Peggy's Summer 2017 Blog

reverse chronological order -- newest at top

Research Poster and Summary

August 25

SURI Poster presentation!

August 24

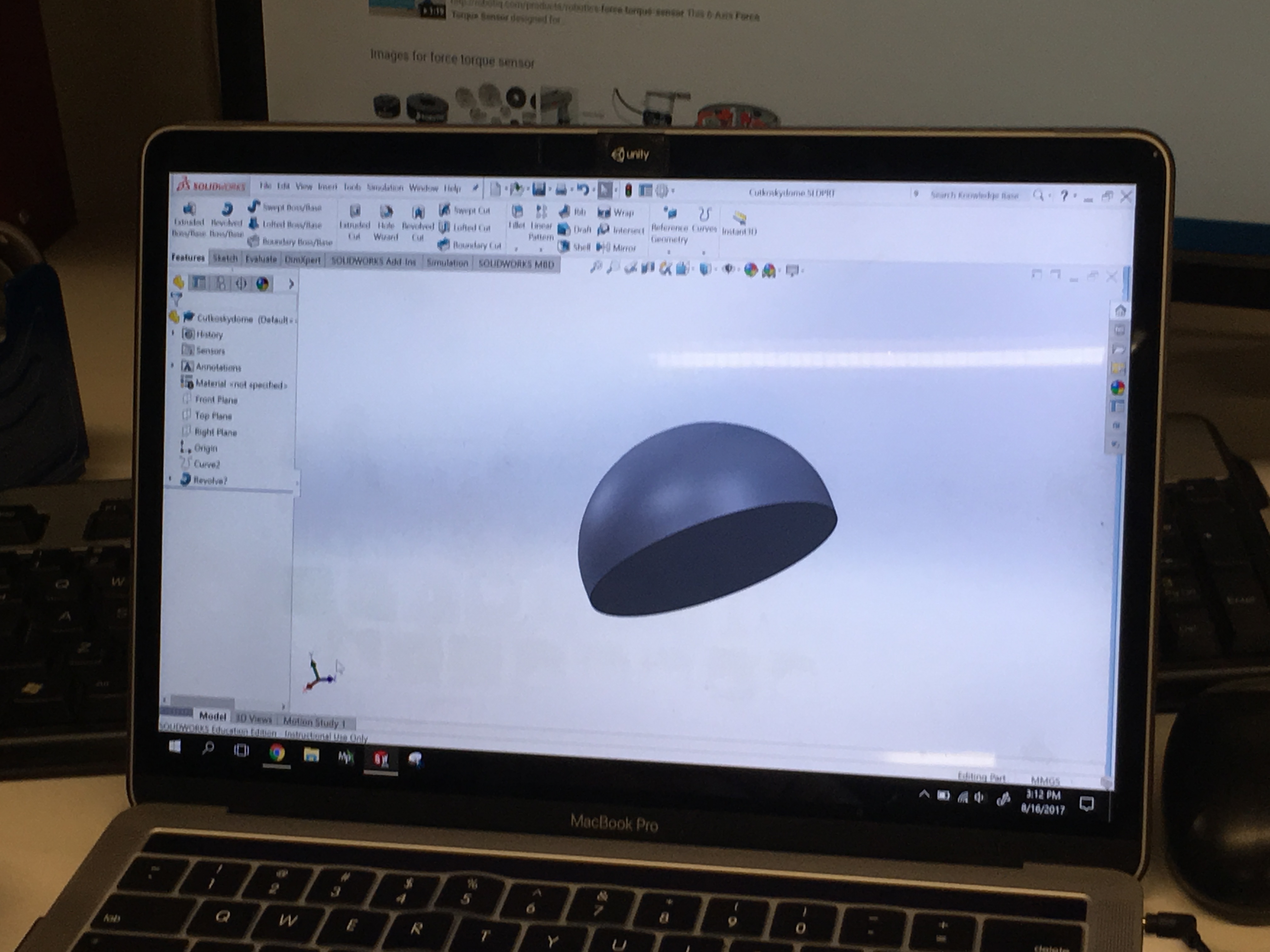

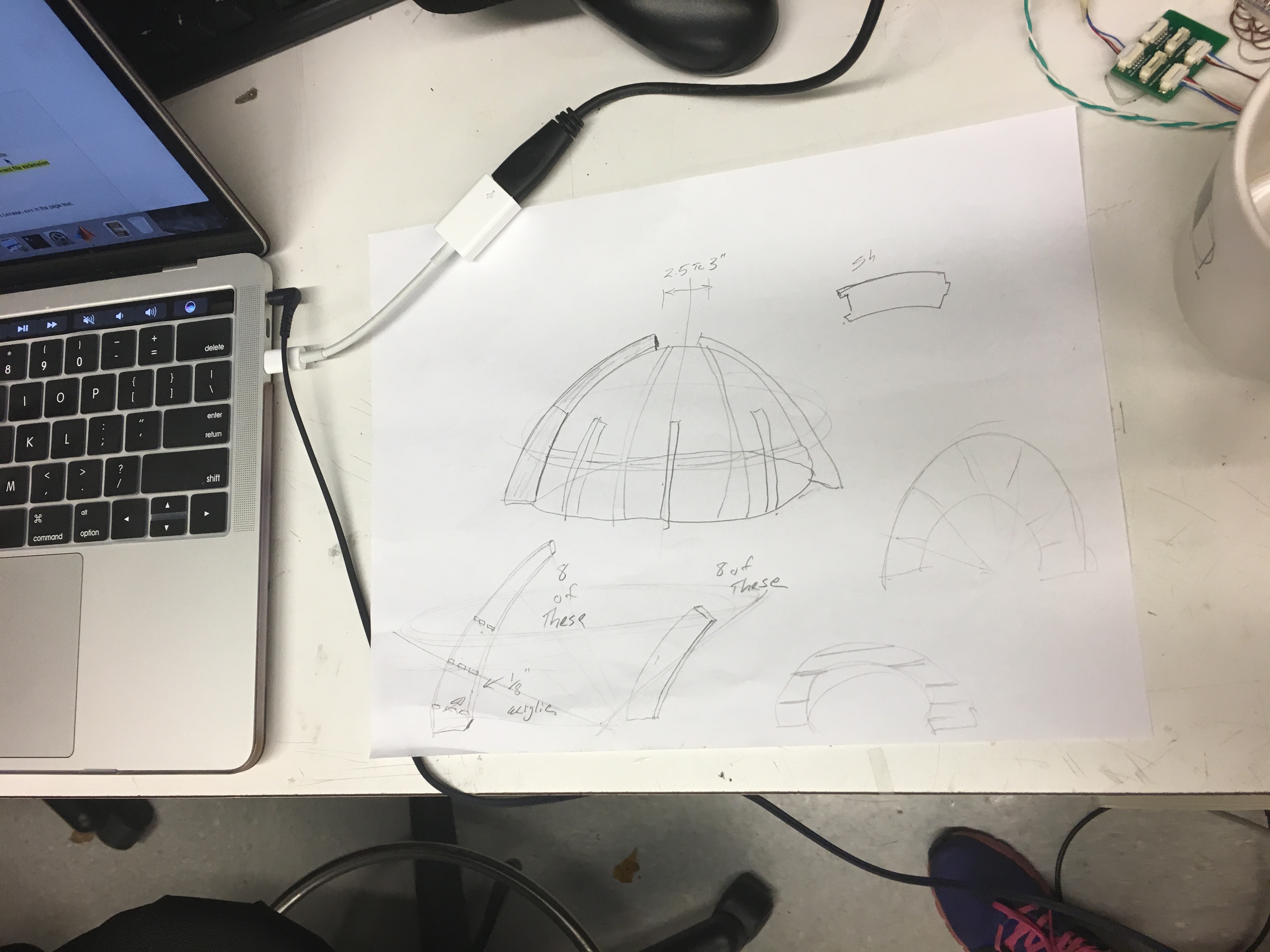

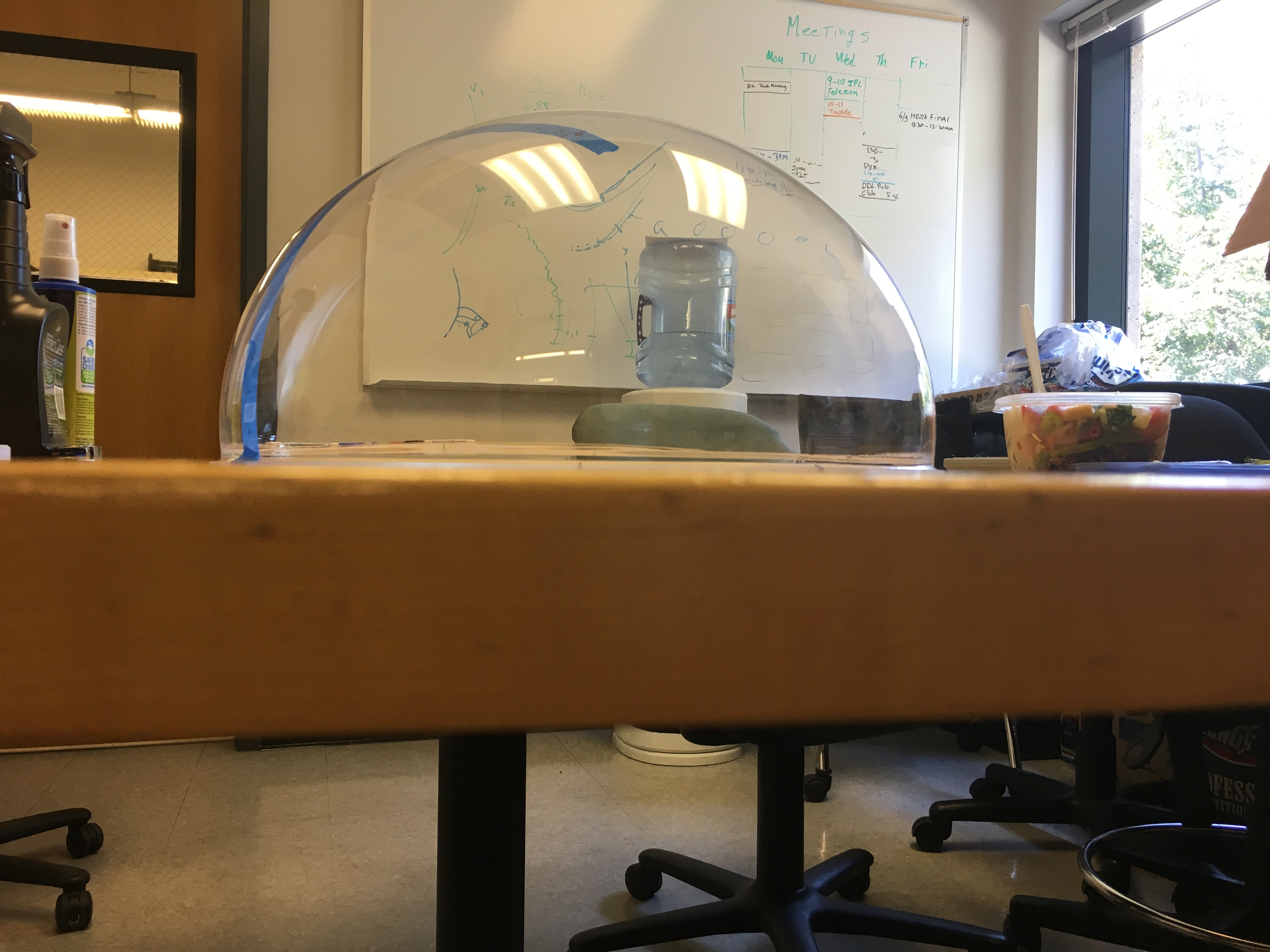

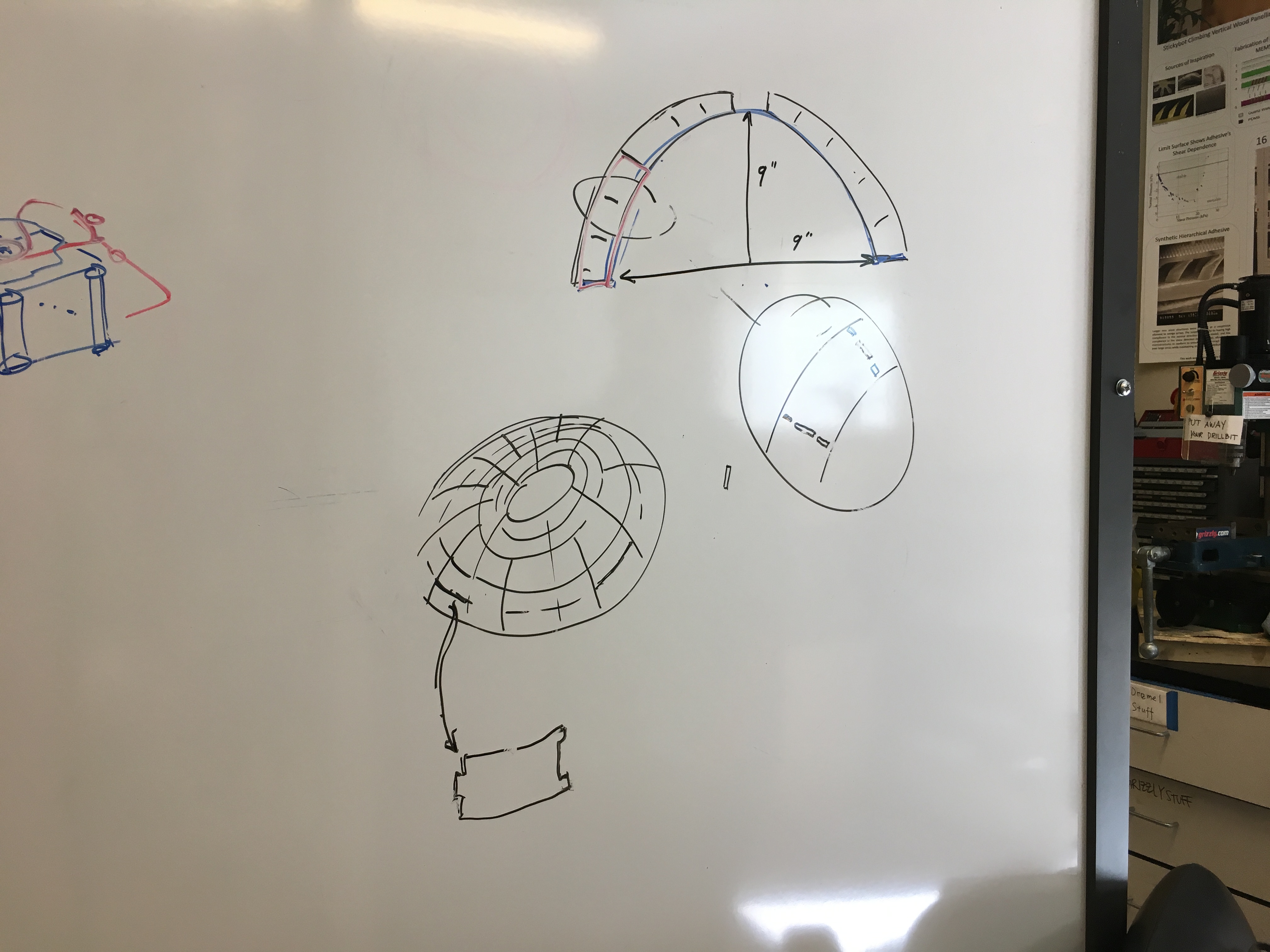

I tried to CAD the shelves of the Brunelleski dome replica today, but only partially succeeded. I have the final picture below, but the shelves are curved inward, which would make it hard to laser cut. I'm still unsure about how to make the shelves all straight and easy to laser cut as well as cutting out pieces for the shelves and ribs to all fit together.

August 23

I used Solidworks to CAD and laser cut an acrylic topping for the linear slide. I then worked on the 2 page research summary for SURI.

August 22

Alex helped me laser cut cardboard ribs for dome in the morning at the TLTL. I then used masking tape to attach the ribs to the dome to see how it looks. It was slightly off by a millimeter or so in some areas, and I sent an email to Mark to ask for his advice. The reply that it was probably good enough that I could start working on the shelves. However, if the curve was consistently off, I could change the points in Solidworks to better fit the curve. The next step is to figure out the angled "shelf" pieces. Those will be each formed by the intersection of a cone with the dome shell and ribs, and each shelf will be from a cone with a different angle. The finishing touches would then be to put the little tabs on the end of each shelf piece and to make matching little slots in the ribs. Mark thinks that 7 layers of tilted shelves would work, from the flat base to uppermost ring, inclusive (roughly one every 15deg of elevation). In the afternoon, Will and I tried to set up the experiment by clamping the motor to the AD20 with zipties. We also tried to think about the best structure and shape for the AD20 so that the ADT Nano can be on a lower level to the linear slide. I also finished my first draft of the SURI poster and sent it to Mark and David.

August 21

I met with Will for an update about the friction experiment and helped set up all the materials. Then, I mainly got started on the SURI poster. Will and Diana were super helpful in giving advice and also sent me the template they used for the Best Poster at MECON. To make the poster, I planned out the layout, wrote the abstract, and laid out the graphics and data on the template, as well as summaries explaining the figures.

August 18

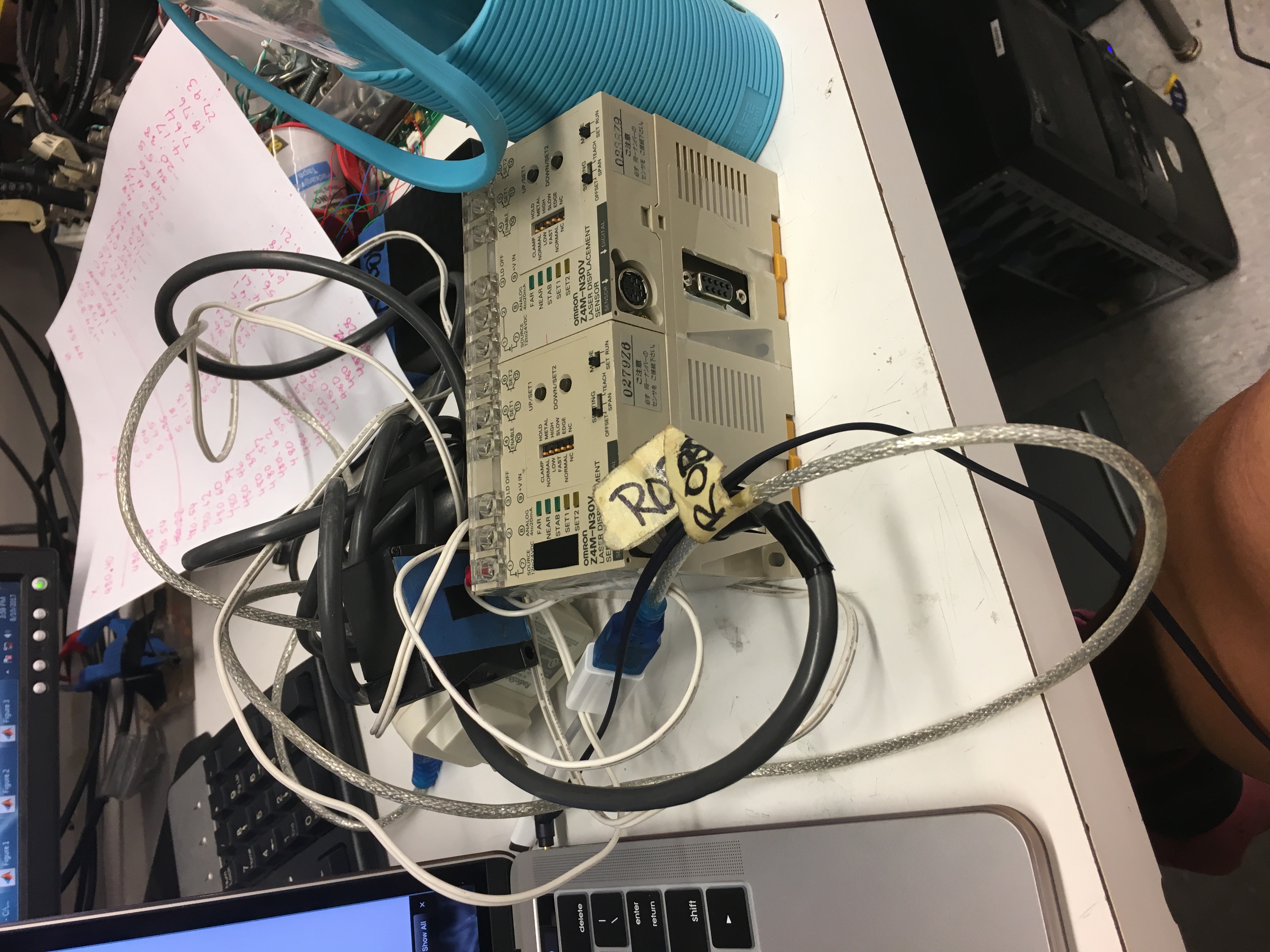

Today, we continued to test the laser micrometer to try to make the error smaller. By changing the resistance value, we were able to get the error to within 5%. We wanted to continue to try to narrow down the error to within 10 or 20 microns still. Then, we had the BDML lab meeting, and I finished CADing the dome ribs in the afternoon. I also cut some pieces of cardboard to laser cut in the Follmer lab. I then started planning the SURI poster that I need to present next Friday.

August 17

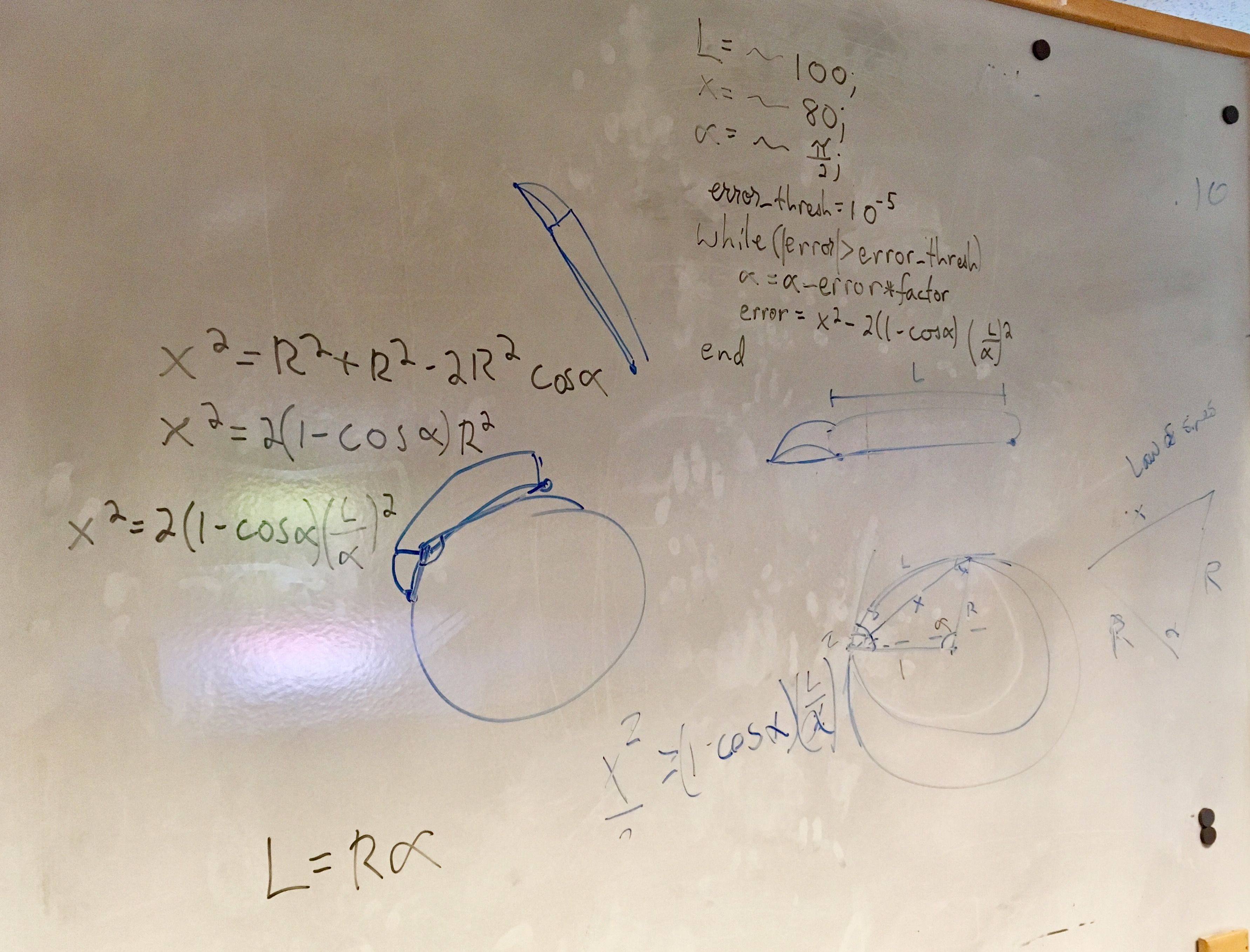

In the morning, I talked about friction experiment with Will and we tried to set up the laser micrometer. I used Python to code the object distance from the dome based on the voltage readings from the computer. However, we wanted the micrometer to be accurate up to 10 microns but the error was from 40 microns to over 100 microns. We tried to test the accuracy by changing the resistance value in the code, using a linear stage and thickness gages. I also continued to CAD Mark's dome.

August 16

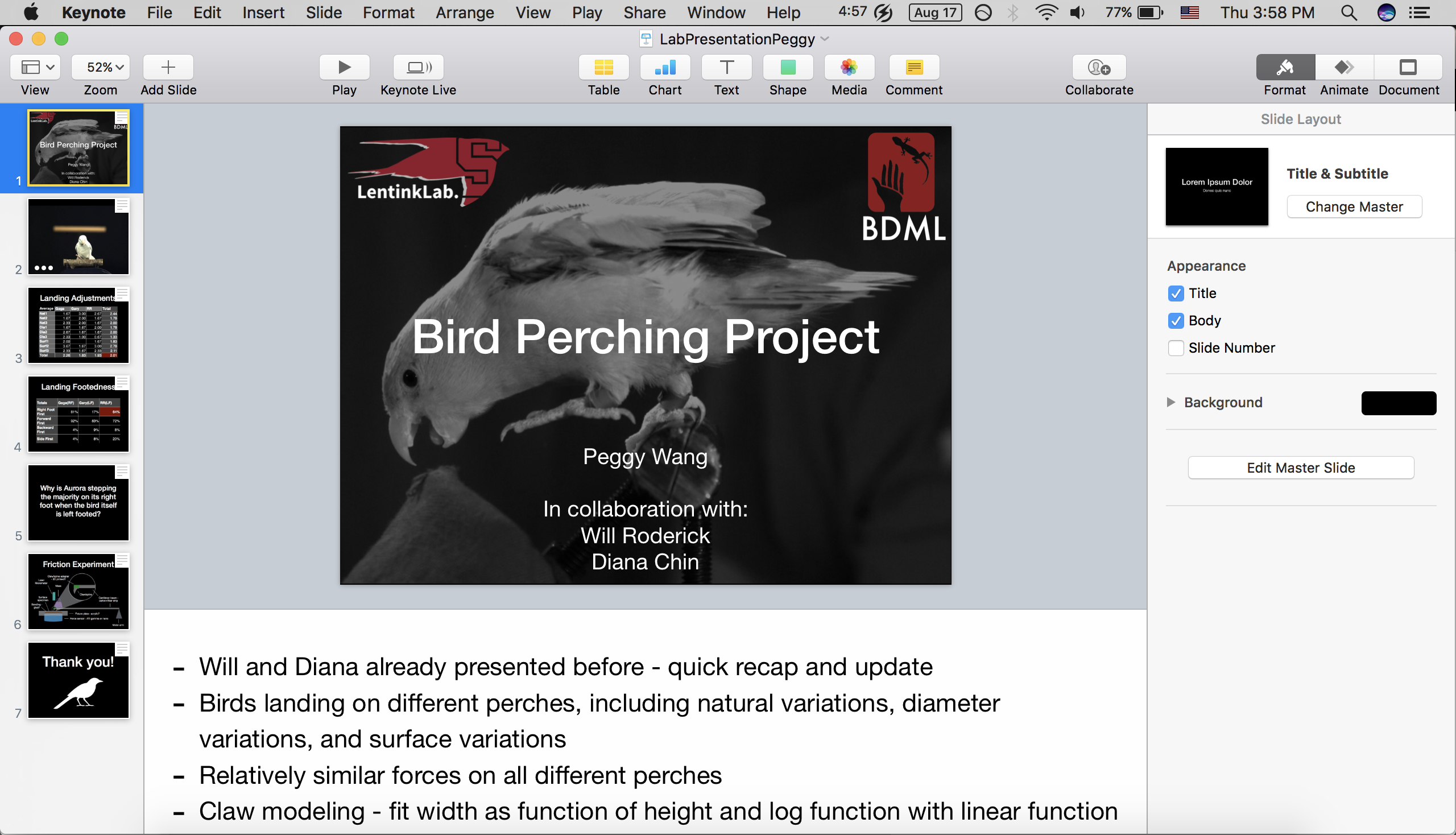

I presented at the Lentink lab meeting, and it went pretty well! I also got to know what the other SURI students were doing in the Lentink lab this summer. Later, I started to CAD Mark's dome in Solidworks and met with him to understand what he wants for the ribs. It was my first time actually using Solidworks for a project without doing tutorials, so that was definitely pretty cool! However, sometimes Solidworks would have random error that makes CADing take a lot longer, especially since I need to Google the error or ask one of the lab members for help.

August 15

I first met with Will about next steps with doing the friction testing, updates, and what to present for the Lentink lab presentation tomorrow. Will helped me get set up with the poster templates for SURI as well as presentation images. I then worked on setting up the presentation for Lentink Lab and also analyzed the data for bird landings.

August 14

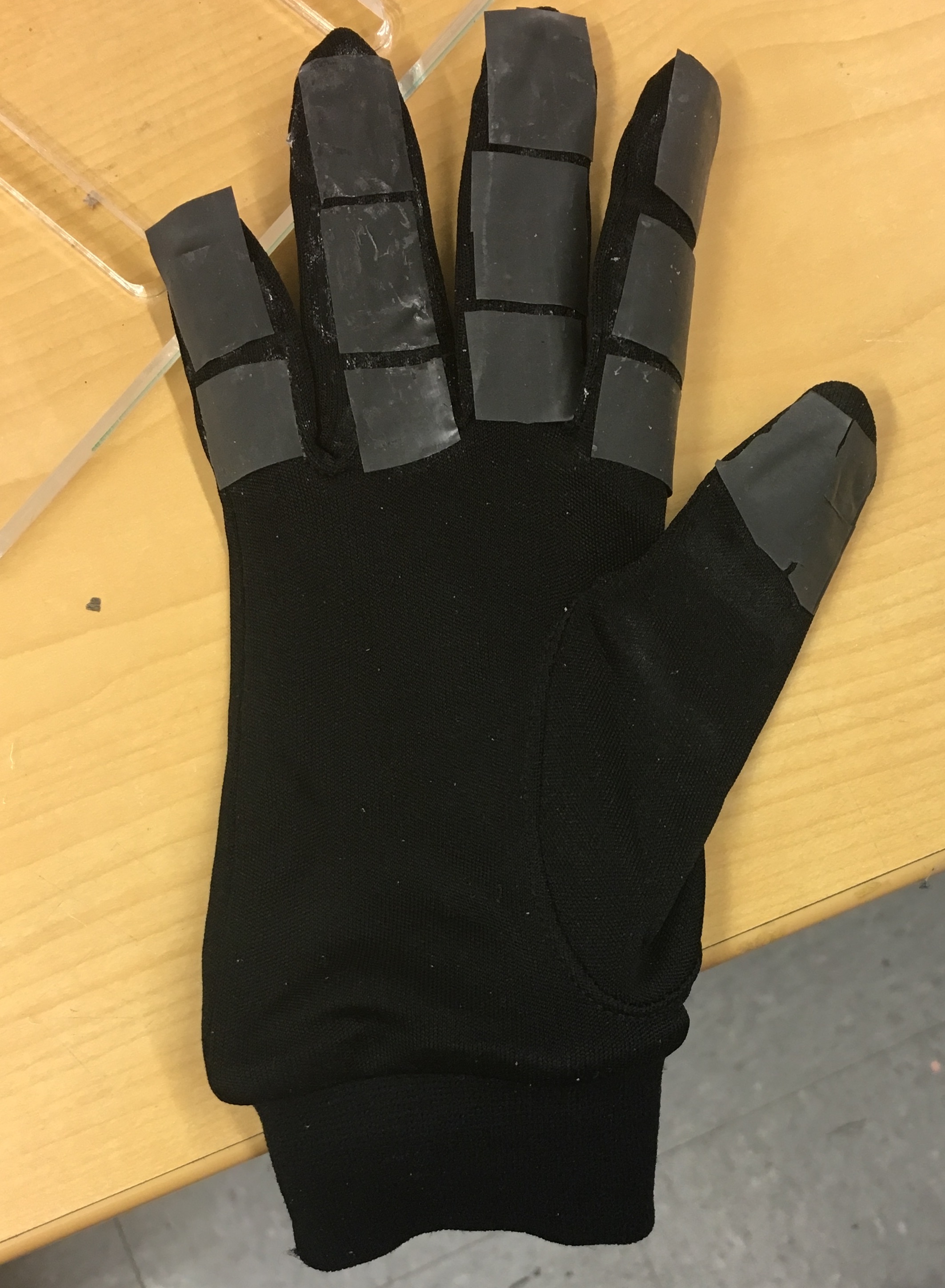

I started the day with a lot of bird point tracking, specifically with the foam surface claw tips. I also imported the UR5 coordinates into Solidworks and edited the points to make a smooth curve in Solidworks to try to CAD a model for the dome. I also met with Amy when we finished casting the Silnylon on the gecko wedges to talking about next steps with gecko gloves. The plan currently is to make a thicker backing on the back of the wedges using two layers of Silnylon and also to glue it on the glove with less glue with only a line of glue in the middle.

August 11

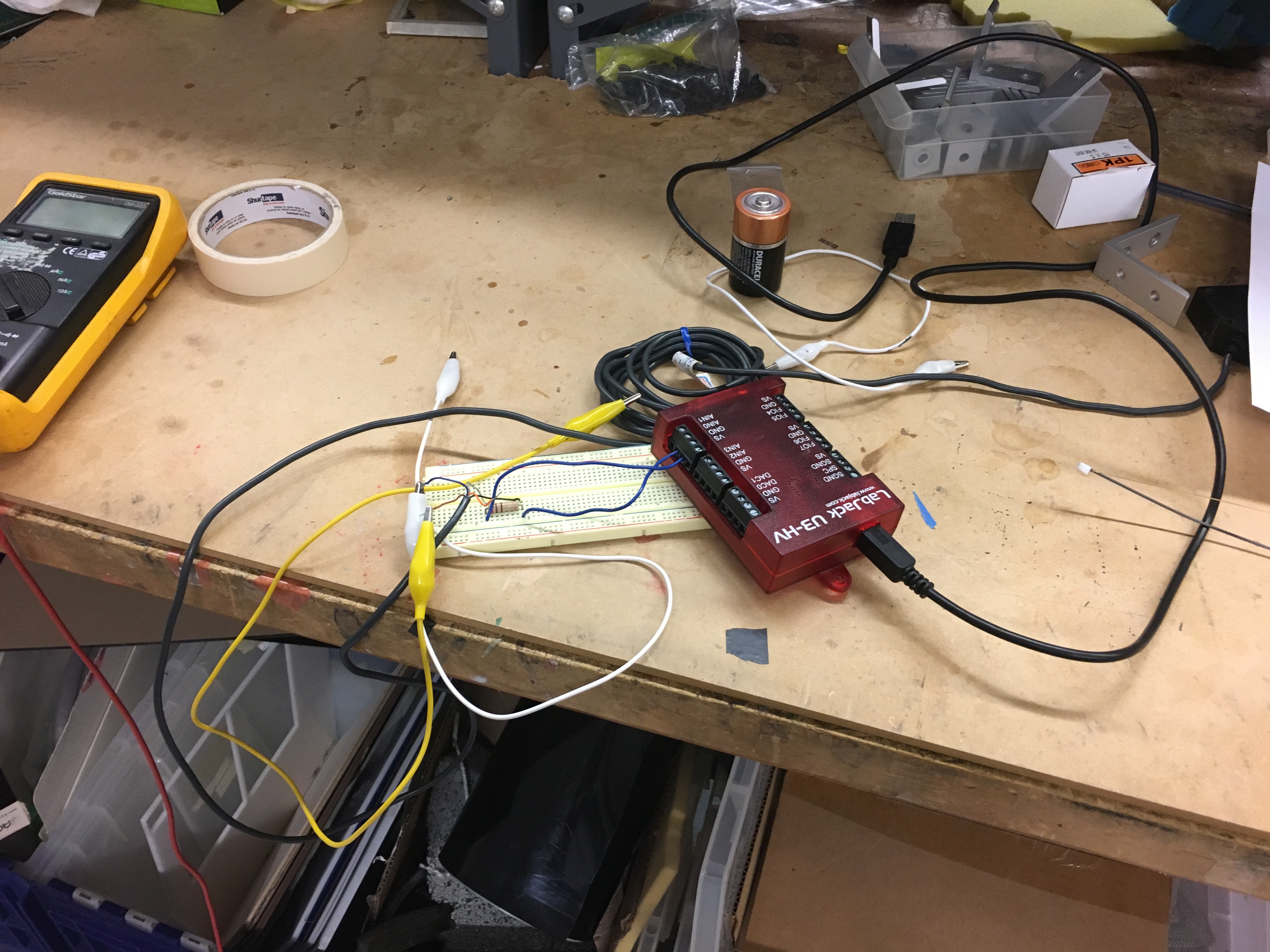

In the morning, I helped with setting up the BDML BBQ and before it started we had a short lab meeting. Afterwards, I asked Mark about how to collect data with the laser micrometers, and he helped me set up the circuit and Anaconda python, along with writing the code needed to read the voltage output by the LabJack and plot a graph based on the time. The next step would be to write code needed for corresponding the voltages to the distance that the micrometer is measuring. Lastly, I went with Amy to TLTL to do the gecko wedges casting on Silnylon, which would hopefully be easier for us to prototype the glove on.

August 10

I finished the point tracking for the diameter surfaces for the claw middle joint and claw tip and started the different surface perches for the claw tip. I also looked into how to collect data with the laser micrometers that we would use for the perching experiments. I first connected one micrometer to the LabJack and the other to the Laser Displacement sensor, and then used the USB to connect it to my Mac. Although I found a driver for the micrometer connected to the LabJack, I couldn't find a program to collect the data into Matlab. My plan is to talk to Tae or Mark about using a DAQ or about other methods of collecting the data, and also talk to Will when he gets back from Hawaii. I also put up the BBQ posters I made around MERL and CDR and talked with Amy about next steps for gecko gloves.

August 9

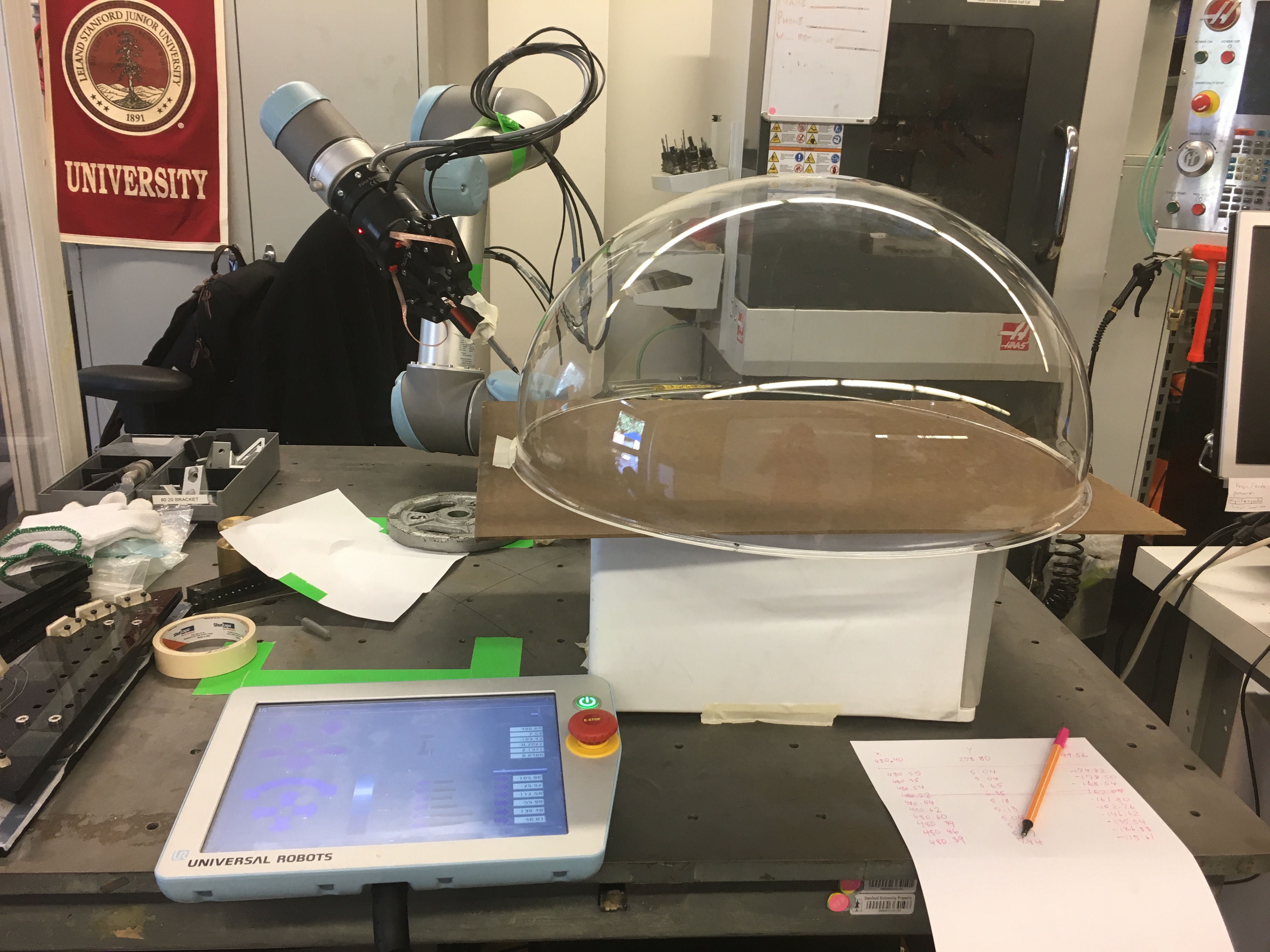

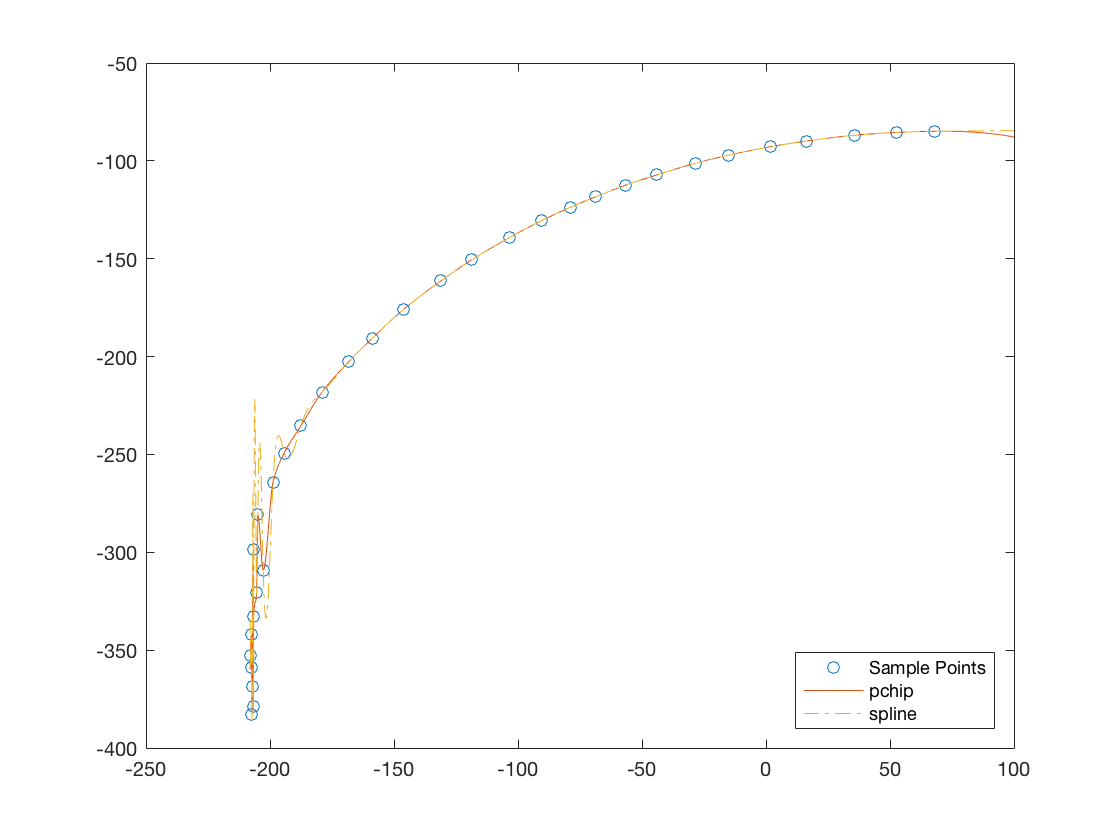

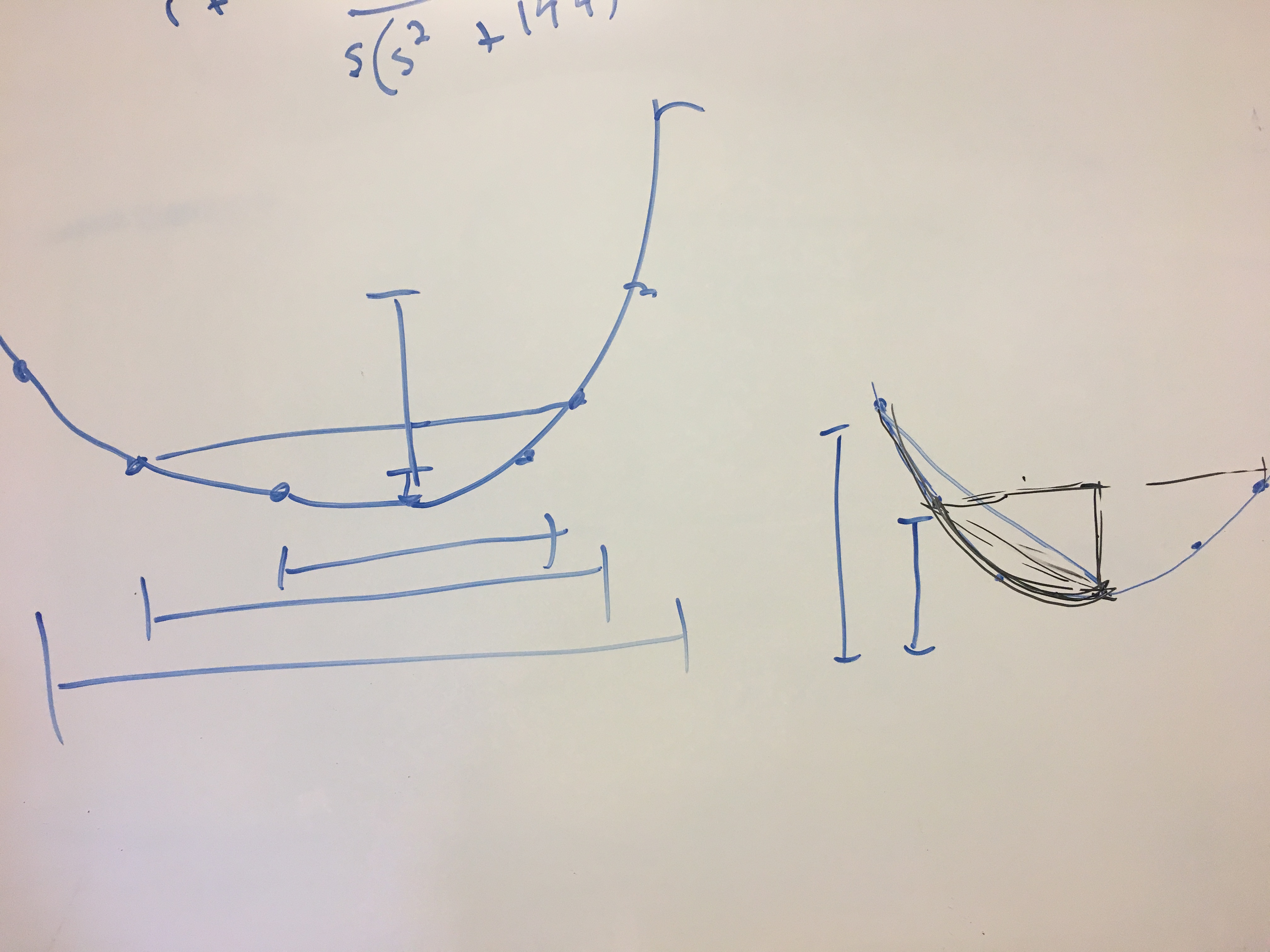

I first measured Mark's dome again using the UR5. This time, to ensure more accurate measurements and to make sure that the robot can reach the bottom of the dome, I constructed a platform under the dome using a storage box and then a flat piece of wood on top of that. Afterwards, I got a much smoother curve data, and Sam showed me how to enter the excel data into Solidworks and construct a curve from then. Afterwards, I did some more point tracking and then played Ultimate Frisbee with the CHARM lab, in which we won with a final score of 12-6 :). I also helped make a poster for the BDML BBQ on Friday.

August 8

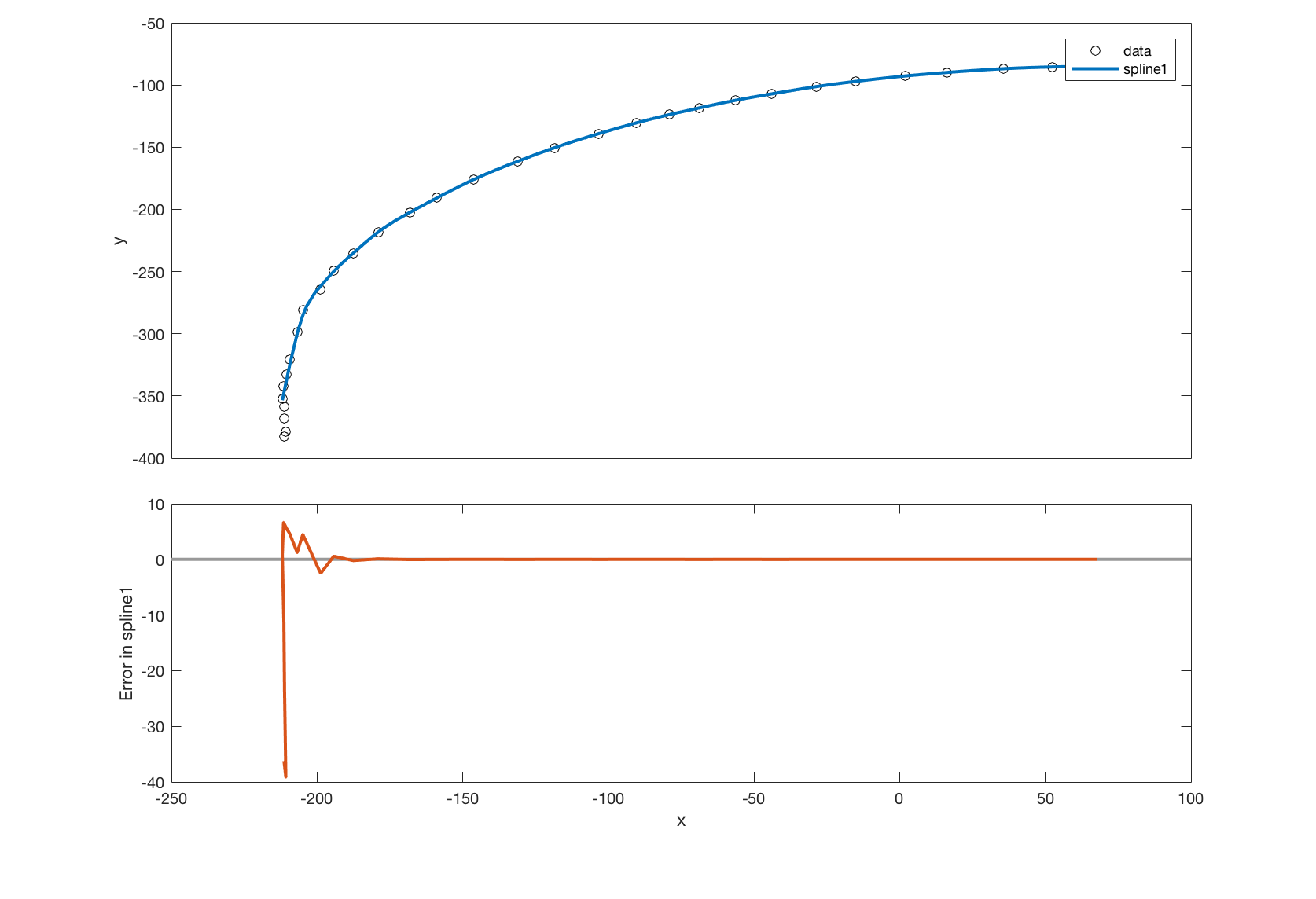

I continued to try to model the dome using Matlab, and tried to used the smoothing spline tool to approximate the curve. Although the smoothing spline tool is closer to the curve, it can't approximate the vertical segments and takes too much into account the outlier points. I plan on using the UR5 robot again tomorrow and put the dome on a platform to make it easier to measure the bottom coordinates, and then trying to measure all the coordinates in one iteration of using the robot for it to be more accurate. I also did a lot of bird point tracking on the claw middle joint.

August 7

I checked in with Mark on the measuring of the dome, and then used Matlab to plot the data. The graph is shown below, which isn't a great curve near the bottom left coordinates. I may just have to retake the data with the robot again with the dome on a higher platform. I also did a lot of point tracking :)

August 4

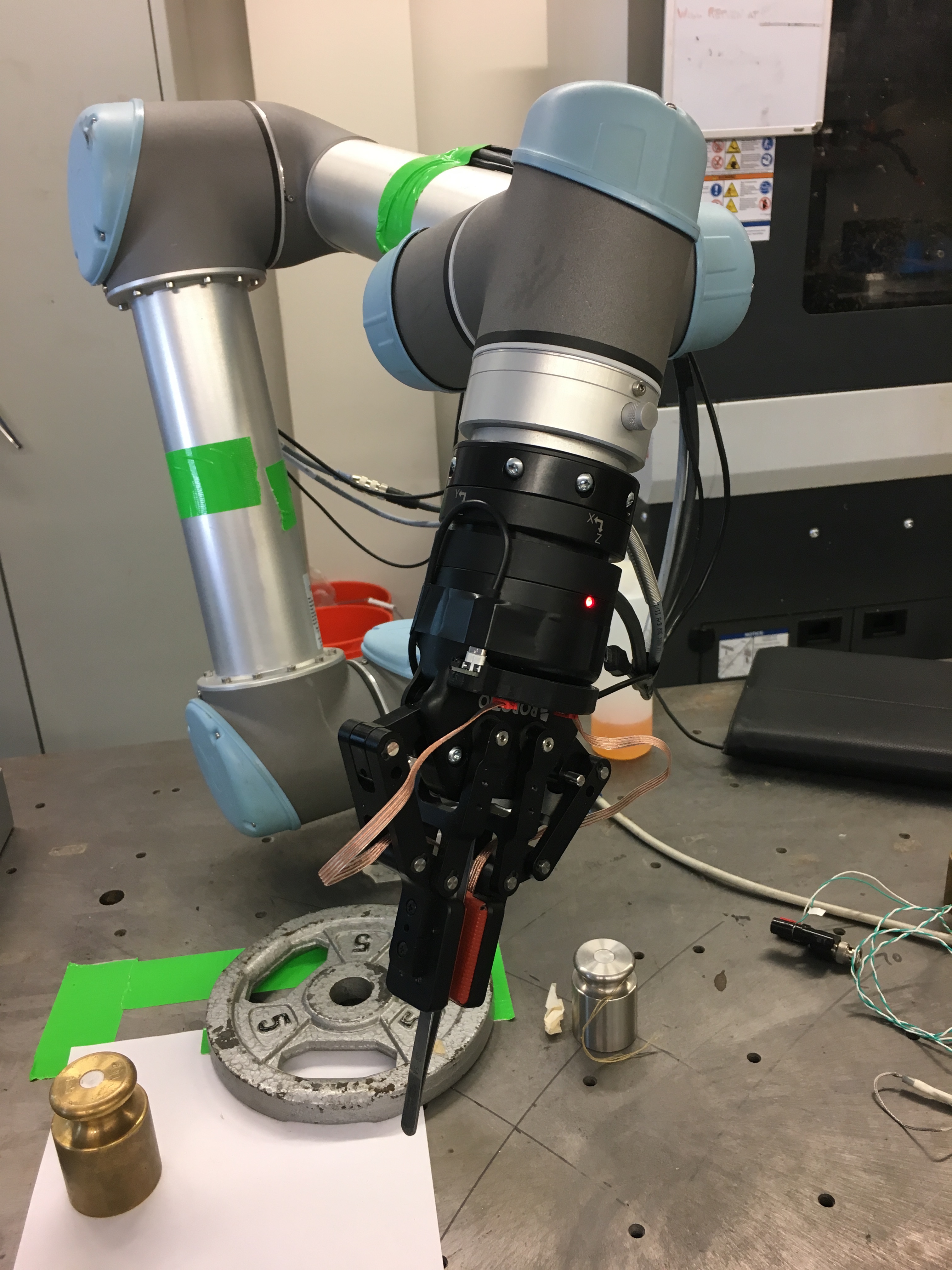

I first went to the BDML lab meeting in the morning, and then I did a lot of bird claw joint point tracking during the day. Wilson also helped me use the UR5 to measure the lower few points on the dome to try to get more accurate coordinates. I put the points onto an Excel spreadsheet and plan on using Solidworks or Matlab to construct a spline of them on Monday.

August 3

I did point tracking during the day, and then met with Will and Diana to do bird data analysis in the afternoon. We analyzed all the data for the bird takeoff and landing forces and talked about claw modeling. I also talked with Will afterwards about what my plans are for the week that he's in Hawaii. I then used the UR5 to collect coordinates for the dome, and plan on splining it tomorrow. I'm now sure how accurate the coordinates are since it was hard getting the coordinates of the dome close to the bottom because of the limited way that the UR5 can move, so I think those coordinates are less accurate.

August 2

I finished the diameter variation videos for the bird point tracking. Alex told me of an alternative method to measure the curvature of the dome by taking a picture of the dome and processing the boundary using Matlab, but after talking to other people in the lab it seems like the UR5 would be faster and more efficient. I then started to test how to change the tool tip coordinates for the UR5 and plan on using the UR5 to measure the coordinates of the dome tomorrow.

August 1

I did a lot of the claw tip point tracking today, and plan on finishing the diameter variation videos by tomorrow. I also talked with Wilson and Ryo about using the Universal Robot in the lab to find out the coordinates of the curvature of the dome. At the perching meeting, I found out that Alessandro has a lot of experience with the Universal Robot, so I plan on asking him if I ran into any problems. Alessandro also explained the coordinate transformations of the tool extension of the robot to me using matrix algebra. I plan on looking into those transformations later on this week and either doing the math by hand or coding it into the robot. In the afternoon, I re-measured the center of the dome and put the masking tape and curvature points on it in preparation of measuring it with the robot.

July 31

I did a lot of point tracking today in the beginning, and got more than half way done with the diameter surfaces. In the afternoon, I talked with Mark and Sam about making the CAD model for the kinda hemispheric dome. Mark first suggested that I should just cut out pieces of cardboard that tries to approximate the curvature surface, and then asking Drew and Sam about scanning the dome. When I talked with Sam about scanning the dome, we realized that since the dome is clear and symmetrical, it wouldn't be feasible to scan it. Instead, Sam suggested that I laser cut different size circles for the cross section of the dome and then measuring the radius of the circle and the height that the circle fits in the dome and using those measurements to form a splice in Solidworks. We ran the idea by Mark and then decided that we can just use the Coordinate Measuring Robot in the lab to measure the coordinates for the dome.

July 28

I did a lot of point tracking today for all day, and almost finished the claw point for the diameter 1 surface.

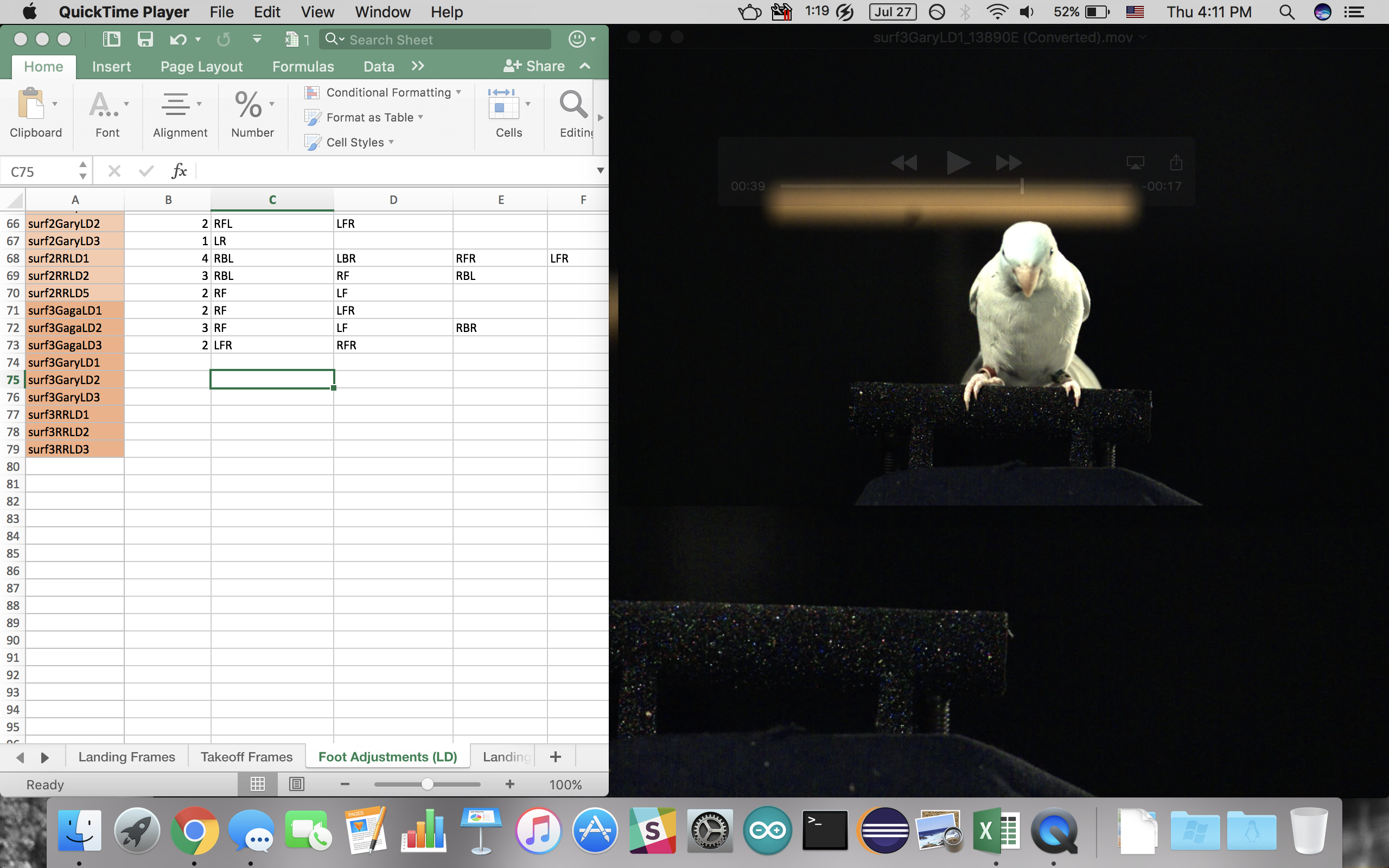

July 27

I finished collecting the data for the bird adjustments today! I also did a lot of bird point tracking while I listened to the Living Machines conference speakers.

July 26

Today was the first official conference day for Living Machines, and I learned a lot about new advances in the Soft Robotics field today. I thought that the robotic worm and the microbio fuel cells were most interesting. Afterwards, I went back to BDML and continued to get data on bird adjustments, which I plan on finishing tomorrow.

July 25

Today was the first day for the workshops of Living Machines, a conference about Bio-inspired Robotics that Dr. Cutkosky helped organized this year. Sam and I volunteered at the Evolutionary and Developmental approach workshop, which talked about how animal evolution and natural selection concepts can be applied to robotics. I mainly helped make sure that the screens all ended up working and directed the people to lunch places on campus.

July 24

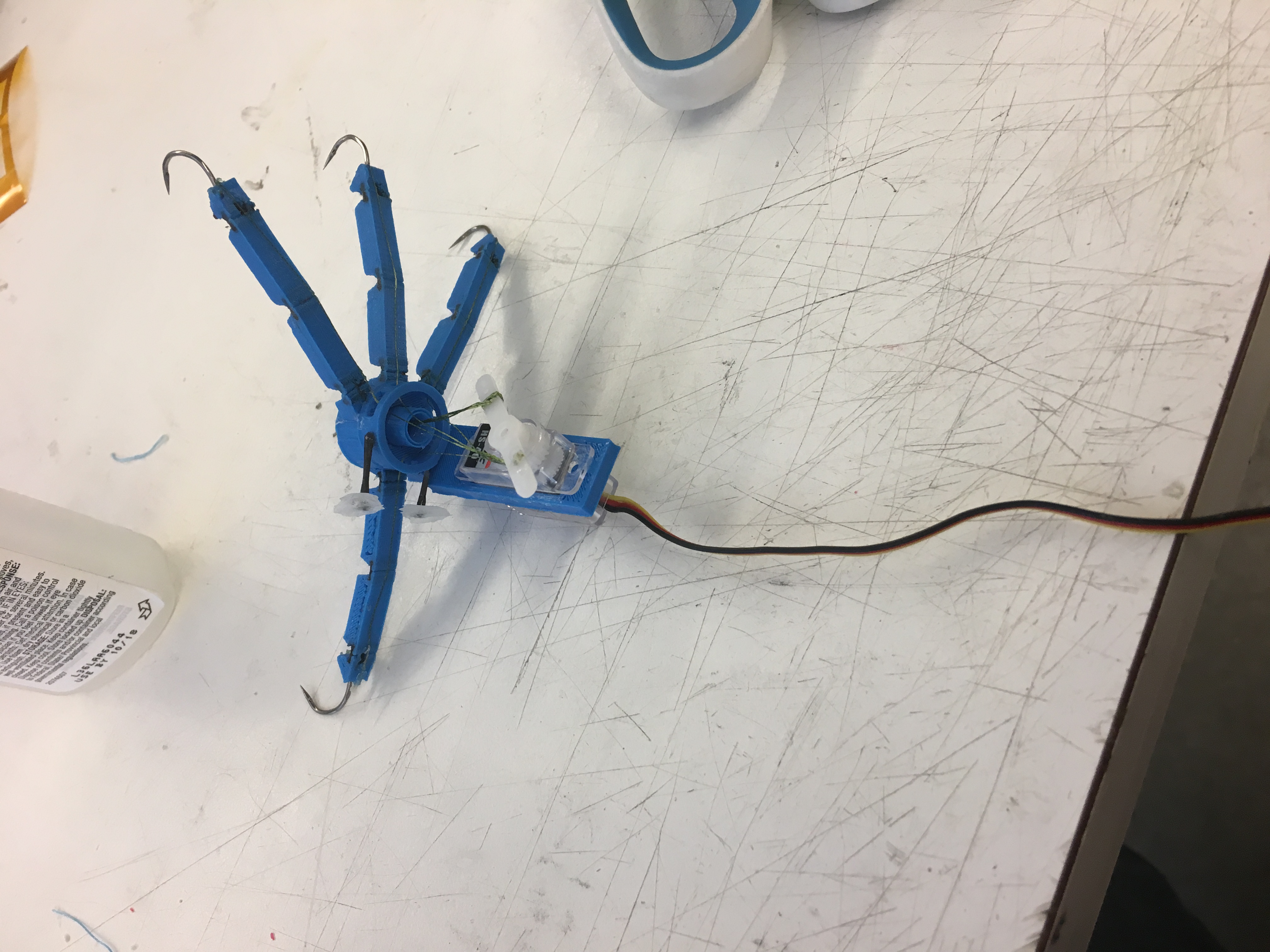

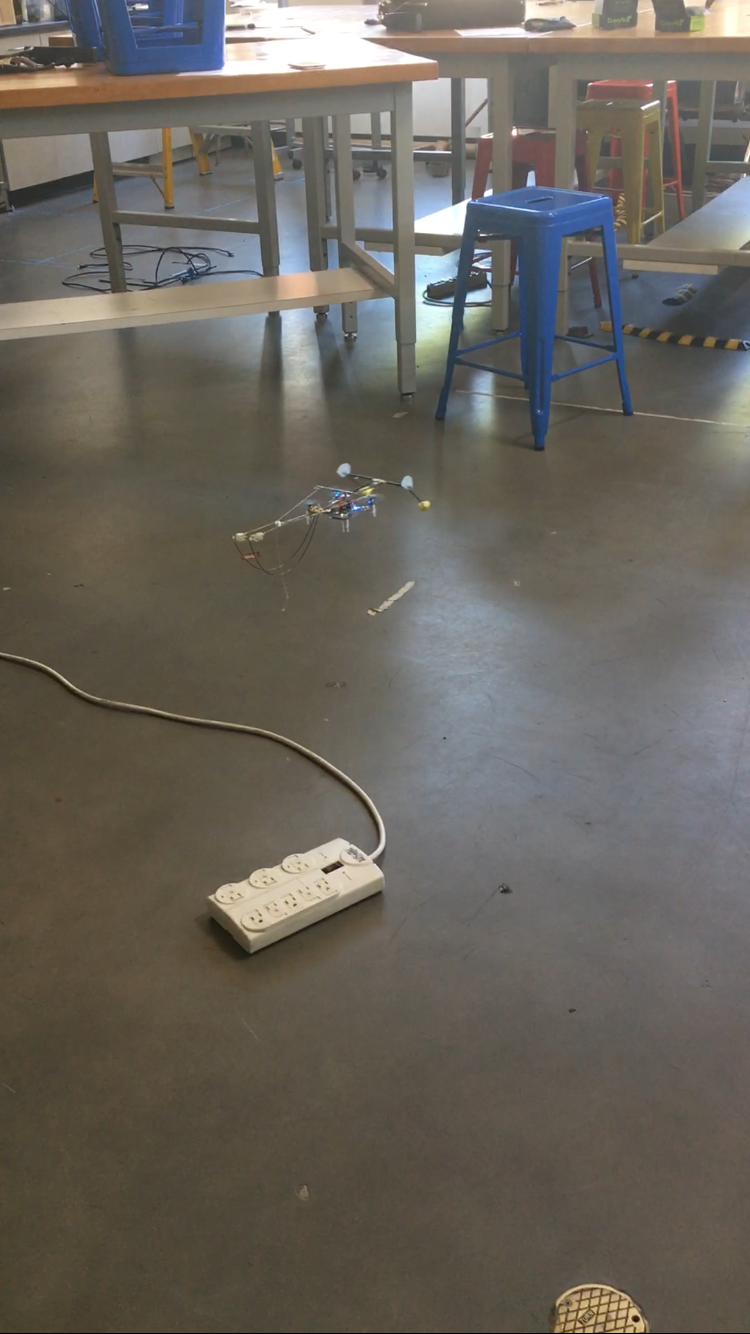

I continued to watch the videos and collect bird adjustment data. Later, I talked to Amy about the design of gecko glove to prevent the glove stretching, the slipping of fingers inside the glove, and the loading direction of wedges to have them be most effective. One way to do that would just to have a non-stretch material inside the glove, such as the pink silk, and also to put a velcro strap on the back of the hand. I will be making a prototype of that later this week. In the afternoon, I talked with Will about claw modeling, and we determined that we can use the positive part of the solution of a quadratic equation to model the function. I also helped Will fix the bird claw mechanism for Living Machines tomorrow. The mechanism is shown below, and the servo motor was connected to an Arduino and breadboard so when a button is pressed the claw can contract.

July 21

I went to the BDML lab meeting in the morning, where Michael and Kat talked about their work on the AR and haptic MRI needle integration. In the afternoon, I started measuring the dimensions of the hemispheric dome. I found that the radius and diameter was pretty similar to that of a hemisphere, but the curvature was not. Therefore, I have to try to figure out what the exact curvature of the dome is, and started doing that by approximating it with pieces of paper cut similar to the curvature.

July 20

I first met with Will and Diana in the morning about the big overarching questions for the bird perching experiments. Afterwards, I talked with Will about the design of the friction and indentation experiment along with which video to track for justifying the points we're tracking. Mark's dome also came in today, so I'll be making measurements on that pretty soon and CADing the supports. I also continued to make the red nylon silicon gecko glove prototype, and continued with bird landing adjustments.

July 19

This morning, I had a meeting with Will and Diana to talk about the big overarching questions about how to guide the perching experiments and how to justify certain points that we track if reviewers ask about it. Then, I went to the Lentink lab meeting and heard about Amanda's bird morphing research and how they're making a pidgeonbot with movable wings. After that, I used epoxy to put gecko wedges on the silicon nylon material, but found out later that some of the epoxy got stuck to the front of the wedges. Therefore, Mark helped me think of ways to prevent that from happening by putting black tape, watercolor paint, and soap on the adhesive. We found out that black tape works the best out of the three and that if red tape was available, it would be the best. I also finished looking at the preliminary bird perching adjustments and got some data from that.

July 18

I continued to work on the gecko glove today. I talked to Amy and Mark about different ways to put the adhesive on the glove to make it easier to pick up things, since when I tested the gecko glove I couldn't really feel a difference in the force. Ideally, the gecko adhesive strips would be orientated in a way where the shear force on both sides combine into a tension force straight upwards into the palm, similar to the way the curved surface gripper is used in this page. I also talked to Jason about casting the gecko adhesives directly onto the fabric, because then that would make it easier to sew the fabric with the adhesive straight to the glove. Later, I helped Drew with screwing in the motors for the newer version of SCAMP and talked with Will and Michael about better ways or algorithms to point track the bird claws.

July 17

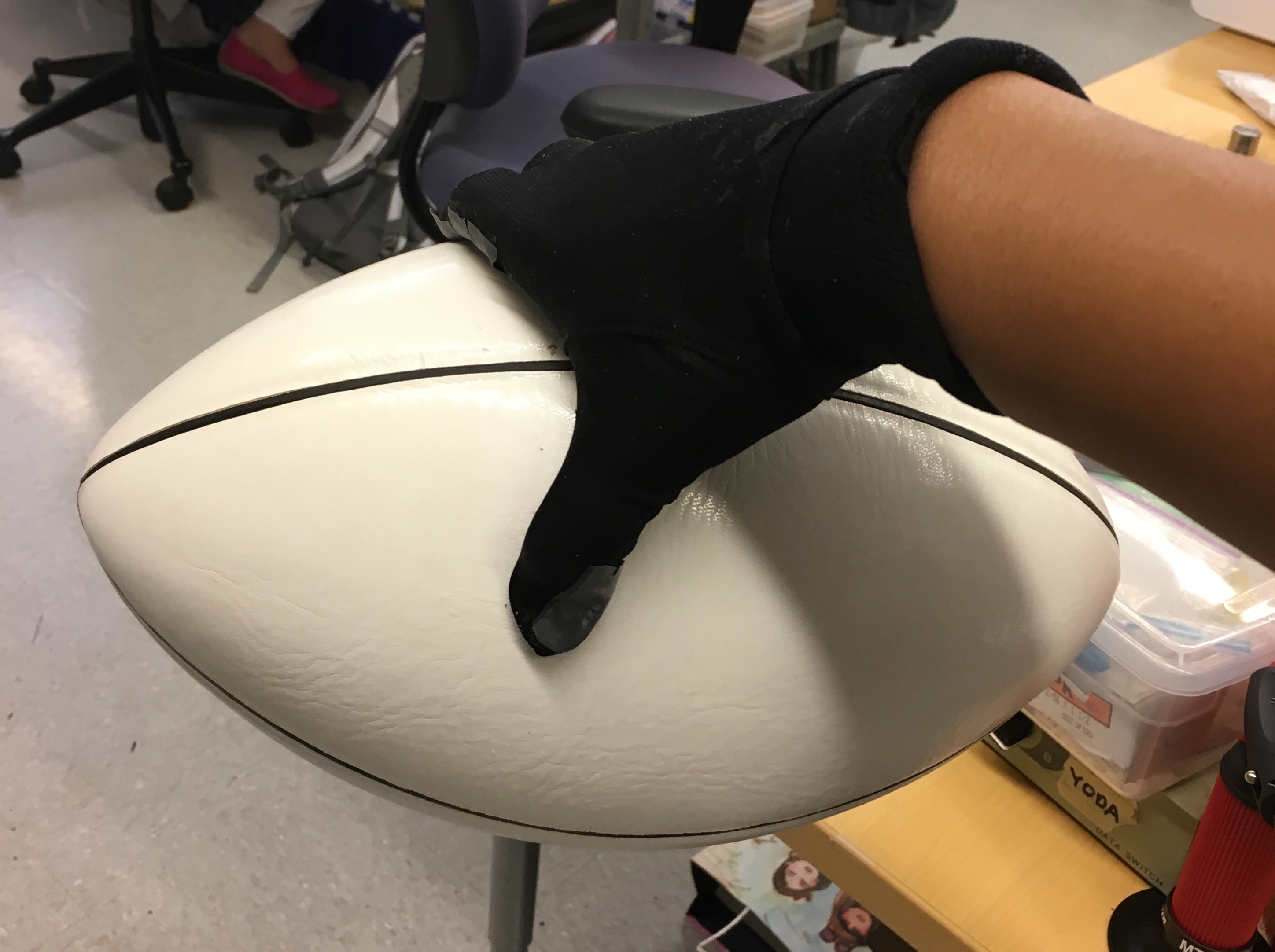

Today, I finished up the loose ends for making the gecko adhesive wedges glove, including adding extra adhesive around the thumb and trying to get rid of the extra epoxy on the adhesive. I also finished making the flat PDMS glove, and tested the gecko glove picking up different things. Additionally, I looked at the claw adjustments for bird landings, and realized that the best view was the zoomed out side view. Many of the slippings were very subtle, so I have to look into that more.

July 14

I first talked to Will about the preliminary claw angle plots that he made from the Teflon and Sandpaper plots. There was some noise but we can clearly see where the bird notices the perching and stretches out its claws, to when it closes its claws around the perch and then some claw curling. We then had a BDML lab meeting, where Will presented all the data we got so far. It was cool finally seeing some of our hard work being presented! Afterwards, we had our first MERL BBQ for lunch, and I saw some friends who are also doing SURI. In the afternoon, I made the my first prototypes of the gecko gloves, which turned out pretty well!

July 13

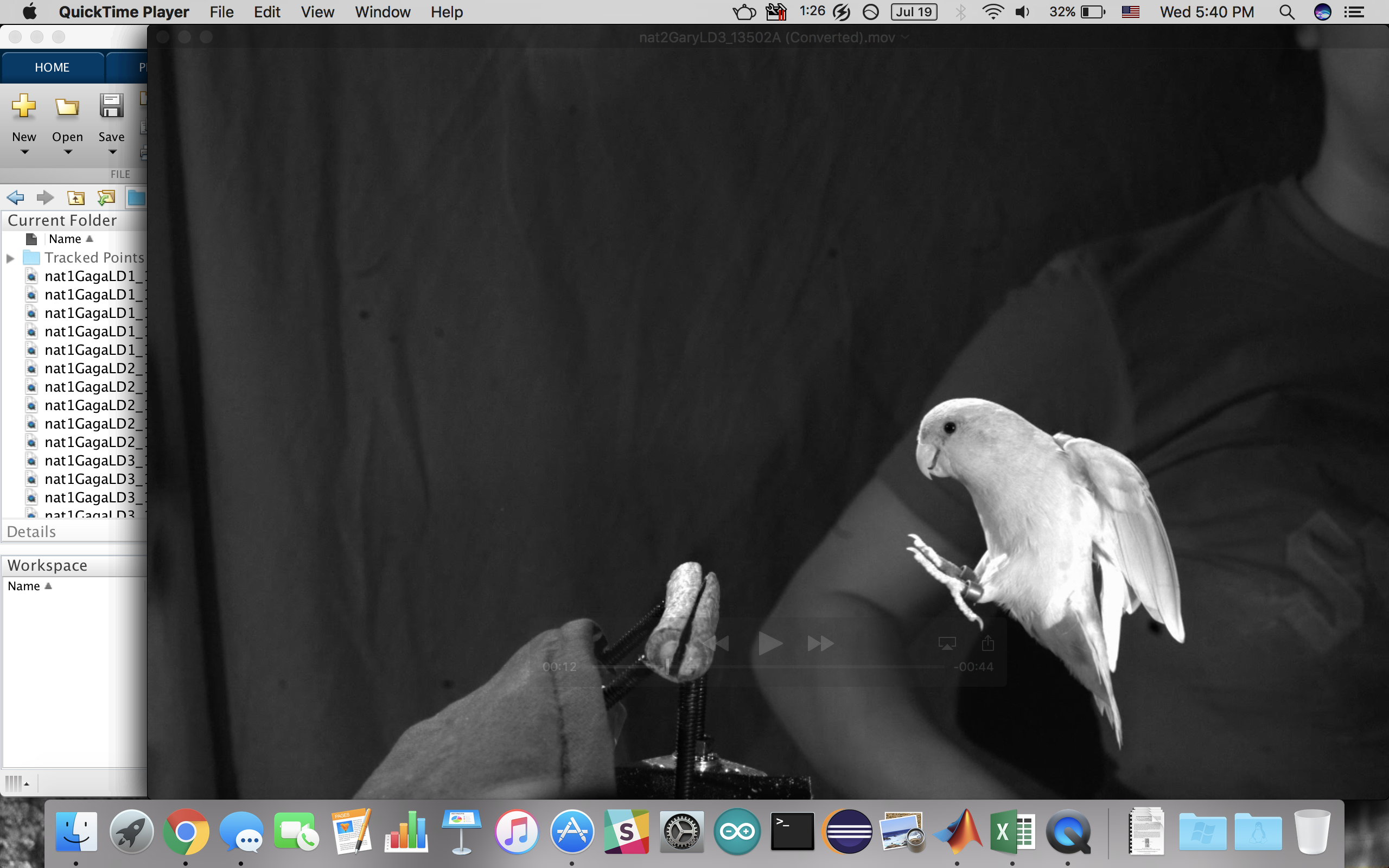

First, I talked to Will in the morning about standardizing landing and takeoff point tracking frames. To correct for the different coordinates when switching to a different camera, Will used of Euler's integration for the existing data. I will also be taking charge of observing the number of adjustments the bird makes before takeoff and after landing, including how the claw lifts and slips. I also finished making a Matlab code for calculating claw angles based on the length of the claw and how much the claw curls.

July 12

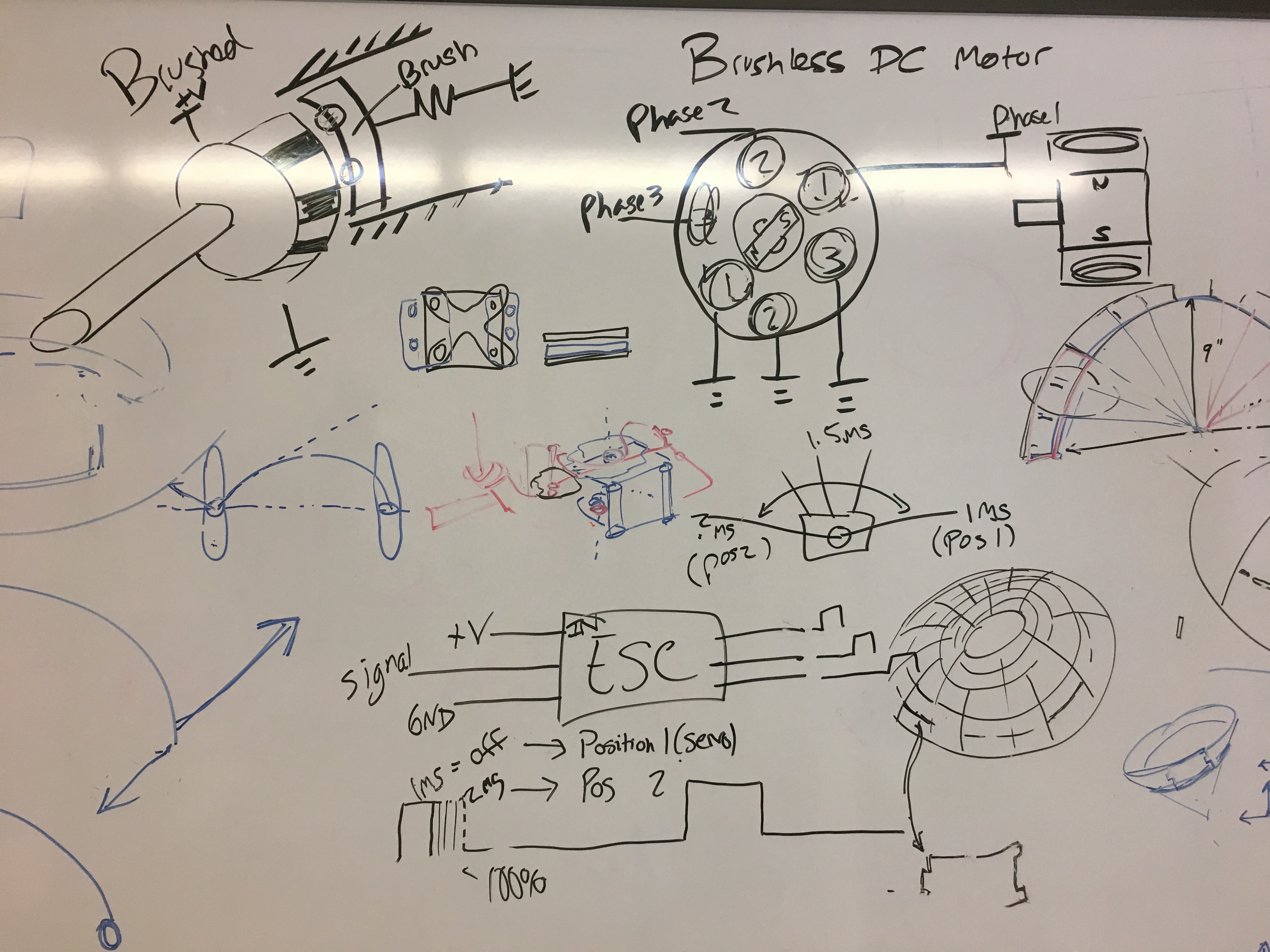

I first went to a Lentink lab meeting where Will and Diana both presented on the perching project. Diana talked about the Aerodynamic Force Platform that she's working on, and then about the bird perch experiment videos that we did. She talked about the experimental setup, the variation between the natural, diameter, and surface branches, and the relative similarity of data between different surfaces and different flights in both the takeoff and landing. Diana also mentioned the footedness of birds and the kinematics and bird point tracking that we are all currently working on. Will talked about next steps and experiments for the perching project, and he talked about claw modeling, friction measurement of the surfaces, and measuring the material properties of the different perching surfaces. We then met with David Lentink afterwards where he gave suggestions on the project moving forward. I helped Drew solder the ESC wires to the board for SCAMP in the afternoon and then talked to Will about point tracking afterwards.

July 11

I did a lot of point tracking in the morning, mainly on the claw tip and the middle claw joint. I then met with Will, where he explained the lab presentation slides that he and Diana will do tomorrow and also clarified the claw curling and which points he think are important. I decided to focus on the claw middle joint since Will is unsure if we want to track both front and back claw tips, or just one of the claw tips when it curls.

July 10

I first did point tracking again in the morning. Then, I met with Will and Diana to talk about next steps for the bird experiments. Will explained the claw modeling to me, and I saw the Diana's analyzation of the preliminary data for the forces of the bird when they took off and landed on the perch. We decided to mainly focus point tracking on the closest camera view and also moreso on the landing videos rather than the takeoff videos. We also wanted to look at the ways the birds curls its claws and decided to track until the bird moves its foot to "settle" on the branch. Later, I met with Amy to talk about building gecko adhesive gloves for Ford's manufacturing uses. Amy explained that the adhesive is made using PDMS and how she prototyped several types of gloves before then. Mark also noted that a company called nanoGriptech made gecko-like adhesive gloves, but they used suction cups instead of the BDML adhesive, which wouldn't be able to work in space.

July 7

First, I met with Will in the morning to discuss focused points for point tracking, and we determined that we should focus on tracking all the points for two videos and then see the preliminary data put together. Will also explained claw modeling to me and we discussed different ways to figure out the midpoints for the claw and a unified index to classify claws. In the afternoon, I helped Drew with soldering wires to the ESC for SCAMP and continued to do point tracking on the new points.

July 6

In the morning, I looked at Matlab point tracking algorithms to try to figure out if there is a better way to automate point tracking the bird claws and also emailed Michael to get his advice. Later, in the afternoon, I helped Drew make a roof for SCAMP perching experiments. Drew also helped explain the difference between brushed and brushless motors. I then started point tracking again in the afternoon after Will finished transferring the files from his hard drive to my hard drive.

July 5

I went to a Lentink lab meeting with Will today and heard a really cool presentation from Marc Deetjen about how to use math models and algorithms to 3D reconstruct bird wings and bodies while they're flying with high speed cameras. I started on the point tracking of the birds using Matlab, which takes a long time. During the afternoon, Will explained claw modeling to me and how we're going to be making experiments for that later, and we also had an update meeting with the SuperSCAMP team.

July 4

Independence day! No lab work today.

July 3

I met with Will and Diana this morning and we talked about what we're going to do moving forward on the perching experiments. We decided to do experiments with indentation, friction, and surface measurement and modeling. We also decided which points to track, including the bird eye, tail, and four points on the claws. I met with Will afterwards to get trained on the point tracking software and to design the experimental setup for the friction experiment. I will be getting started with point tracking on the tip of the claw starting Wednesday. Will also recommended some papers that I wanted to read, including papers on bird claws, the composition of bark, and bio-inspired UAV perching. In the afternoon, I helped Mark upload all the goals from the lab retreat into a gallery on this wiki.

Week Two Summary

This week, I got started on the perching project by finishing collecting the data from the bird takeoff frames. I also learned more about Solidworks and about other cool projects that people are doing in the lab.

July 1

Lab retreat! We all went to Butano State Park, where we barbecued, discussed lab goals, and hiked. That was pretty fun! We saw some redwood trees, banana slugs, and almost clear fish. Will and I also talked about how we can do the perching project during the summer.

June 30

I finished the bird takeoff frame data collection today, and met again with Diana for an update on the project. Diana, me, and Will will all meet together on Monday for next steps when Will gets back. The lab meeting today was also super exciting, and I got to learn about project updates and designs for SuperSCAMP. Matt Estrada, who just got back from Switzerland, also gave a presentation about his bioinspired multi-modal robots, which was super cool.

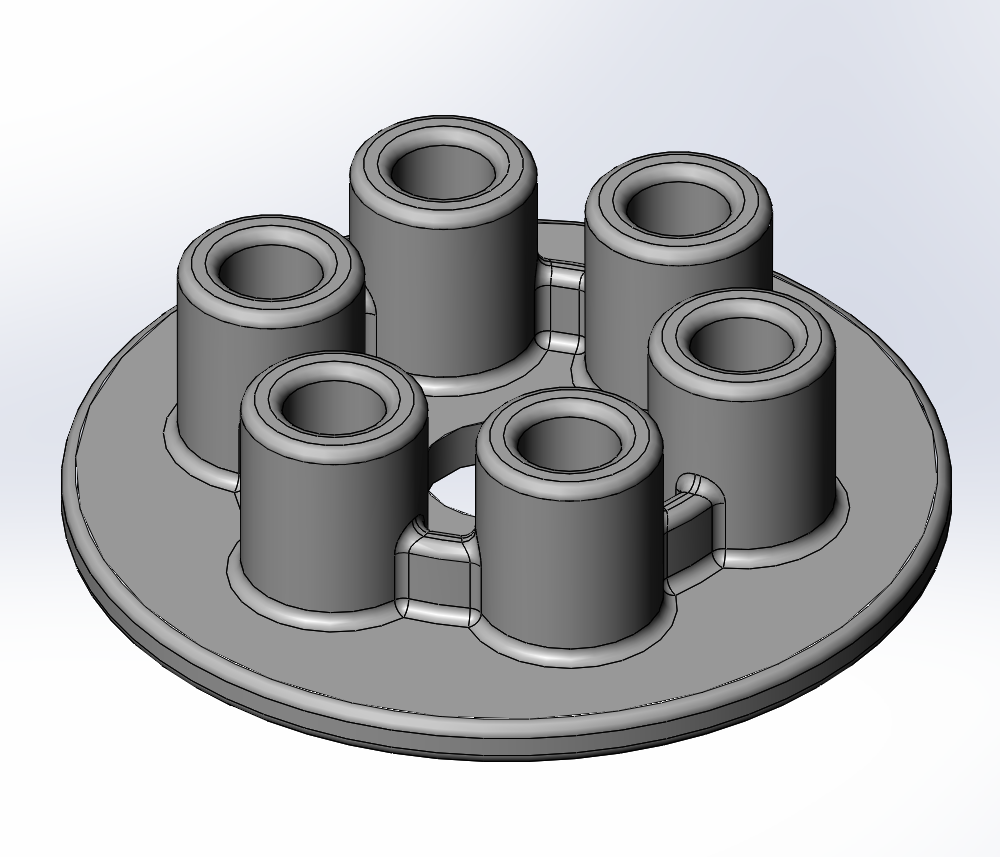

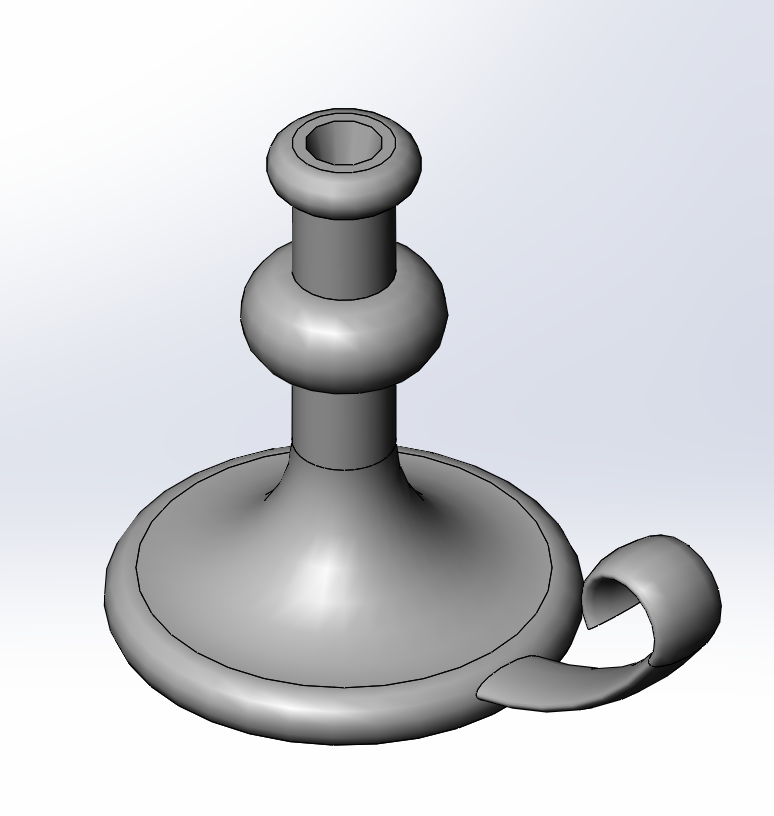

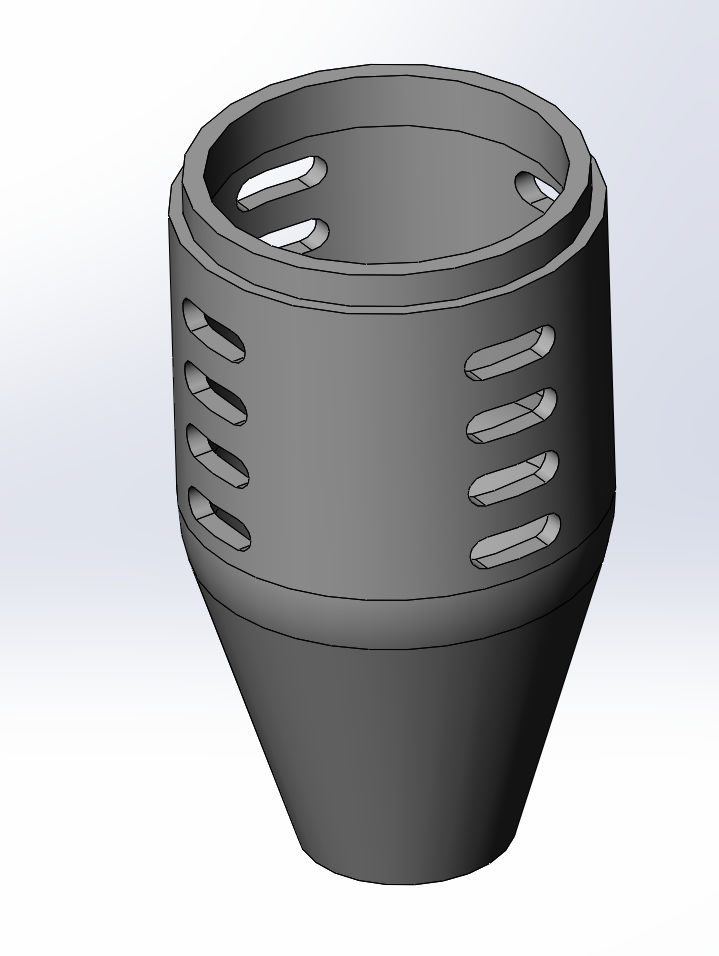

I also continued to learn Solidworks by doing the built-in tutorials, and ended up CADing a pressure plate, candlestick, and some type of housing.

June 29

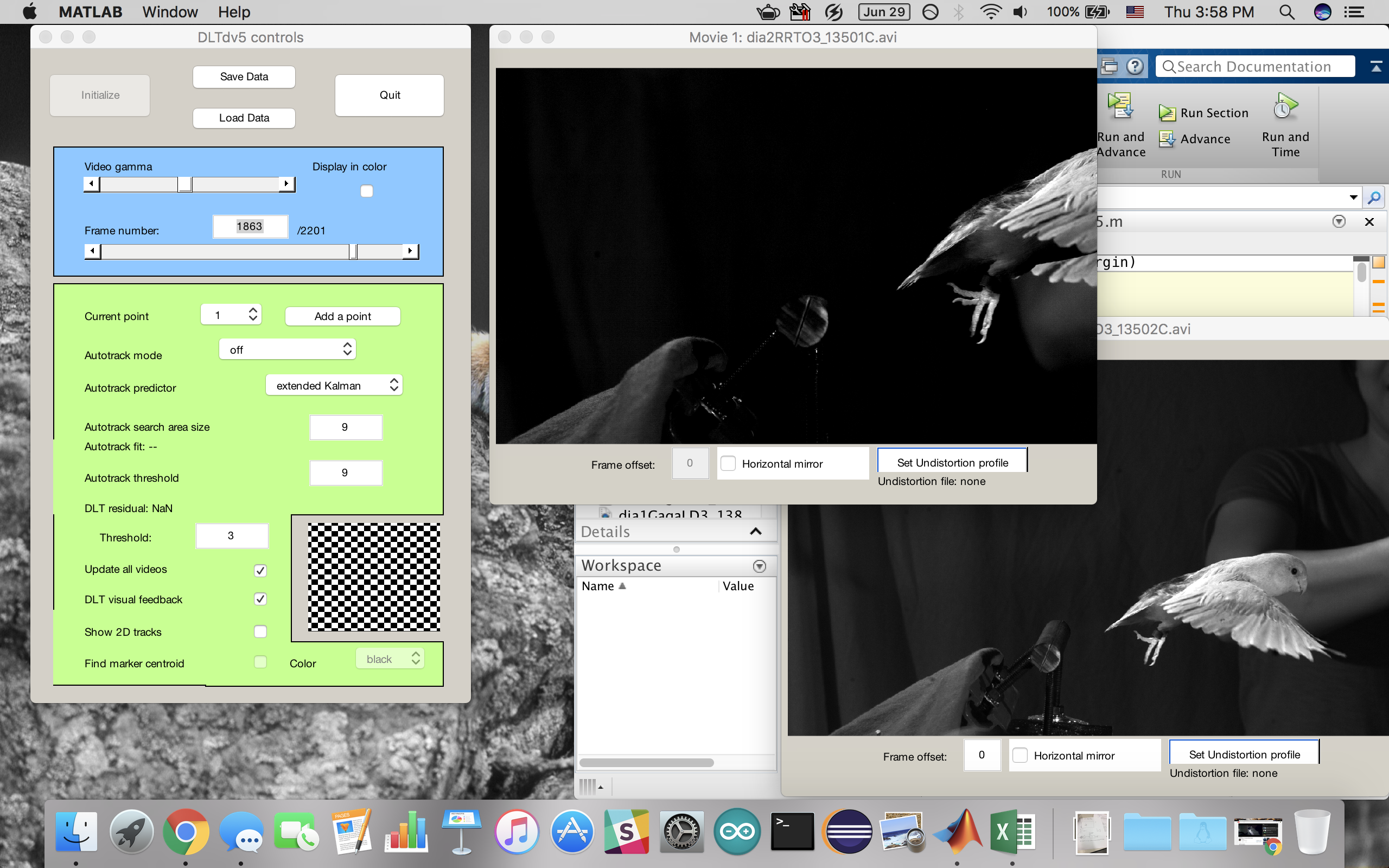

I met with Diana for the first time today! She updated me on how where the bird perching project is and showed me the Matlab code/software used for point tracking and bird kinematics. I was given the task of watching a bunch of bird videos and seeing which frames the birds took off from the perch, and when they started and ended their first downstroke. I finished half of the data for that and am going to work on the other half tomorrow. Here's a picture of me doing data collection of the birds:

I also helped Wilson make plaster rocks for the Spiny Hands, and hopefully that will help me with making the plaster for the Renaissance hemisphere dome later on. I also continued to read "Principles of Animal Locomotion".

June 28

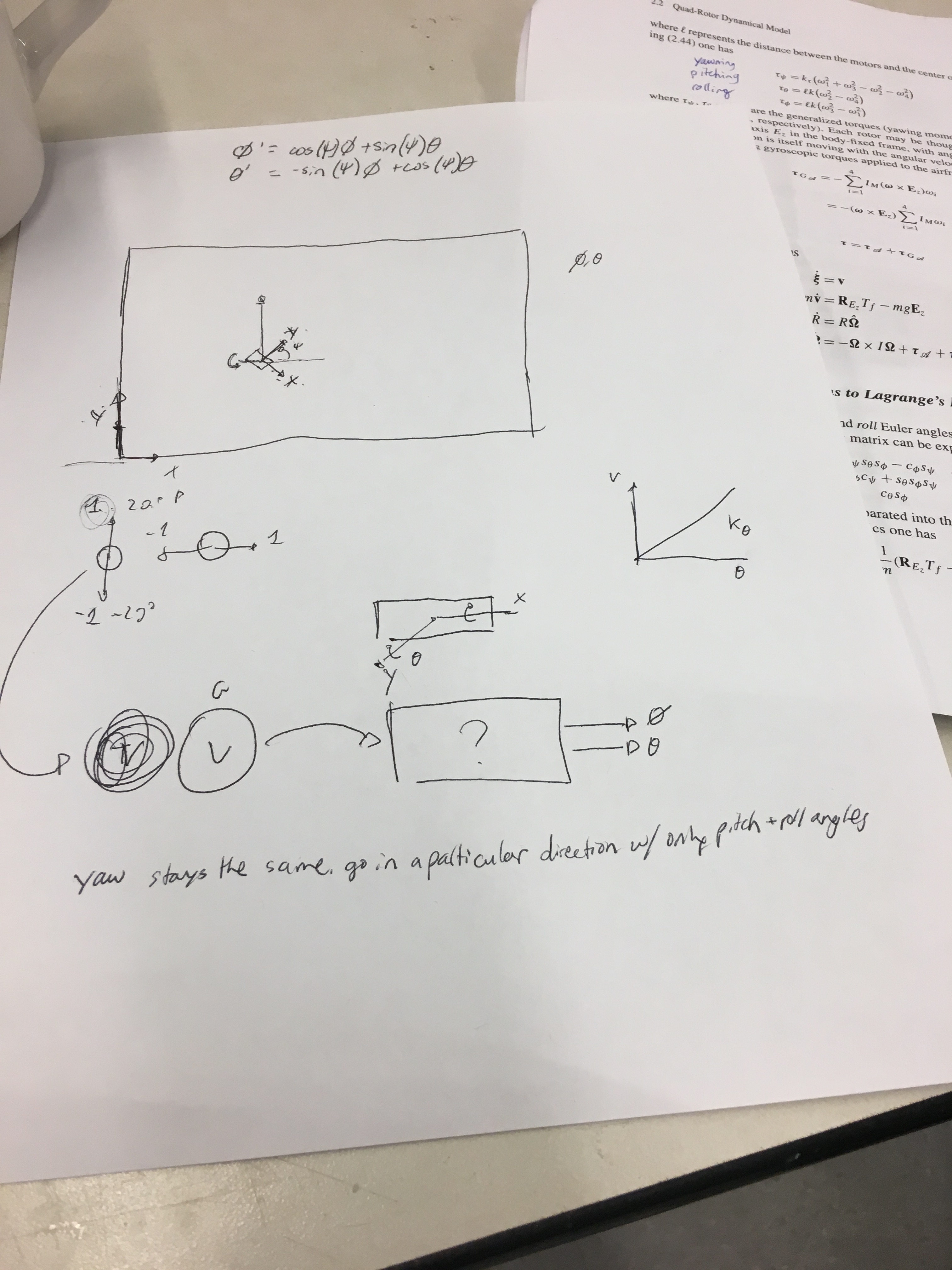

I continued to research stuff about the orientation angle of the Crazyflie, and met with Alessandro with the questions I had. He explained the orientation pitch and roll angles to me, and I continued to try to understand why the equation works that way. I also got started on a reading that Will recommended, which is "Principles of Animal Locomotion".

June 27

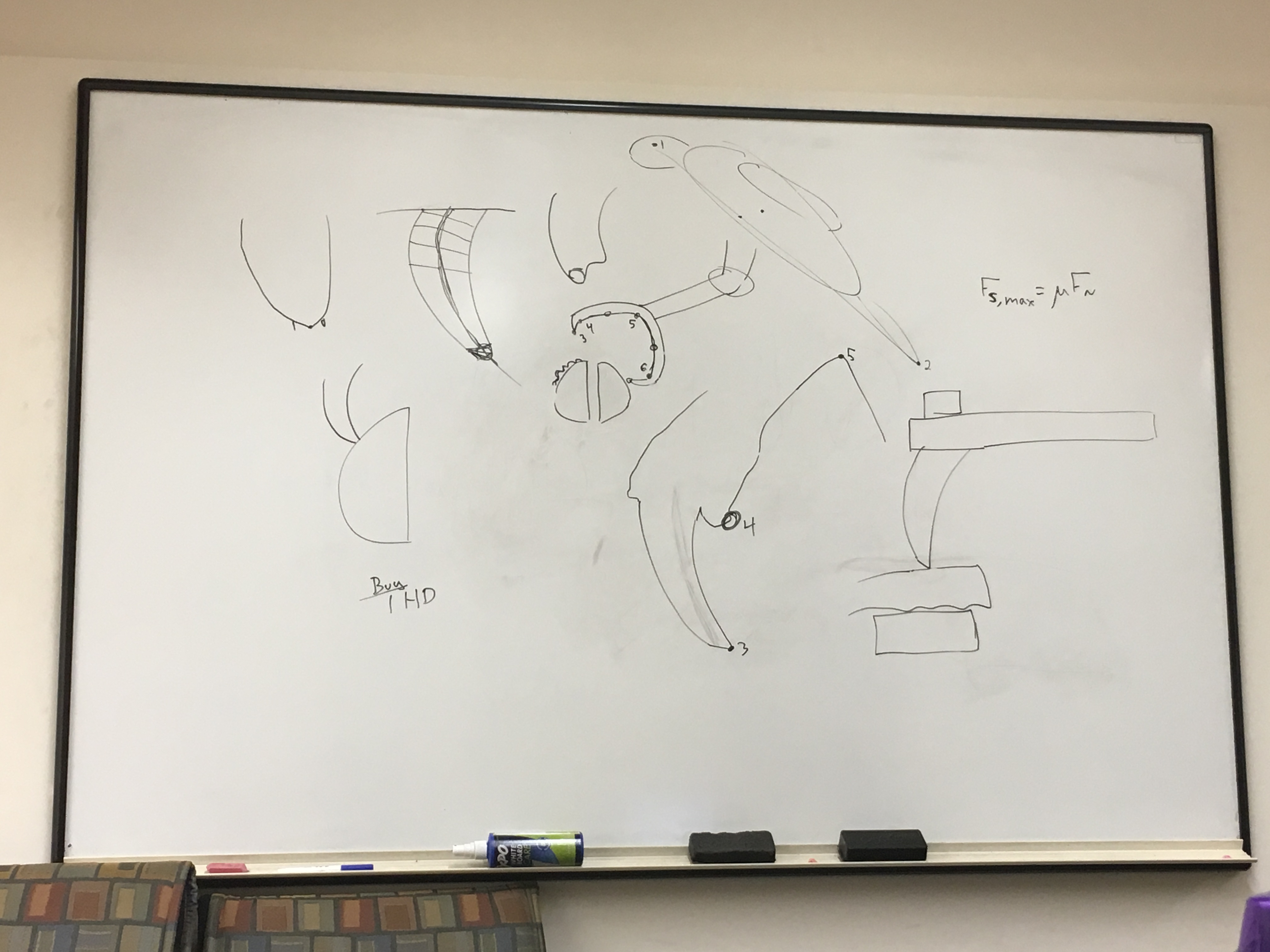

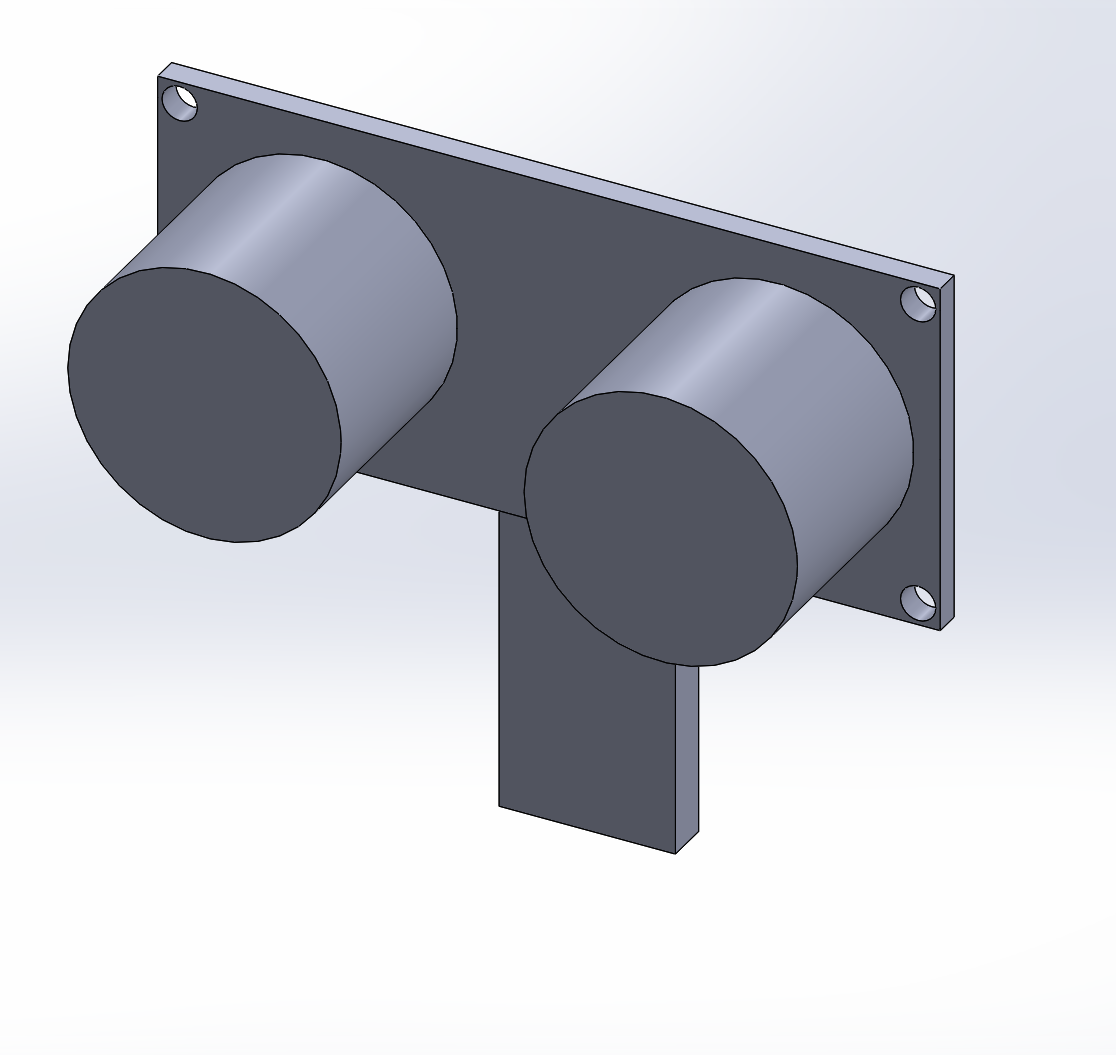

In the morning, I was curious as to how the gecko adhesive mold was made, so Jason showed me the CNC machine and process. Since I haven't taken any ME machining classes, I wouldn't be able to use the CNC just yet, however. I also set up a meeting with Diana (who helps Will work with the birds) in the Lentink lab on Thursday, where I can get a head start on starting to learn and help with the kinematic and force analyses with bird perching. Also, Dr. Cutkoksy drew a design of the thing he wanted me to CAD for his Renaissance class next year. I also helped CAD a distance sensor for Drew.

June 26

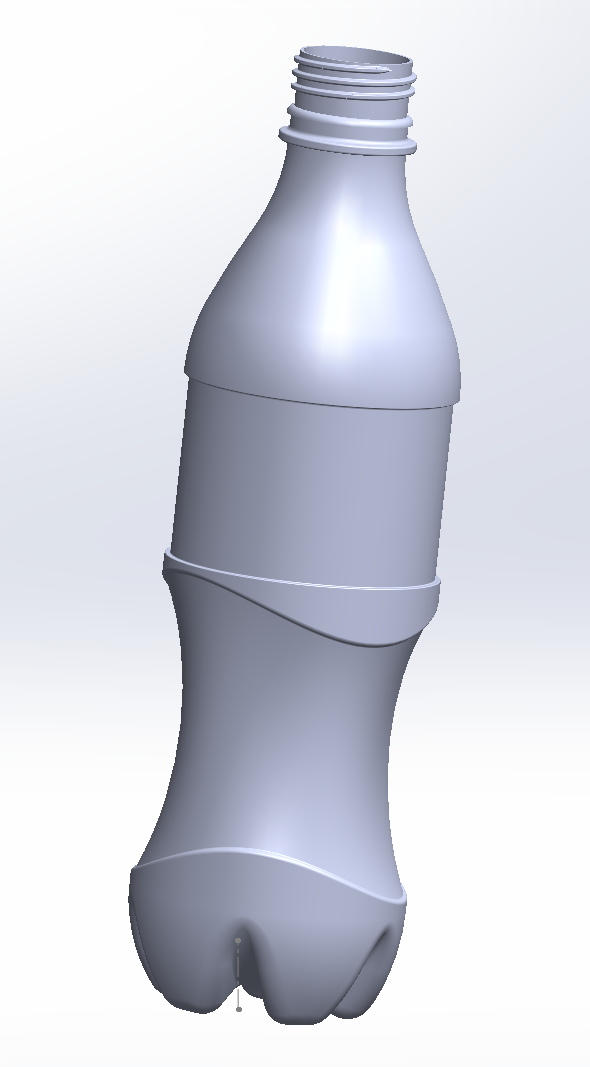

Finished the BDML lab specific safety training with Tae. I also finished the tutorial with CADing the coke bottle!

Week One Summary

Figured out that I wanted to work with Will on experimenting with bird perching, and help with SuperSCAMP and learn Solidworks during downtime. Unfortunately, Will won't be back until July, and I will be meeting Diana first next week.

Papers Read:

- "Touchdown to take-off: at the interface of flight and surface locomotion" (2017)

- "Climbing with adhesion: from bioinspiration to biounderstanding" (2015)

- "Scaling Hard Vertical Surfaces with Compliant Microspine Arrays" (2006)

- "Wing-Assisted Incline Running and the Evolution of Flight" (2003)

- "A Multimodal Robot for Perching and Climbing on Vertical Outdoor Surfaces" (2017)

- "Modeling the Quad-Rotor Mini-Rotorcraft" (2013)

June 23

Dr. Cutkosky wanted me to get ready to CAD things such as a Renaissance machine hemisphere, so I started learning Solidworks through Youtube tutorials. I got started on learning about extrusions and things while making a camera, and started a tutorial making a coke bottle.

I also helped Alessandro film SCAMP after he updated the control system.

June 22

Alessandro explained the basics of quadcopter handling and gave some resources on how to understand the yaw, pitch, and roll of a quad. I read some papers on SCAMP to try to understand how that works and also tried to understand how to code the controls of the crazyflie when the yaw angle can't be changed but needed the quadcopter to go in a certain direction (with respect to the ground orientation) knowing only roll and pitch angles. I also got to fly the Crazyflie for a bit!

In particular, the paper "Modeling the Quad-Rotor Mini-Rotorcraft" (2013) was pretty helpful in terms of getting an overview on quad dynamics and math models.

June 21

Today was a day for lab cleanup. We all worked together to clean the lab workspace up. I also met with Will to finalize things to do this summer, including coding the coordinate transformations for SuperSCAMP, building it next week, and designing friction and index experiments for the bird perching.

June 19

Today is my first day in the lab! This morning, I started with going to the SURI (Summer Undergraduate Research Institute) kickoff meeting, where I met a bunch of other students working on different labs. I then went to the BDML where I met with Dr. Mark Cutkosky where he got me started on lab logistics, including this blog. I also got an overview of the different projects in the lab, and decided to focus on SuperSCAMP and bird perching. After that, I went with Alessandro to test the quad and read papers on how SCAMP worked.

Blog Instructions

- Look at a couple of other blogs for examples:

- AudreysBlog, ChrisKimesSummerBlog, StickySummer

- Check out features like JuliasFirstGallery (append ?action=source to URL to view syntax)

- Note that you need to resize images (e.g. 800x600) before uploading, else page takes forever to load.