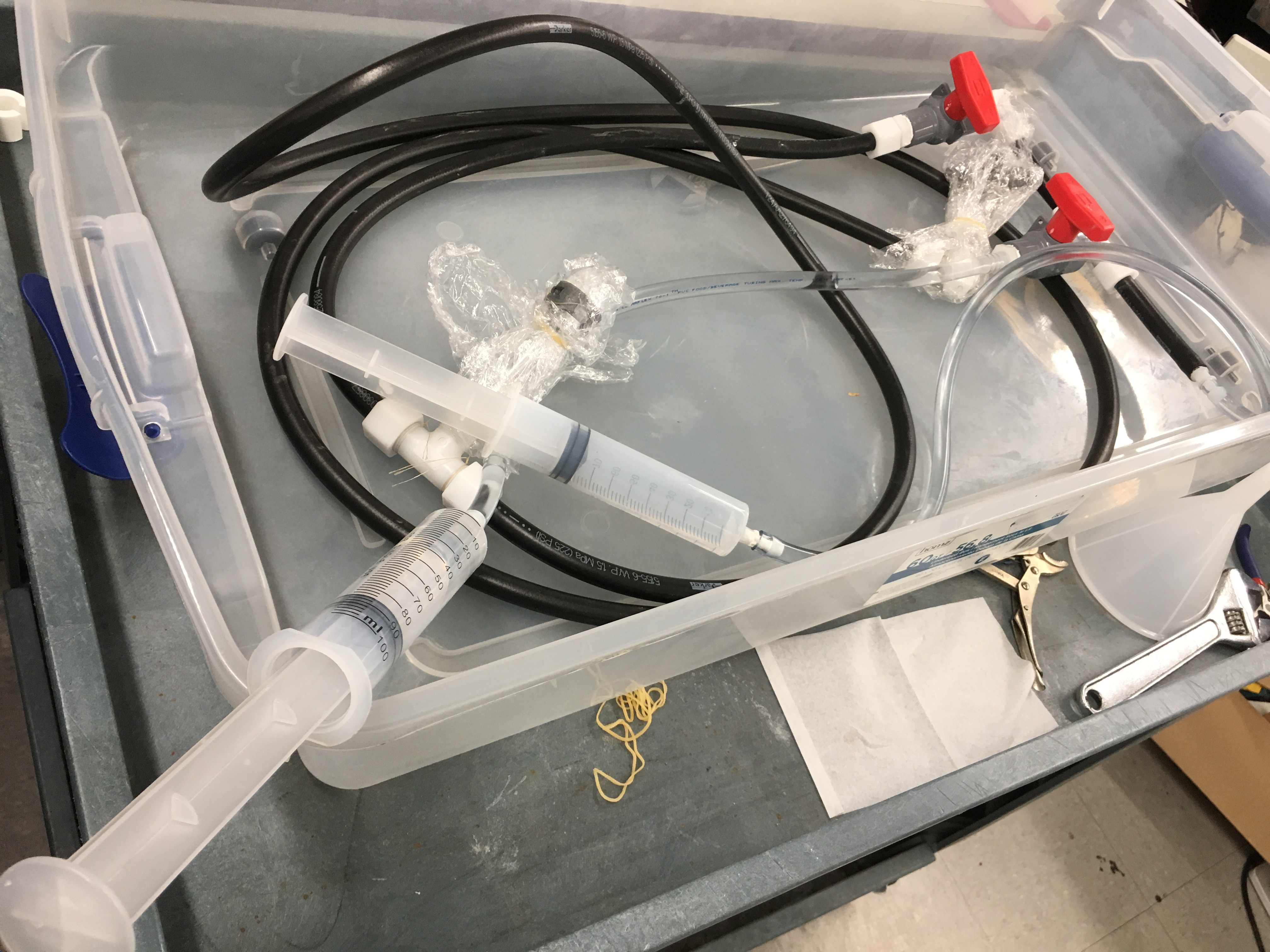

- Helped Sam, Allison, and Ileana fill hydraulic line with oil for the In-Bore MRI-guided Liver Biopsy Haptic Device

Sam orchestrates the oil fill

Closeup of oil-filled line

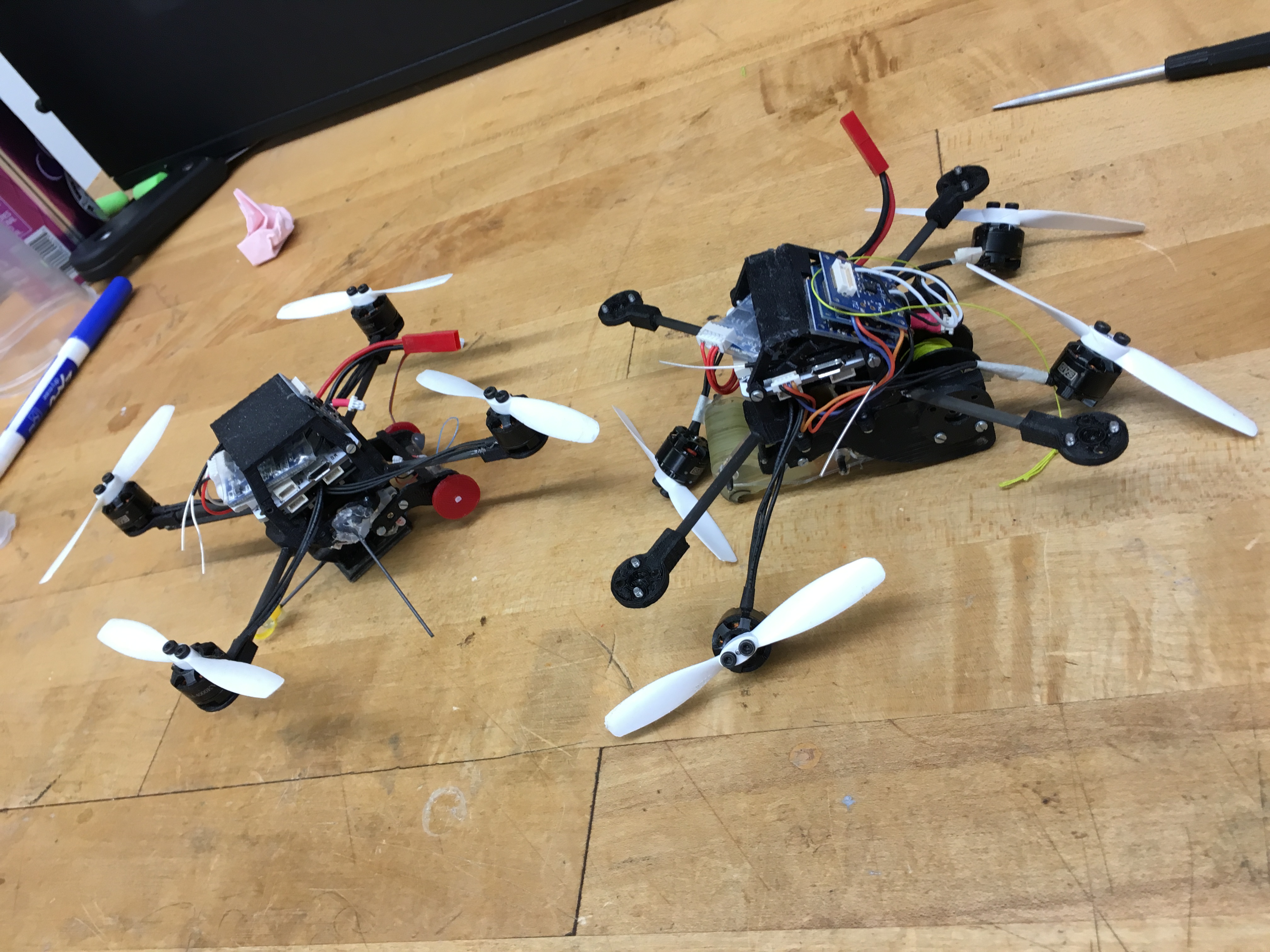

- Dismantled the motor and prop assemblies from 2 quad copters for Mark's upcoming conference. Thank you for making me feel at home by being able to use a hand tool!

Quad copters

- Going through tutorials in Onshape-the only product development platform that unites CAD, data management, collaboration tools and real-time analytics

- Massive upgrade from my AutoCAD 2003 skill set

- Goal is to finish Tony's NASA Bi-Stable Gripper drawing on Onshape

- First week big takeaway was the interaction with scale. In my shop, we deal with inches and fractions, typically down to a maximum of 1/32". At BDML, they converse down to microns (aka: micrometer/micrometre). A micron is equal to one thousandth of a millimeter, 0.001 mm, or about 0.000039 inch

- This is a personal paradigm shift from the directly visible to that which is indiscernible(not counting aides like a microscope)

Page last modified on August 02, 2019, at 02:06 pm