August 17:

For grabbing onto curved surfaces the 1 cm tiles can wrap around a surface that has a radius greater than .625 meters. Our larger tiles (1.5 cm) can go around a surface that has a radius greater than 1.4 meters. For a .625 meter radius curve and a 20 cm pad, the inside tiles need 8 mm of compression in the preload mechanism. We might be able to get this if we use a gel or foam.

August 14:

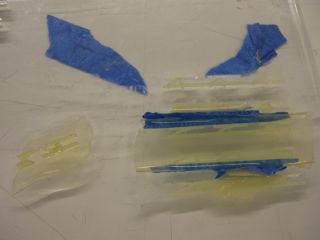

I cut some small tiles (1 cm x 1 cm) at high power and some at extreme low power. Eric thinks that the low power one is not warped and is stickier when placed on glass. Applying super glue to the back might be causing warping, though.

August 13:

The new tendon design has two low angle (15 degree) 1/8" tendons and a square preload in the center. The tendons are made from VytaFlex 60 and the preload supports are made from VytaFlex 10. The tendons feel good (they have a good amount of stretch and bend) but the preload mechanism is a little stiff.

August 8:

There seems to be a preload problem possibly due to warping. The tiles do not perform without preload and need a significant amount to get a decent amount of loading (more than would be possible when made on a large scale). The warping could come from the heat from the laser cutter, the glue that is used, or damage from testing. The problem of warping seems to get worse with the small tiles and it is difficult to get any load from them with small amounts of preload.

July 28:

The fabric in the tendon seems to be too stiff and causes stress concentrations. Elliot came up with a new idea of having a string tendon connected to a cantilever beam. As the tile loads, the beam bends, providing some compliance. This worked pretty well when we made a quick prototype with foam as the preload and a rough-cut cantilever.

July 25: We came up with a theoretical model for a flexible tendon system. The problem with connecting a string to each tendon and then pulling from one location is that the angle of load becomes too great for the bottom tile. This model involves a support system where each string runs over a rigid support connected to the tile below it. The string pushes into the support, pushing the tile below back into the wall and making the resultant force more like the desired force in both magnitude and direction. We modeled this in MotionGenesis and ran into some problems with the system being statically indeterminate. To go around this problem, we set some variables as constants and iterated until the result was reasonable (adjusting these constants on each run).

July 12: After testing many shapes and materials, the two that seem to work the best are the wide, Vytaflex 60 with the embedded fabric and what we call the anteater tendon made from one of the softest urethanes. We've created several jigs to help place the tendons and align the patches so that everything is lined up and spaced properly. instead of superglue, we are now using urebond to make the urethanes bond to fiberglass. We have also gotten a lot better at cutting the molds for the tendons. They are a lot cleaner after doing two passes on each side of 3/16" acrylic. We also found a way around needing to secure the middle pieces of the mold by making discontinuities in the base of the tendons. We are starting to scale up our design, moving from 2 tiles to 11. The two tiles that we tested with the post-treated adhesive held 1700 g, so it looks like we will reach our target weight.

June 25: The tendons were not too difficult to remove, but the tops warped as soon as they came in contact with super glue (making it very difficult to maintain their geometry when attaching the adhesive pads). The fabric works very well at making the tendon stiff in tension. The orientation of the weave does not seem to make a difference. We also need to get new adhesive pads and be very careful about keeping them clean and away from super glue.

June 22:

The tendons could not be removed from the mold, so we cut a new one and immediately put mold release inside. We filled eight molds all with the softer polymer and a thin piece of fabric in the tendon. It took many cuts to get the tendon to be wide enough to fit the fabric. We also tried two orientations of the weave of the fabric. The different geometries included an angled top and/or the arm moved forward to help with preloading.

What happens when you forget mold release:

June 21: Critical Lesson Learned - Always remember the mold release!!!!

Transformed into a chocolate predator and scavenged the sculpture garden. Once transformed back to human, I made my prototype for landing/climbing. It's not functional, but it demonstrates the idea of diagonal feet on a rotating axis. Elliot and I made more molds for tendons to test stiffer material. Again, we forgot the mold release.

June 20:

We made a whole finger using the new tendon design. The rear tendon seems to make the back too stiff, so we cut all of them off. They also didn't seem to be necessary for release. The finger works pretty well, but the polymer is a little too soft. When it fails, each pad sems to pop off on the top. We now want to test with a stiffer polymer and different tendon shapes that have no back tendon and a more secure arm.

June 19:

The day started with an introduction to the hand and the programming/interface to manipulate it. I also changed the laser-cutting drawing for the tendon mold so the rear tendon is well-connected and the front support does not get cut all the way through to the base.

June 18: First day in the lab.

I learned a lot about the different projects in the lab. I spent most of the day working with Elliot on a new design for the adhesive climbing fingers. He found that using patches of adhesive on flexible tendons was more effective than one rigid finger. We tried to figure out which orientation of patches and tendons would be the most efficient. We transferred some adhesive onto a thin sheet to make more patches for prototyping. We then laser-cut a mold to make a set of tendons so a whole finger could be made. The mold release was accidentally forgotten in the process, so hopefully we can remove it tomorrow after it cures.