Category: SummerBlogs

Week 8 (August 9 - 13)

Final Updates

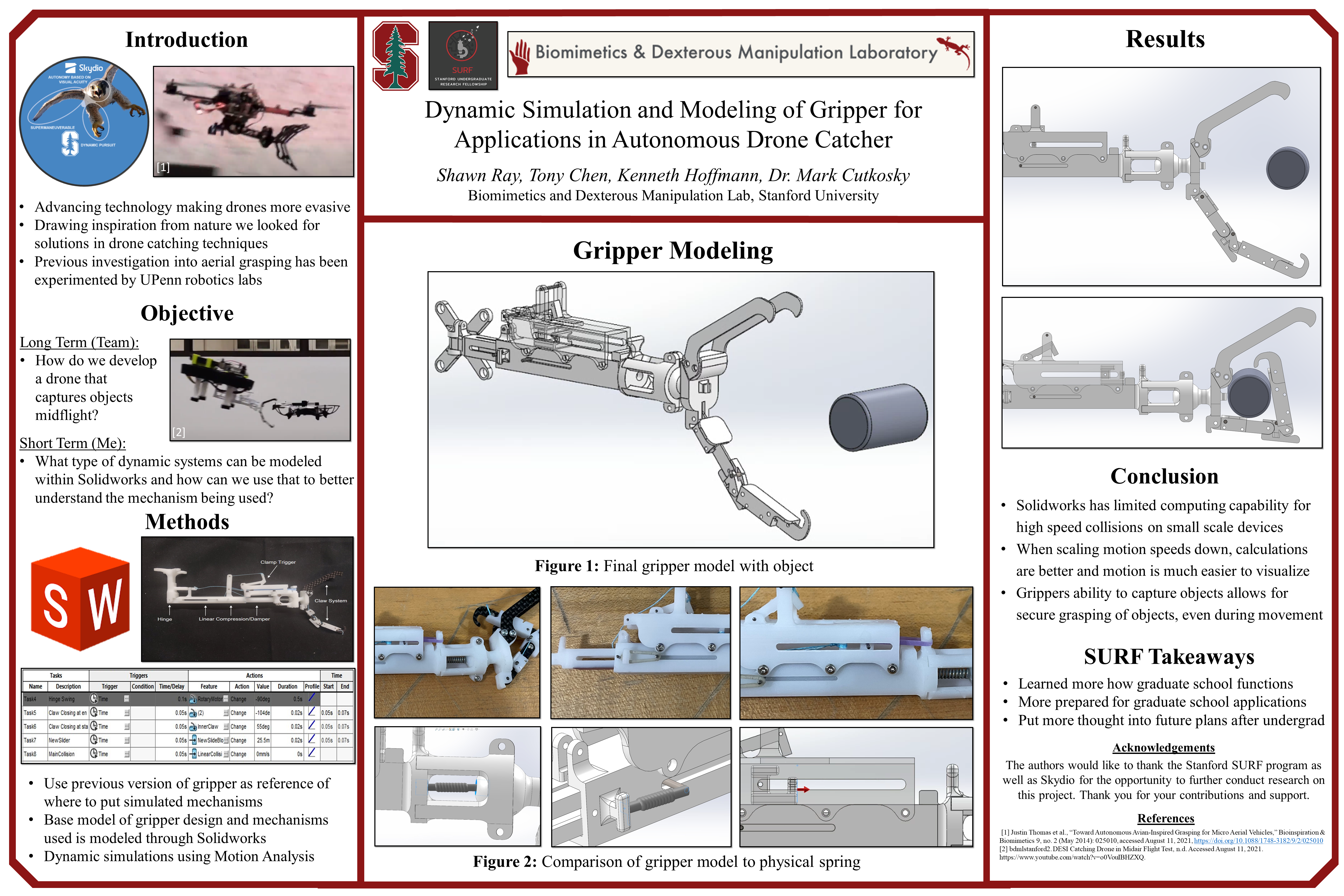

Final poster used in End of Summer presentation

August 12 - 13

It's the last days of the SURF program and despite the circumstances of being virtual, it's been a great experience and I've definitely learned a lot! I've wrapped up my poster presentation, shown above, and copied all of my work and files over to the main BDML drive. I was hoping to get much farther with this project over the summer but I ran into a ton of issues I wasn't expecting. Luckily, I was able to learn from these blocks and I now have a better understanding of the Solidworks software.

This summer experience has been great and I'm so thankful for the experience and for the people I've been working with over the summer, Tony, Kenneth, and Mark! It was great hearing about the many different areas around the lab and I hope to meet everyone in person one day!

August 11 - Presentation Day!!

Videos referenced in Lightning Talk:

August 10

Credit: The Emperor's New Groove

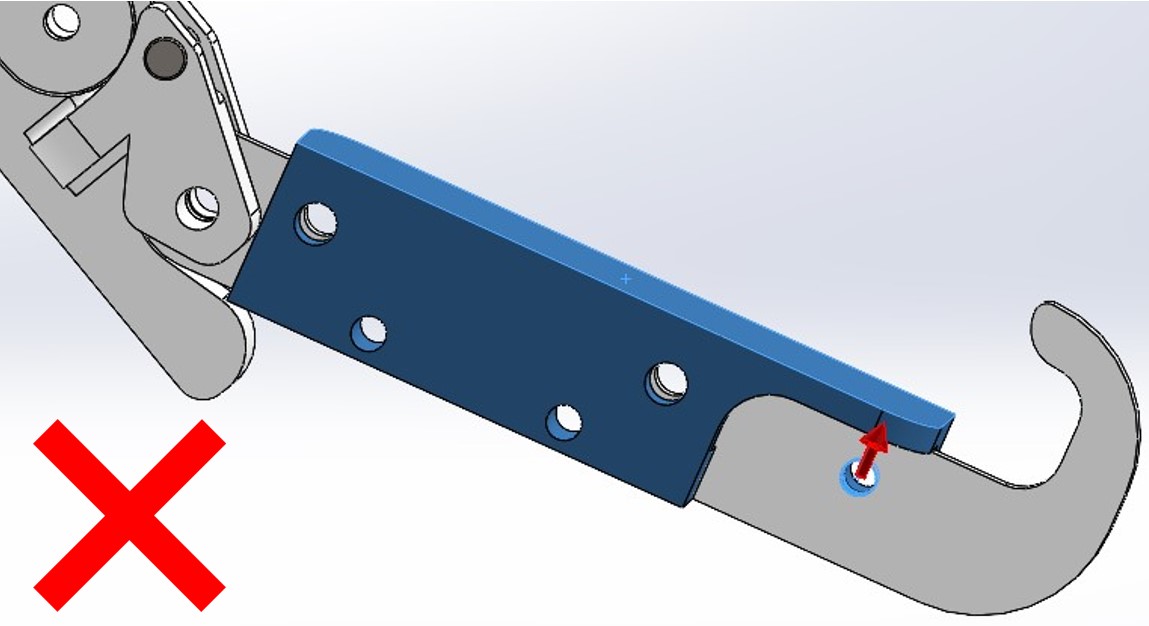

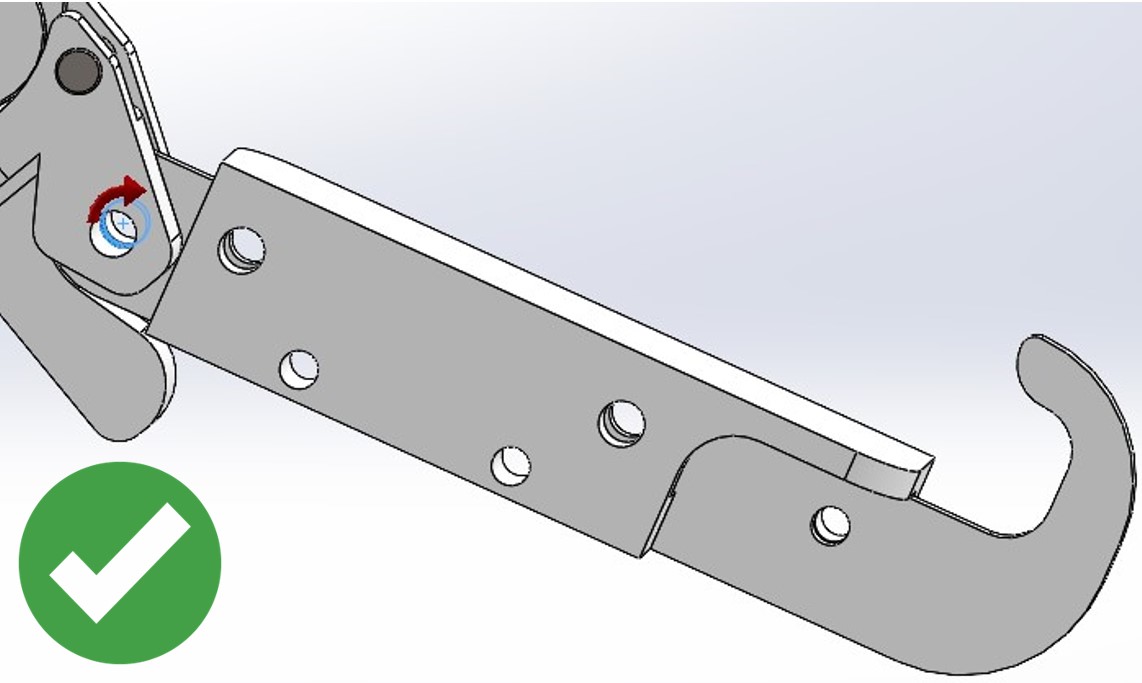

I've made some great progress today and have been working very hard to get this simulation right, luckily it's all coming together. *see gif* I've also learned something pretty interesting about Solidworks and how it processes data for it's simulations. The seems to run better when applying rotational motors rather than applying a force to a body.

I've put in two pictures for reference, the picture on the left shows the application of a force being applied for movement, this is what created more errors, while the picture on the right shows the rotational motor being applied for movement, which gave the smoothest results.

Linear force onto claw which causes errors

Rotational motor to joint which runs without errors

One thing that was very helpful today was a meeting I had with Tony that made me think more about what I'm wanting to do in the future. My main takeaway from our conversation was that with this new experience I've gained from the SURF program to prepare for grad school, where do I go from here? Tony brought up some great points about how different paths can be when taking, or not taking, the route through grad school. To be able to make a good decision about how to move forward, I'll need to get some industry experience and compare the two. Not only that but I'll need to really think about what it is that I want for my future and what goals/passions do I have. It's something I've thought about for a while and it wasn't a new topic for me, but this time I felt more inclined to really look into what I want for the future. Thankfully, I've got some time to decide and I'll definitely be thinking about this topic more critically over the next few weeks.

August 9

Today I've been working towards getting the claw to close with a force applied. I've been able to keep using Event-Based Motion within Solidworks without any additional errors. The gif shown is the claw being closed using the Event-Based Motion as well as the slide block being activated simultaneously. With the final presentation coming up this Wednesday, I've been working non stop on these simulations. The hope right now is to complete enough that can show how a clear problem was able to be solved with the project. Nothing like a deadline to speed up work, ha!

Claw of gripper closing simultaneously with slide block

Week 7.1 (August 5 - 8)

August 8

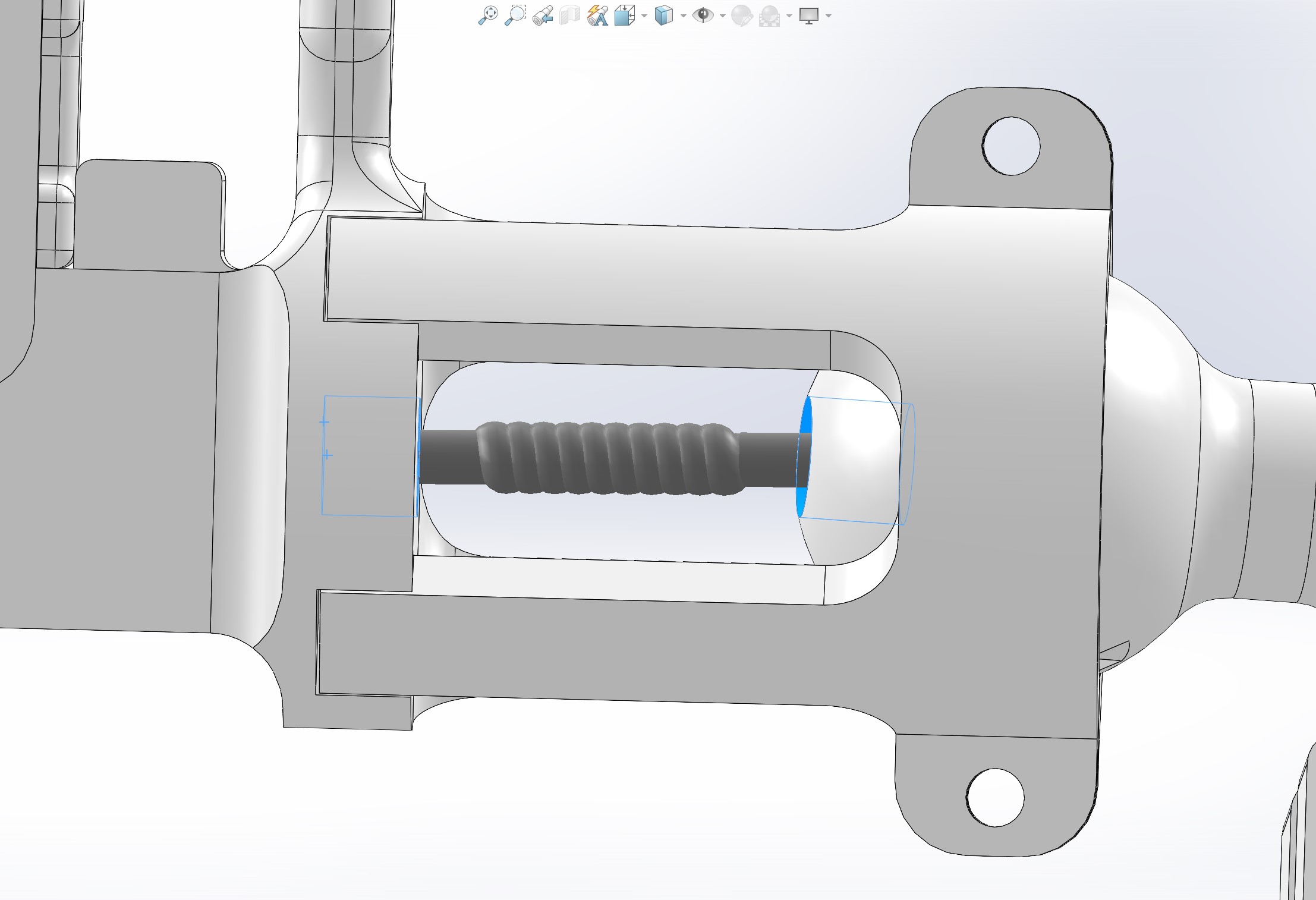

Found the problem!!! Wow...didn't think it would be such a quick solution either ;_; So apparently the software has a frame rate that is used for running the simulation (a feature I've known about for a while) HOWEVER this frame rate has major implications on how fast the software is able to calculate the physical properties in the solid objects. This essentially means that if the frame rate isn't high enough, or the accuracy isn't set properly, the entire system glitches upon contact and gives the errors I've been getting so often recently. So, I've adjusted the frame rates properly and was able to run a simulation with the slide block in action! The gif shown is the quick release slide block that will be triggering the claw system to move. It's not completely finished but I should be able to easily finish the latch tomorrow morning. As I was looking through tutorials I learned more about Event-Based Motion within Solidworks, which should be perfect for setting and activating the claw system. Fingers crossed it'll work by the end of the day tomorrow!

Internal slide block with spring applied force

August 7

I've started to take the approach I took before when running into errors, just going step by step to find the issue. I've looked into every mate and mate type available and still haven't been able to figure out what the problem is in the model simulation. I'm still looking through tutorials on how to solve these issues but haven't been able to figure out the errors yet.

August 5 - 6

After running simulations for the gripper, there have been many errors beginning to appear seemingly out of nowhere. For what simulations I could run through, the model seemed to create strange errors that phased solid objects through each other even though there were clear mates defined. I've been using the desktop in the lab by remote access to run simulations, which has been running simulations much quicker than my laptop. I've looked into some tutorials into fixing the new errors but nothing has seemed to give a clear answer just yet.

Week 7.0 (July 30 - August 4)

Due to personal circumstances, no further work or progress was able to be completed during these days.

Week 6 (July 26 - 29)

July 29

Since I've figured out the error with the solid body meshing problem, I've been able to continue the force applications to the model. So far they've been working without any issues and I've been able to work through the model changes when force is applied. Unfortunately, the computer lab I've been working with on campus has had to close for the day to install software updates for the upcoming fall semester. So, I've been able to make some progress but it has been very slow with my computer and I've only been able to run through my simulation a few times, none of which being smooth enough to get video of. I don't have much time tomorrow, but I'm hoping I'll be able to finish up in the computer lab tomorrow and get some smooth video and smooth run throughs for the model before the weekend.

July 28

I've been able to rebuild the model and begin running basic simulations again. I've gone back to the previous model with added in springs and no cord system in place and it seems to be running just fine as it did beforehand. I've been adding in different values of basic direct forces on the model, starting with 5N and working my way up to 50N. During this process I noticed that some of the parts will overlap during the computation side of the simulation and create errors. Since the solid bodies can mesh together before adding contacts, the model simulation will register two objects as one if they are touching at any point. I've spent most of my time going through the model and making sure there aren't any merging points throughout the model.

July 26 - 27

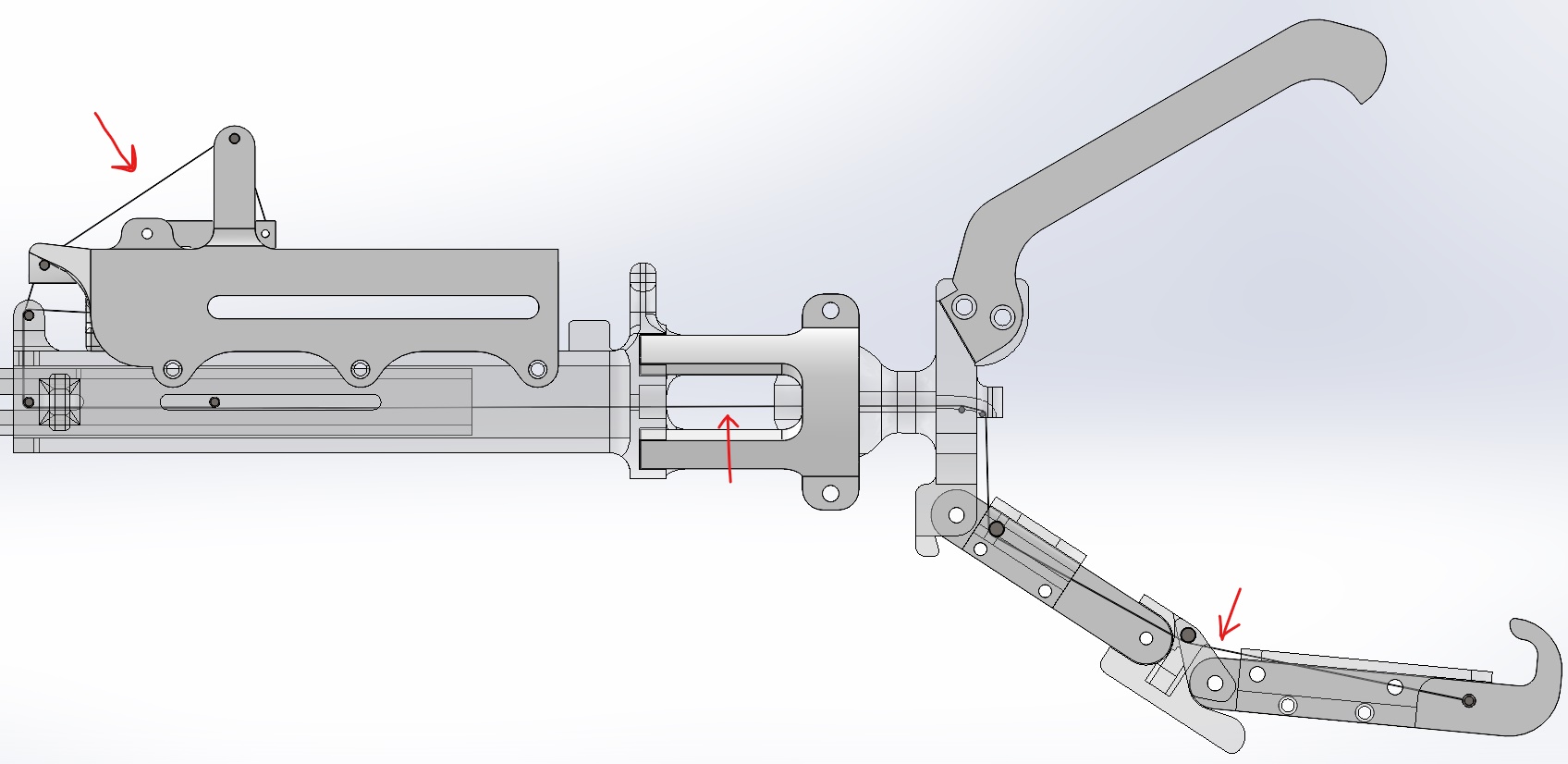

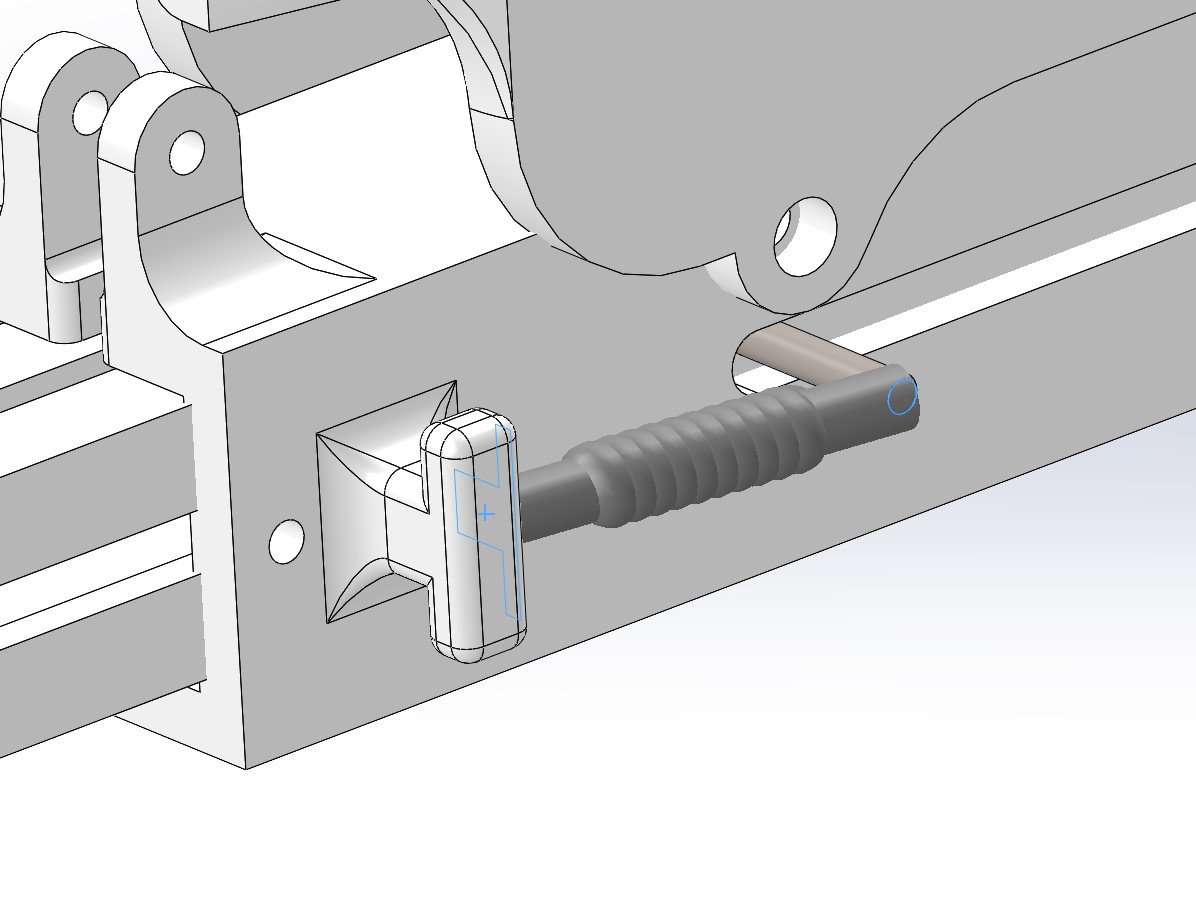

Slow progress again for Monday and Tuesday. I spent most of these past couple of days moving out a family member's apartment without any extra help since people had unexpectedly gotten sick. I was able to make a bit of progress on the cord system for the model but because of the complexity of the model and how much time I have left in the program, I'll be able to accomplish more tasks if I stop working on the cord system and focus on the simulation and finite element analysis (FEA). As you can see from the image, I was able to model the cord through the gripper but the simulation process for a cord with this many turning points is very time consuming and I don't think it would be beneficial to try and push it through when there are many other tasks I can finish without the cord system in place. The picture shown has some parts that are transparent for better viewing of the cord.

Internal cord system indicated by red arrows

Week 5 (July 19 - 23)

July 23

Progress has been a bit slower today for the cord modeling. I've been watching more tutorials about the more advanced mates I'll be needing to use for the whole cord system to properly function within the gripper. I've learned how to utilize more mates for the model, the linear coupler mate and the path mate. Due to a family illness, I was only able to get through tutorials about fitting the cord into the model, I wasn't able to make any progress on the model itself nor was I able to make it to our usual Friday meeting. It was a bit of a bummer missing out on the meeting because we were discussing a couple of papers Mark had us skim over, but I'll hopefully be able to catch the last few meetings for the summer.

July 22

Great progress today! I've figured out that I've been using the wrong types of mates yet again, ha! I've learned how to couple two types of mechanical mates together in order to make the pulley system work, the gear mate and the rack and pinion mate. These mates help with giving the path of the cord in the pulley system and allow for a smooth action/reaction movement for the cord. In the gifs shown, you can see how by moving the mechanisms L-shaped holder, you're able to continually rotate the pins of contact for the cord. The checkered pattern is applied to aid in viewing pin rotations.

Rack and pinion gear rotation

July 20 - 21

I've been implementing the pulley system for the cord and I've been going back forth between tutorials and modeling. It seems pretty straight forward but looks time consuming. The pulley systems works by a system of offset and distance mates that set the solid body motion between two set areas. The time consuming issue with this system of mates is that there are multiple turning points throughout the model and, to my knowledge, each need their own set of constraints to move within. I've been working implement this system as best I could but I'll have to continue to make further progress this week and I'll hopefully be able to fully implement the cord into the system before Friday's meeting.

July 19

Not much progress for today, I've been trying to find more ways to set up the force application and I think I've found a good method to start implementing into the system. There is an application within Solidworks that allows for a cord pulley system to be implemented. It took a while to find this application system tutorial but I'm glad I've found it because I think it will be a perfect fit for the cord/rubber band system's within the gripper model. I'll hopefully be able implement this tomorrow and make further progress on the model.

Week 4 (July 12 - 16)

July 16

Not much progress today, I've been learning more about how and where to apply forces in Solidworks. My simulations are getting to a point that they'll take more than 30 minutes to run so I'll have to wait until Monday to test my files on the desktop computers at my university's engineering lab which should work well for the simulations. So, since I'll be having to wait for access to the computers, I've just been focusing on learning more features available on Solidworks associated with the motion analysis tab. There are options to apply forces onto specific points and edges of the model as well as force analysis features that will show the distribution of forces when one is applied. Hopefully I'll be able to run the simulations quicker on Monday and be able to put the forces into place and maybe even start getting data for force distribution across the model.

July 15

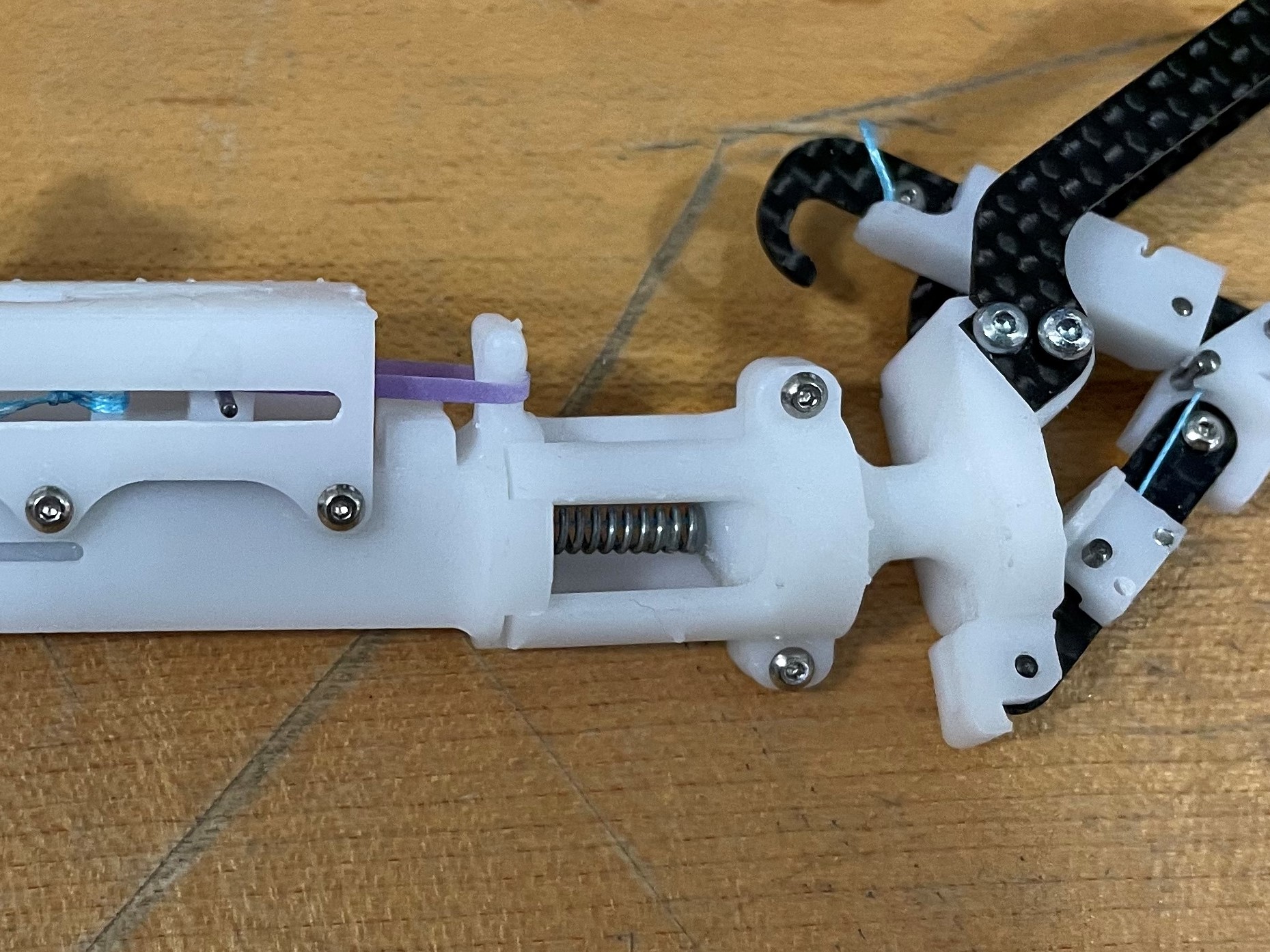

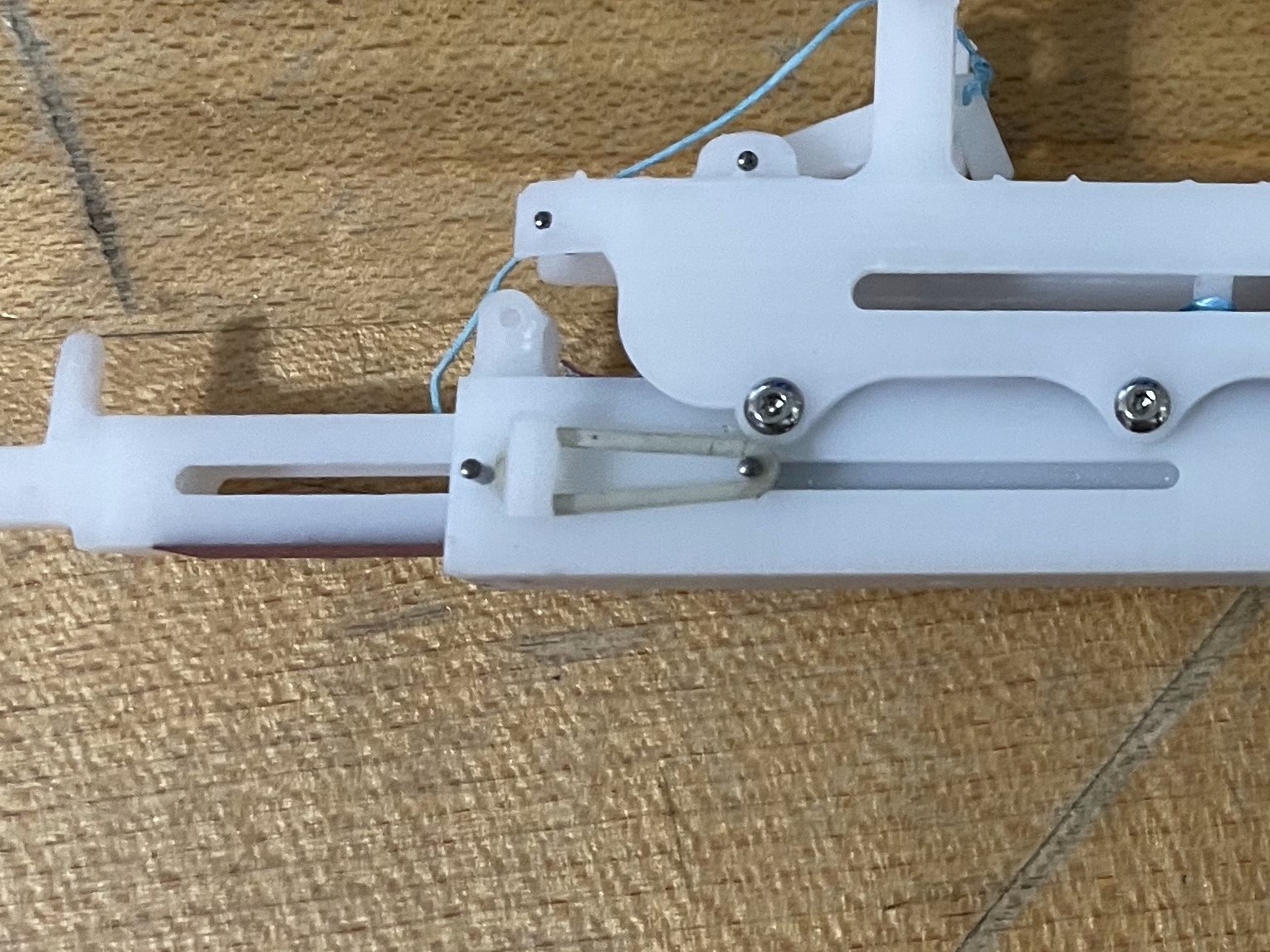

Todays progress is moving along well; I've been able to successfully add in the springs to the model and run the analysis without any errors. A much smoother day than most! The images are the locations of the springs I've placed onto the model, based off of the rubber band design of the physical gripper tool which is compared for reference. No meetings or deadlines today so I'm glad I was able to get so much done.

While I didn't have any errors, I'm noticing that I'm getting to the point where the model simulations are too large for my computer to process quickly. The gif shown took around 20 minutes to run though, while the first motions took less than a couple minutes. I have some high performance desktops at my university so I'll have to most likely working from there to run my simulations and motion analysis models quicker. Tony offered to set up a remote desktop in case there are still issues so I'll be sure to keep that in mind for future simulations. Tomorrow I'm hoping to add a couple more springs to keep the ball and socket rotator from spinning so much and give it a bit more control.

Motion Analysis with springs and gravity

Stabilization spring for ball and socket joint

Stabilization spring for ball and socket joint

Linear spring mimicking rubber bands

Stabilization spring for ball and socket joint

July 14

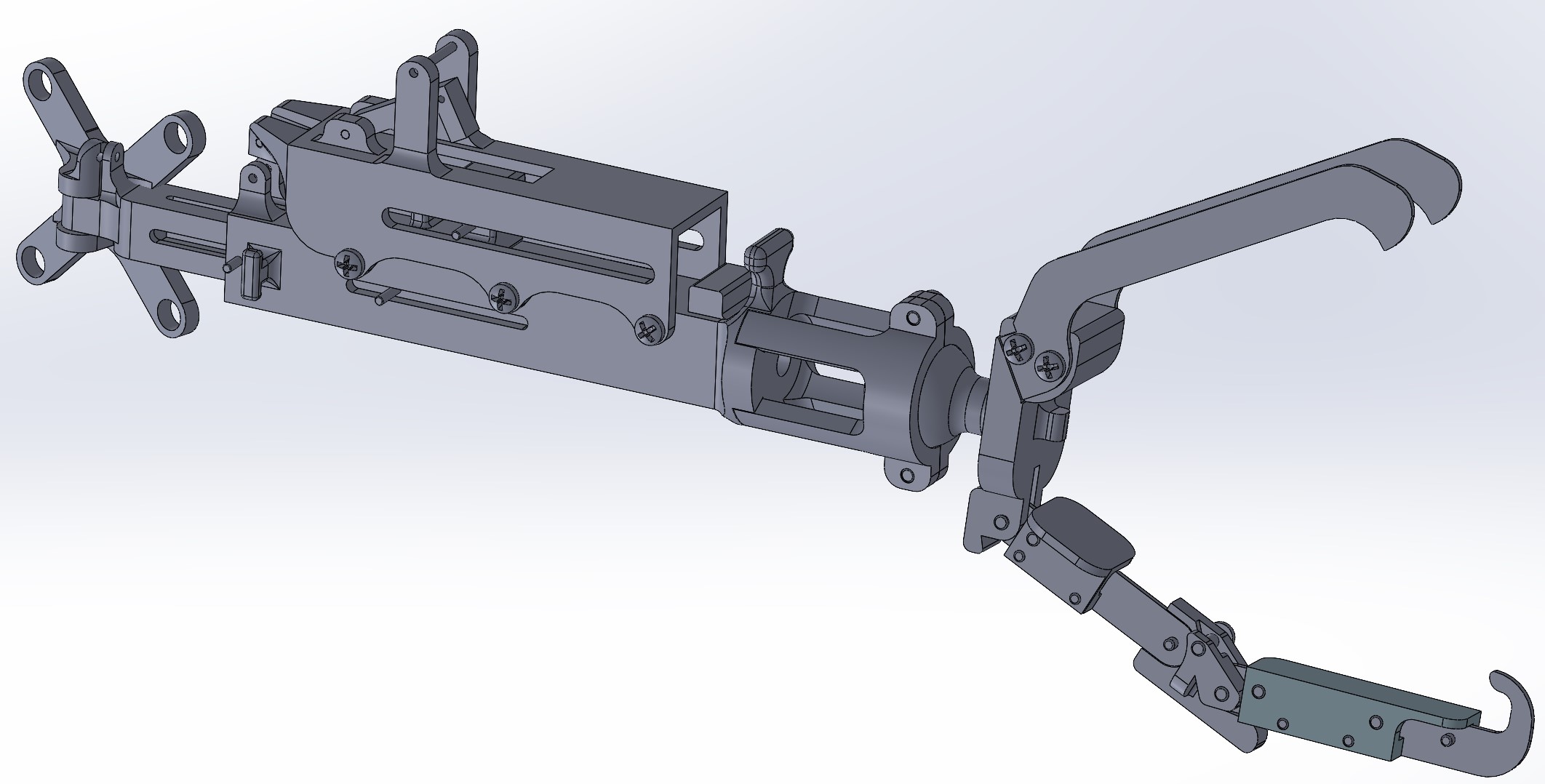

I've been able to fully assemble the gripper device and was able to run a motion analysis with no external forces other than gravity, which is the gif shown. With the help I received, I was able to keep the number of mates down to a number much lower than I previously had run. I've noticed that the motion analysis tends to give errors on certain types of solid body contact, so I significantly limited the number of solid body contact pairs I implemented. This seemed to also help the error problem I've been having and I haven't encountered any errors so far after that change. Hopefully tomorrow I'll be able to run the model with springs added in and without any issues or errors.

Motion Analysis without springs and only gravity

July 13

Today I learned good advice from the team and while I hit some roadblocks in my modeling this morning, I think I've made good progress. I went through the model and rebuilt it again but still continued to run into issues. I'm pretty sure the issue is how I'm mating the parts together which is causing the software to create errors. Luckily, the advice from Mark and the DESI team, the team working on the entire drone catching system, helped point me in the right direction. During our meeting Mark explained how sometimes when working on a project and you hit a block, it helps to try and simplify the issues more and go by a step by step test approach. This was very helpful for me because reflecting on past projects, I've noticed that it's easy for me to overcomplicate problems and get caught up in the "complex solution" when sometimes it helps to take a step back and work from the fundamentals.

So, I talked with Kenneth after our DESI meeting and he was able to walk me through a new rebuild model. This was so so helpful for me because even though I'd looked into the different ways to use the mechanical mates in Solidworks, I hadn't thought of ways to transfer it over to the model in order to cut down on the number of mates used. We went back and forth modeling and running the motion analysis to make sure that if any errors came up we'd know what caused them. The main difference between what we rebuilt and what I'd been trying to do is that there were far fewer mates used in our rebuild than I used in mine. Now that we've gone through that, I'll hopefully be able to finish the model tomorrow so that we can start on getting data from the model as soon as possible.

July 12

Wow, it's already the halfway week of the program. That went by so fast. Well, good news, I've finally been able to keep a consistent work flow and get some progress on my project. Bad news, I'm running into a lot of errors that I'm not sure how to address. I talked with Tony and Kenneth, another grad student on the project, about the issues I was having in Solidworks and they were able to get me headed in the right direction to find good ways to solve the problem. The main issue I ran into was that there were strange warnings and errors coming up when I tried to run the Motion Analysis: "design over constrained", "design under constrained", "analysis runs zero inertia", "redundant mates". I looked into all of these issues and none seemed to solve the issue. After some research and help from Kenneth, I think I'm on the right track to fixing these issues. Apparently there is a issue with how Solidworks processes coincident mates that are run through the Motion Analysis component, so I've been rebuilding the model, yes a third time ;_; and taking a step by step approach to building and running, building and running. I wasn't able to get far because by the time I started to rebuild the model, it was the end of the day and I needed to finish my GRE work for the SURF classes.

Week 3 (July 6 - 9)

July 9

Today we had our general lab meeting with a student going over an update of their research progress. I always enjoy our weekly meetings because I'm able to get a better sense of what's going on around the lab and how people are solving problems. Today for my modeling progress I ran into problems running the simulation and motion analysis. I'm not sure what the problem was or how it came up but there seemed to be an error in rendering the model for viewing. There were parts that became fixed that somehow couldn't be changed and were causing a ripple effect across the model, causing it to seize up and not move past the first .5 seconds of rendering time. I took most of the day trying to fix the issues and find a way to fix the issue without having to reassemble the model from the start. I'll look more into the problem if I have time over the weekend but from what help I've been finding online, the only solution may be to reassemble all of the parts. Ha, it should be faster this time since I know how everything works and fits together now!

July 7 - 8

Motivation has been a bit difficult the past week, I thought it may have been the long weekend but it's been something I've been struggling with for most of the summer. It's not so much the program but I think the fact I've been doing most of my work from home and my time outside has been pretty limited. Today's progress was pretty slow but I'm happy I was able to make some progress forward. I finished the model's pin connections and adding the bottom claw connections in Solidworks, but I've been having trouble with the tendon connections within the model that allow the parts to move jointly.

Full grasp tool with bottom claw attachment

By the time I ran into trouble with the tendons I had meetings lined up for the rest of the day and haven't been able to work on it since. I should have more time tomorrow and I'll be going over the tendon problems with Tony so I should be able to find a solution for that soon.

July 6

Long day today but not for my lab work. The SURF program had lots of assignments due today and most of my time went into making sure I could turn them in on time. The largest one was called an Individual Development Plan (or IDP) which was very time consuming but was very helpful because of how I was able to break down the different aspects of what I expected from the program and the future. Areas like "Expectations of the SURF program", "Graduate schools/programs to apply for", and "Industry to help meet goals". Tomorrow I'm hoping to finish my model assembly and motion analysis so that I'll be able to move onto the next portion of my project.

Week 2 (June 28 - July 2)

July 2

Today was just focused on completing more work for the Solidworks models. I've been working on adding the final pieces to the model so that I can begin adding more motion features to the overall assembly. We also had a lab meeting today where I was able to present a few slides over what Solidworks is used for and what features would best be of use to the lab. It was a quick presentation that I was able to create a few slides for while other members of the lab had slides going over other useful softwares like Matlab, Unix, and Gazebo.

July 1

I got a lot done today! I'd say it's probably my most productive day so far and I'm happy with the progress I'm making in the project. Part of the help has been connecting with other SURF scholars and being able to encourage each other through our projects and regularly meet with each other, virtually of course.

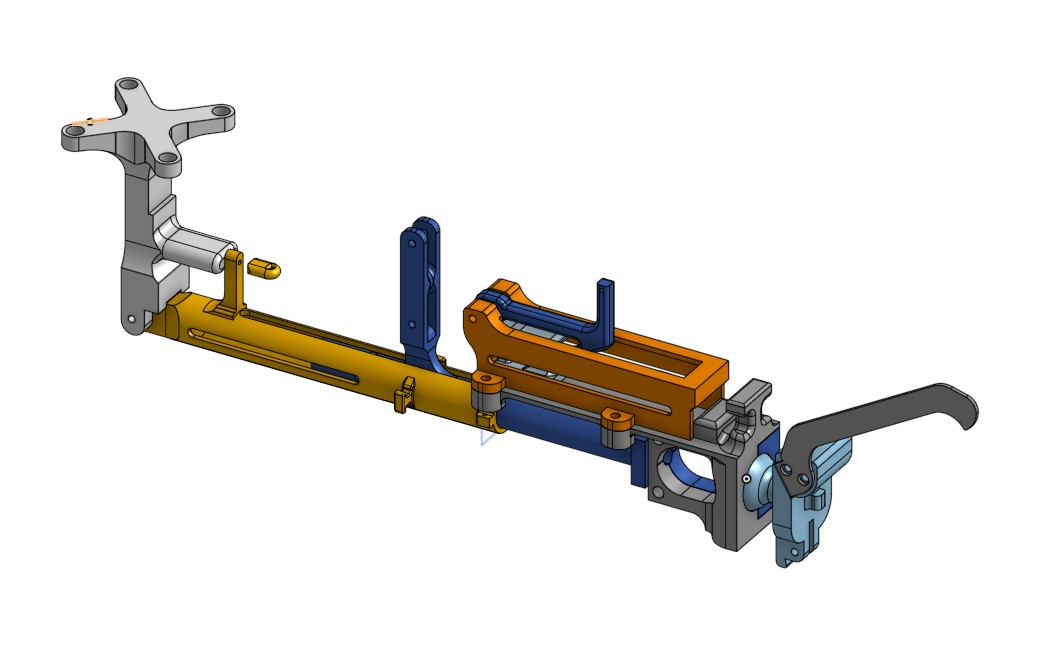

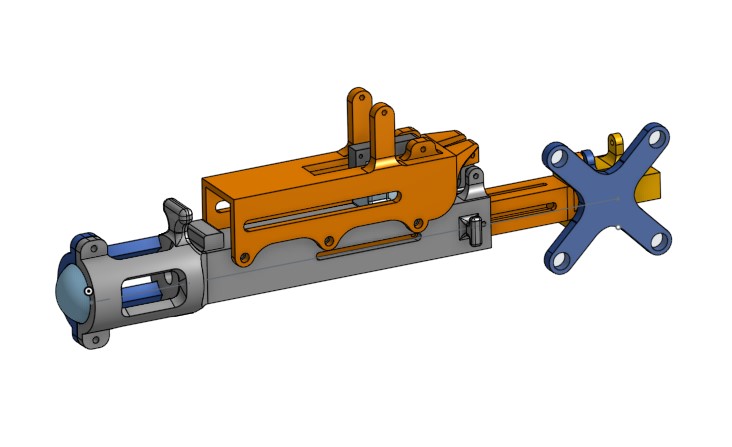

For Solidworks, I've been able to run the first motion analysis for the project and even though it's not fully actuated it will get there soon! The gif shown is the motion analysis I was able to run for today with gravity acting on the tool and the picture is just a side profile of the device with previously modeled pins and screws. In addition to this, I've been able to finish up the Solidworks slides for the meeting tomorrow. Nothing too complicated, I just put together some quick slides going over how Solidworks can be utilized and what features are key to look for to use in our project. This week included a split between tasks including the modeling for the grasp tool and organizing slides for our upcoming meeting about softwares being used.

Motion analysis of grasp tool

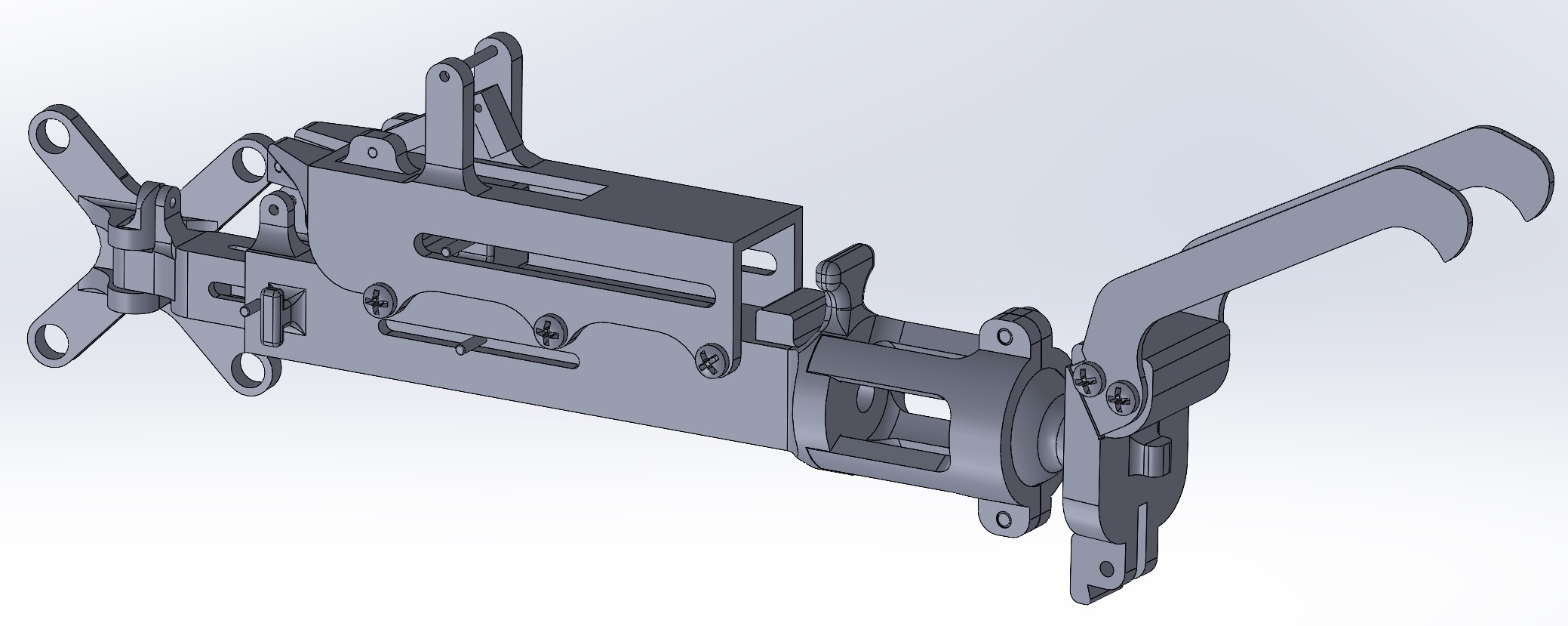

Side profile of motion analysis of grasp tool

June 30

Today Tony and I went over what things we'll be needing to finish before our next meeting on Friday. For the group I'm working in, we're going to be presenting all of the possible softwares that could be needed or used for the project. Tony and I will be working on presenting Solidworks to the group so today I spent the day working on a short five slide presentation summarizing Solidworks and how it can best be utilized for the project.

June 29

Today the group I'm working with on the grasping quad held a meeting to go over some progress updates. I was able to meet the other people on the team in charge of different areas of the quad as well as learn what all goes into the goals we're trying to accomplish. I wasn't able to complete as much work as usual today because of the work and meetings for the SURF program but I should have more flexibility to complete more work tomorrow and the rest of the week.

June 28

After working to understand the Onshape model of the grasp tool last week, I've spent the day finishing out the final mates of the Onshape model (adding screws and pins) and have been moving onto the Solidworks upload stage. I'm glad to have gotten to this point because now that I'm able to work with the model in Solidworks, I'll be able to begin adding in the flexible features of the tool, which will further allow me to begin simulating and animating a fully working grasp tool.

Week 1 (June 21 - 25)

June 25

Today I met my goal of fully understanding how our grasp tool works! After going through 3D models, pictures, and videos of how the mechanism works, I'm able to clearly understand and describe to someone what's happening and how the system works. I haven't been able to get far enough on the assembly to start importing the model to Solidworks but I've made enough progress that I think I should be able to import it by Monday. This has been the main thing I've worked on today and since the lab is at a retreat for the day, I haven't been able to make much contact with Tony for updates.

This first week of the SURF program has been very helpful for giving me an understanding of what it's like to be an actual graduate student. Much of the work and progress I'm completing requires a large sense of independence and self motivation that is different than I've been used to during my time as an undergrad. While it's been a new adjustment for me, I'm excited about the new adjustment and that I'm getting great experience as a student researcher.

June 23 - 24

The past couple of days, I've focused more on learning the ins and outs of Onshape. I've gotten a better understanding of the grasp tool I'm working with so I was able to use Onshape to start assembling the parts together in order to gain a better idea of how the parts would move together from a hands on approach. I'm hoping to start on the SolidWorks simulation by tomorrow!

Learning about the grasp tool has been a bit challenging virtually, but Tony has been doing a great job in giving me models, pictures, and videos of the grasp tool working and its design characteristics. As we were going over the design, I learned what underactuated systems are and how they function; our fingers are a great representation of this! The design of this grasp tool definitely fits the "Biomimetics" name of the lab; the designs are closely modeled after designs found in nature!

Side profile of grasp tool with claw and hinge mount

Side profile of grasp tool without claw and hinge mount

June 21 - 22

Welcome to my summer research blog! I'm so excited to be starting the Stanford Summer Undergraduate Research Fellowship (SURF) with the BDML. Due to COVID-19, this fellowship will be held virtually but I'm still very excited to gain experience and meet people throughout the summer. This blog will be broken down by the eight weeks of the fellowship and will go over the general progress and milestones of my projects within the lab.

This first couple days, I've gone through the Onshape tutorials and learned how to use the modeling features within the software. I've also been able to set up a daily meeting schedule with the graduate student I'll be working with, Tony Chen. I've also been learning about the Grabbing and Perching Quad and how I can help make improvements to the design.

My goal for the upcoming week is to better my knowledge of how to best use Onshape and fully understand the grasp tool I'll be working with. I'm also planning to finish the assembly of the grasp tool parts and run a simulation through SolidWorks.