Nathan's Summer 2022 Blog

Week 10

Week 9

August 15-19: This week I spent a lot of time working on my poster for the SURI program. The deadline is Friday so I've been meeting with Kenny and Lawrence to perfect my storytelling. Otherwise, I have also been assembling the display case for the space gripper. There were multiple trial and error prints due to the mount's nature, however, we were able to stabilize it. We cut the acrylic for the outside case, but need to refine the dimensions a bit since the base did not give enough leeway. For Kenneth, I used bright pink acrylic paint to color the target load. I also spent time working on the May files of the video logging.

Week 8

August 12: We started the print for the display mount this morning which will take upwards of 12 hours. I also reprinted the top mount with added supports.

August 11: I collected the mounts this morning and they fit pretty well onto the carbon rod. However, I realized that I was unable to drill a hole in the carbon rod so I needed to revert to the original set screw idea. Unfortunately, the top mount did not have tapped holes so it needed to be reprinted. Meanwhile, I attached the bottom mount. Throughout the rest of the day, I finalized the CAD for the display mount with plans to print it tomorrow morning.

August 10: I finished the mounts this morning and send them to print in Kenneth's office. Meanwhile, Tony asked if I could also design a display mount for a BDML space gripper that had been in space. He wants it at an angle so I will try and create a holder similar to that of a laptop. I am not sure if it will balance at first, but I will tinker with it.

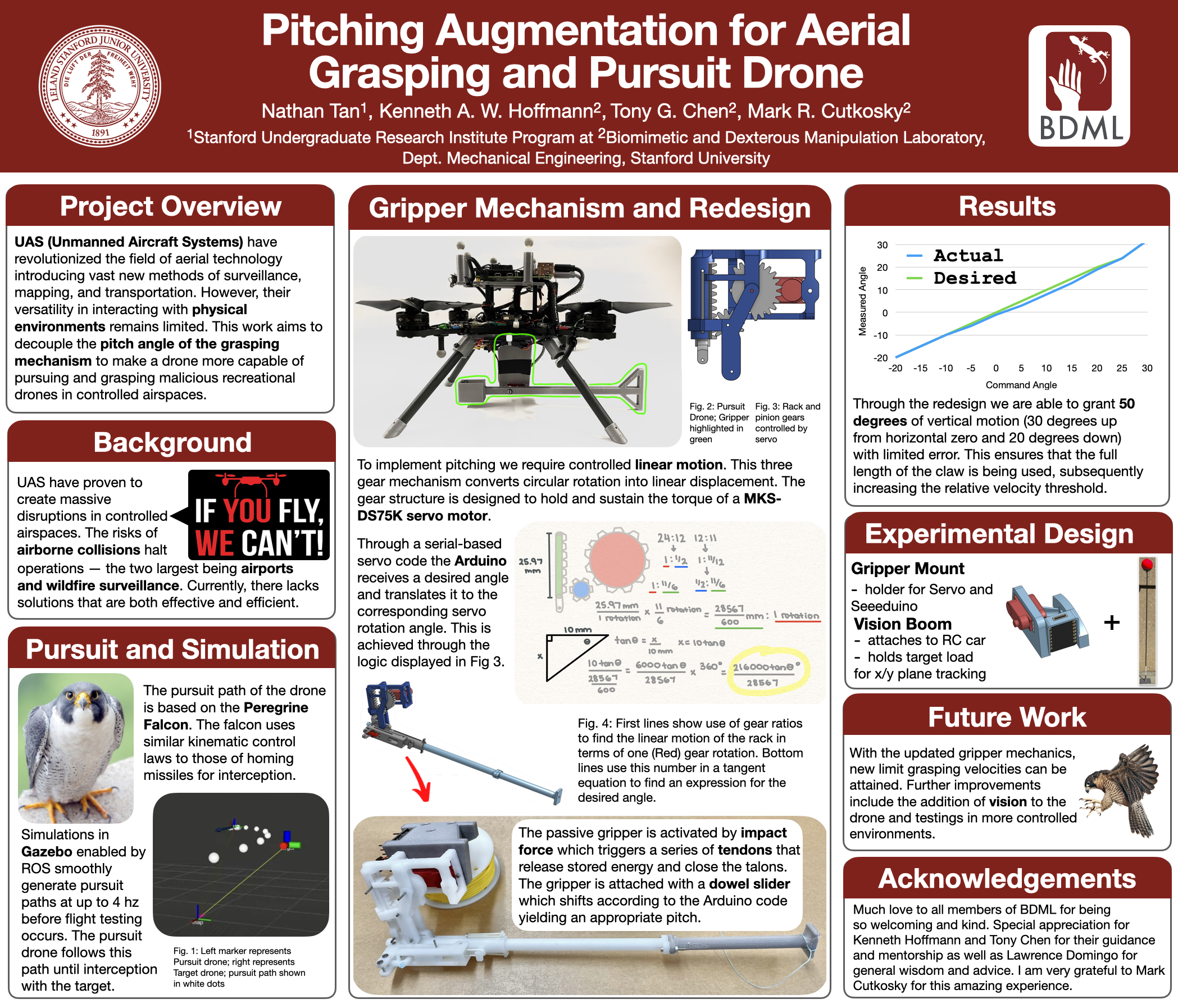

August 9: Today I met with Lawrence to help brainstorm the magnet mechanism idea. I was confused at first because I thought the whole point of the mechanism was to add more time for the talons to grasp the target, so waiting until the capture before the disconnection would be pointless. However, Tony reminded me that it is also to help reset the center of mass. Kenneth also asked if I could work on some mounts for an RC car that will take place of the target drone since we are not worried about the z dimension right now. I have to find a way to connect a meter-long carbon rod to a moving car with limited vibration.

August 8: Back in the lab! I was scheduled to present today for the weekly SURI meeting so I spent the morning finishing my slide deck. Since Kenneth is gone for the week, I'll spend more time working with Tony. Firstly, we'll make more backup grippers since we will begin flight testing soon and expect hardware malfunctions. Then, we'll try and figure out a magnet mechanism to simulate the falcon sweeping motion. At noon I presented for the rest of the SURIs and it went pretty well. I received a lot of questions that I was able to answer for the most part. I took some time later in the day to update my blog and implement gifs for clearer visuals.

Week 7

Gone for Summer Camp

Week 6

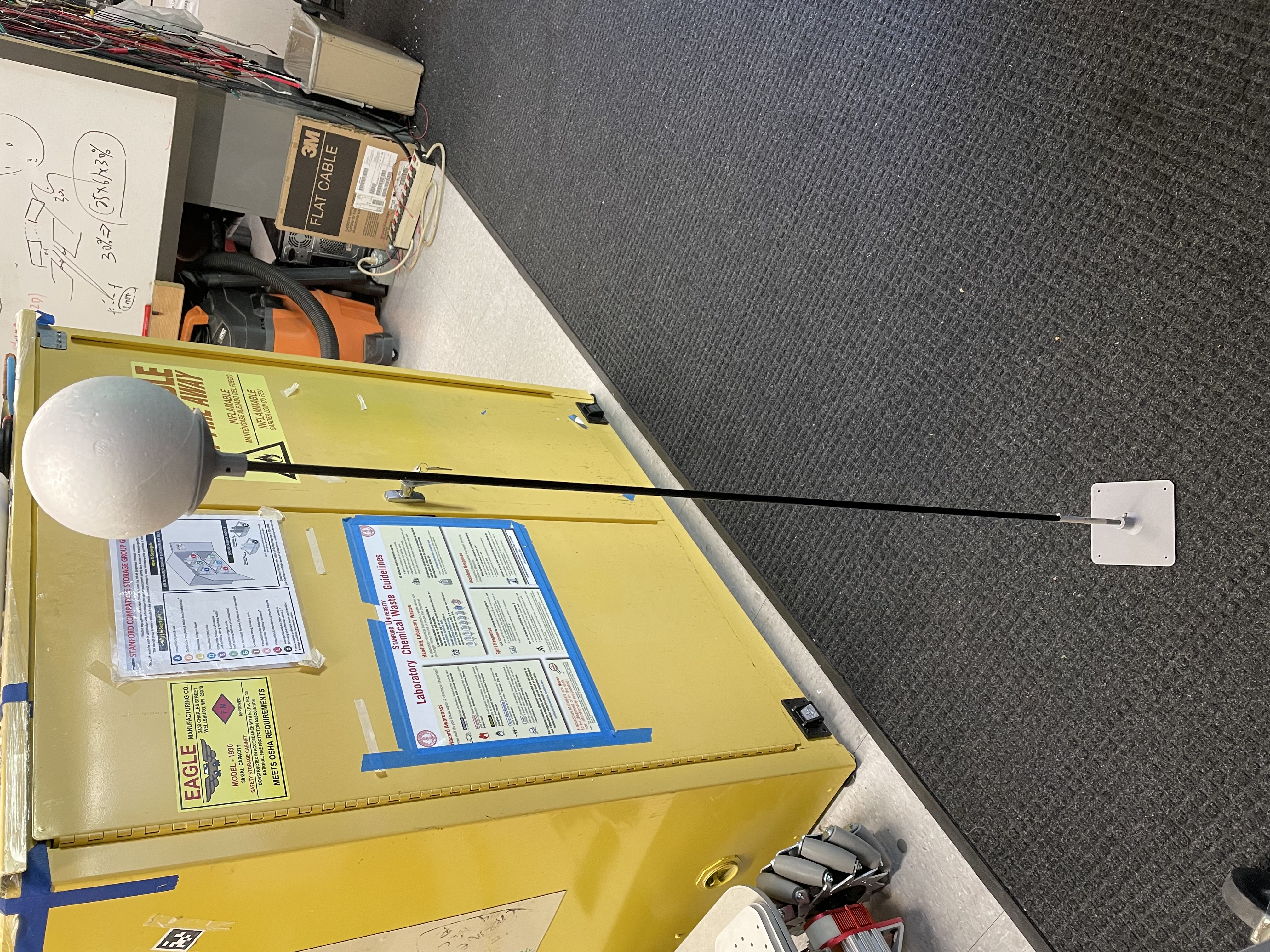

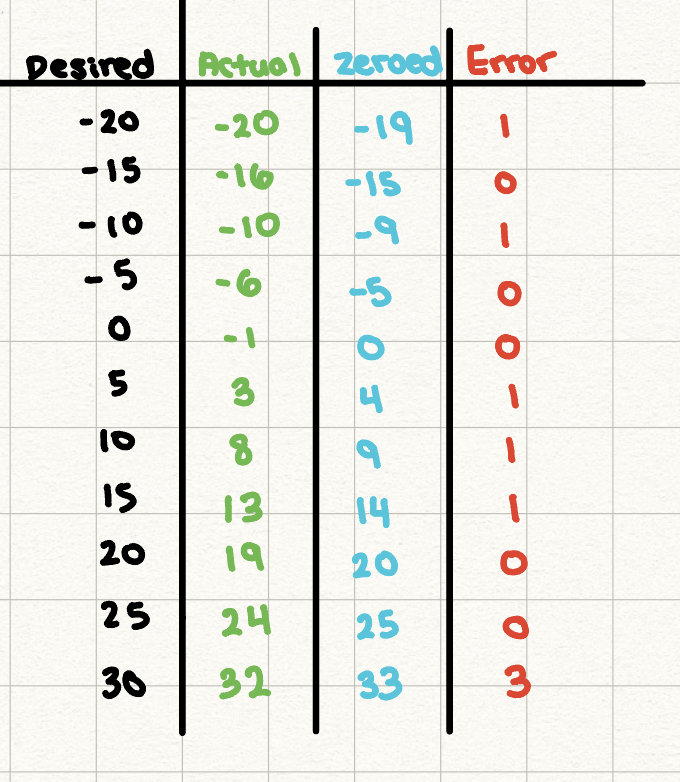

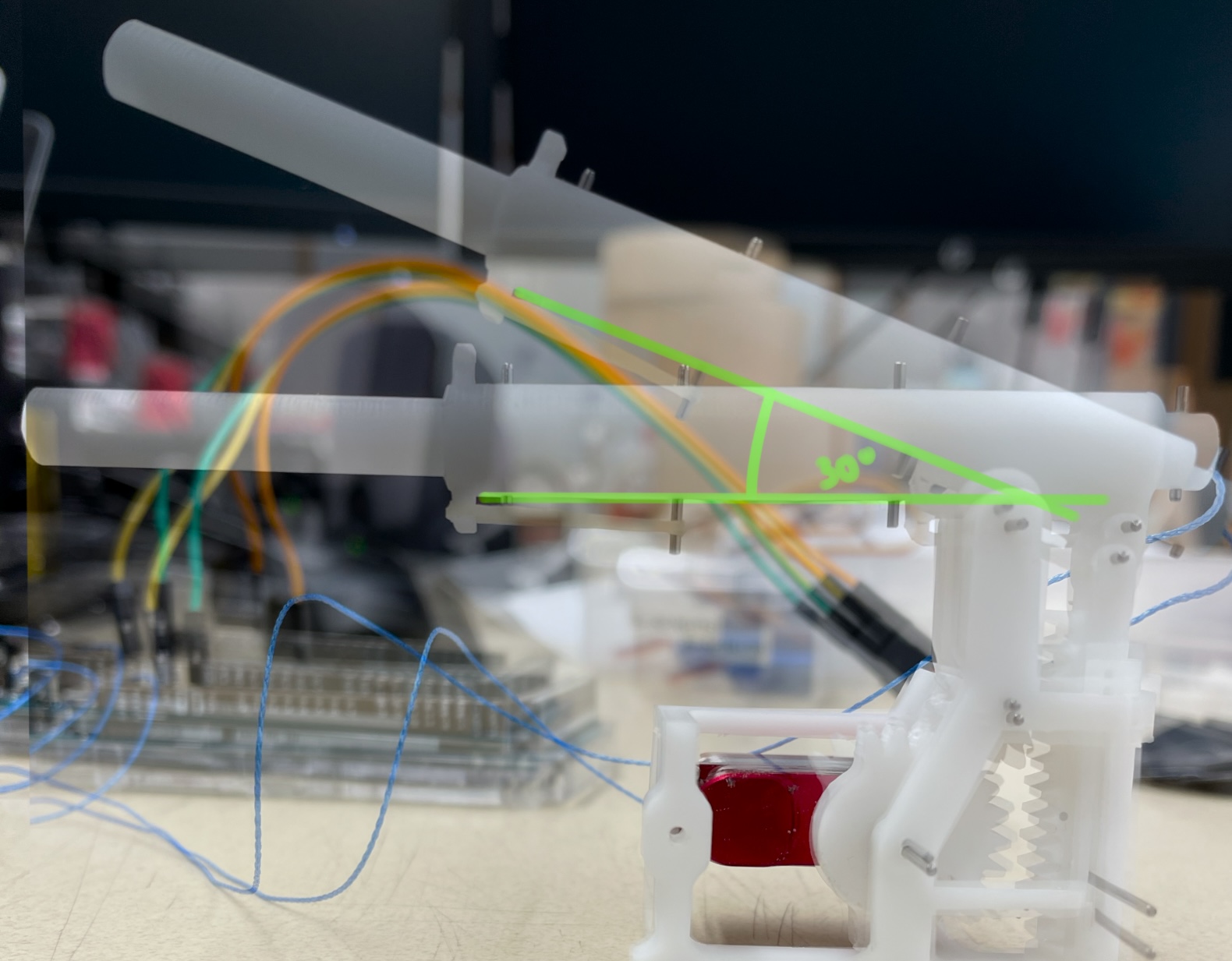

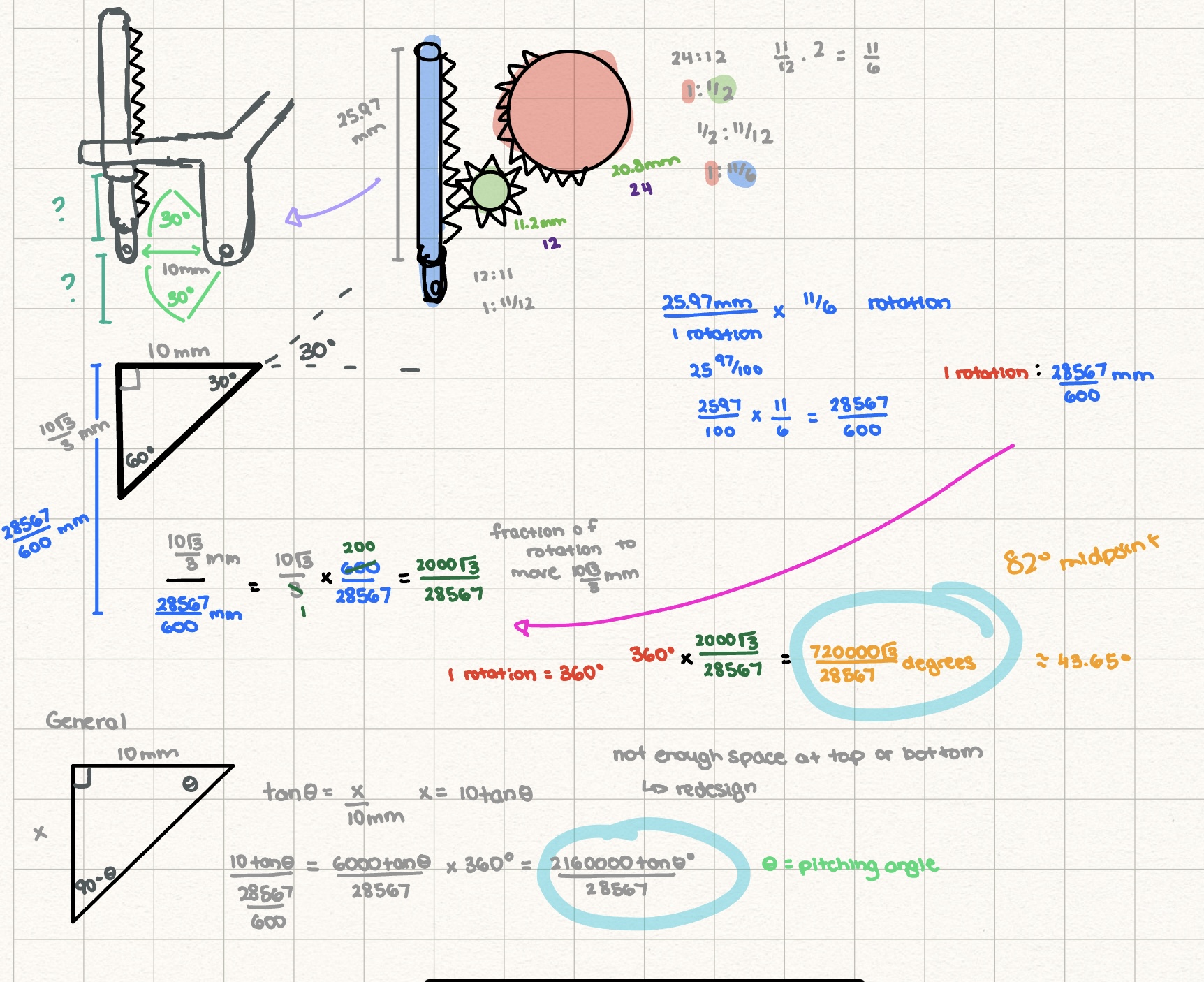

July 29: This morning I finished checking the accuracy with a more secure setup and found that the angle never deviated beyond 2 degrees. The measurement is not exact but I believe it is good enough to test. Any major arithmetic errors will become apparent during flight testing. With the gripper fully assembled apart from the talons, Kenneth put the drone together. We hope to flight test soon, but in the mean time I will continue working with Tony on enhancing the gripper.

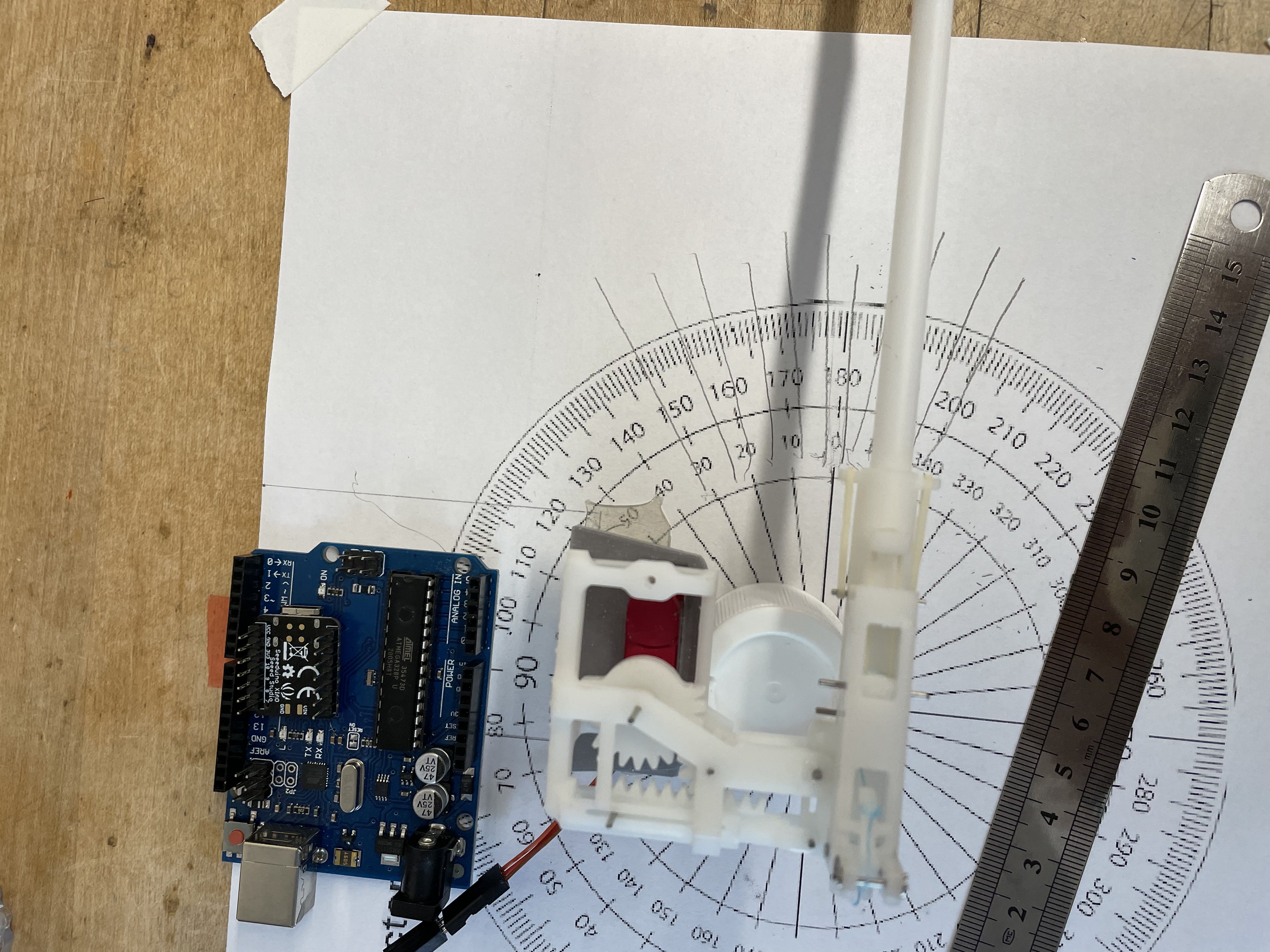

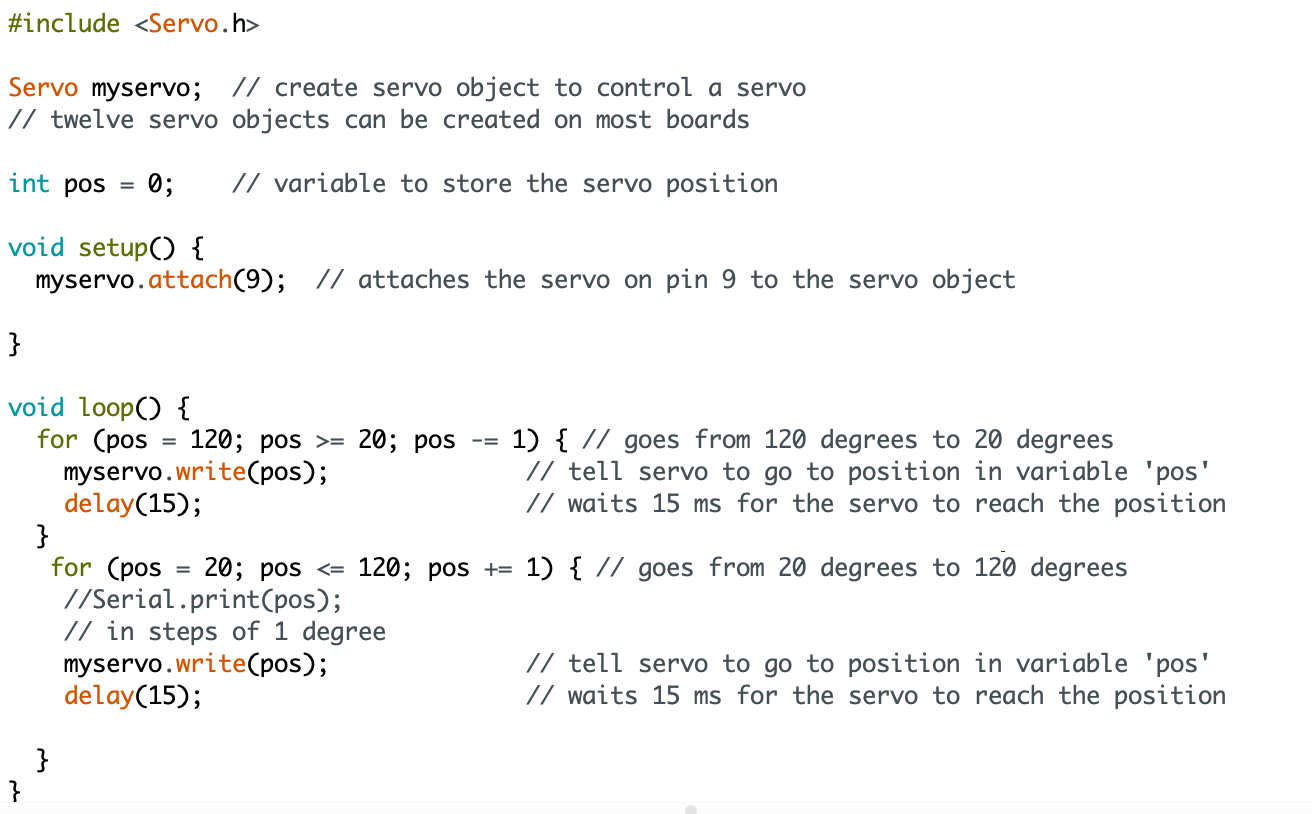

July 28: With the gripper fully assembled, I began working on integrating the Arduino code so we could simply input an angle in the serial monitor and have it instantaneously move. I already had all the logic but needed to search up how to use the serial functions. While making the code we ran into a few bugs which Kenneth, Lawrence, and Tony all worked to fix. After a lot of trial and error, Kenneth found that the problem was in the serial settings and we were able to get it to function. My next task for the day was measuring the accuracy of my logic. I printed out a large-scale protractor and planned on setting up the gripper to angle movement, however, it found it difficult as it did not stand by itself. I tried recording data but it was very scuffed. I decided to approach it again tomorrow with more secure bounds and measurements.

July 27: I finished securing the motion capture devices this morning, but still need to add a bit more tape so they don't rotate. I turned my attention to assembling the full gripper which took some time because multiple parts needed to be sanded down to allow for a nut to be screwed on. A few dowels are still loose, but it functions as intended and is overall secure.

July 26: This morning at the DESI meeting Kenneth showed the videos of our last few trials. Together we planned on integrating the gripper soon, which was ready for the most part but needed a few last adjustments and assembling. This included a new trigger that was more stable and a tube extension so the talons would stick out of the drone. While I waited for those to print, I worked on attaching the motion capture devices to the target drone as they had fallen off after Monday's crashes. After multiple attempts, I decided to tie them onto the propeller guard using taut-line and clove hitches.

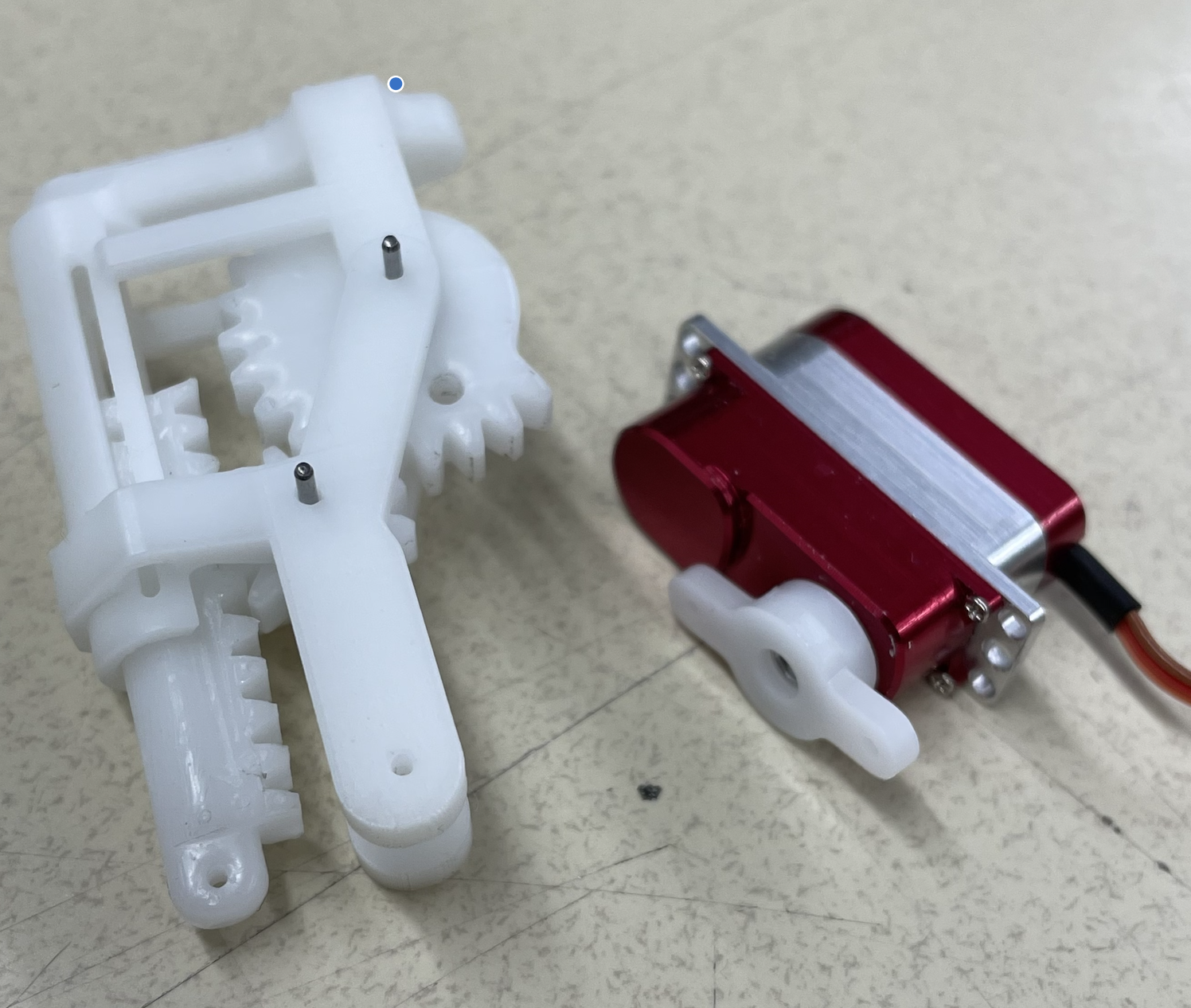

July 25: Kenneth fixed the bugs for the pursuer drone so we were able to test both drones today in the flight room. To prevent the two from crashing, we had the pursuer fly several cm above. During most trials, the pursuer was able to accurately catch up to the target, however, for some reason, this would cause the target to crash. This was annoying, but not too concerning since we are mainly focused on the path of the pursuer which worked well. During one of the trials, the servo broke and when I came back to the lab to open it up, I found that one of the gear teeth had been completely sheared off. Luckily, we have others to spare.

Week 5

July 22: I began the day by rebuilding the gripper with the updated parts and it assembled pretty nicely, however, the triggering latch slipped a lot. I redesigned it to be a bit longer and not have filets so it would stay firmly locked until the mechanism is actually activated. Kenneth and I went to the flight room later in the day but had trouble because the pursuer drone's code was bugging. It struggled because it could not generate a pursuit route that was bound to the limits of the room. While Kenneth debugged, I learned how to operate the target drone using python.

July 21: While Kenneth worked on the code for the pursuer drone, I spent most of the day trying to assemble the gripper. Most of the parts had been printed out but I needed to add the tendons to see if the triggering mechanism would actually work. This proved to be a bit difficult as I would need to tie strings to dowels that were located inside of a tube. I found that the best solution was to use a taut line hitch which I remember from scouting. The taut line allowed me to create a large initial loop that easily fit around the dowel before pulling the end string to tighten it from outside the tube. I had to retie at some point in the day because I forgot there was supposed to be a dowel over the trigger to help pull, but it worked regardless. After testing more of its limits with force the inner trigger broke, so Tony printed a redesign that should allow for smoother activation. Later in the day, I meet with Lawrence to discuss questions over the Yanmar video logging. I had to clarify what technically counts as a prototype since outside testers of the prototype are actually part of the environment.

July 20: This morning we did more flight testing. Initially, we planned to use an actual target drone, but decided to stick with the simulation as we wanted to test a couple more parameters to ensure proper flight on the pursuer. We did multiple runs testing both the speed of the drone and the course updating path. We found that 3 hertz provided the smoothest/most efficient path for the drone to follow. I spent most of the rest of the day video logging for the gestures project and will meet with Lawrence tomorrow to sort out any confusion. I noticed quickly that the Yanmar group makes more gestures than the Volvo group, most likely because they have a physical prototype in their meetings to refer to.

July 19: Today at the DESI meeting Kenneth showcased the dummy gripper's ability to track the z position of the target. Tony discusses changes to the gripper including the use of magnets for the dropping mechanism and the inclusion of bearings. The claw will no longer use a ball-joint in hopes of limiting damage to the actual gripper if a crash were to occur. Not long after the meeting, Kenneth and I went to the flight testing room to see if the drone could follow the pursuit path for a simulated target. Despite all of Kenneth's precautions that it very well might break, the drone was able to fly pretty smoothly and accurately. We tested a couple of different path lengths and velocities which we analyzed later in the day. The position data was convincing so the next goal is to repeat the testing with an actual drone target.

July 18: We printed the new mount this morning and the seeeduino was able to fit pretty snug. I gave Kenneth multiple versions as the dummy gripper being used currently requires a much longer mount. During the SURI meeting, four more students have presentations on their work. Next week, we will have a guest speaker who will talk about online presence. Later in the day, Kenneth invited me to the flight room so I could become acquainted. He showed me how to set up the drone and did some initial flight testing since the drone had not been operated in a while.

Week 4

July 15: In today's general lab meeting Dane and Rachel discussed their progress on the cluster robot. They led us through the overall qualitative goals and asked for input on solidifying more quantitative measures that could be used in a paper. I worked more with Kenneth on designing the new mount and printed a couple of test designs, however, I forgot to add a divet so the V7 frame was not flush with the mount. I added those before Kenneth also asked me to find a way to integrate a seeeduino into the mount. This would be a bit tricky as it was not entirely flat and had to be oriented correctly to allow access to the pins and plug.

July 14: I finished the calculations this morning and met with Kenneth to discuss remodeling the mount for the gripper. He also showed me more of what's happening on the pursuit side of the research. Since Tony was not in today I spent the rest of the day checking the accuracy of my calculations and redesigning the mount to keep the gripper more centralized and closer to the drone.

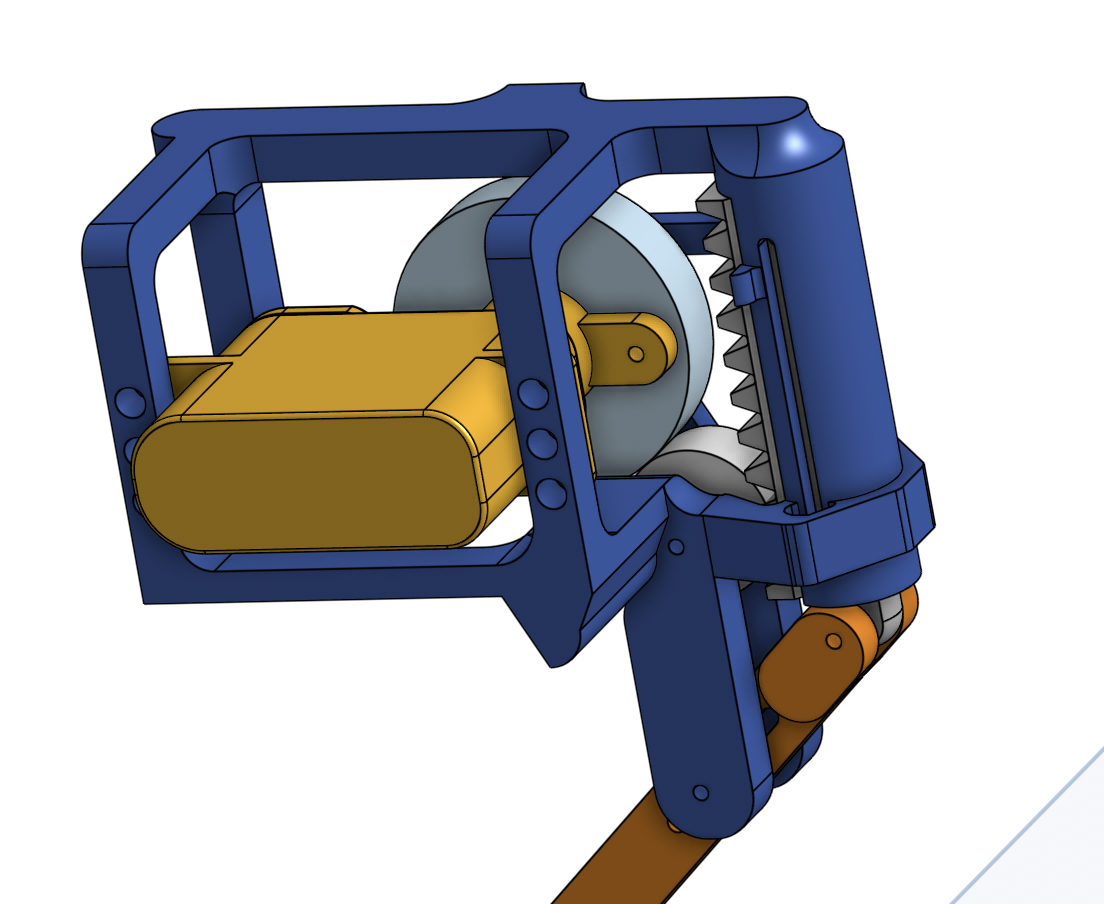

July 13: While Tony designs the rest of the gripper, I went to the CDR to do some video logging with the monitor Lawrence setup. I find it much more productive when I have two screens to work between. When I came back Tony had assembled a mock gripper and told me to attempt calculating how the gear rotations correlated with the angle created by the gripper. After he left, I spent the rest of the day testing calculations to see how accurate I could get.

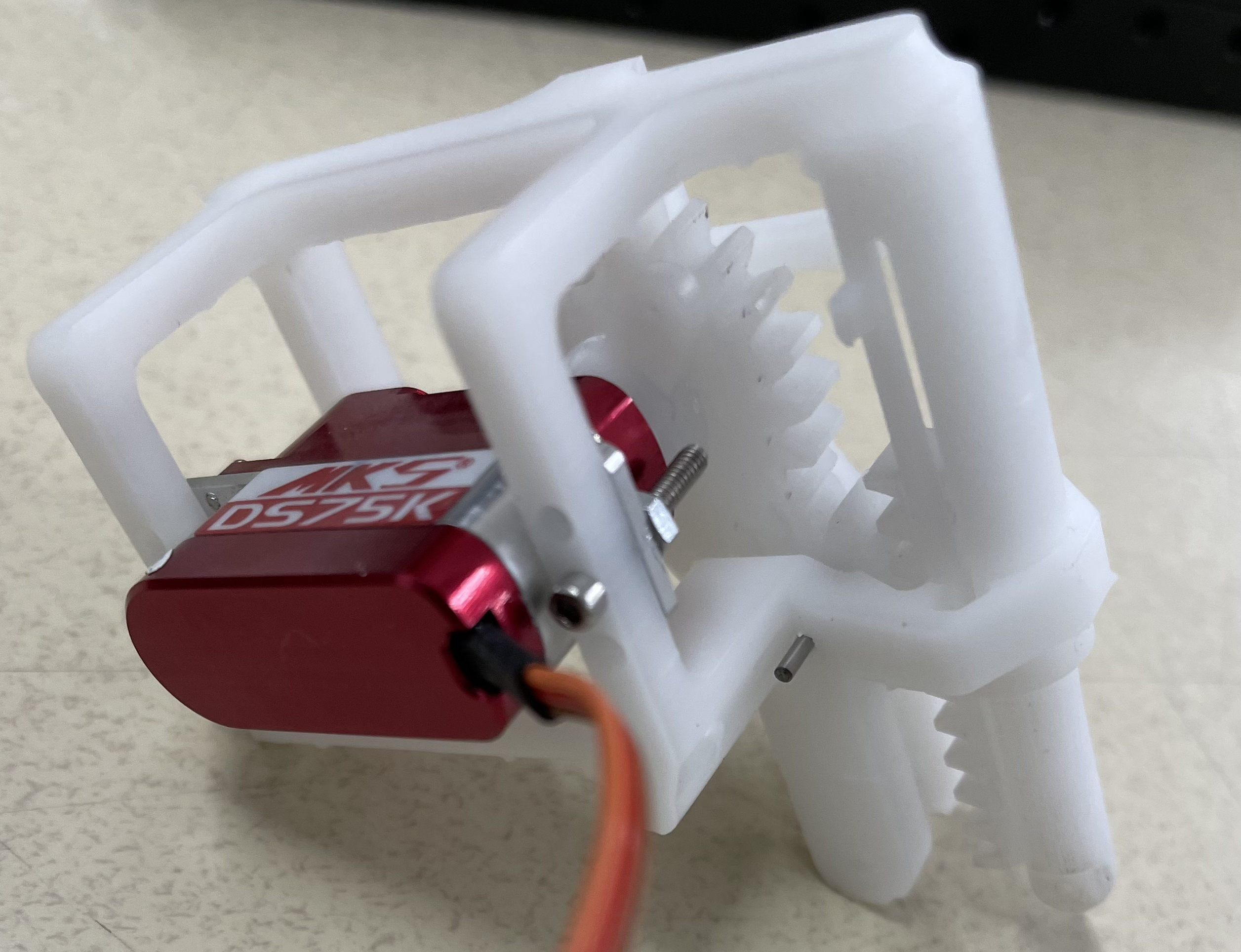

July 12: Today at the weekly DESI meeting I was able to showcase the servo motor design to the rest of the team. Flight testing may begin within the next few days so Tony and I working towards finishing the new gripper/teaching me how to assemble in case of breaks. To fully test the function of the motor I attached a holder for the gripper which allowed me to gauge the minimum and maximum height. After a bit of sanding down, I was able to get the gripper holder to move smoothly within a large vertical range. I will continue assembling once Tony has printed the rest of the gripper. Later in the day, Lawrence led a tutorial on soldering and crimping which was very informative. I am not sure how much I will use these skills, but it is nice to have them in my back pocket.

July 11: This week's goal is to finish the gripper model so flight testing can resume. This morning I assembled the V7 prototype again and found that it was actually running smoothly. I was able to adjust the code to give a wider range of motion and cleaner transition. While Tony printed the rest of the gripper, I did more CADing to improve the V7 structure in a way that allows for easy motor placement as last time I had to sand down the sides. During the weekly SURI cohort meeting, four students from the CharmLab gave presentations on their work.

Week 3

July 8: In our general meeting today we showcased the tadpole bot project as well as advancements in the cardiac project. Not too much to do besides continue testing the motor since Tony is gone. I got the gears to spin, but sometimes they got caught when I added all three gears. I also had to sand down the edges to fit the motor in which I did not account for when initially cading the frame.

July 7: Tony is out for the next couple of days because he is getting married :). I tried to continue working with Arduino to test the torque of the gears but the motor was acting strange and while attempting to remove it, the frame broke. I began printing another frame but it would take 5 hours so I turned my focus for the day onto the gestures data collection. Lawrence set up a monitor in the CDR so I can have two screens allowing me to track multiple videos at the same time (topview/sideview). This was very helpful and made logging much more effective.

July 6: I continued where I left off with Arduino tutorials before attending the Design Research Meeting upon Lawrence's request. There were limited attendees due to scheduling issues, but they told me that the usual procedure included reporting back about project progress. After lunch, Tony gave us a formal Arduino tutorial where he described the background of the microchip and its applications. He used the servo motor as an example which was helpful since I am currently working on activating the drone gripper motor. I began working with the Arduino servo code before meeting again with Lawrence quickly to go over questions about data collection. Together we clarified differences in rhythmic beat gestures and actual points. The rest of the day was spent tinkering with the V7 prototype to see if it can sustain the motor. Part of the adapter got caught on the side of the frame, so I was forced to disassemble and remove some plastic.

July 5: This morning was the DESI meeting where Kenneth showed more development on the drone pursuit simulation. Tony and I reported back that we are currently testing the servo motor on the pitching model and will eventually attempt to implement it into the previous prototype. I finished the Matlab tutorial and began assembling the motor to the new gripper structure. It took a bit of work because the parts were so small and I dropped multiple pieces. I ended up gluing the motor to the gear since there was no other way to attach the two. For now it fits, but we will test later if it will break under the pressure of the motor. I spent the remainder of the day doing Arduino tutorials so I can learn how to activate the motor.

Week 2

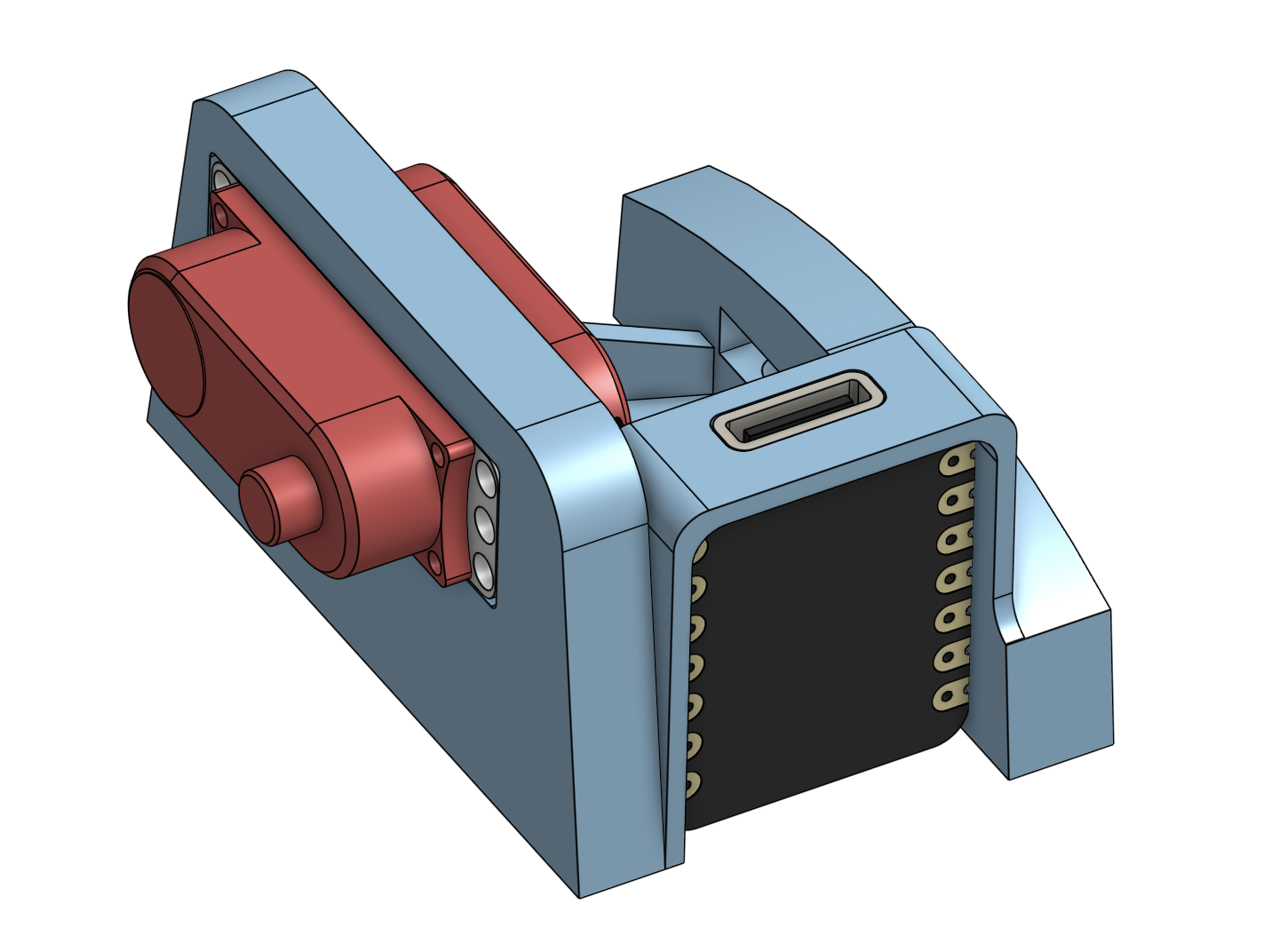

July 1: My goal for today was to finish the CAD model for the servo motor support structure. This is what I spent the morning working on along with continuing tutorials for Matlab. At eleven we had a lab meeting where Carlo and Tony presented the current research on ReachBot. Afterward, we attended the weekly bbq hosted by another lab in the MERL. In the afternoon, I finished the servo motor support model and gave it to Tony to print. Since my earbuds died, I spent the rest of the day reading the section of "Mind in Motion" that Lawrence assigned to help me understand the purpose of the Gestures Project.

June 30: Clean-up Day! I was assigned to the pneumatics, tubes, and seals and spent the entire day sorting small parts with Dominic. I can confirm Dominic said "Holy Moly" twelve times and "I'm tired" seven times.

June 29: The first half of the day involved continuing to adapt the V7 prototype to support the servo motor. To help myself visualize the movement of parts, I drew the model on my ipad. This allowed me to understand the structure better and decide which components of the structure were able to be removed/enhanced. Later Lawrence invited me to join the CDR general meeting where they were discussing the future of the DesignX program. Straight after the meeting, I met with Lawrence to review some of the gestures videos and set a schedule for my data collection. We decided on two videos per week with meetings to discuss any questions I have. As soon as I got back, Mark asked me to sit in on the ReachBot meeting so I could show the group the Maya software for ground simulation. At the meeting, it was decided that I would learn Matlab in order to eventually help Carlo with simulation. Mark sent me a tutorial on Matlab but I did not have access so I continued to work on the V7 prototype. I will figure out in the upcoming days how to balance work between the Gesture Project, DESI, and ReachBot.

June 28: Today was an early start. I arrived at 8:40 am and worked on some CAD before the morning DESI meeting. At the meeting, I learned about the pursuit side of the project through Kenneth's simulation of the drone. (Gazebo) The rest of the day I worked on updating the V7 prototype model to sustain a servo motor that would connect to the main gear. I also spent some time testing the 3D model for the latest supported structure.

June 27: This morning I met independently with Tony to discuss the design of the DESI gripper. He informed me of the next steps of the project which include building a new claw that accommodates for drone dip. I spent the remainder of the morning familiarizing myself with the drone project and learning how the grasping mechanism works. At noon, we had our weekly SURI meeting where we listened to a panel of Ph.D. students answer questions about their experiences. It was interesting to hear their varying perspectives on balancing work with interest and reassuring to know that each had different paths to success. Next, I visited the CDR to meet with Lawrence and set expectations for the "Prototyping and Sketching in Remote Collaboration" project. My work this summer mainly deals with data collection from a series of videos that represent design collaboration. I will analyze the gestures of individuals in the hopes of finding a pattern between gesture evolvement and product actualization. We decided to schedule a meeting time later in the week once I was more solidified in my role for the DESI project. In the afternoon, we received a Flexiv tutorial from Rachel where I was able to control a robot hand with an Xbox controller. That was honestly the only intuitive aspect for me, but it was very cool to learn the capabilities of the machine. The remainder of the day was spent on OnShape improving the structure of the drone grasper. Tony helped me towards the end as I initially struggled working with a more complex CAD model.

Week 1

June 24: Friday began with a general lab meeting that mainly involved the logistics of scheduling for the upcoming months. Next, we were given a laser tutorial by HoJong which to place in the room across from our lab. I am not sure if I will end up using the laser cutter but it was fascinating to learn how the machine works. Soon after the laser tutorial was an OnShape tutorial with Rachel where we were given useful tips and advice for mechanical engineering modeling. Improving my CAD skills is a high priority for this summer so I found the tutorial to be extremely useful. Finally, we were given a casting tutorial by Tony where we created small parts for a gripper. I learned the intricate process of forming silicon/urethane models and hope to use that learning in my future projects.

June 23: Power still has not been fixed, so SURIs were instructed to work at home. I continued practicing OnShape through online tutorials by finding models and attempting to recreate them.

June 22: Power is still out, however, the lab had a treat planned anyways. We drove down to half moon bay to spend some time at the beach before moving to a state park to cook bbq. Towards the end of the trip we wrote down our goals for the summer. Overall, it was a great experience and fun way to meet everyone in the lab.

June 21: Today, I took the desk at the far right corner of the lab to start working on some projects. I joined the drone meeting in the morning and learned about their goal of catching airborne items. Next, I met with Brian who explained the ReachBot project to me. I was able to renew my Maya subscription to import terrain designs from sketchfab into a modeling software that would be used to help visualize the robot's scanning. After a lunch break, Dane gave us a lab safety tour where we learned where materials were within the building. Shortly after the power went out and we decided to wrap up for the day since the internet was down.

June 20: First day! I started by joining the SURI Kick-Off Meeting where we learned about the general outline of the program including deadlines, pre-assignments, and weekly cohort meetings. I was then introduced to the BDML lab where I was given a lab orientation. Mark granted us access to the lab website and taught us how to write this blog. I sat in on a Tactile Meeting for the TRI project and learned about the research questions regarding understanding gestures and identifying processes in robotic arms. I found the project very interesting as it deals with human interaction and multi-dimensional decision-making. The rest of the day was spent completing the STARS training required for lab access. Before we left, Tony gave us a quick lab tour in which he explained the founding of the lab and keystone projects. I also asked for a brief summary of the drone study as I was trying to gauge my interest.