Optical sensors

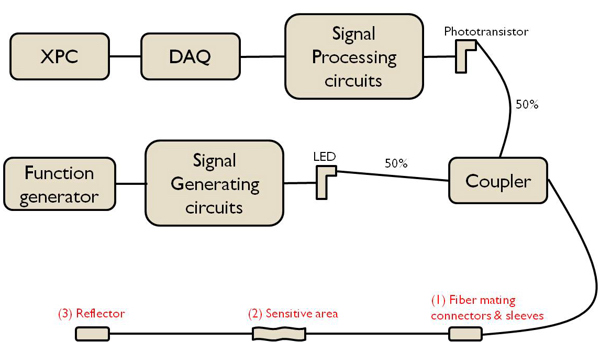

- Overall System

- Curvature sensor

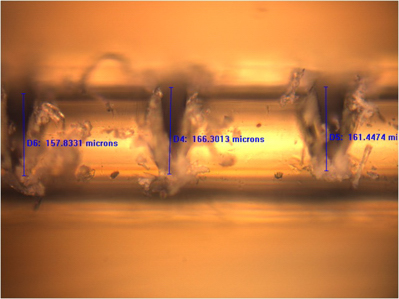

Fiber cut (side)

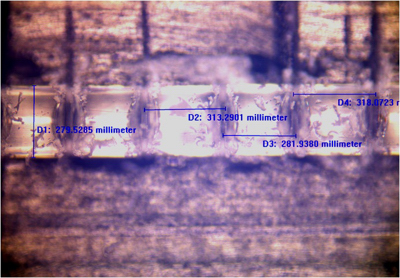

Fiber cut (Top)

Curvature Sensor System

The closed-loop control of an active needle requires the bending angle information in real time. This angle could be estimated using an optical curvature sensor based on bending loss of an optical fiber, whose sensitivity can be increased with machining on its cladding.

- Machining on plastic fiber

- Cleaning plastic chips after cutting

- Reflector at fiber tip

- Sensitivity

- Curvature estimation

- Temperature sensor

Because our active needle uses thermal phase change of an SMA wire, its temperature information is essential not only to avoid heat-induced tissue damage but also to contol the SMA wire precisly. Optical temperature sensor using FBG is satisfying the size requirement and MR-compatibility well, although strain/bending compensation is necessary. Pure temperature change can be estimated using the wavelength change got from the fiber with a FBG and the geometry information got from the curvature sensor.

- Sensitivity

- Strain/Bending compensation model

Page last modified on July 25, 2011, at 11:24 am