Grasping and Manipulation via Tactile Sensing

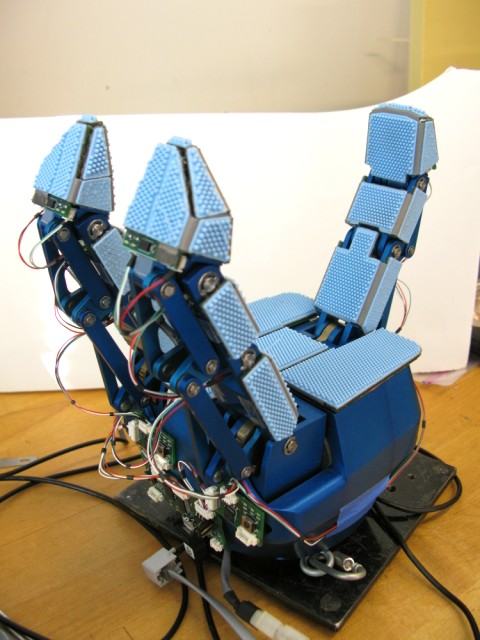

Finished and installed sensor suite on the Robotiq Adaptive Gripper

Background

Although we rely heavily on vision to interact with the objects around us, it is by no means necessary. Some good examples are removing your wallet from inside a bag or reaching out to grab one's mouse while concentrating on the computer screen. In both of these cases you have a rough estimate of where the object is relative to your body and you get low quality visual feedback about the relative positioning of your hand while you try to grab the item.

This work focuses on grasping and manipulating "blind", using only tactile feedback from sensors we have designed. The various sensors are processed to determine tactile events, such as making/breaking contact or slip between the hand and an object, as well as contact location and static pressure. These events and the continuous contact information can then be used to control more complex manipulations.

Experimental Setup

For our experiments we have built a custom tactile sensor suite for a Robotiq Adaptive Gripper which is attached to an AdeptOne, 5-DoF, SCARA industrial robot arm.

The Adaptive Gripper is an under-actuated hand with three three-phalanx fingers. Each finger has a single motor to open/close it, with a spring-loaded transmission linkage which allows the fingers to wrap around large objects and pinch smaller objects. A fourth motor controls the spread of the index/middle fingers and can be used to pinch very small objects between them.

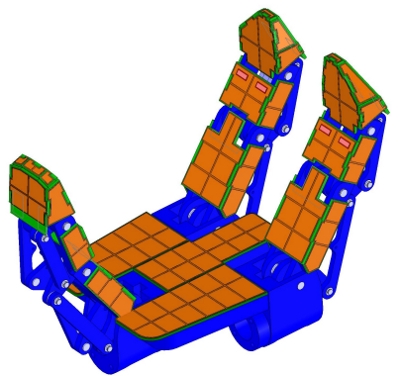

CAD rendering of the hand and sensors showing taxel locations.

Tactile Sensors

The tactile sensor suite we've designed for the Adaptive gripper covers virtually every surface with normal-pressure-sensing taxels. In addition, the sensor on the distal phalange of each finger is equipped with a 3-axis MEMS accelerometer to provide dynamic data at the fingertips at 800Hz.

There are a total of 132 pressure taxels in the suite. On average they are 1.5-2cm2 with 1-1.5cm center-to-center spacing, although their size and shapes vary as can be seen in the CAD rendering. Since they are hand assembled the sensitivity varies, but the most sensitive taxels can distinguish forces on the order of 20mN (~2 gram weight) and saturate under forces in the 100N range. The sensors are sampled at 100Hz giving them a bandwidth of 50Hz, well within the range of "fast acting" human tactile sensors.

Control

We are using WillowGarage's ROS framework for controlling the arm, hand, and tactile sensors and have written custom hardware interface nodes for all three. We plan to make those nodes, as well as any tactile processing nodes, available for use by other researchers.