A summary of what I have been up to:

MRI guided biopsies can be painful for patients due to inaccurate needle insertion. Doctors may insert needles several times before obtaining a good sample. Currently, I have been working with Santhi Elayaperumal and radiologist Bruce Daniel to improve a manipulator prototype that would allow for a doctor to maneuver a needle inside an MRI machine without the need for repeated insertion and withdrawal.

For more information and pictures about the project, visit the private.passivemanipulatorprototypes page.

Here is my blog from June 20th-July11: Old BDML site

Summer Blog: July 11 onward:

July 6-13, 2011: Acryllic Prototype

- I created two main prototypes for tracks that would guide the rails of our manipulator. Previously, we'd had difficulty keeping our epoxy prototyping in line and moving smoothly.

- My first one was made of foamcore and the rods from our last supply run. The second involved closet door tracks made of heavy metal. In an attempt to remain MRI compatible, we combined the two prototypes and decided to cut the pieces from acrylic.

- On Friday, Kelly and Santhi gave us an Arduino tutorial. I managed to get a lightbulb to light while pushing a button, but making a paper robot is still on my to-do list.

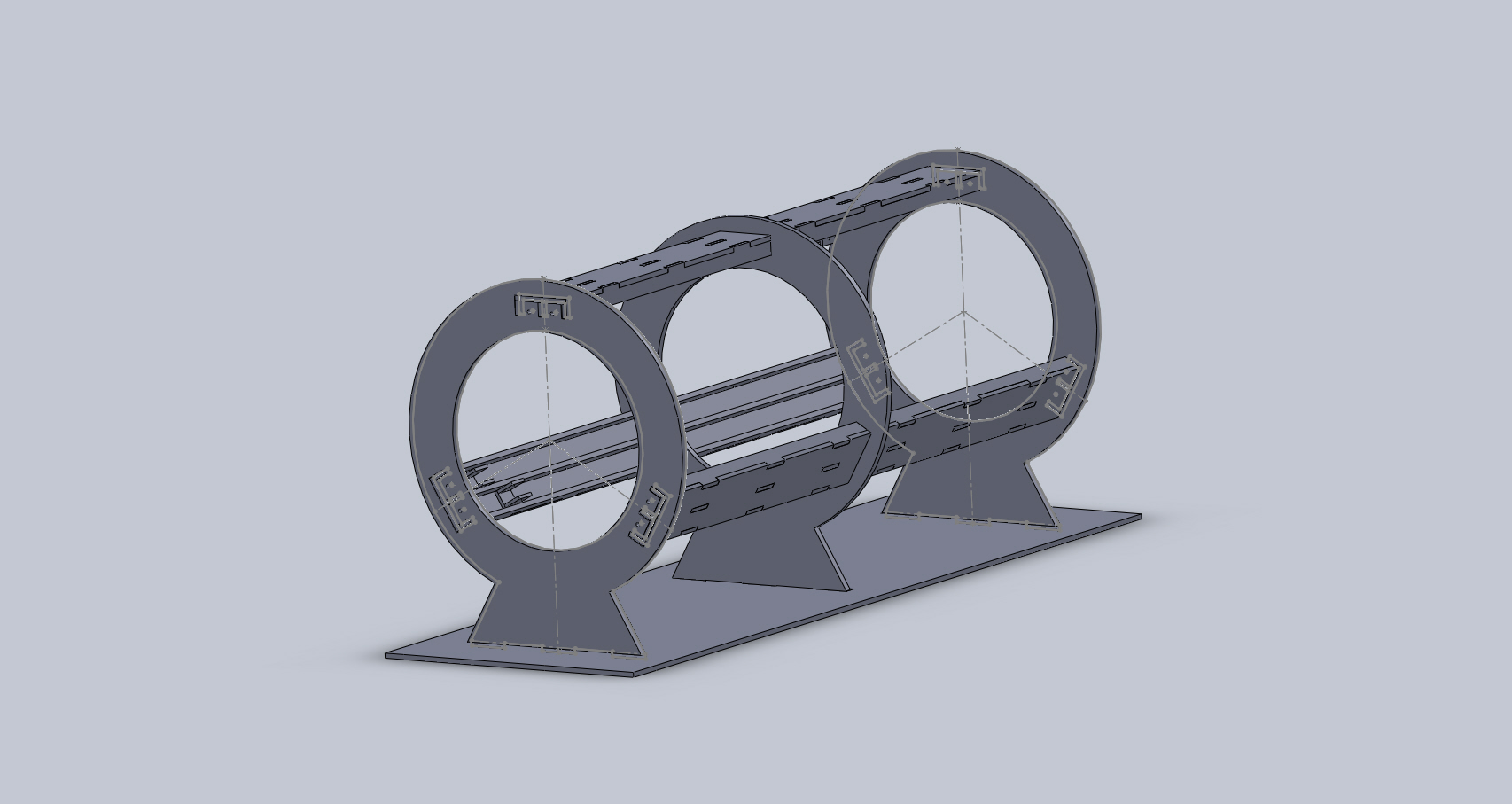

- Monday (July 11): I went to the hobby store with Santhi to more ball joints and plastic rods. We experimented with putting wax on our tracks, but resolved to make an acryllic prototype instead. Since then, I have been struggling with SolidWorks to create the pieces. Here is the full assembly:

- Tuesday (July 12): Weekly haptics meeting

- Mark would like us to work a bit on the delta mechanism.

- Wednesday (July 13): Reuben helped me cut some pieces on Salisbury's lasercam

- We didn't accurately measure the width of the acrylic pieces (pieces we thought were 1/4 in. turned out to be .235 in.). A bit frustrating but hopefully we'll get a prototype by the end of the week.

- Reuben taught me how to chamfer and use a reamer. I learned a lot about precision from him (13/1000th of an inch can make a big difference!). He also threw out the plastic calipers I brought and gave me some new metal ones.

July 14, 2011: Fingers-Crossed for an Acryllic Prototype

- Spent the morning organizing the solidworks files and remeasuring our acrylic pieces. I found the intro to robotics course online and started listening to the lectures and reading the books Santhi gave me (who knew there was so much I did NOT know?.

- At 3:30, we went to get our pieces cut yet again. At 7:00, we returned to the lab with sore arms and a bunch of acrylic pieces to assemble.

July 20, 2011: Stewart/Delta Platforms Made

- For the last week or so, I have been assembling our acrylic prototype. I got familiar with epoxy, gorilla glue, biocompatible string, acrylic glue, hacksaws, etc. etc. Santhi and I also went on another hobby store/hardware store run and cleaned out the stores of ball and socket joints and steel rods (so don't go looking for them around here).

- Some things that Santhi and I realized: tilting is NOT reversed in the Stewart platform.

- We had some difficulty cutting the steel rods, but Mark showed me some tricks to using the hacksaw (oil and slow movements). He also mentioned that perhaps using aluminum rods would be lighter and easier next time.

- I prototyped ways to attach the joints to the rod and ended up using string, spacers, and a lot of hot glue.

- We brought our finished prototype to meeting on Tuesday, but the joints were still wobbly and the rods kept slipping. Thus, we resolved to cut our pieces out of acrylic. We also simplified our design such that we had 12 sliders rather than our original 24.

- Meanwhile, we also put Richie to work (he is visiting for the week) on AutoDesk and prototyping a delta mechanism. He built one out of Legos that works pretty well.

- We disassembled our last Stewart prototype and turned it into a Delta. In doing so, we realized that it did not work, AT ALL. The rotation was not so great because of the small platforms and the twisting/tilting did nothing.

- Santhi and I will talk tomorrow about where we hope to go with the project (build more or learn more about the kinematics?). She hopes to write a paper for the IROS conference in September, which I would like to volunteer for.

- We may put pictures up soon-which would make it a lot easier to follow what I am saying-but we are unsure of whether we should do so before a paper gets published or a patent.

July 21, 2011: Further Exploration of Stewart Kinematics

- I started the morning by taking pictures and videos of our prototype. I took some measurements on how our prototype moves and we changed the manipulator into different configurations (for example, putting a delta mechanism outside and a stewart platform in the middle-this did not work).

- Santhi and I realized that insertion would be easier if the joint angles were locked, and thus spent some time brainstorming how best to get this done. We want the arms to lock during insertion, but we also want them to be able to unlock during manipulation. On Monday, I will attach cables to see if the angles will lock the right way.

- Santhi taught me a little bit about Jacobian matrices and serial/parallel robots. We started a patent search, and she also showed me how to download articles to Mendelay.

- Mark told us we could do kinematic simulations in Autodesk/SolidWorks, and with Kelly's help (Kelly is our Autodesk TA), I will pick this up Monday.

July 26, 2011: Introduction to Robotics

- I started my week back by straightening out the struts at the Lego end of our prototype. After re-gluing the pieces together, I reconfigured our prototype into the delta mechanism in hopes that the joints would stay up better.

- Sadly, it seems that a configuration for a delta would suit a different design better, as the configuration felt too forced and the limbs seemed too short.

- Regluing the struts, however, strengthened the stewart platform. The uniformity also made the design smoother.

- At the haptics meeting, we listened to Wisit's conference presentation. I also talked to Wisit and Pete (who just came back from China) and we plan to meet tomorrow to further discuss how I can help with studies in the HPL and sensor building.

- I spent the rest of the day going over some of Santhi's Introduction to Robotics homework assignments and reading up in her course reader. The kinematics of our platform is a high priority this week as we hope to write a paper for a conference in September. Tomorrow, I will get to work on finishing up the Solidworks files.

July 27, 2011: Introduction to Robotics

- I did a search for MRI compatible materials and started thinking about designing a new prototype using ball bearings and the lazy susan idea. I sketched out some ideas and plan on refining them with Santhi.

- Late in the morning, I met with Pete and Wisit (who are working in the HPL on portable haptics for osteoarthritis patients) to talk about designing a way to attach sensors on the foot. They were debating whether to buy a sensor or make on.

- Last summer, they were trying to build a sensor but did not have a good way of attaching it to the foot. Pete thought this would be a good project for me, and Wisit sent me the Solidworks files to go through later in the day.

- I explored the IEEE RAS website and looked at some papers on parallel mechanisms:

- Kinematic Performance Analysis on a New Spatial Rotation 3-DOFs Parallel Robot Mechanism (Guohua Cui & Wanjun Hao, 2009)

- Kinematic Analysis of a Flexible Six-DOF Parallel Mechanism(Feng-Shui Jin et. al, 2006)

- Over lunch, we discussed the MERL BBQ that we are hosting this Friday. Engineers really know how to brainstorm, especially about food, and we, the summer students, were given the job of planning, cooking, going for the Costco run-work hours indeed.

July 28, 2011: Delta Robots

- I started the morning playing with our Stewart platform prototype. As we eventually want to attach a needle to the slave side of our machine, I attached a pencil and attempted to insert it through an orange, banana, foam core, anything I could find.

- To do: get a needle from Soek-Chang

- I soon found that we had a problem with the twisting of the slave side. When "shimmying" the needle into the orange, the slave side no longer sat straight and there was no way to untwist it.

- Thus, I tried our idea of attaching cables from the base triangles to the center triangle. This didn't work out too well either: the tensions were a pain to deal with and the joints twisted depending on how the string was tied.

- As I'd looked up some lazy susan parts yesterday, I then researched and brainstormed some new ideas for our next prototype (see manipulator page):

- Force Dimension: http://www.forcedimension.com/omega3-movie

- I'm thinking of combining a lazy susan and a delta mechanism: that way, the delta will allow pure translation and the lazy susan will be use to achieve rotation.

July 29, 2011: Autodesk

- I spent the morning switching over Solidworks files into Autodesk and met with Kelly to talk about doing a kinematic analysis on the prototype that we have.

- We hosted our MERL BBQ today, so I spent the rest of the morning grilling.

- In the afternoon, I finished up with Autodesk and met with Bruce briefly to show him our prototype.

- I also took a look through the files Wisit sent me on the angle sensing project and will meet with Pete Monday to go through them.

August 1, 2011: Autodesk, continued

- Kelly gave me a good book on Autodesk before leaving, which I used to help me finish the assembly files of our prototype (they will be up shortly). I'm going to try to skim through the whole book by the end of the week (100 pgs a day?) to solidify my knowledge of Autodesk.

- I pulled out the Novint Falcon from Santhi's office and have been looking at it to get ideas for our next prototype.

- After lunch, I met with Pete to go over the Solidworks files. Wisit is in Atlanta for a conference, but he offered to get his roommate to find the last prototype and potentiometers so I can get to work on the attachment.

- To do: maximize the plate surface area around the ankle without letting it touch the ankle or the ground; bring in an athletic shoe tomorrow.

- I have also been making my way through Santhi's robotics books (slowly, but surely).

August 2, 2011: A Look at the Delta Mechanism

- I brought our prototype to lab meeting today to get some feedback: the prototype stayed together much better and people were able to play with it without it breaking apart (joints are a little sloppy still).

- Pete presented what he did in China: working with stroke rehabilitation using haptic feedback training

- I talked with Pete a bit more about our plans for the attachment piece (for the sensor to the shoe).

- Mark, still a big supporter of the Delta, took me to Gates to see the force dimension delta. The movement was smooth and very nice, and he gave me a bunch of suggestions for starting with the next prototype: springs, ball joints, etc.

- The platform on our mechanism needs to be bigger.

- I received an email from Francois, founder of force dimension, who was very willing to help with ideas and a tour when he gets back from Japan

- I then drew out some files on autocad to connect our slider pieces such that they would form a delta configuration and am, again, making my way through Santhi's robotics homework (3 more to go!)

August 3, 2011: A Look at the Delta Mechanism

- I finished the Autodesk book that Kelly gave me this morning-there are a ton of things you can do with Autodesk! Some stuff might be useful for us, but most of it was just good to know.

- I then opened up our assembly and welded the base together (I thought this would mimic the fact that we put acrylic on all our parts), and I practiced doing some kinematics simulations by following the sites Kelly sent out.

- I then looked over Pete's solidworks files and fixed the dimensions of the attachment pieces.

August 5, 2011: A Lot of Solidworks and Some New Ideas

- I spent the morning cleaning up the Solidworks files on the old angle sensor attachment. I finally finished and, feeling satisfied with myself, headed back to the lab. Unfortunately, Pete and Wisit found a newer version of the files and thought it might be better for me to help with prototyping their new pebble idea and come back to the attachment later.

- Their new idea involves using currents to generate magnetic fields that would lift up an acrylic pebble (thank you physics43). Thus, this would fit into an insole.

- Feeling a little burnt out, I finished attaching the slider attachments to Santhi's manipulator and spent the afternoon trying to convert our assembly into an iassembly in Autodesk. I think I will spend the mornings on the manipulator and the late afternoons helping to prototype the pebble.

- The parts for our next prototype are ready to order, but I'll wait until Monday to get the Pcard from Matt.

To do this weekend:

- make a solidworks sketch for our pebble and a flexible platform.

- find a straw

- finish the intro to robotics lecture

August 24, 2011: Summary of my past Twenty Days (oops)

- But first, my to-do list (here instead of in my notebook:

- drill holes for the platforms of our prototype

- finish the prototype (by after lunch)

- clean out room 126

- finish Solidworks files for poster

- DO POSTER AND TWO PAGE WRITE UP!! (this is actually the first thing I have to do, which I clearly want to do)

- blog about it!

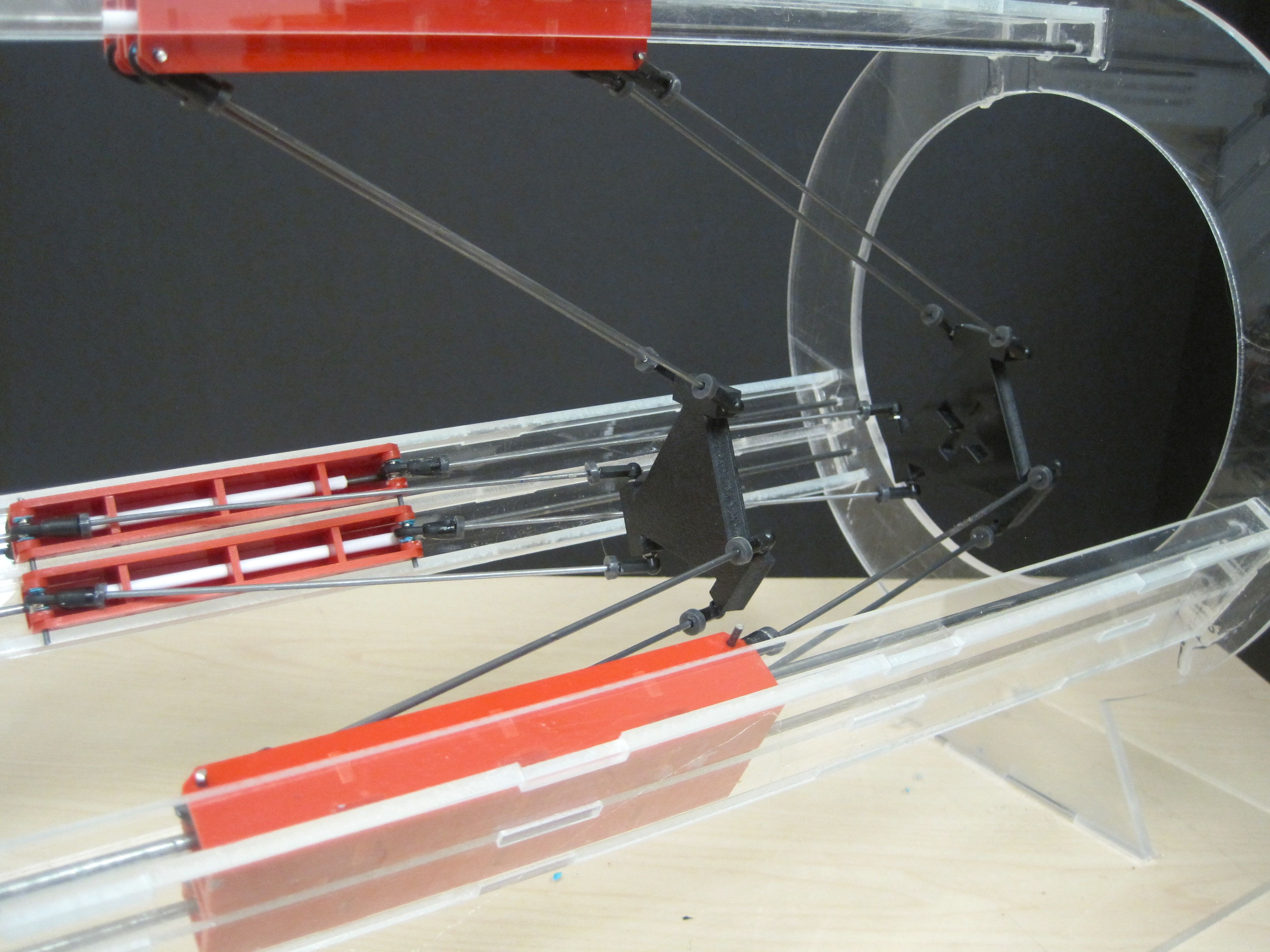

- For the past several weeks, I have been working to finish the delta prototype. We based our design off the force dimensions robot that Mark showed me in Khatib's lab. Using similar ideas, I have found that a delta mechanism works much smoother than the stewart that we had.

- I ran with this idea for several weeks, creating some parts but also reusing some of our old stewart parts.

- We thought to move to the delta since the delta is smoother and seemingly more accurate. However, we would have to find another way to get our other 3 degrees of freedom.

- The initial idea was to use a lazy susan and cables to allow these DOF.

- The final delta is presented at the SURI poster presentation and is show here:

- Santhi would like to get a paper published comparing these two mechanisms. We have also looked into patents.

- In terms of my future work with the lab, I hope to attend the conference where the paper will be presented.

- Some other images I took along the way:

SURI Poster

Page last modified on June 15, 2012, at 11:25 AM