June 20

- Orientation from almost all of the lab - possible projects include airplane at-wall reorientation, Zman human scale, and tactile and force sensing. I feel like I have a lot of freedom to find places where I can be useful, and I'm pretty bright-eyed and excited about it all. I also got some good introduction to the Adept, the laser cutters, and the cnc machines, and feel confident that I can start using them pretty quickly.

June 21

- Got started on the laser cutter working on some inexpensive mold techniques for squishy dielectric pressure sensors - John and Barrett's stuff. The laser cutter is a lot faster than the cnc machine so if it worked out it could be really cool. After a quick walk-through of laser cutter basics, left Michela to run more iterations on different materials.

- Introduction to airplane issues from Alexis - looking at issues in crawling, jumping, and integration. I have some reading to do.

- StickyBot - asperities, hook sizes, suspension. Perching - balanced damping, best angle of approach. Cory - successful probablistic model for non-linear perching dynamics.

June 22

- Designed solidworks model for jumping airplane based on Alexis' current glider, but scaled up to foamboard dimensions.

- Cut out a test wing over on the Epilog. Extremely easy, but the machine is a little small for cutting out the main fuselage.

- Followed Eric over to the PRL to try and use their laser-cutter. Discovered that I'd designed everything on the one computer at Stanford using the 2011-2012 version of solidworks. Hilarity ensues. After finally producing a useable template, return to the PRL to discover that lasercamm doesn't seem to be working, giving us the opportunity of receiving a gentle ribbing from Craig as he signs in as the correct user. We also are informed that foamcore is not allowed on the PRL laser cutter because it's inhomogenuous (sp?). This finally transforms my afternoon into watching Eric calibrate the HAAS and trying to fiddle with awkwardly formatted Solidworks parts. But I do have an opportunity to count the seemingly egregious number of lathes (6) and to note the various HAAS nicknames (HAAS-pital,-tile, and -ta la vista, baby).

- Got the old hydraulic launcher working and tested it out with the old fixed-wing airplane. Have a few more papers to read and a little design work to do, but should be able to run some experiments soon! As always, hydraulics give me good feelings inside.

June 24

- Purchased more material for airplane construction.

- Group meeting ends up assigning me as task manager for airplane reorient project. Brainstormed options which met with the most approval were controlled falling/propeller-driven climbing, rocker-action manuevering, and using airelons/elevators to adjust normal force on each leg.

- Helped straighten up MERL 126 and started thinking of how to use it as an airplane space.

- Went back to take a little more careful approach to my solidworks model airplane - I want to have a really good handle on it before I get my shot at the big lasercamm early next week.

- Mark obtained a couple compressed air tanks - spent some time tinkering with the small lab one, but it ended up that the big red one from the 310 loft should work better (there's no compressed air down the hall ...)

- Updated summer work page. Gave myself the option of an infinite loop by typing that last sentence.

June 25

- Spent the morning getting ready to laser-cut two new planes out of the material I purchased. Finished solid-works, arranged into really efficient dxf file - I had two sheets, and I'd need both to make one plane - but there was a lot of wasted space because some parts wouldn't fit on the same sheet efficiently. After some careful fiddling, I think I can get two planes out of the two sheets - saving the lab at least $5.12 or so. Oh yeah.

- Began prototyping magnet locking mechanisms for jump-glider. Started with two eraser-sized magnets, which worked best when they were located close to the pivot point because they had a wider range of wing angles where they could successfully snag the wing. Moved next to a smaller set of magnets farther from the pivot point, and put a stop in. My testing methods aren't the most scientific I've used, but there seems to be some definite promise that this will work well. I get really satisfied whenever the wing locks smoothly into place.

June 26

- Still working on finding the right magnets and the right position for the magnets. Ran some more tests in the morning, really started itching for an actual airplane in-hand to test ideas out on more directly.

- Since the airplanes we've built previously are designed for powered flight, they're not really optimized for gliding, so I spent some time playing around with a simple balsa-and-carbon glider to get a sense of how a good glider can get the most out of non-powered flight. I also was introduced to the matlab code for simulating our jump-gliding.

- With the larger laser cutters all tied up or off limits, I decided to abandon hopes of immediately getting my planes cut out the easy way and decided to cut out the large pieces - fuselage parts - by hand. I managed to create both vertical pieces and one set of horizontal fuselage parts. I also got some experience with foam-friendly superglue, which seemed to like sticking to my fingers more than it did to the carbon tubing. Not that I blame it.

June 27 - July 11

- Lost regular updates in the bugginess of TWiki and the shuffle over to PmWiki, but a lot of cool stuff has happened with the jumpgliding. We found out that the drag from the horizontal surfaces on the body of the plane had a significant impact on jump height, and factored that into our model. We also discovered that the center of mass needed to be closer to the center of pressure to make the gliding phase more stable. The swivel works well, but the carbon rod has to be kept rigid during take-off or we lose energy to bending and flapping. Combined, our better flights covered more distance than a similar point mass.

A few example videos:

A typical launch. - 4.6 MB

Point mass. - 9.5 MB

July 12 - August 25

- When in doubt, blog! The reorienting project only needed a few runs to confirm that the right leg suspension should make for a fairly straightforward propellor-driven upward climbing technique, while advances in spine release mechanisms has made downclimbing a real option. I feel like there's a sound basis for development of reorienting tactics that can be applied almost immediately to the new plane Alexis is building to integrate perching and take-off. As for jumping, major developments have mostly involved trying to get a more dramatic increase in distance traveled, so that we have a more effective demonstration to justify the jumping project. This led us to double the area of the wing, which according to the simulation would buy us an extra two to three meters of gorgeous gliding performance. However, in practice, the larger wing has yet to produce a flight of awesomeness equal to the simulations prediction. Our best launches to date have only gone about a meter farther than a point mass - which, although it represents an improvement over the half-meter of our previous jumper, is not living up to our expectations. We have been able to produce more and more consistent flights, allowing us to fine-tune performance through the addition of an actively controlled elevator, but so far our improvement using the elevator is still incremental. The delay has proved quite interesting, though, in that it has taught us about the sensitivity of certain parts of the design. One that keeps returning to haunt us is the friction at the pin joint. After switching to some on-hand bearings, our performance improved, but still hasn't approached the ideal case. Ordering even nicer bearings is one of our immediate next steps, but other design issues have presented themselves throughout the process. Of these, the two that are most interesting right now are the torque created by the horizontal stabilizor during rising and the precise positioning of mass and aerodynamic forces to optimize controlled gliding.

August 30

- Exciting times! I rebuilt the launchpad in hopes of ensuring consistent performance - the previous version had received two makeshift extensions and was starting to look a little slipshod. In the meantime, new bearings arrived from McMaster, which I was able to test this morning. We got two kinds - a lubricant-free kind using a very slippery plastic, and shiny new metal ones. After I eventually created a consistent test rig, I was pleased to note that both of them look like better performers than our previous bearings. Our measurement standard is oscillation half-life using a simple weighted pendulum. Our previous bearings had a half-life of around thirty-five seconds. The plastic ones could last 80-85 seconds, but would lose half of that time when the pendulum was moved out farther from the bearing to simulate a moment from inertial drag of the wing. The metal ones, by contrast, had a half-life of almost three minutes, which was reduced to a little over two minutes with the added moment. This surprised us, as just playing with the bearings by hand had convinced us that the plastic ones would have superior performance. It could just be that the plastic deforms too easily under any kind of load. I've carefully installed the metal bearings and am now waiting for the epoxy to dry so I can test them out and make sure I didn't get any glue in their inner workings.

Old (un)Faithful.

New Sleekness.

September 6

- Update on new bearings - working well but not as well as we had hoped! The first set got glue in them, necessitating replacement, and the second set might be slightly misaligned, resulting in poorer-than-expected friction performance (still better than the previous bearings, though). We ordered more and are considering how best to minimize the friction involved. The bearings are functional though, and have in part paved the way for the next bullet point, below.

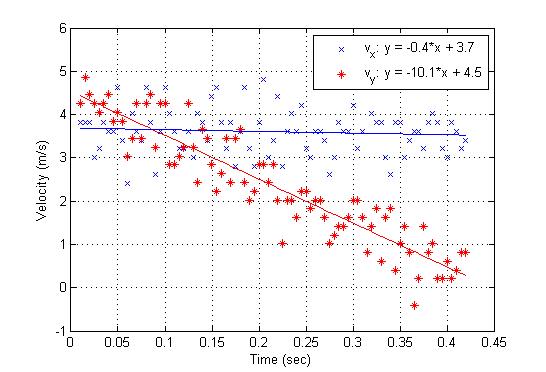

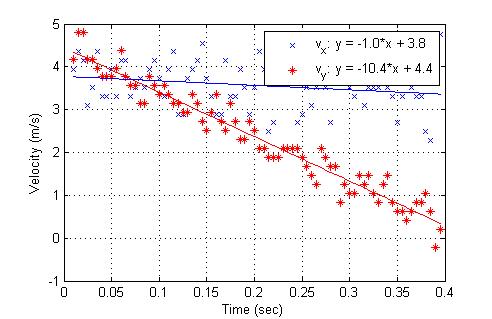

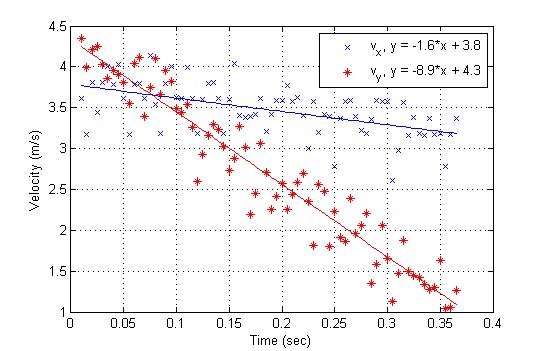

- Good news! We've made a significant improvement to our flight distance (2m!). After installing the new launcher, we were able to remove the area we'd added to the nose of the wing to compensate for some angular velocity during the flight. This immediately increased our jumping height significantly, but video analysis told us that we were still losing a good portion of our horizontal velocity, when compared with a point mass and even when compared with the plane bereft of its wings. However, when we cut out new wings and attached them so that all of the wing is located behind the pin joint, we saw a marked improvement! This lead to a new distance record and some very nice graphs, below. The graphs are, in order: v_x and v_y for a point mass, v_x and v_y for the plane without its wings (same weight), and v_x and v_y for the plane with the new wings.

Wrench.

Wingless.

Current Plane.

Page last modified on June 15, 2012, at 09:47 am