July 30

Shear/normal sensor updates

1. noise level on channel possibly due to misalignment in fabrication process

2. started dynamic characterization for sensor

3. CDC chip time sync issues

June 17

Check Bias offset for each individual sensor (#define in sensors.h). Bias offset determines the 0 state in ADC counts. Noramal sensor: start at 10K counts, which is on the low end of 0 to 2^16. Shear sensor: keep it towards the middle of 0 to 2^16 (roughly 32K).

SensorInit() maps sensor readings to ADCs on the chip.

new matlab scripts:

- updated display in

- updated noise processing in 2 scripts (

- run 10s of data

June 10

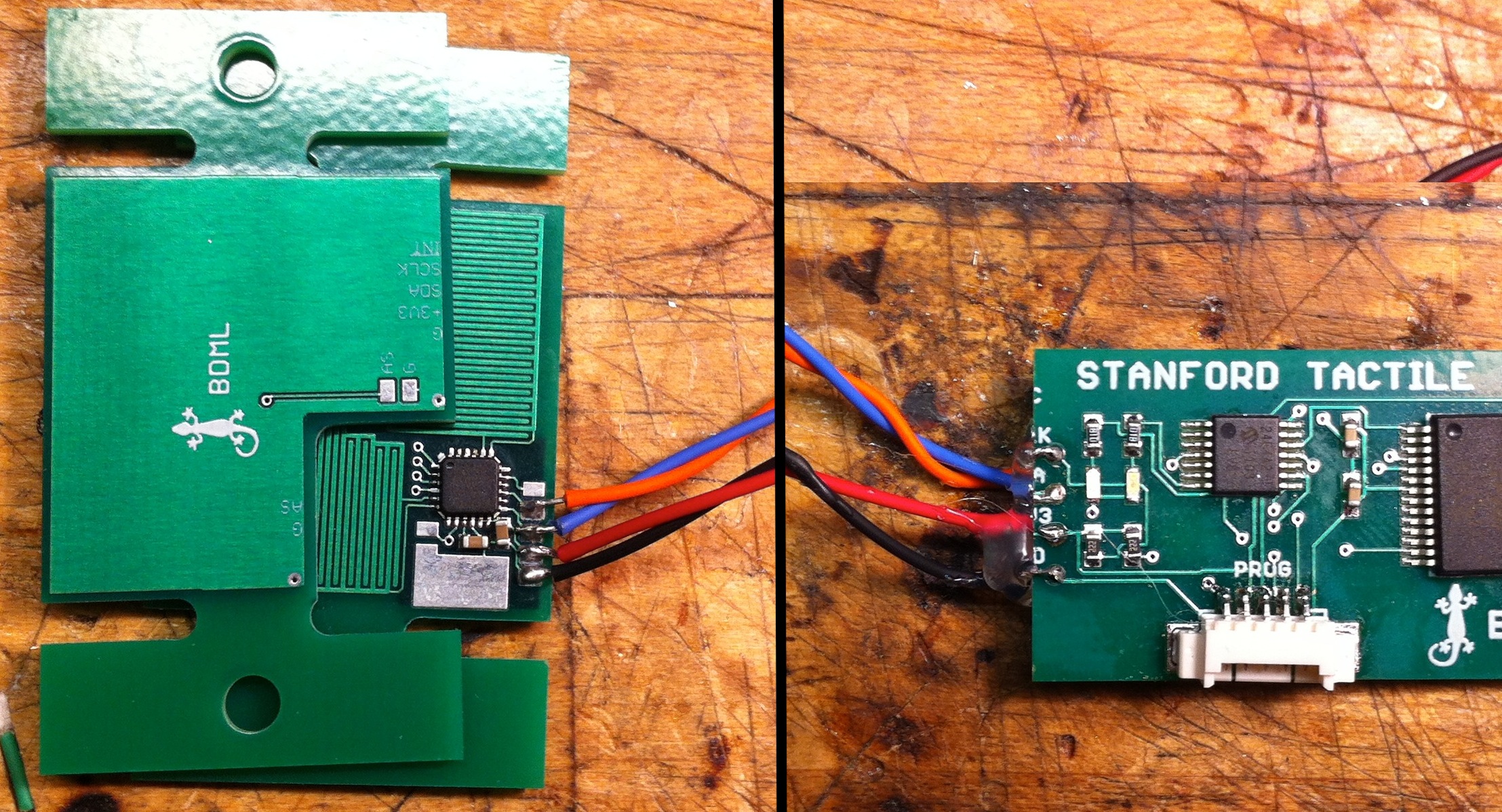

Wiring the interrogator to the sensor.

May 27

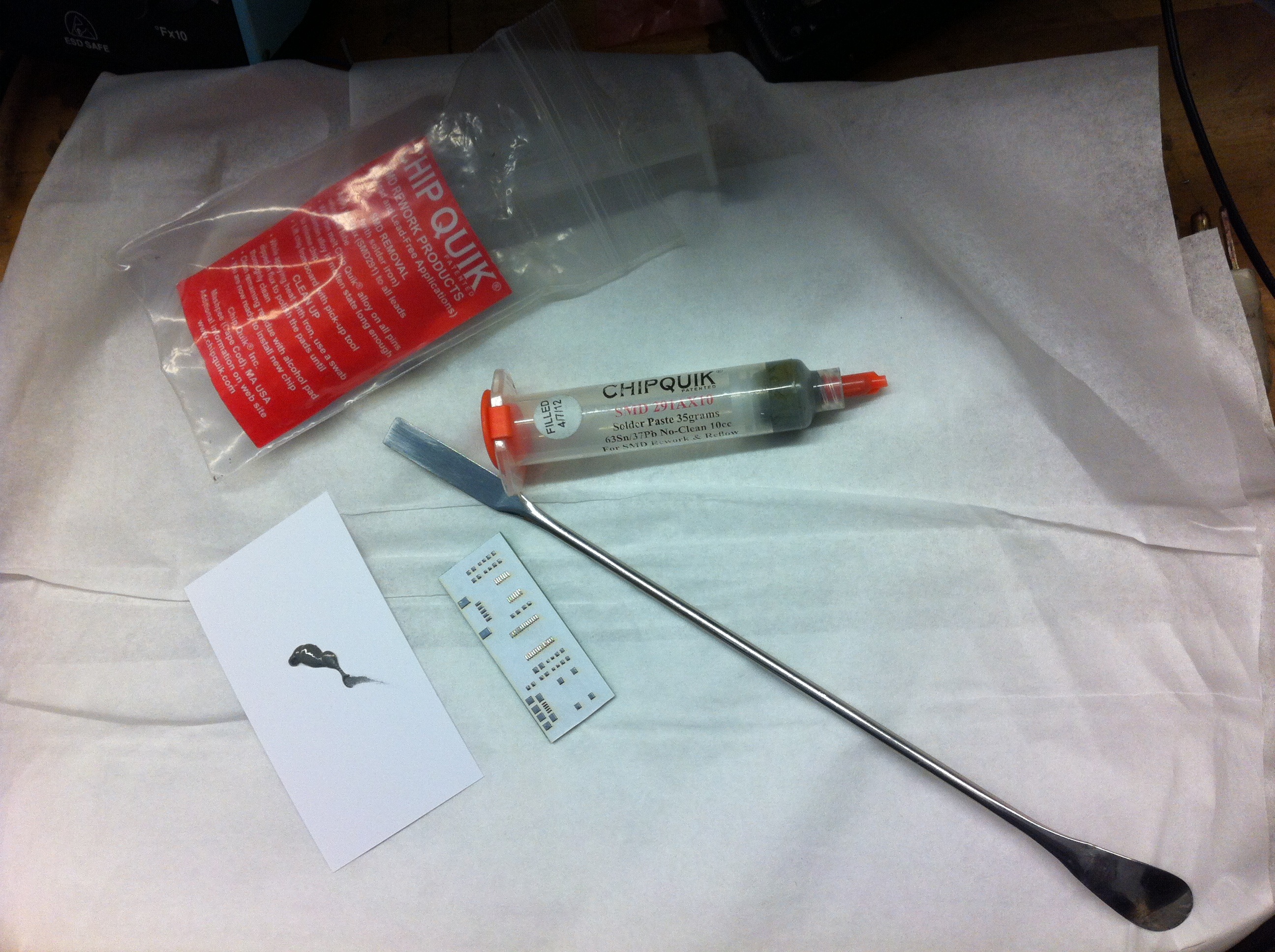

Practiced sensor fabrication process: populating components and reflowing solder paste.

Use 1x zoom on microscope when populating. Start with smaller components. Make sure that polarity is correct for diodes. Lightly tap down the components to get them to stick in the solder paste, but note that there is not much force holding them.

Use small amounts of solder paste at a time to prevent it being wicked away by the stencil.

Set oven at 360deg F. Use ceramic capacitors inside the oven as a flat surface.

May 22

Sensor fabrication kit from Alice:

- BOM for components from digikey

- Red-E tape

- plastidip

Tools needed at JPL

- vacuum chamber to degas the silicone

- microscope and fine soldering iron

need 4 sensors for Rudra by mid-June

characterize sensor response on different materials

schedule

when Nikhil goes down JPL, he will begin setting up and running experiments while Nikhil makes more sensors.

interpretation and processing of sensor data for footfalls